Patents

Literature

96results about How to "Improve culling efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

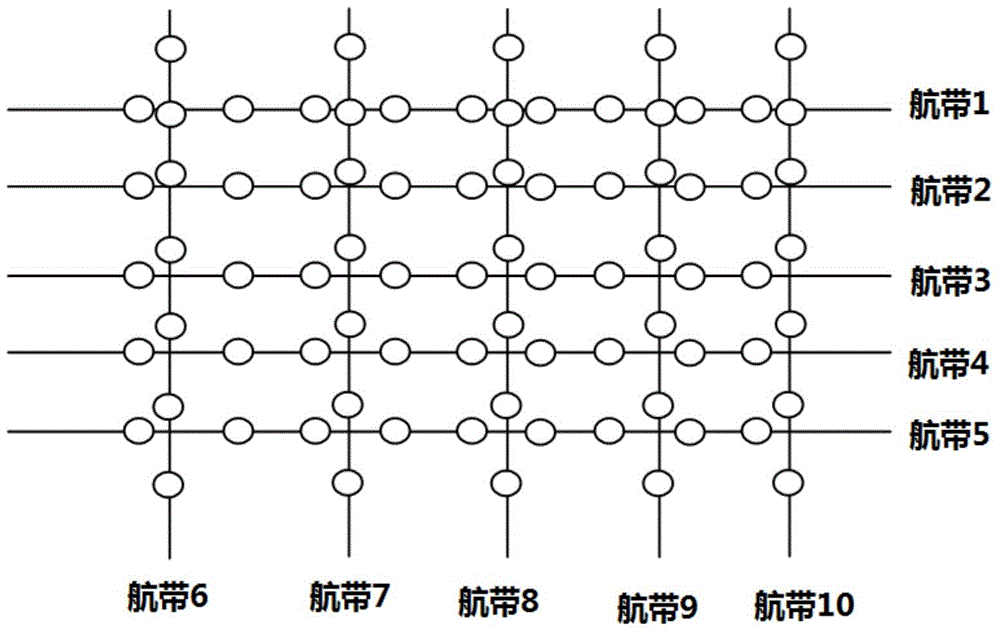

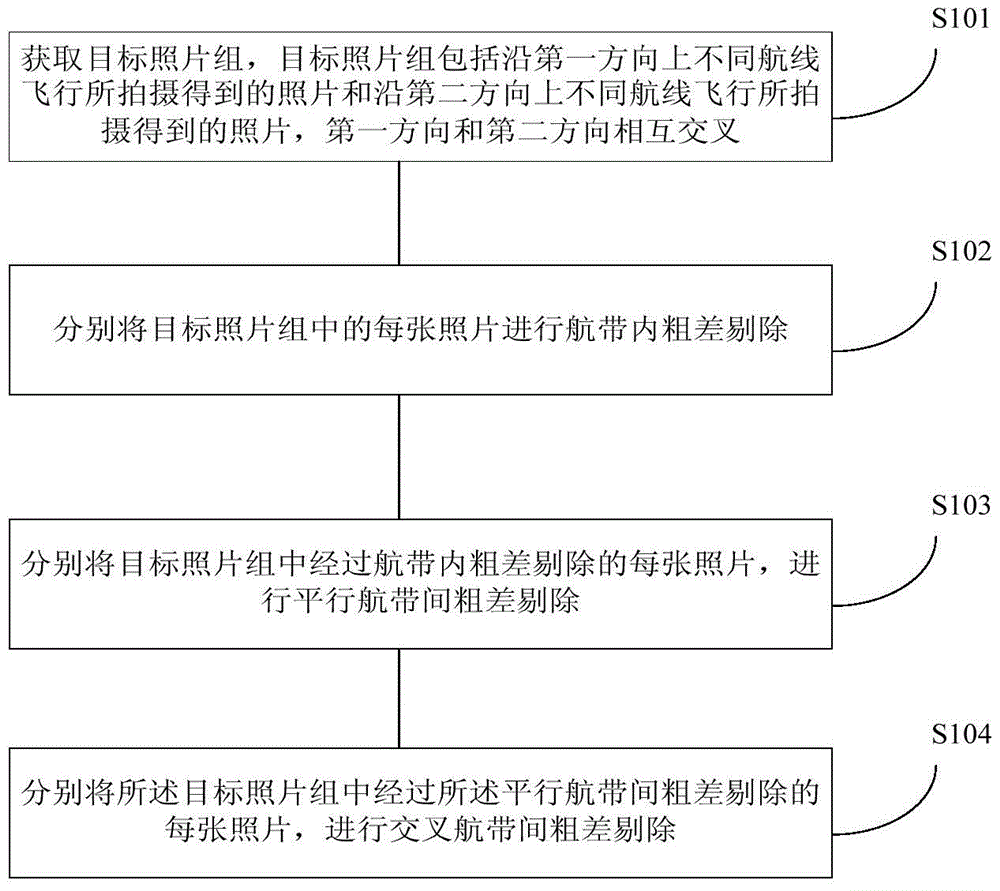

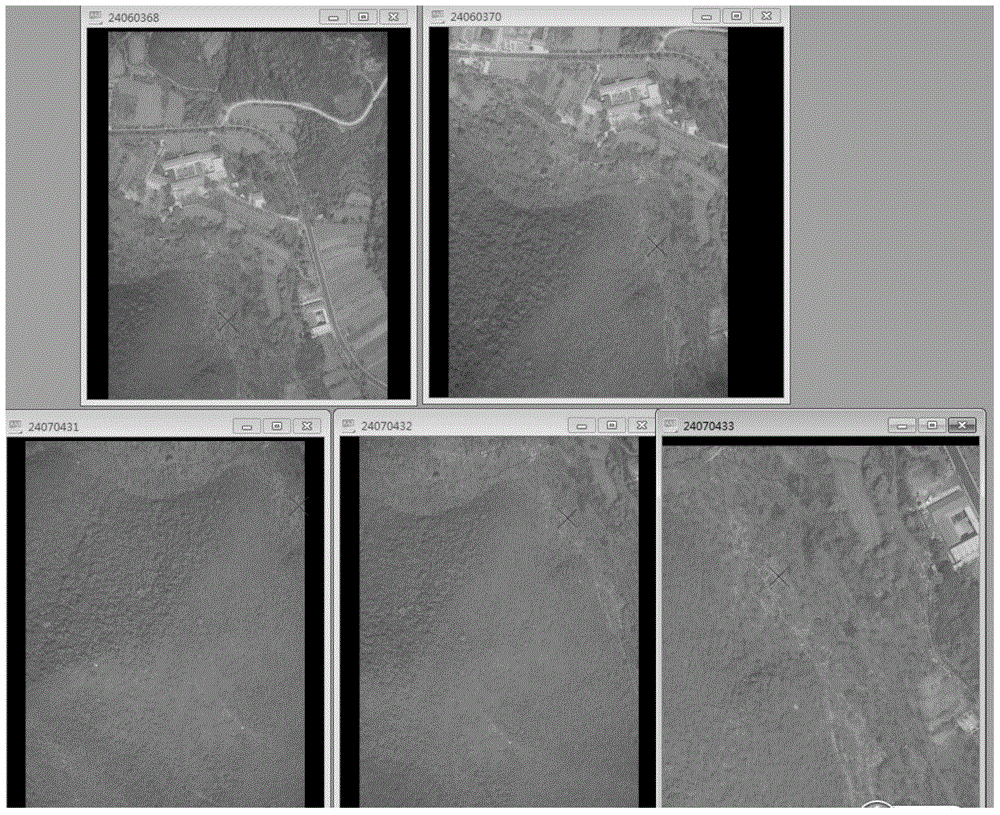

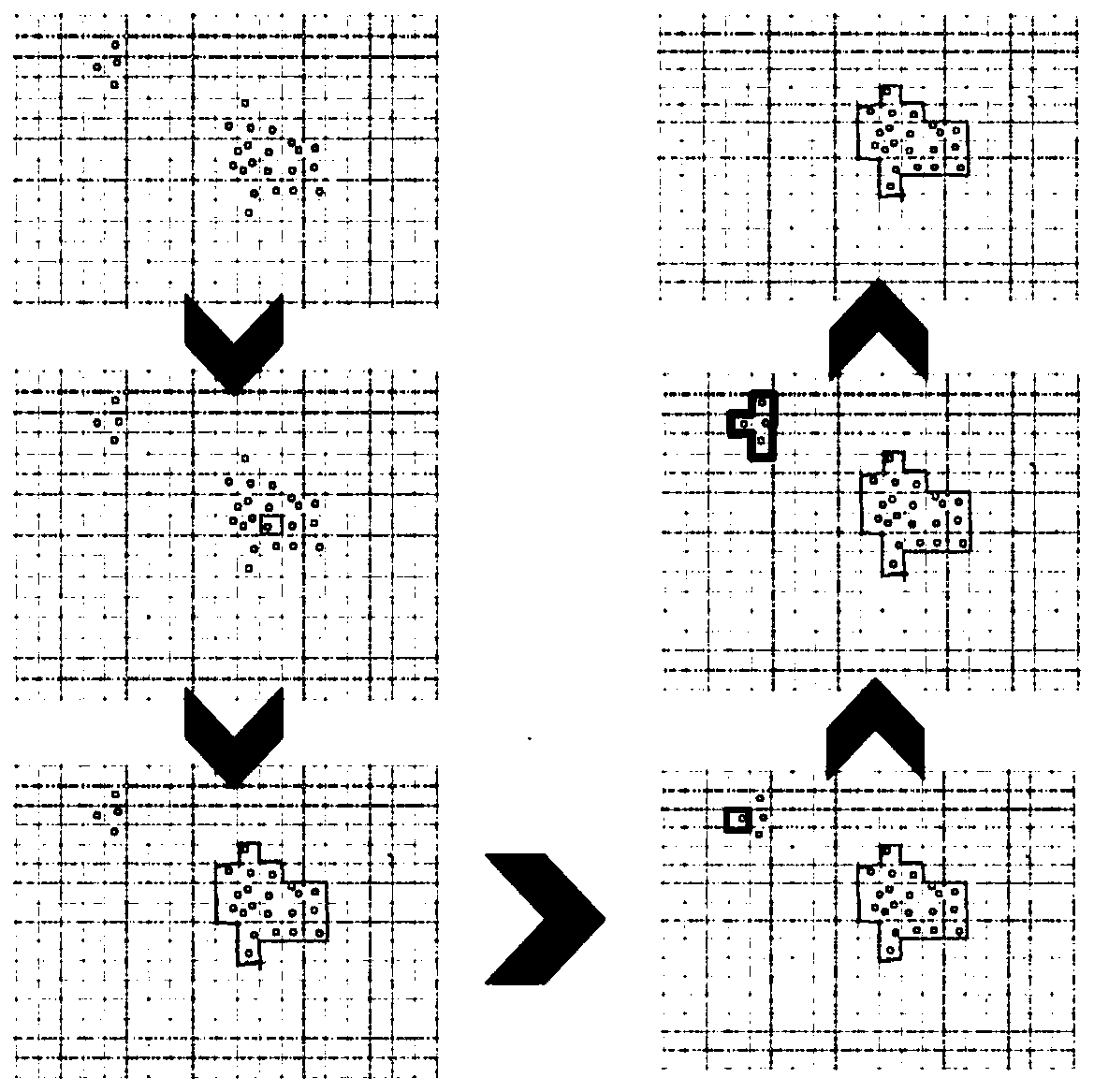

Elimination method for gross error in unmanned aerial vehicle image matching on cross air strip and device thereof

ActiveCN105761257AHigh precisionImprove culling efficiencyImage enhancementImage analysisUncrewed vehicleImage matching

The invention provides an elimination method for gross error in unmanned aerial vehicle image matching on a cross air strip and a device thereof, and relates to the field of air survey. According to the elimination method for gross error in unmanned aerial vehicle image matching on the cross air strip, a composite gross error elimination method of different types of air strips is adopted, and gross error elimination in the same air strip, gross error elimination between parallel air strips and gross error elimination between the cross air strips are performed on the sequence of identical point pairs so that precision of the last remaining identical point pairs is enabled to be higher, the connection state is enabled to be more stable, and elimination efficiency is higher.

