High-power modular lead-acid battery formation charging/discharging system

A lead-acid battery, modular technology, applied in the field of charging and discharging systems, can solve the problems of electric energy waste, large harmonic components, low inverter efficiency, etc., and achieve the effects of enhanced scalability, improved system efficiency, and improved system efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with accompanying drawing, the present invention is described in detail as follows:

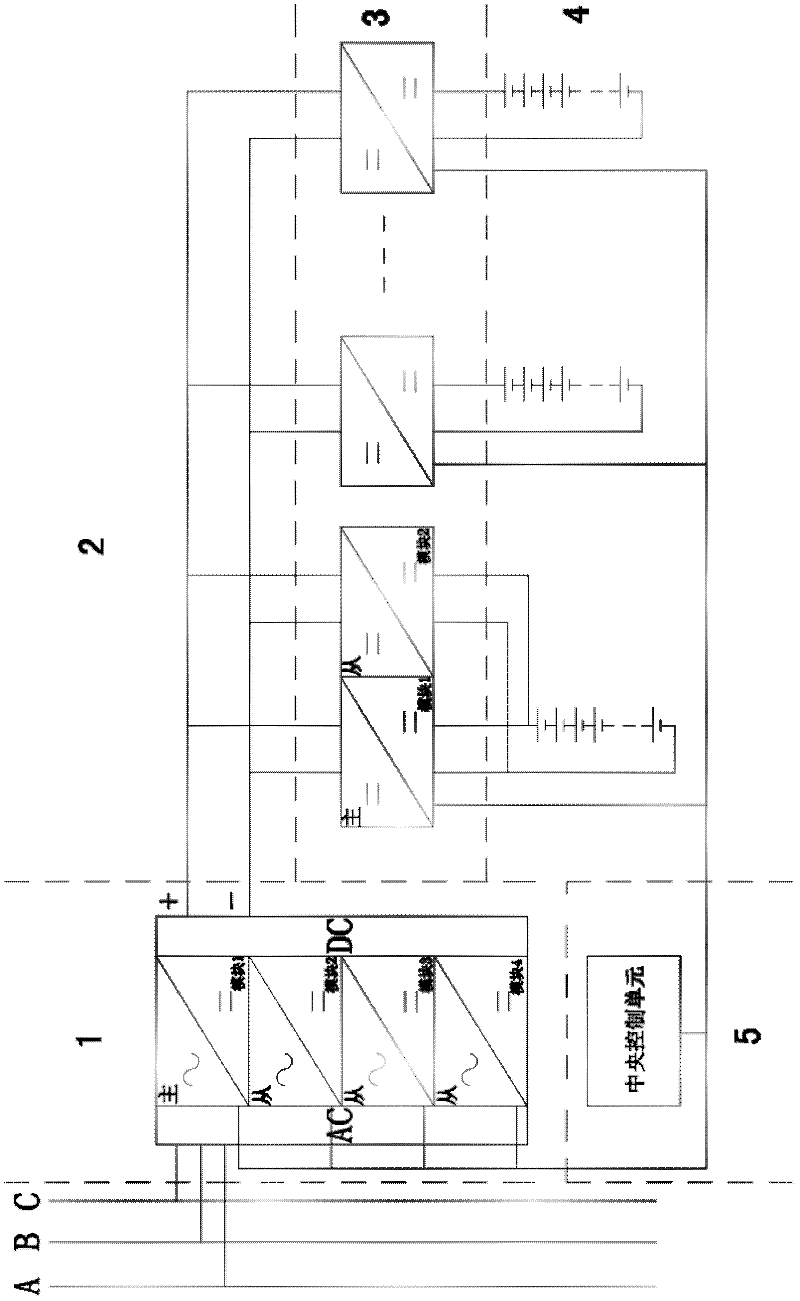

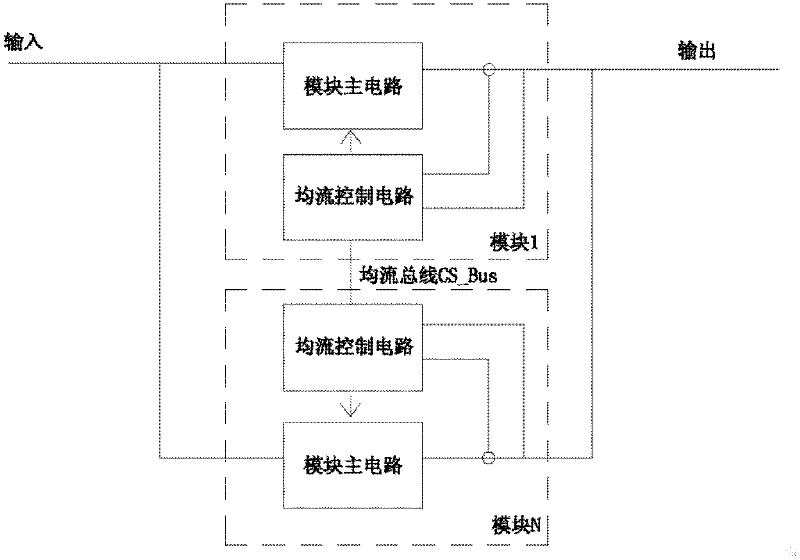

[0022] like figure 1 As shown, the modular storage battery charging and discharging system described in the present invention includes a reversible DC power supply module, a DC bus, a variable current charging and discharging module, and a central control unit.

