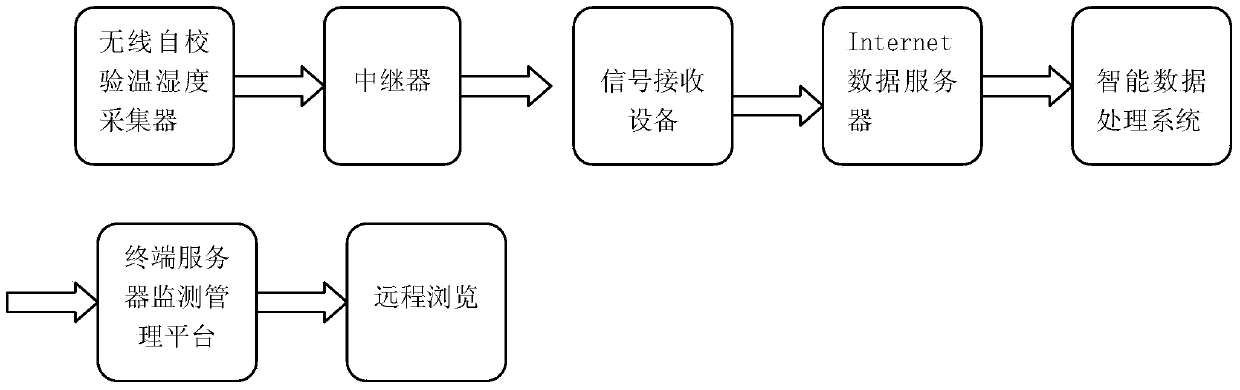

Wireless self-check temperature and humidity primary tobacco maintenance detecting method

A detection method and self-calibration technology, applied to measuring devices, instruments, etc., can solve problems such as low efficiency, small contribution to improving management, and insufficient comprehensiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