Owner:CHINA TOPRS TECH

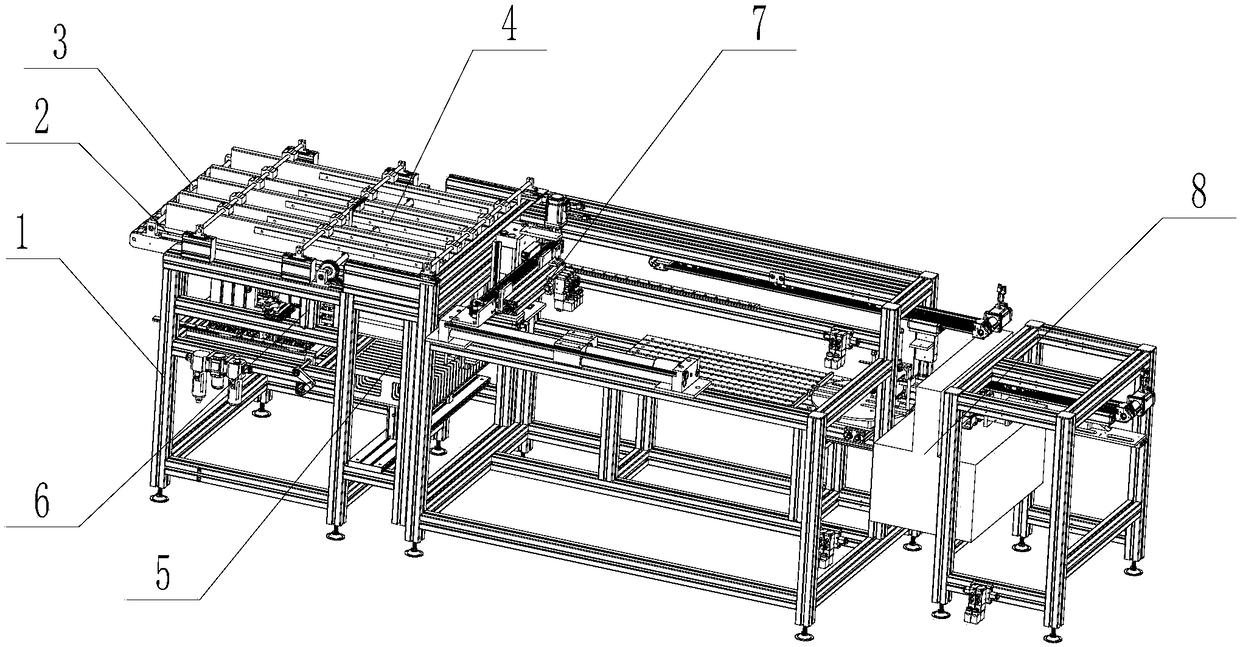

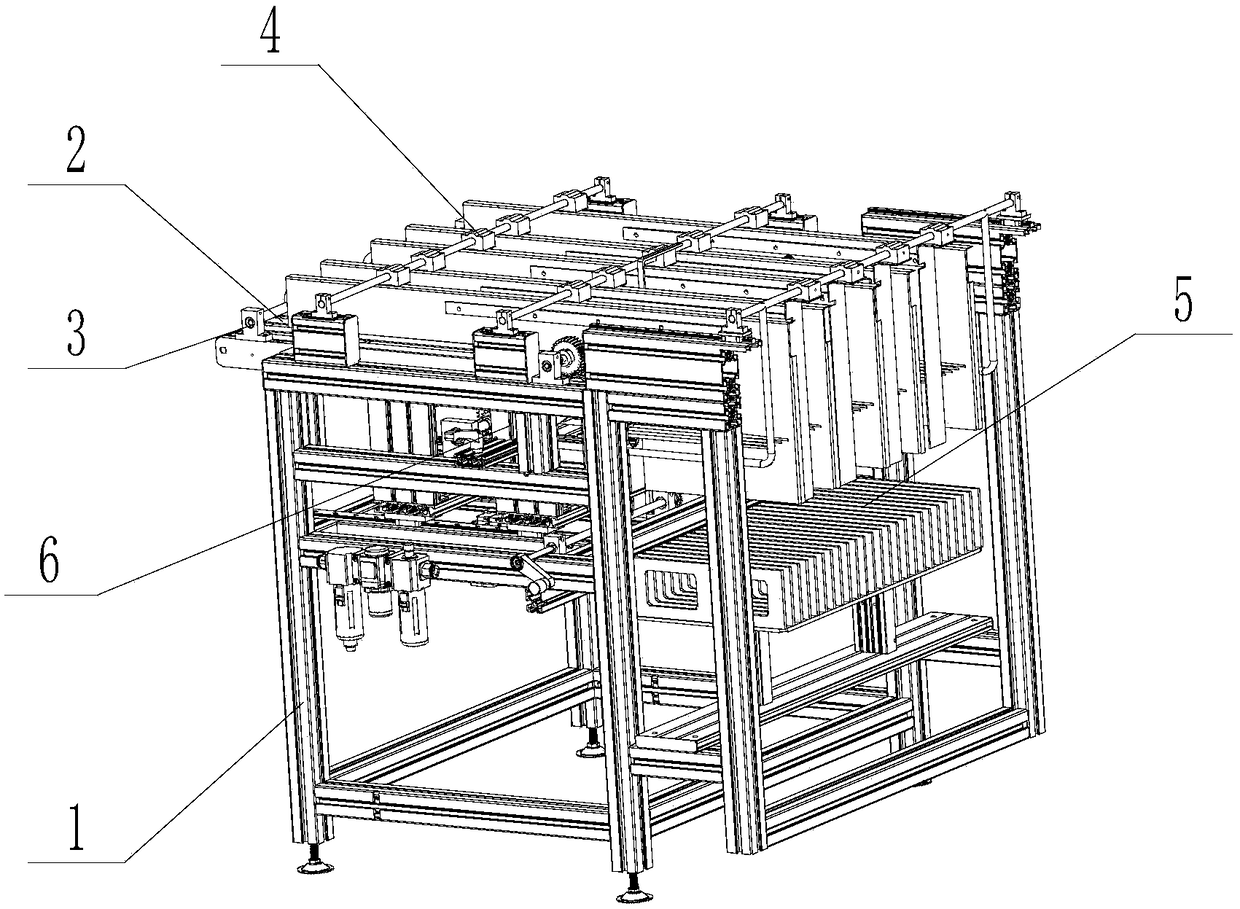

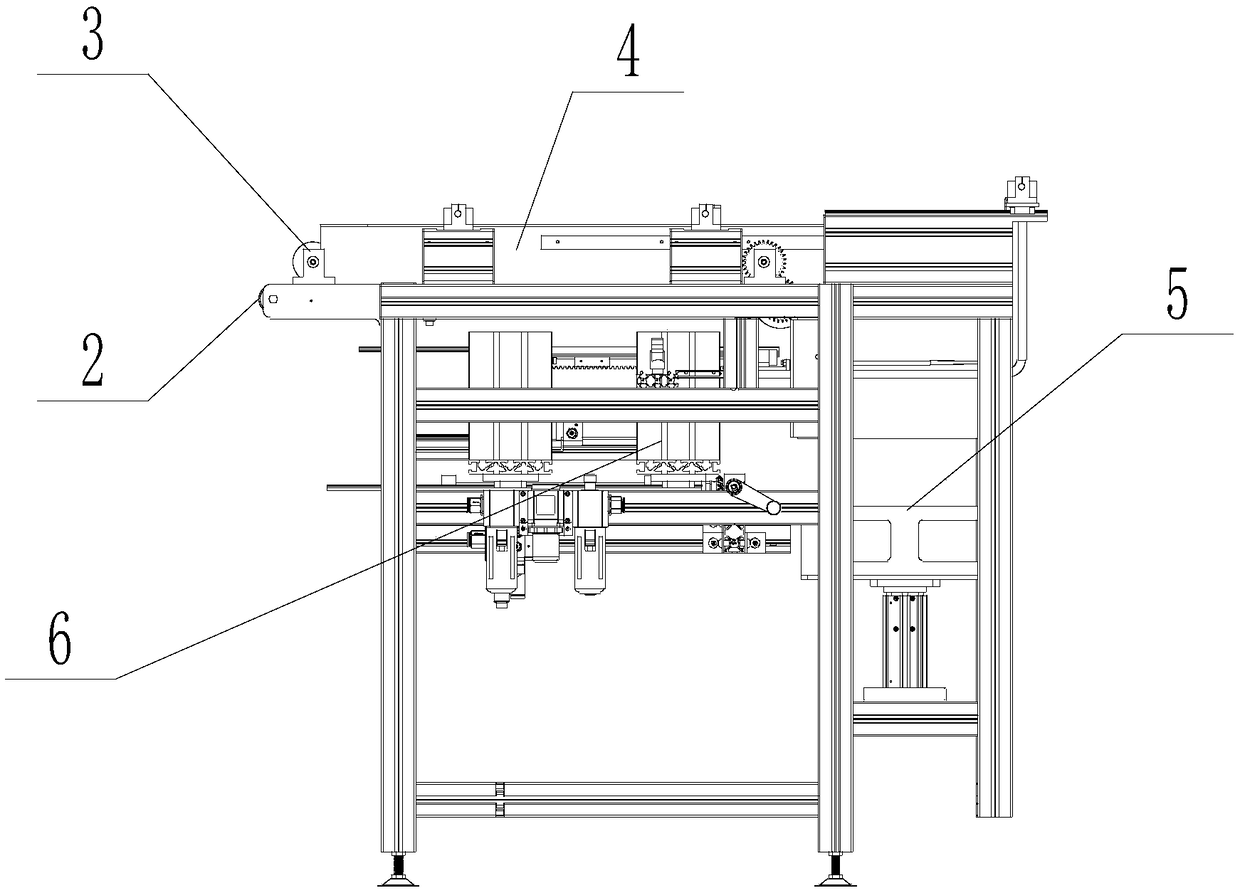

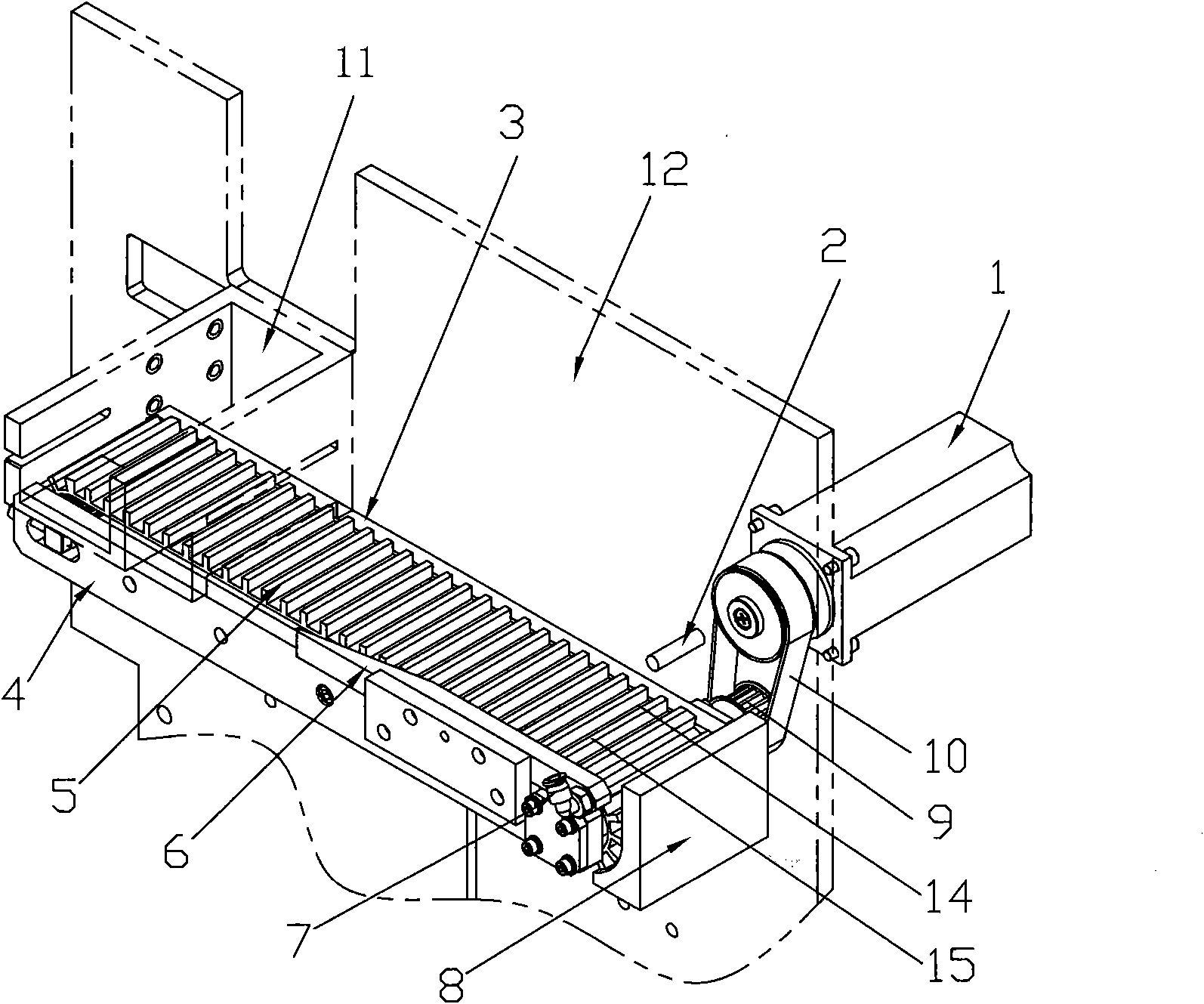

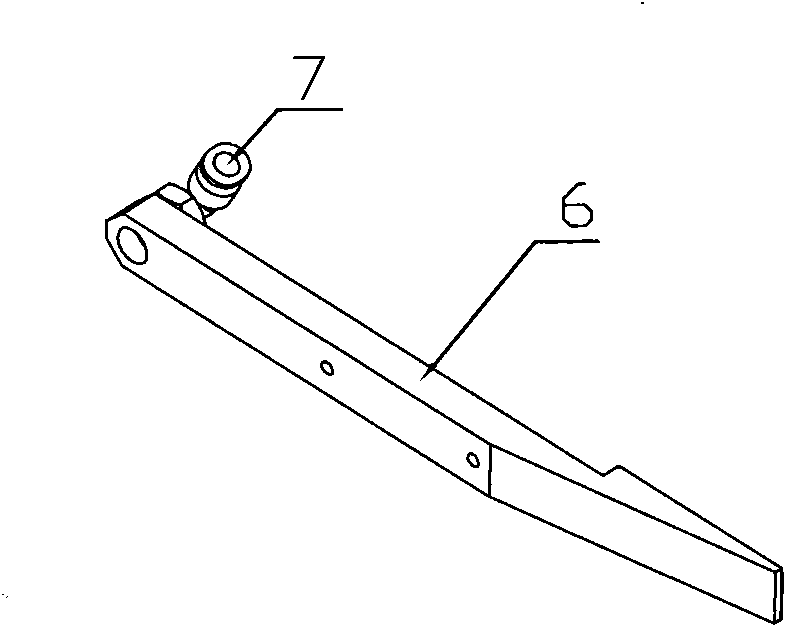

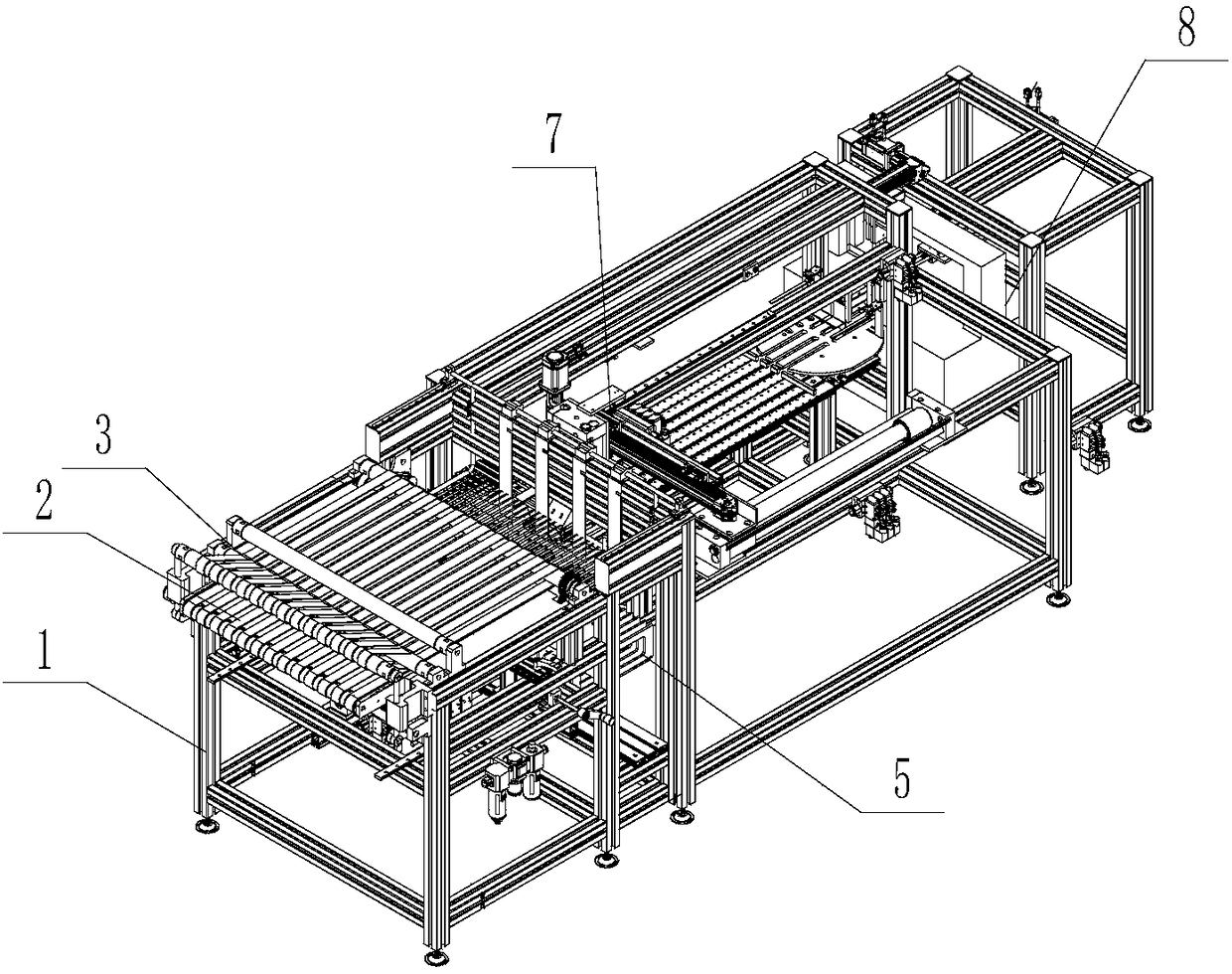

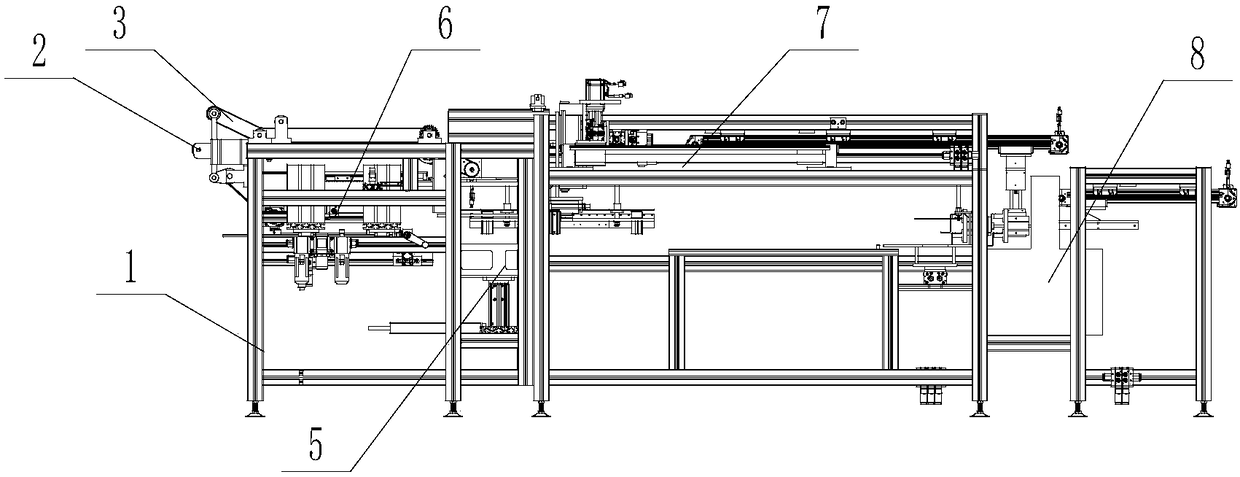

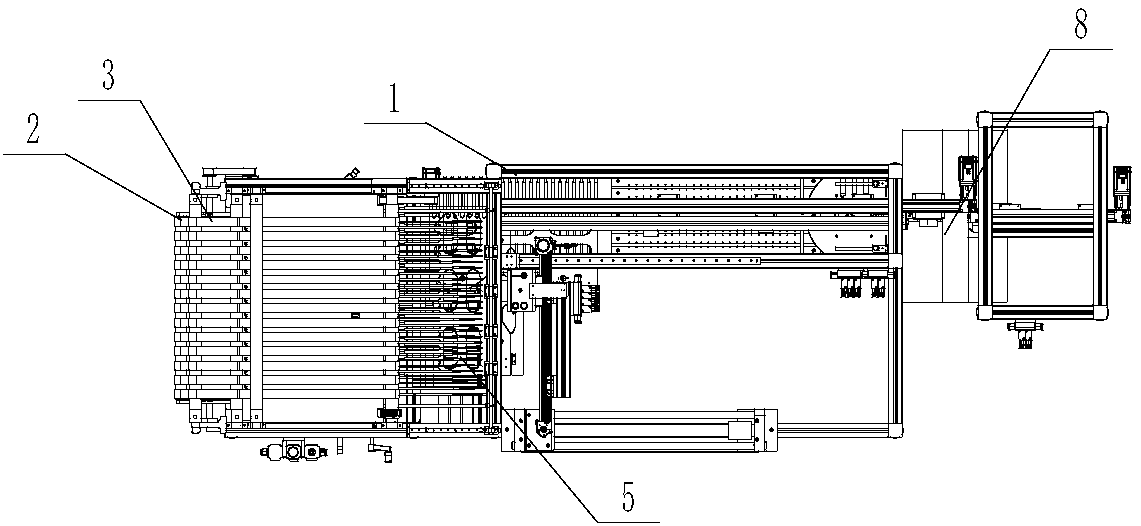

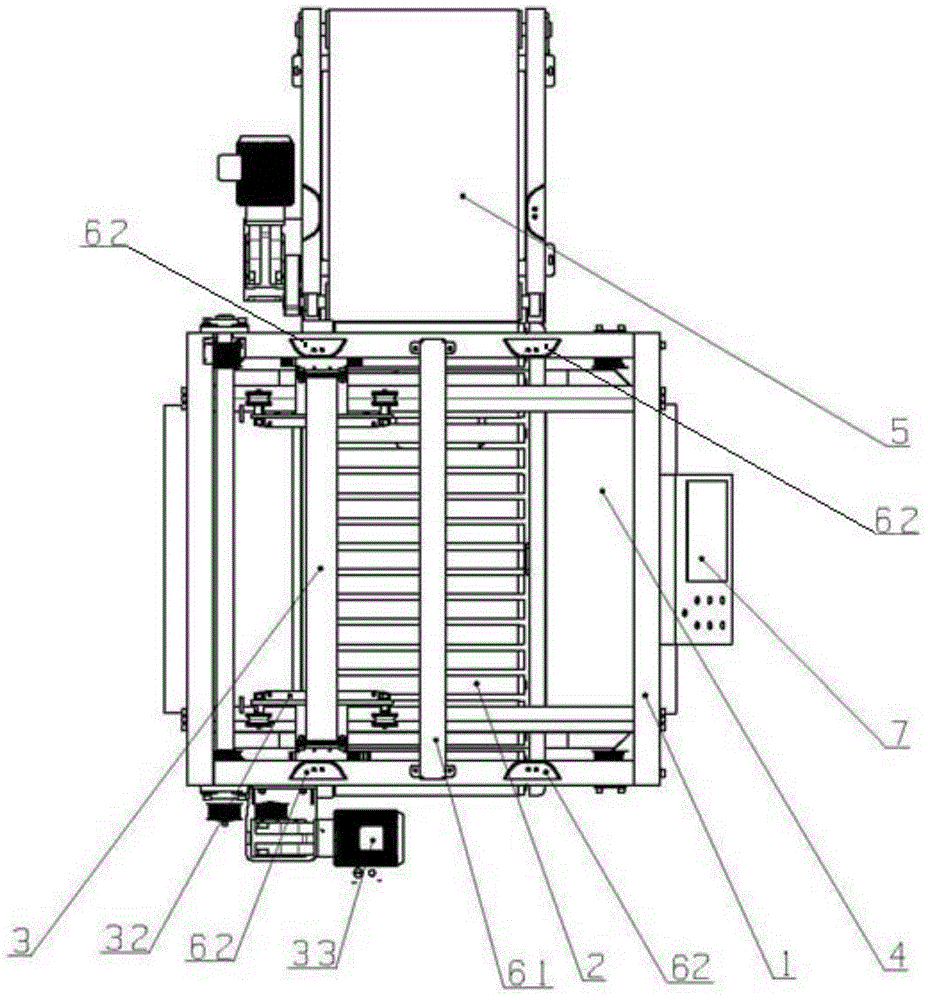

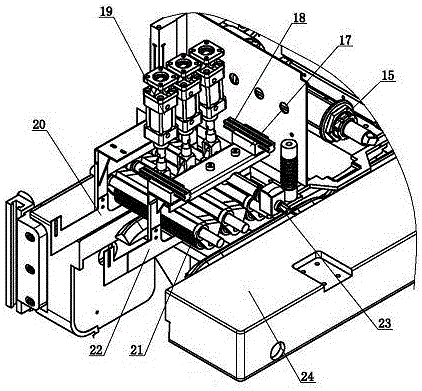

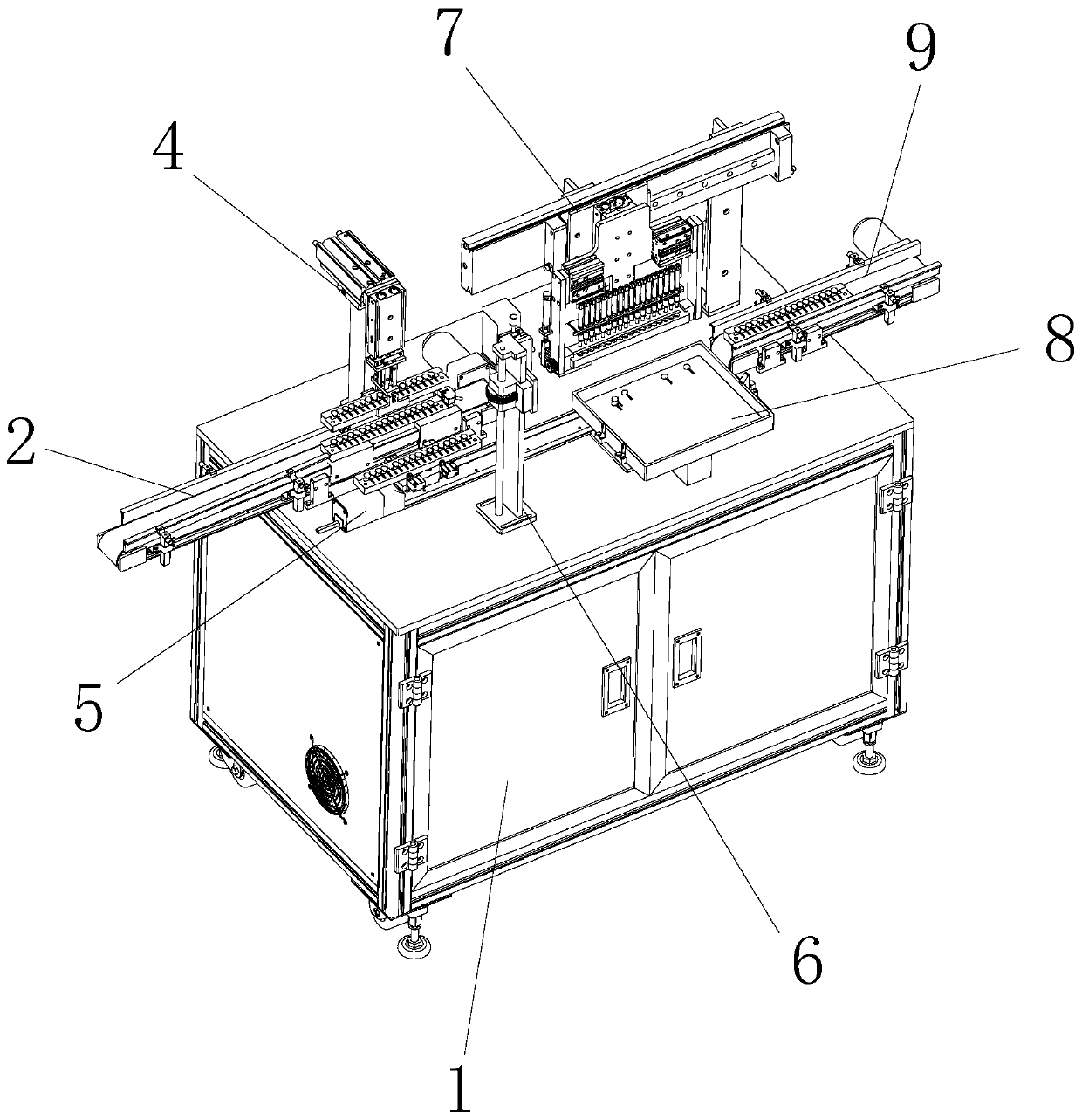

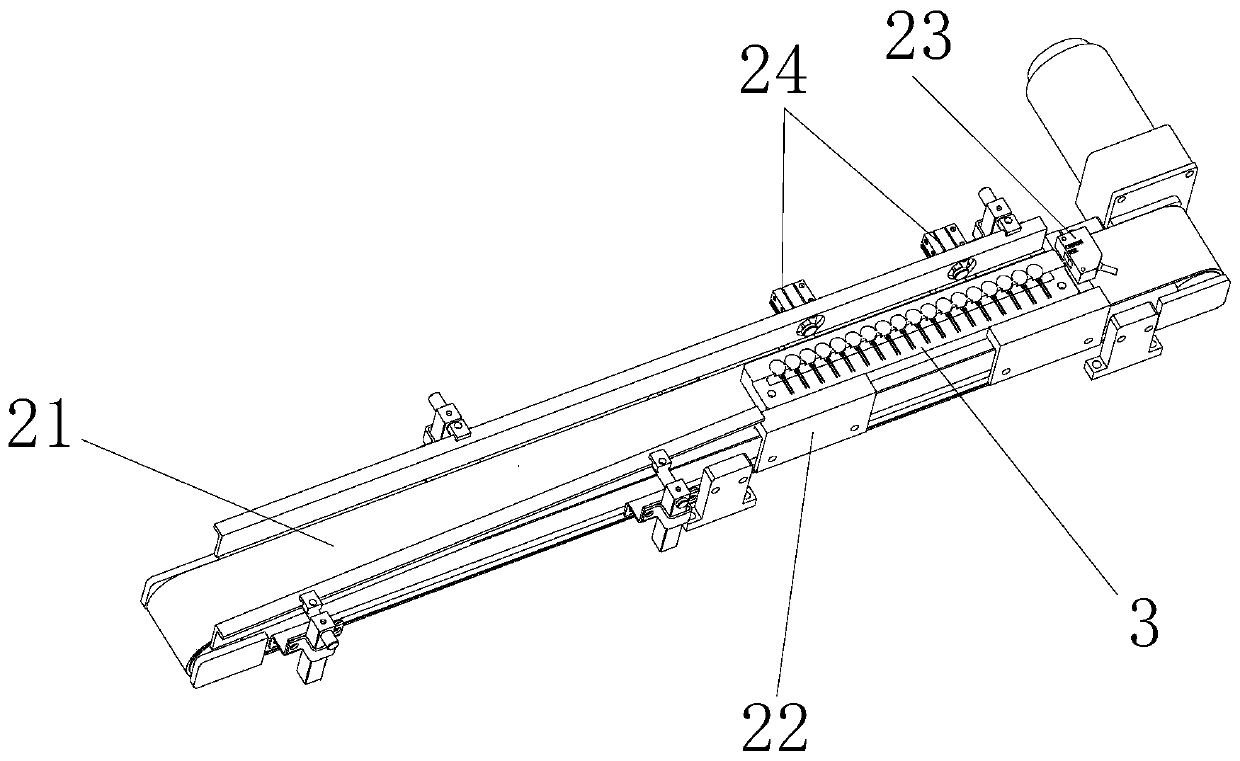

