Automatic wine bottle cover putting device

A wine bottle and automatic technology, which is applied in the field of liquor automatic production equipment, can solve problems such as broken bottle caps, and achieve the effects of increasing production flexibility, improving removal efficiency, and reducing motion strokes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

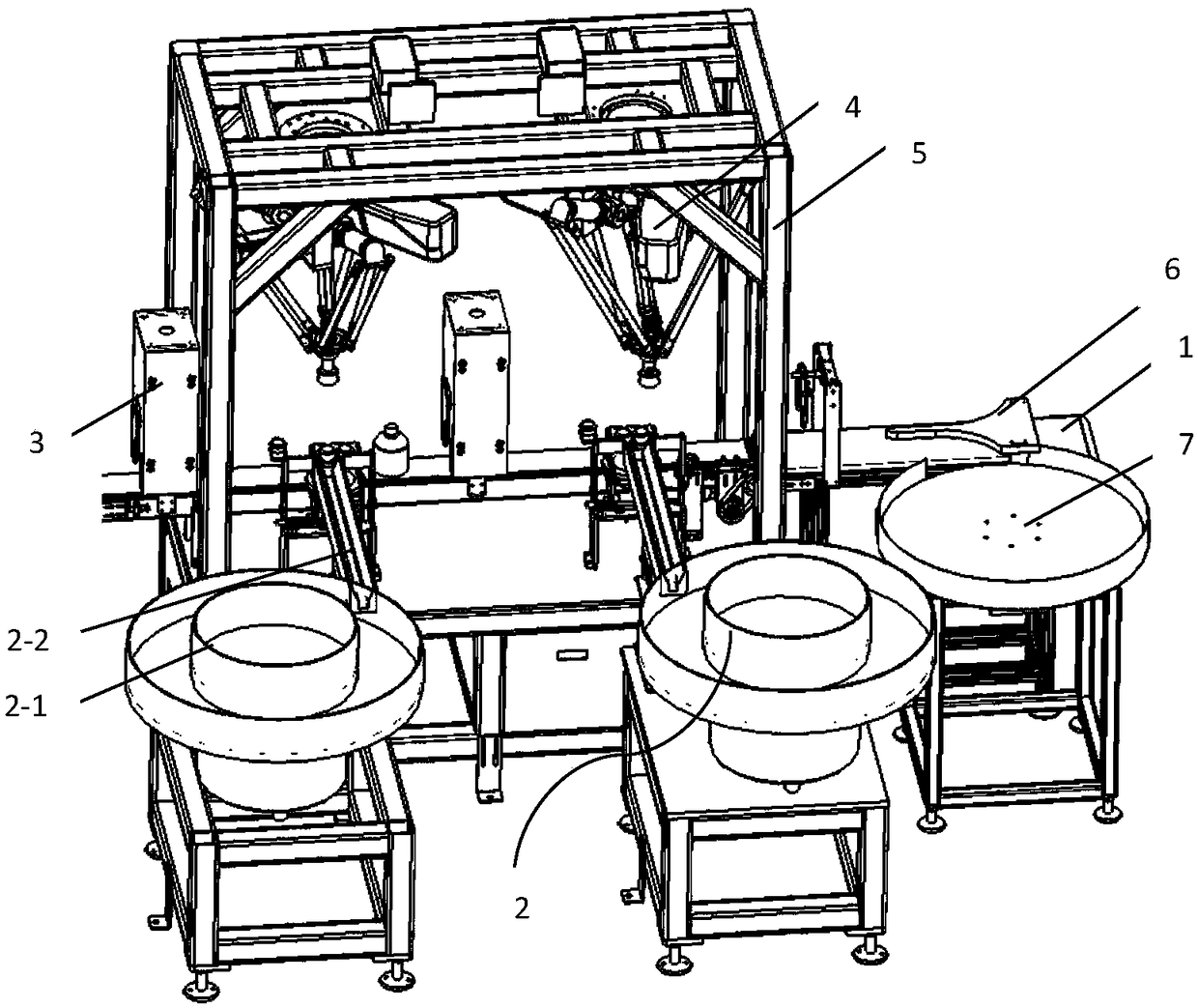

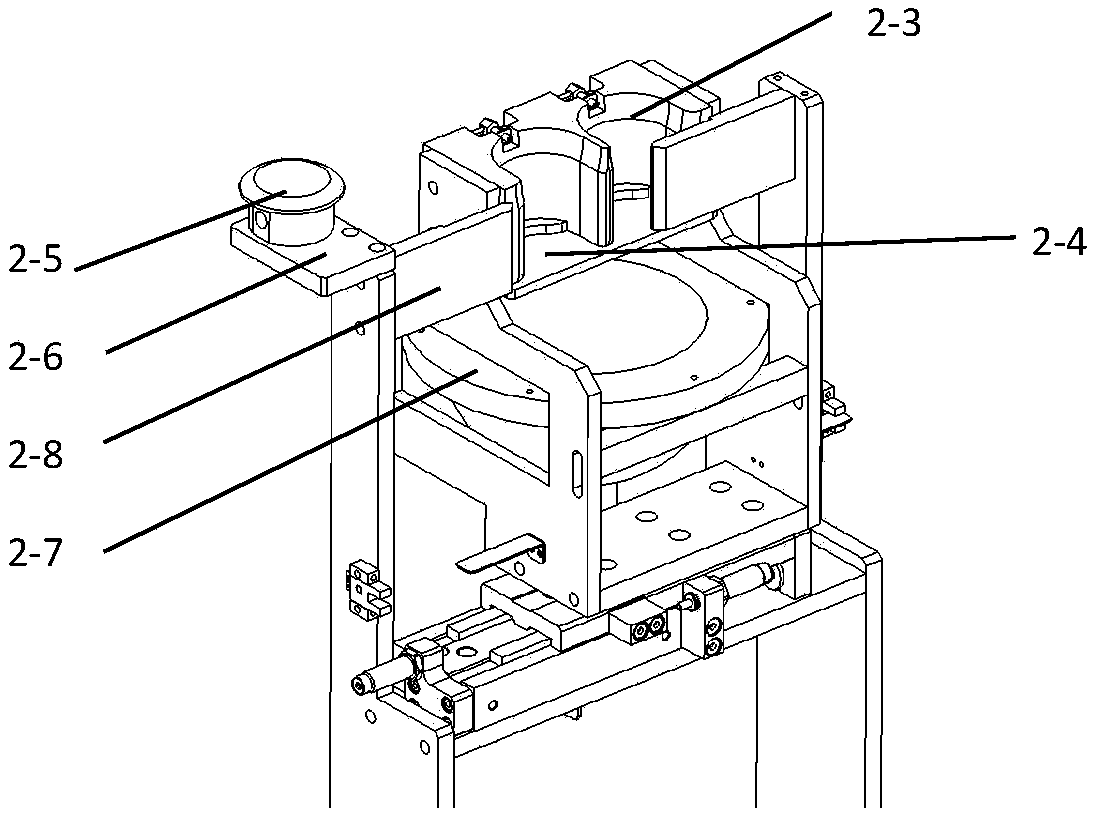

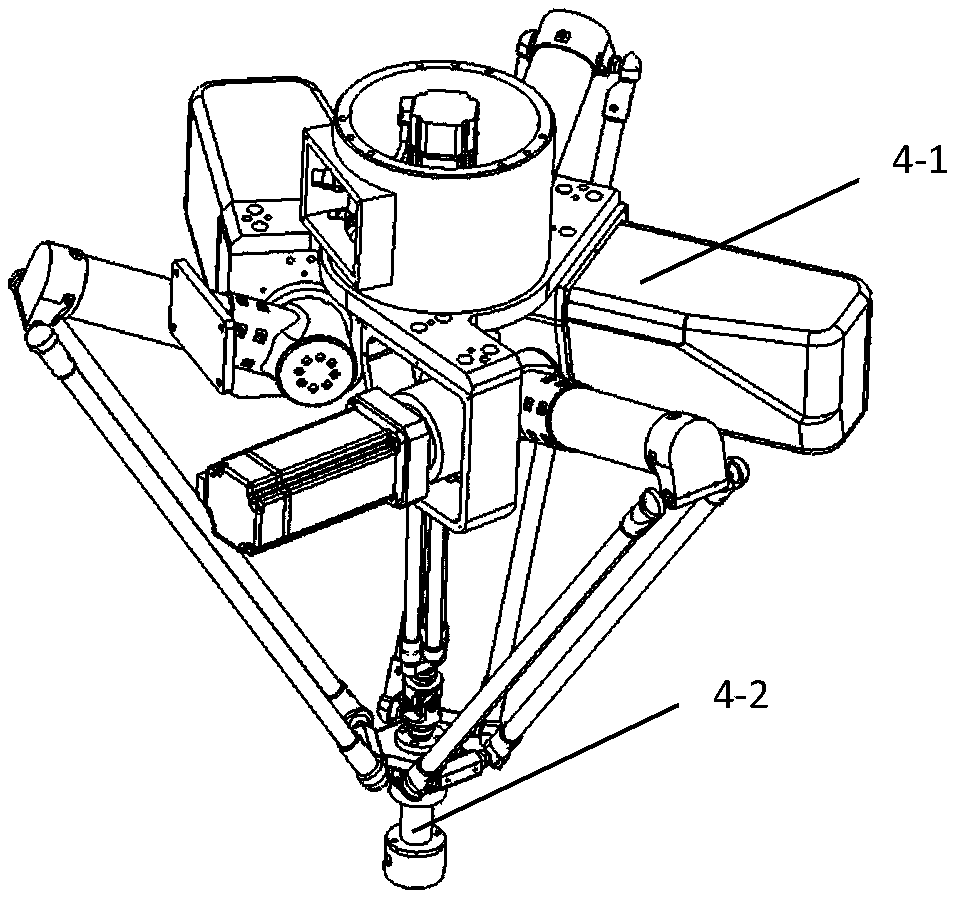

[0024] Such as figure 1 , figure 2 As shown, a wine bottle automatic capping device provided by the present invention includes a first conveying line 1 and two wine bottle capping units, and the two wine bottle capping units are sequentially arranged along the moving direction of the first conveying line 1, The structure of the two wine bottle upper cover units is the same, and the wine bottle upper cover unit includes a posture adjustment unit 2, a first visual detection mechanism 3 and a handling robot 4, and the first visual detection mechanism 3 and the handling robot 4 move along the first conveying line 1 The direction of movement is sequentially set above the first conveying line 1, and the attitude adjustment unit 2 is set on one side of the first visual inspection mechanism 3. The first visual inspection mechanism 1 is used to detect the attitude of the wine bottle, that is, to detect the shape of the special-shaped wine bottle. In order to identify, the posture adj...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com