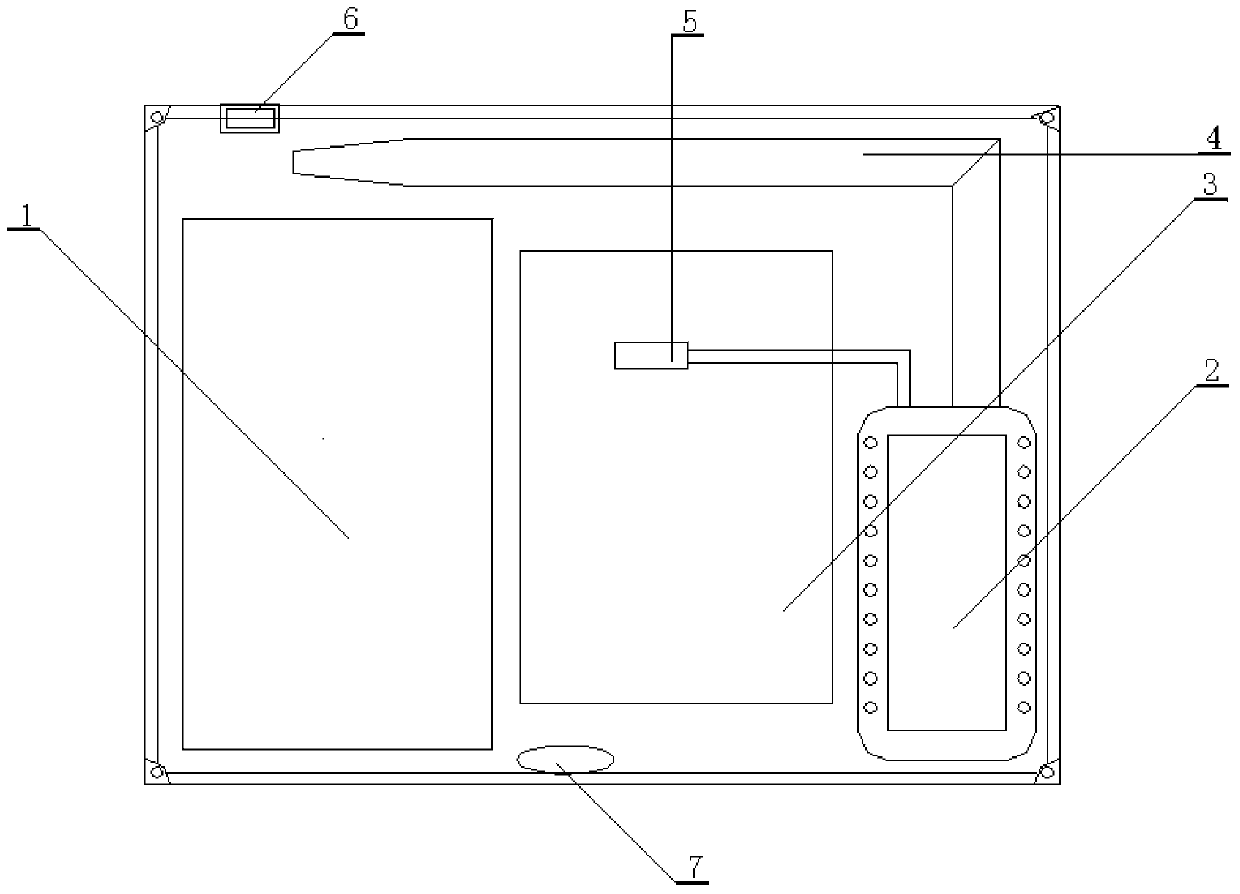

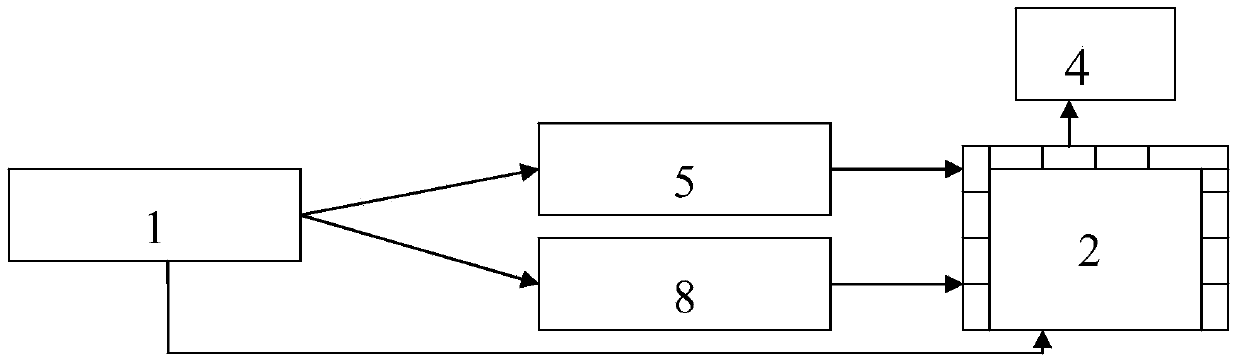

[0024] Such as figure 1 and figure 2 As shown, in the wireless self-calibration temperature and humidity collector, the battery (1) is connected to the temperature and humidity sensor (5) and the voltage simulation circuit (8), and the temperature and humidity sensor (5) and the voltage simulation circuit (8) are connected to the wireless signal transmission The chip set (2) is connected, the wireless signal transmission chip set (2) is connected to the antenna (4), the aluminum sleeve is welded on the back of the heating plate (3), and the temperature and humidity sensor (5) is fixed inside the aluminum sleeve. The heating plate (3) is an anodized aluminum profile cooling plate on the surface. The antenna (4) includes a rubber sleeve and an SMA connector. The wireless signal transmission chipset (2) utilizes the AT89C51-ADV chipset. The battery (1) is a high-energy Ni-MH low self-discharge battery. The wireless signal transmission chipset, temperature and humidity sensor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com