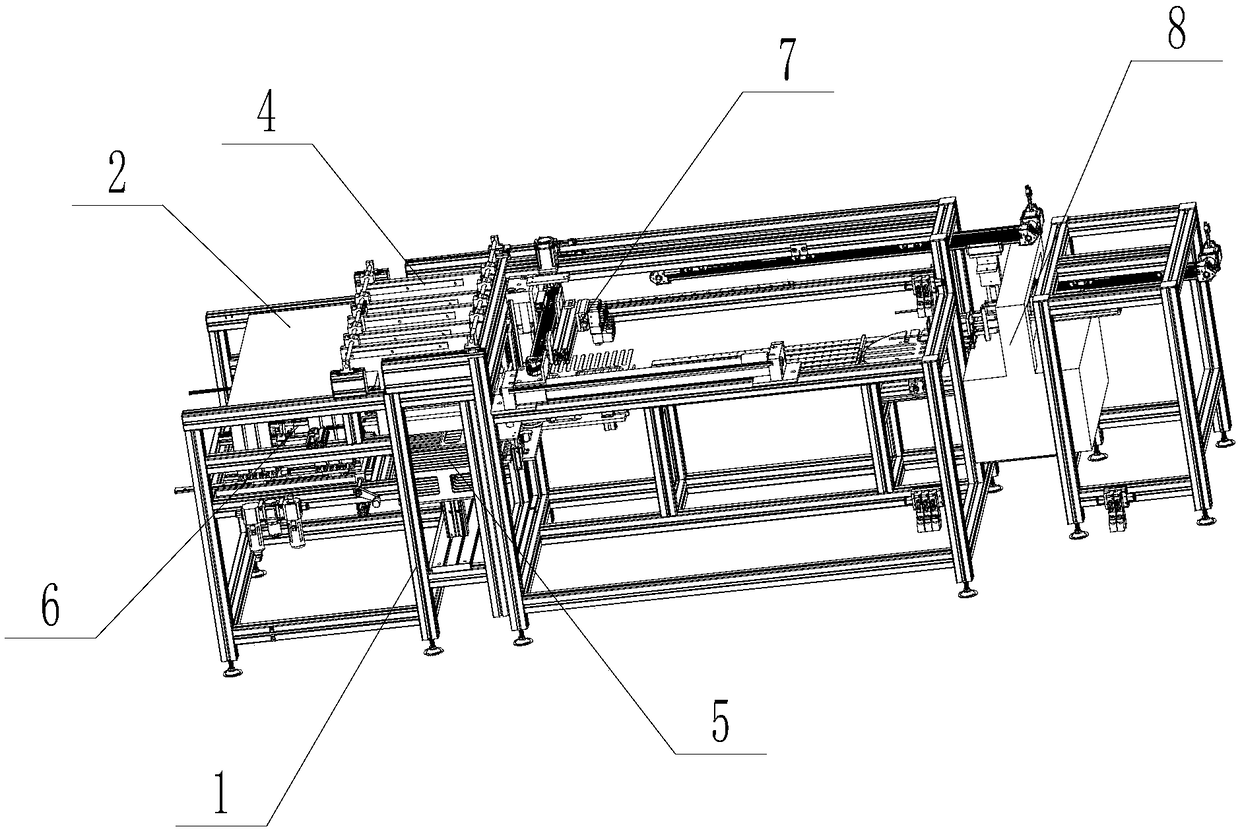

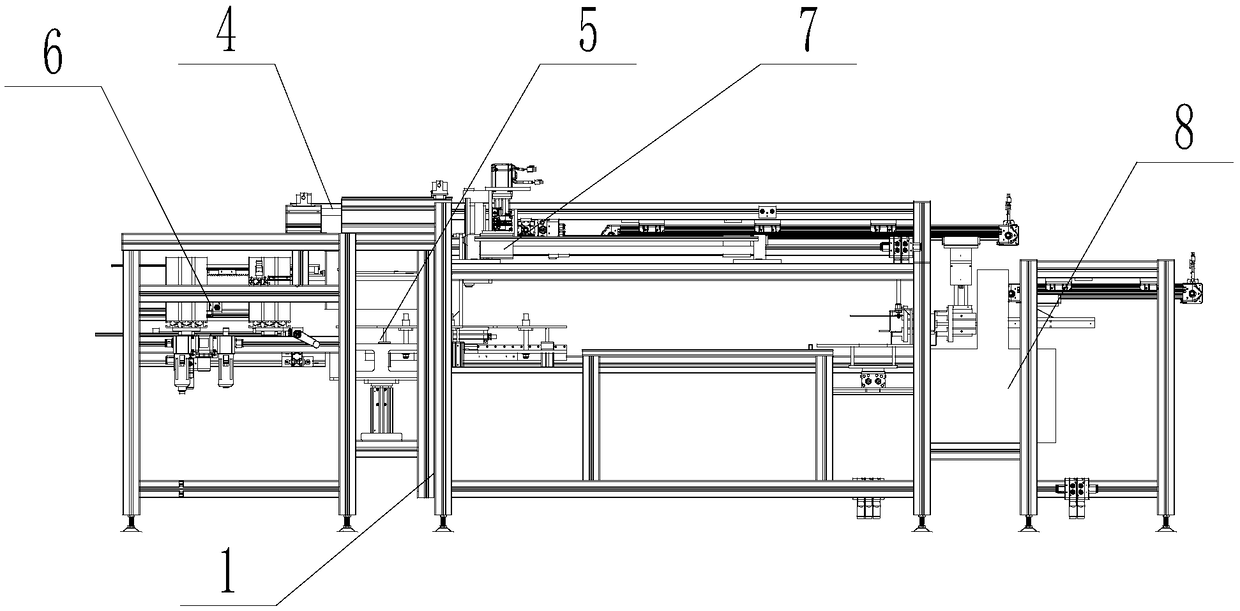

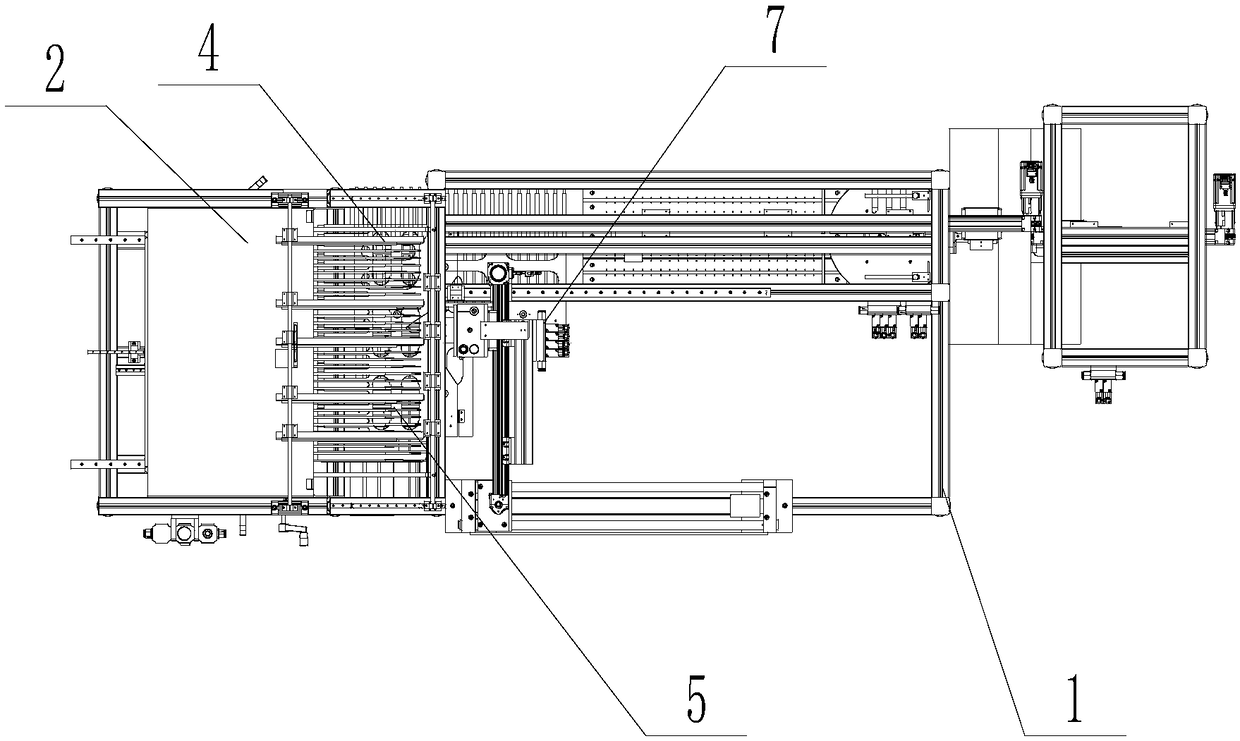

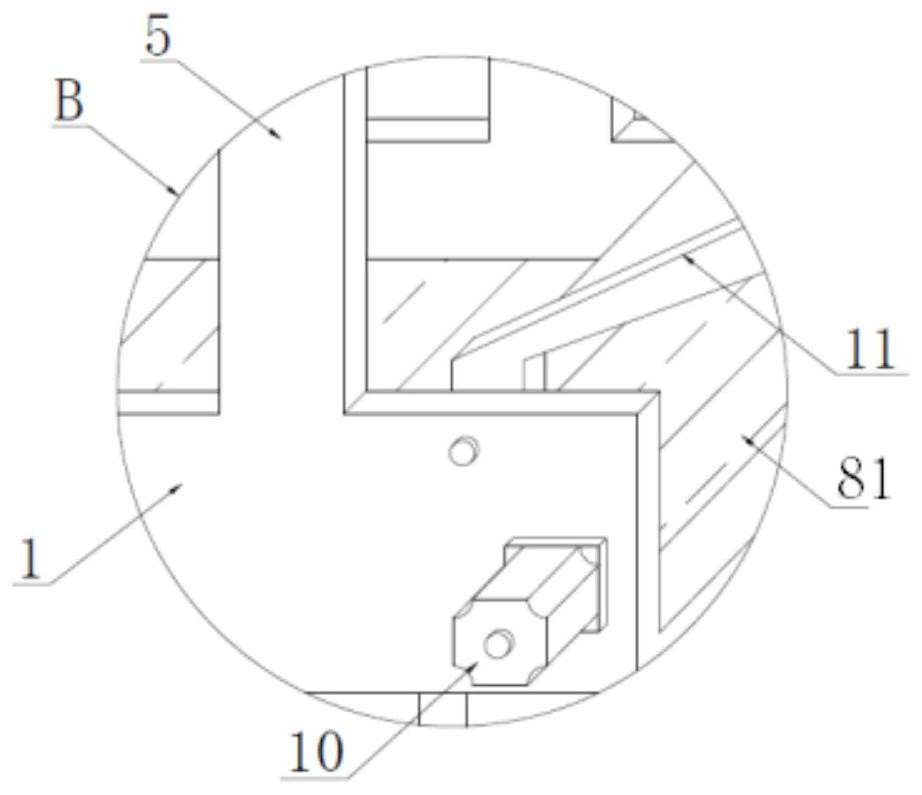

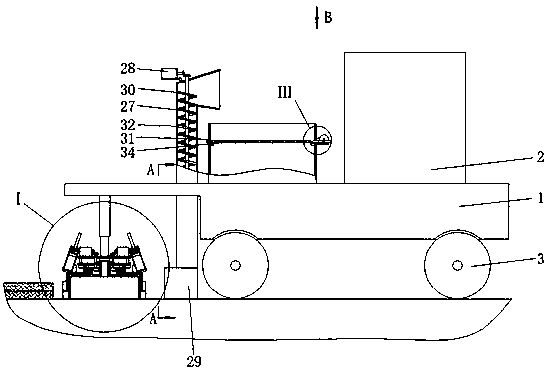

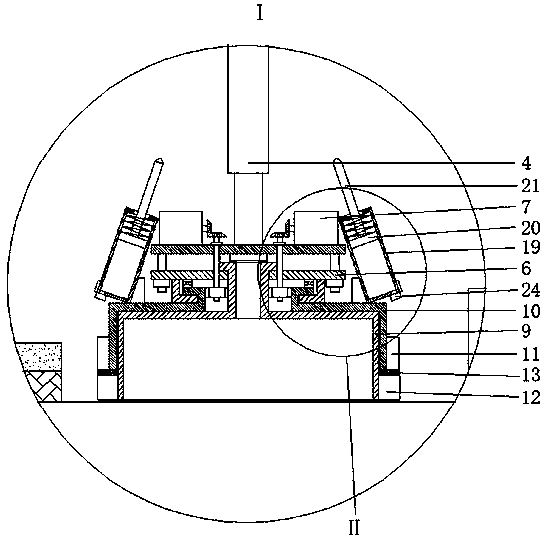

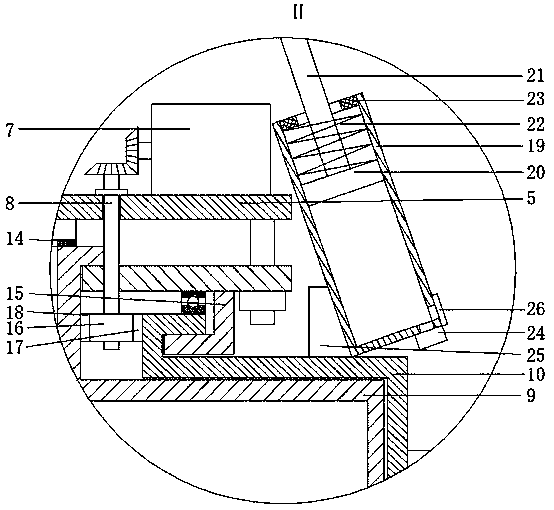

High-speed intelligent identification bag sorting machine

ActiveCN108773535AHigh-speed automatic strappingImprove bundling efficiencyPackaging automatic controlBundling machine detailsAgricultural engineeringPlastic bag

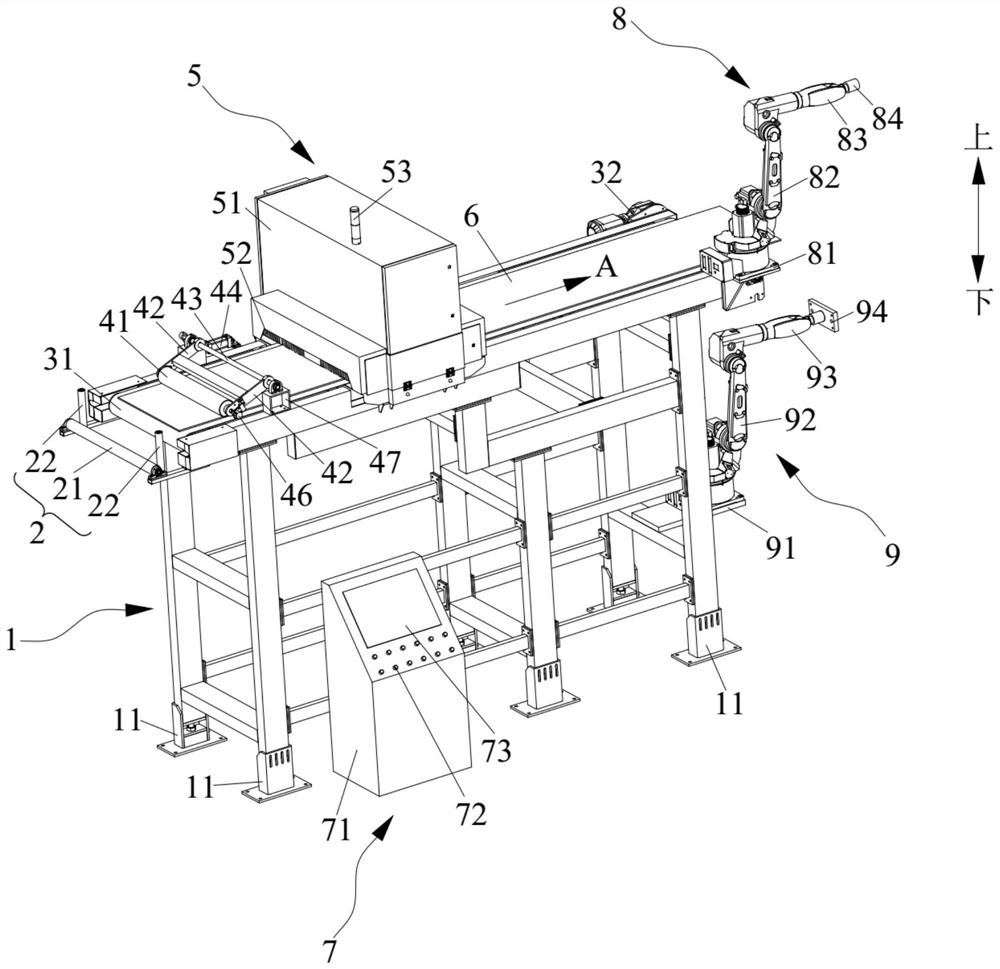

The invention discloses a high-speed intelligent identification bag sorting machine. The high-speed intelligent identification bag sorting machine comprises an integral machine frame, a feeding transmission module, a pressing wheel module, a separation baffle module, a discharging groove module, a reciprocating material pushing block rod module, a transfer module and a bundling module. The feedingtransmission module, the pressing wheel module, the separation baffle module, the discharging groove module, the reciprocating material pushing block rod module, the transfer module and the bundlingmodule are all arranged on the integral machine frame. The high-speed intelligent identification bag sorting machine can realize automatic bundling of plastic bags with high bundling efficiency and low labor cost, can be adjusted to adapt to the automatic bundling of plastic bags with different widths, lengths and thicknesses, and has a wide application range. The unqualified products can be detected and rejected with high rejection efficiency.