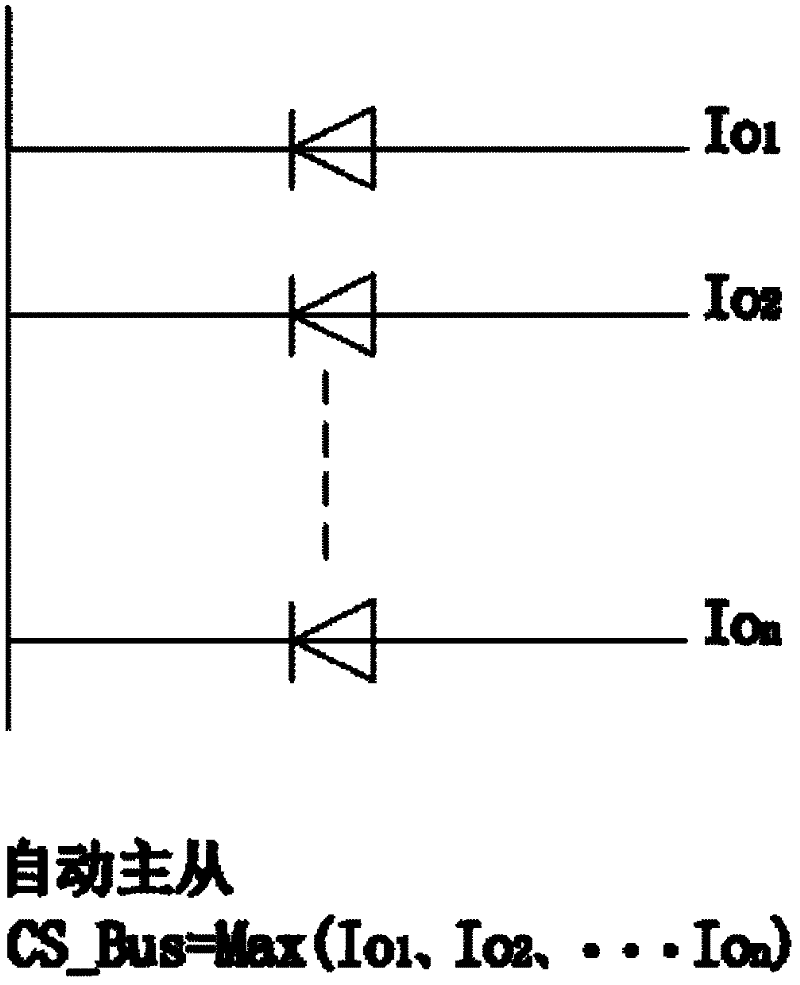

[0023] In the present invention, the reversible DC power supply module 1 and the variable current charging and discharging module 3 can be connected in parallel according to actual needs, and are not limited to the structures in the above-mentioned embodiments.

[0024] The central control unit is connected to the reversible DC power supply module and the variable current charging and discharging module through the bus, and automatically controls the input quantity of the reversible DC power supply module and coordinates the rotation of the modules through the monitored DC bus voltage and current, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com