Owner:浙江创派智能科技有限公司

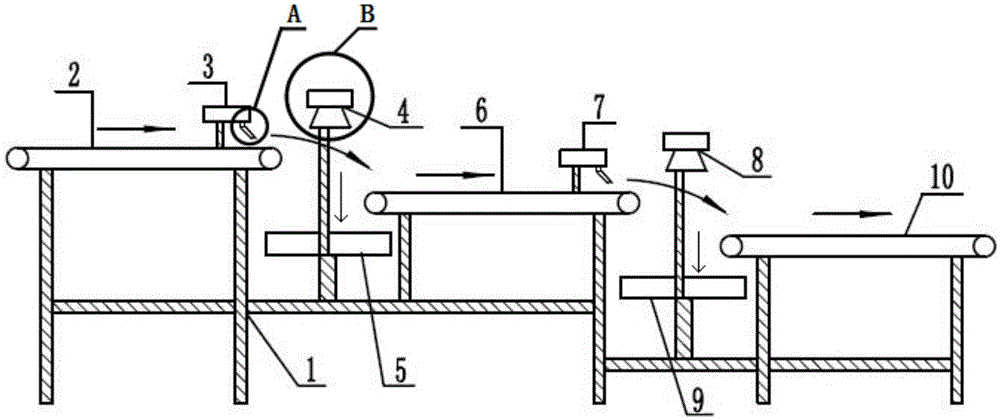

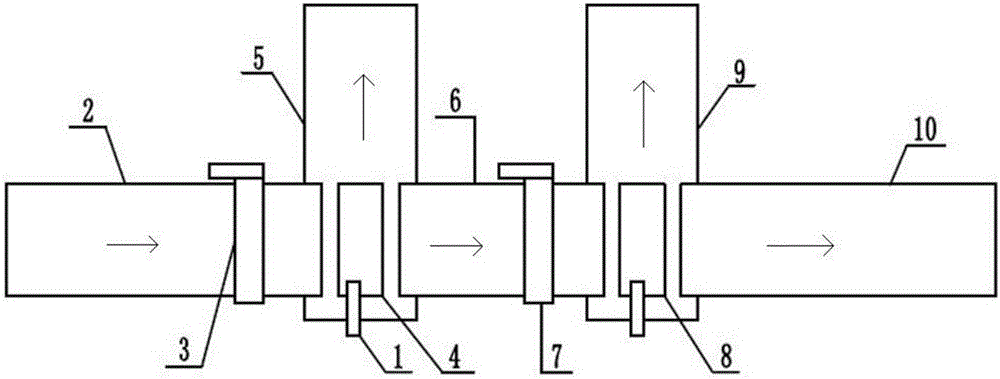

On-line detection and rejection device for cigarette packaging machine to reject cigarette

InactiveCN102431668AOrderly rowsReduce wastePackaging cigarettePackaging cigarsDrive shaftEngineering

The invention discloses an on-line detection and rejection device for a cigarette packaging machine to reject cigarettes and belongs to the technical field of cigarette making machines. The on-line detection and rejection device comprises a detection belt, a drive motor, a baffle, a wedge-shaped stop dog, side plates arranged on two sides of the detection belt and a hollow-head detection sensor, wherein a motor output shaft and the drive shaft of the detection belt are connected by virtue of a driving belt; one end of the detection belt is positioned below the smoke outlet of a baiting hopper; the other end of the detection belt is provided with the baffle; the side plate on one side of the detection belt is provided with the wedge-shaped stop dog; the end part, adjacent to the baffle, of the wedge-shaped stop dog is provided with a rejection air tap; and the part, which corresponds to the wedge-shaped stop dog, of the side plate on the other side is provided with the hollow-head detection sensor. According to the on-line detection and rejection device, hollow-head cigarettes in the baiting hopper of a recovery plant can be detected and rejected to reduce waste in the cigarette package and improve the effective operation rate. In addition, a plurality of cigarettes can be simultaneously discharged so as to improve the detection and rejection efficiencies.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

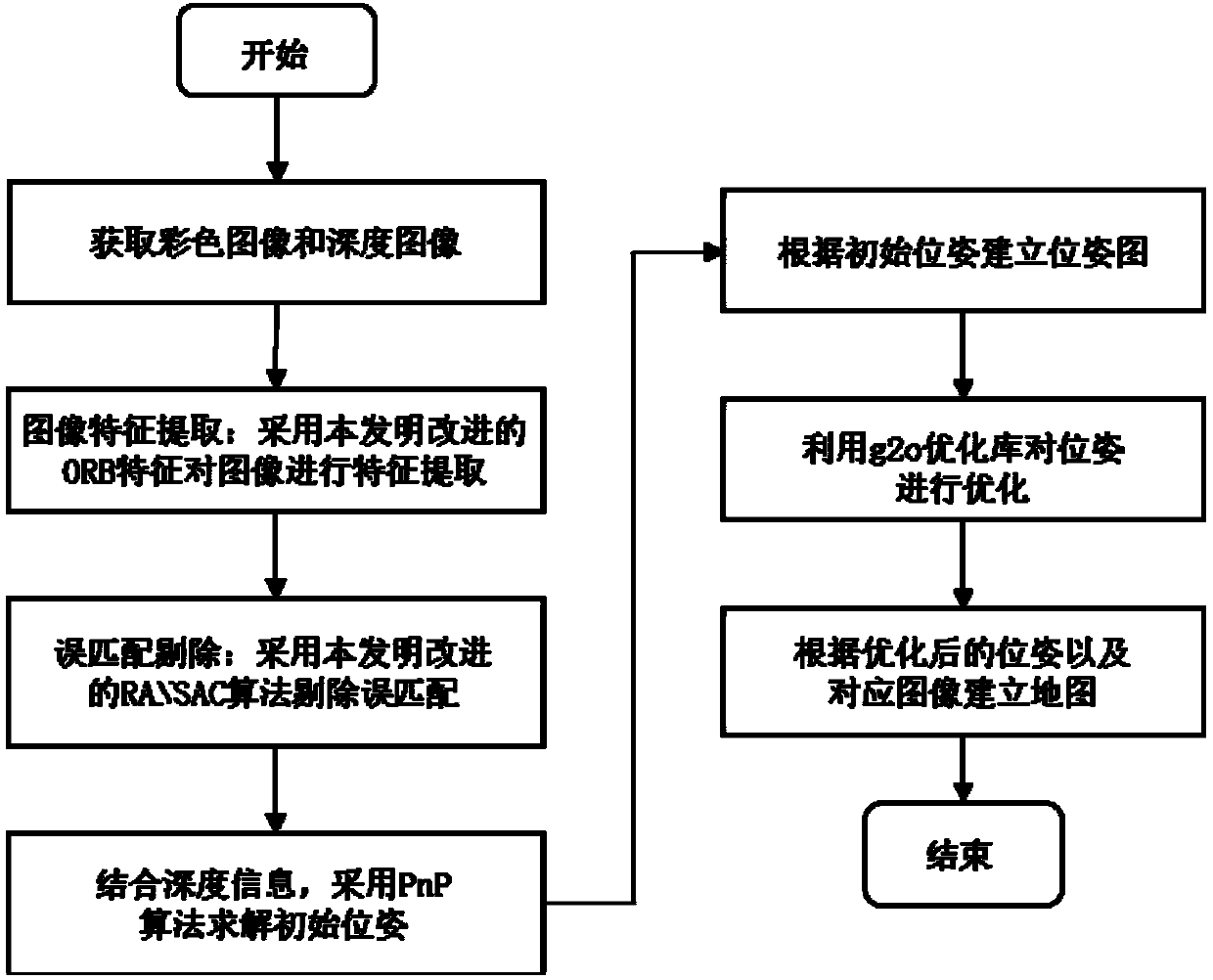

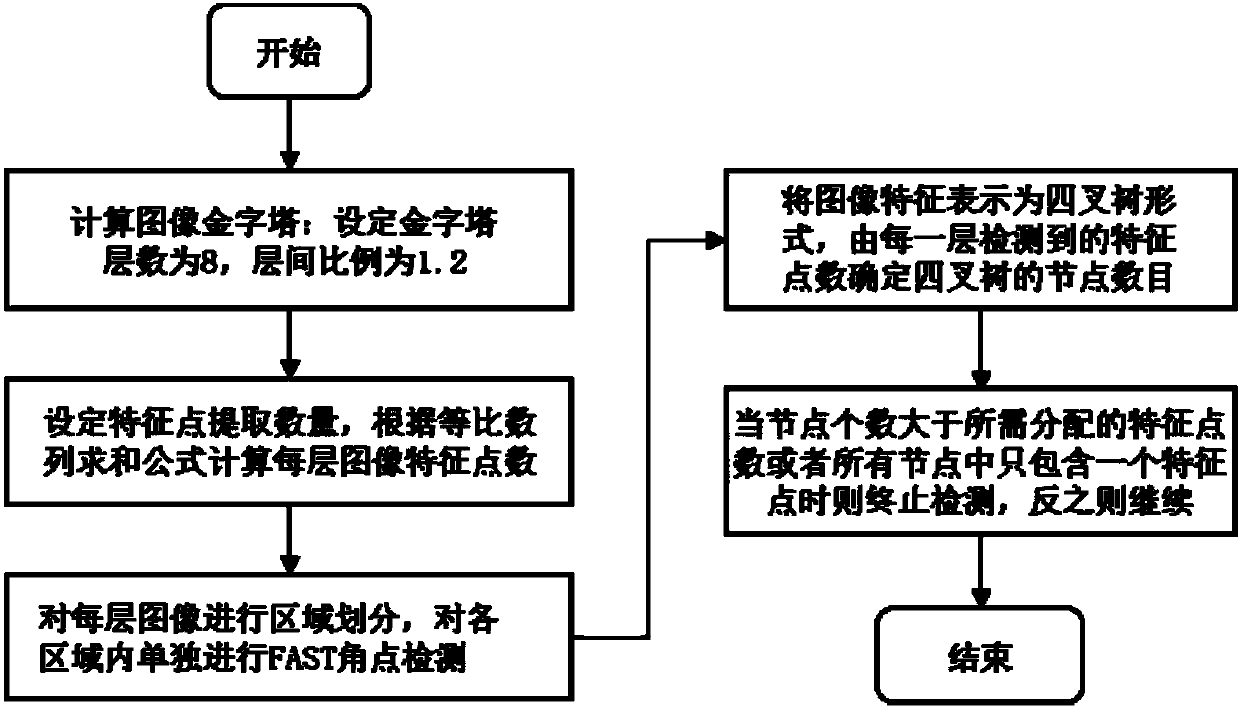

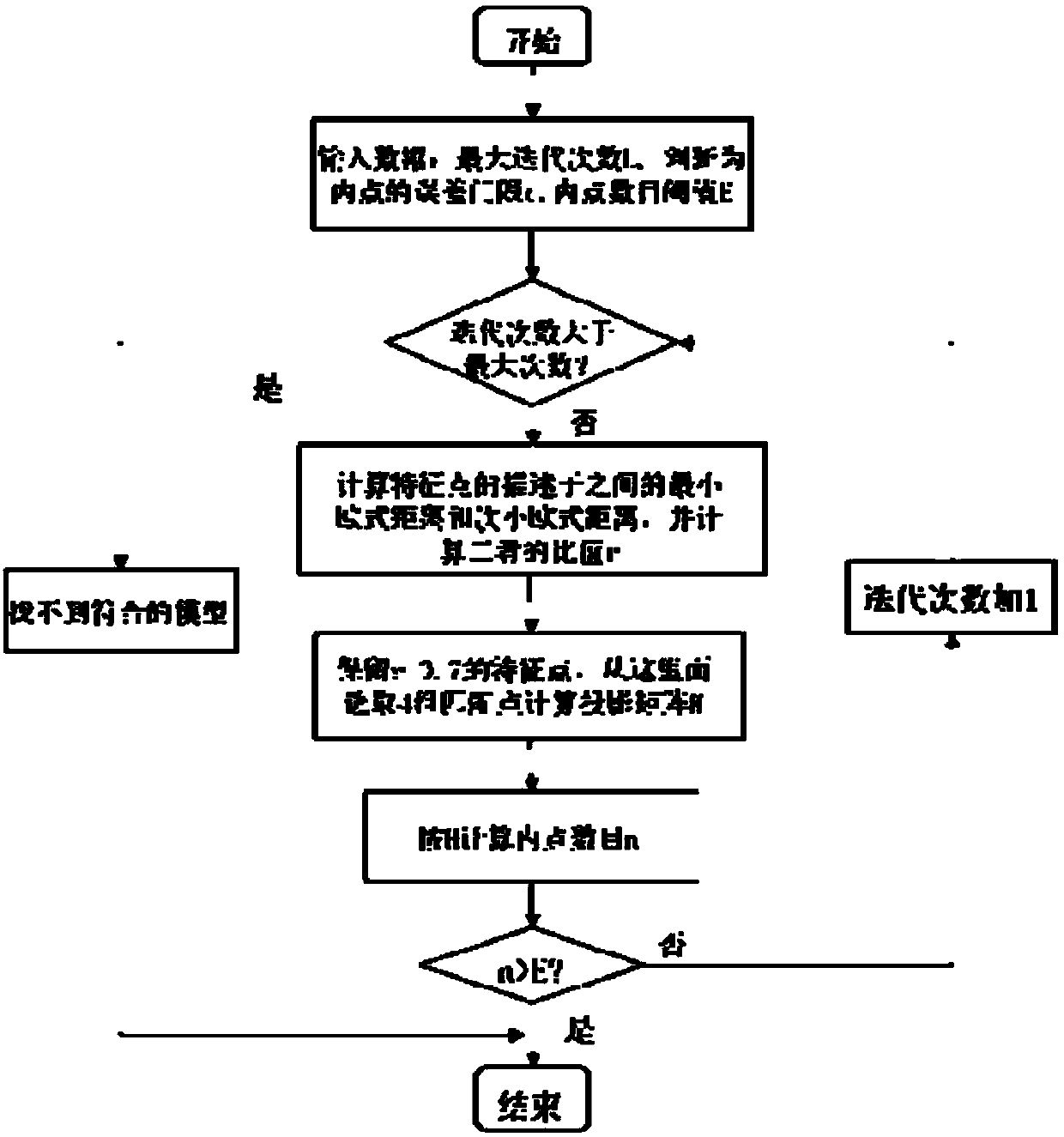

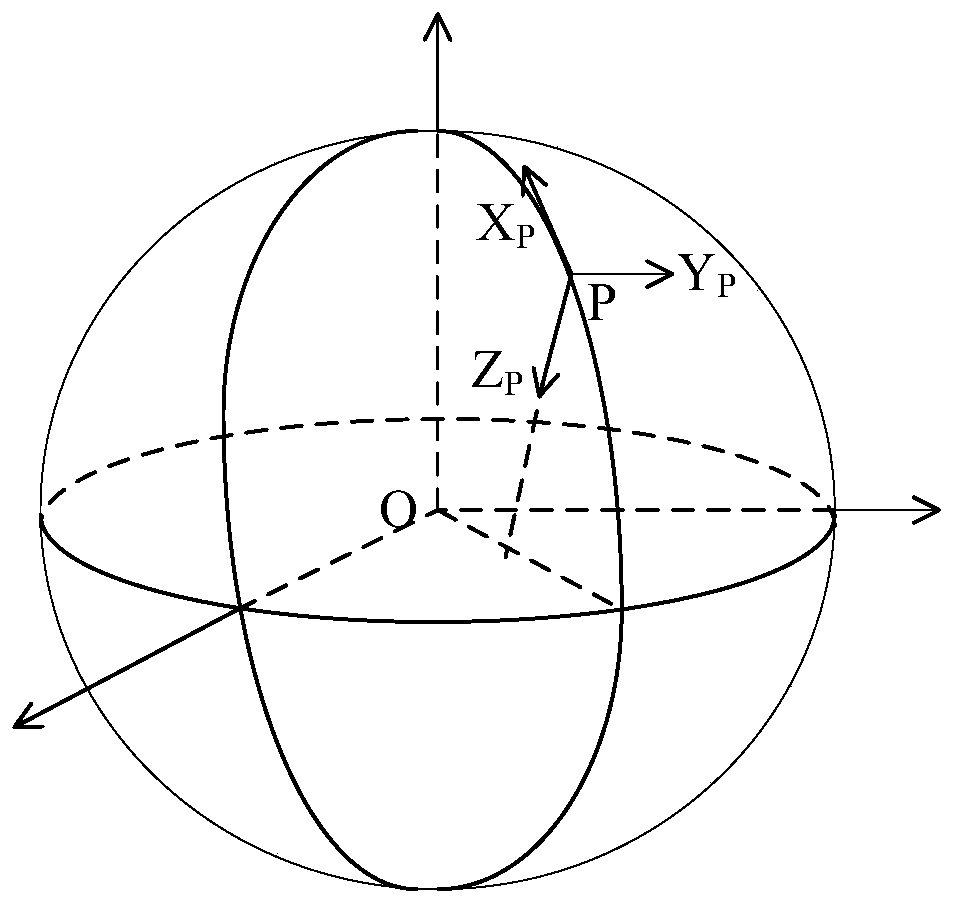

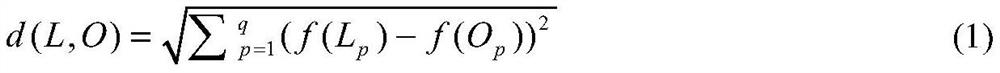

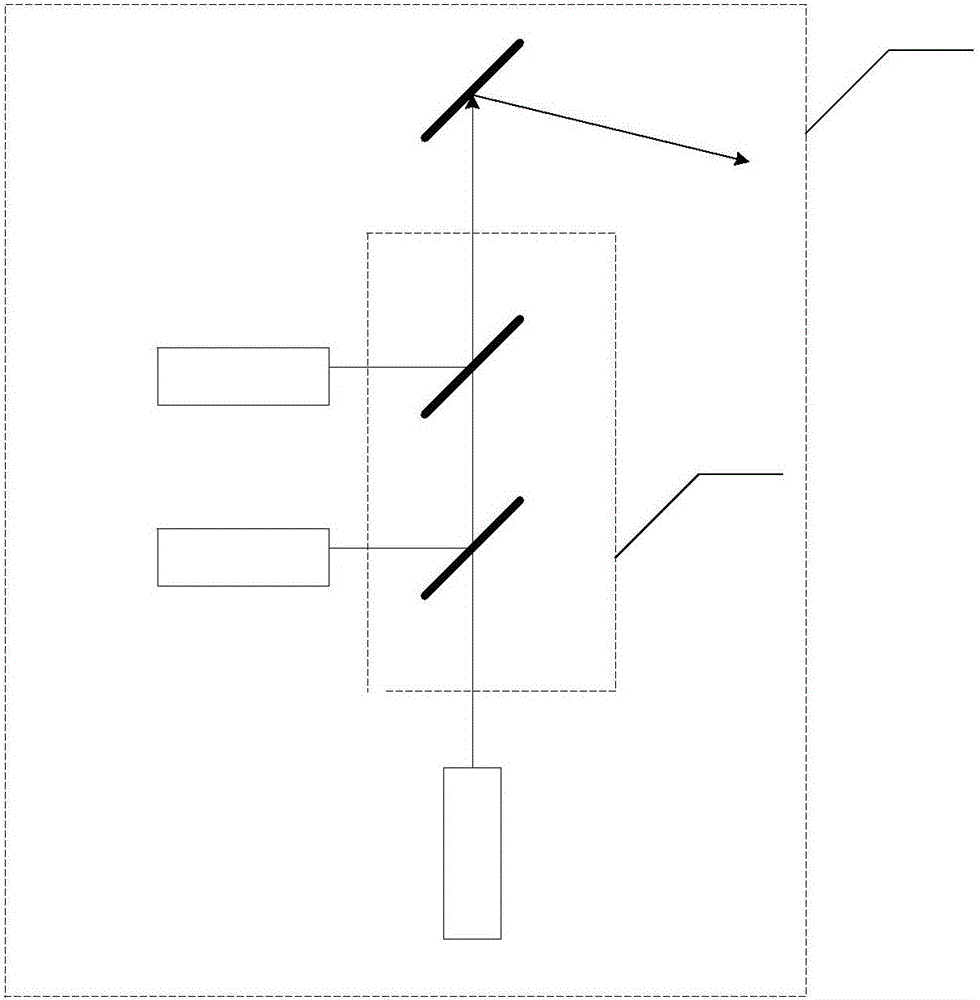

Synchronous localization and mapping method based on improved image matching strategy

InactiveCN108416385AImprove robustnessImprove culling efficiencyCharacter and pattern recognitionFeature matchingPoint cloud

The invention provides a synchronous localization and mapping method based on an improved image matching strategy. According to the method, Oriented FAST (Oriented Features from Accelerated Segment Test) angular point detection is performed on each area of the image by using the improved ORB feature, the descriptor of the feature point is calculated and then feature matching and screening are performed by using an improved RANSAC algorithm; finally the initial attitude of the robot is solved by using the PnP (Perspersctive-n-Point) method, an attitude graph is generated by using the obtained initial attitude, and then the attitude is updated by using the Levenberg-Marquardt method and the attitude is optimized by using the g2o (General Graphic Optimization, G2O) optimization library; and finally the optimized attitude and the corresponding frame are combined together so as to generate the point cloud map. According to the method, the mismatch eliminating efficiency can be enhanced andthe robustness of the tracking process can be improved so as to obtain the accurate map.

Owner:BEIJING UNIV OF TECH

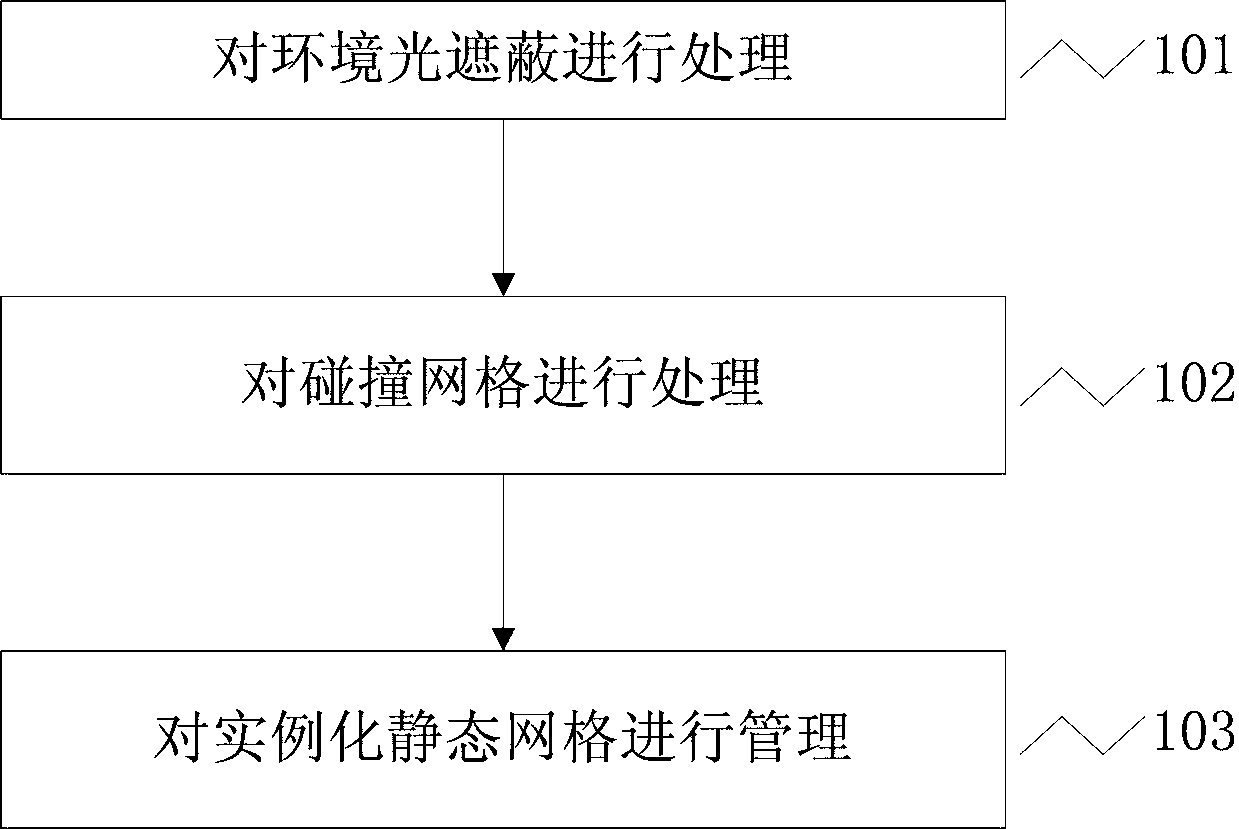

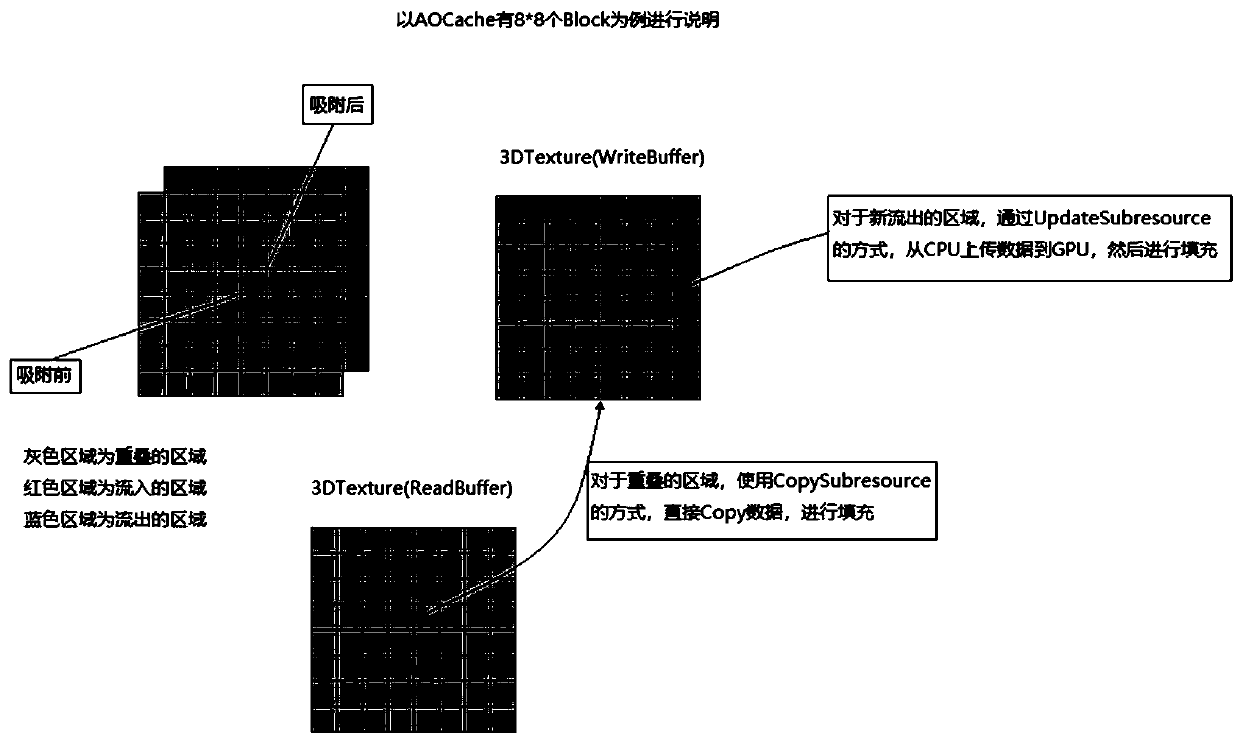

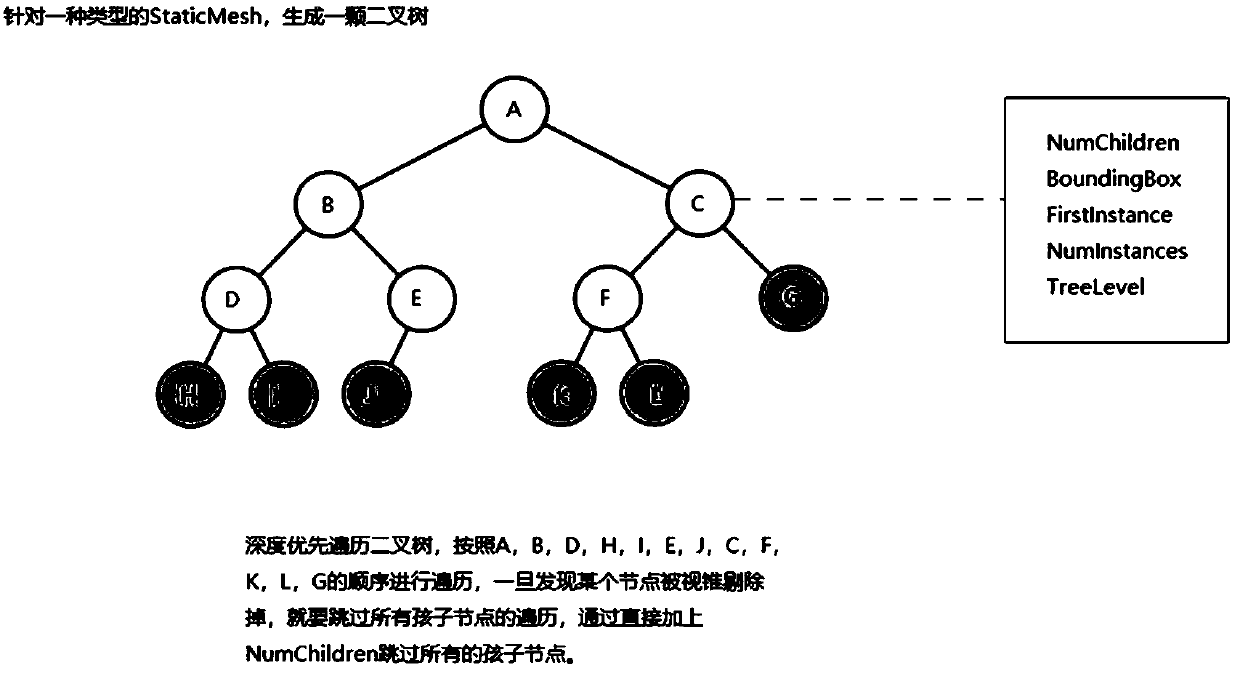

Management method of voxel landform

The invention provides a management method of voxel landform. The management method comprises the following steps that (1) landform is selected and built, the environment lighttight shield informationof the landform is calculated and stored into 3D texture, and environment lighttight shield is processed; (2) collision mesh is processed by using a cubic surface extraction algorithm and a GreedyMeshing algorithm, and (3) static mesh are instantiated by using binary tree. The management method of voxel landform ensures the execution efficiency of calculating the environment lighttight shield byusing the simplified environment lighttight shield algorithm, guarantees the high efficiency of mesh extraction by using the simple cubic surface extraction algorithm, manages the instantiated staticmesh by using the binary tree, and improves the view-frustum culling efficiency.

Owner:SNAIL GAMES

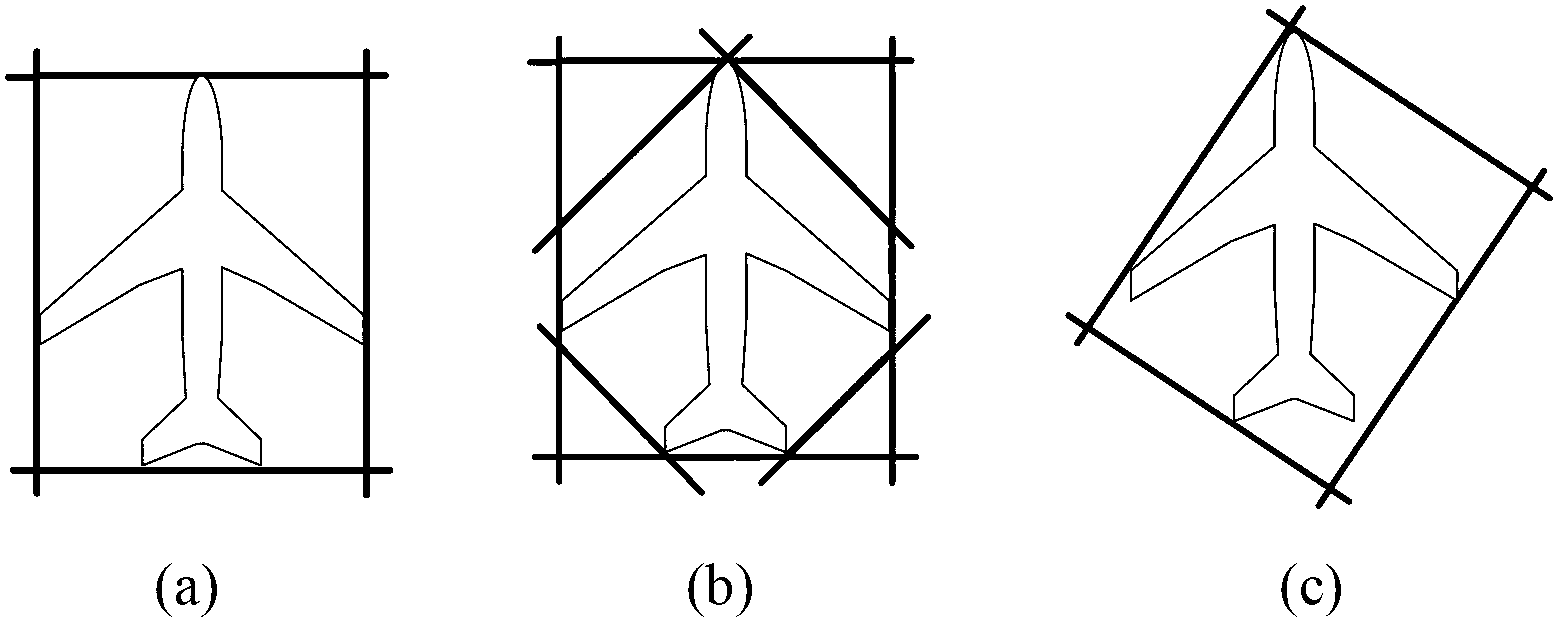

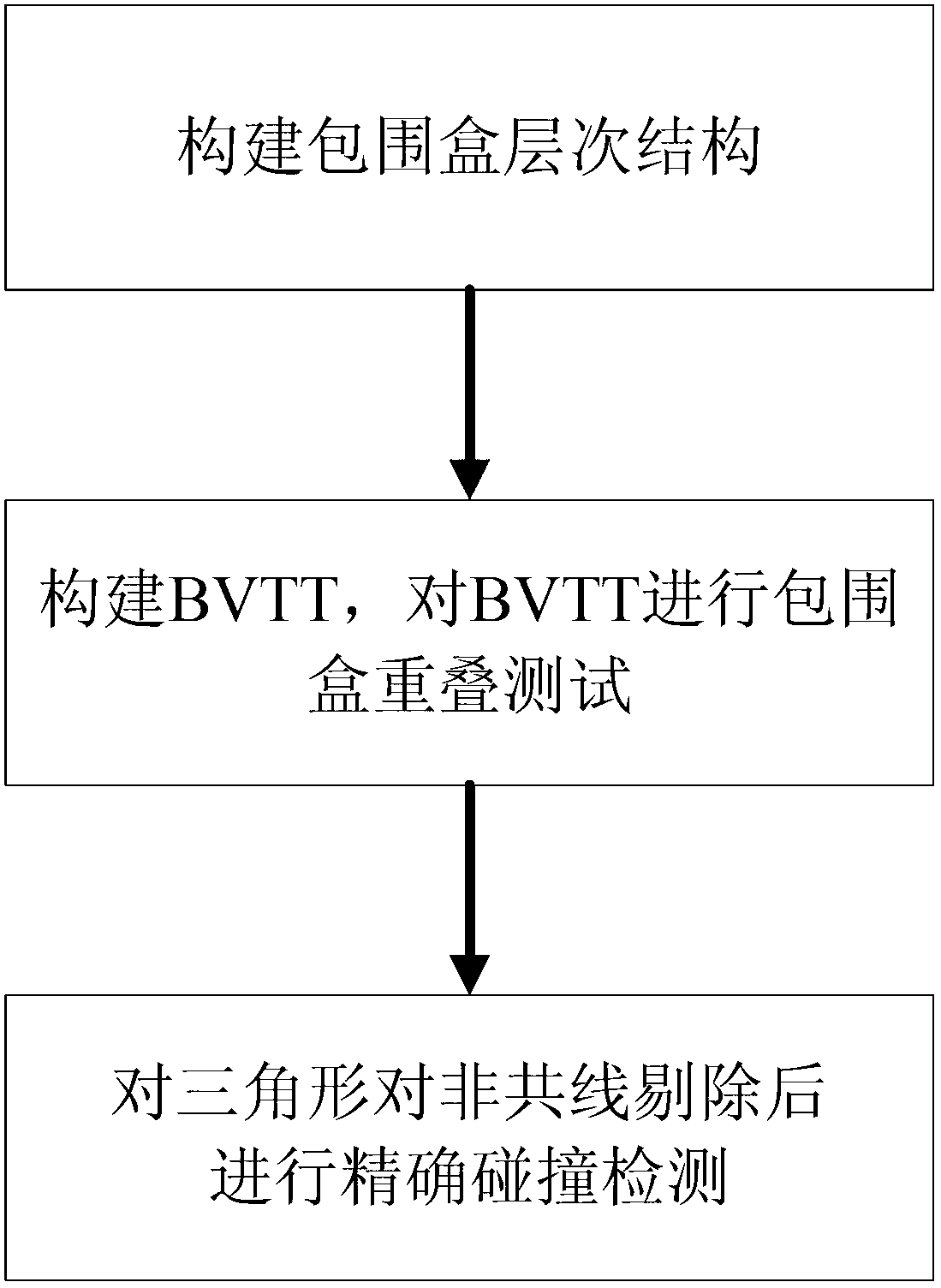

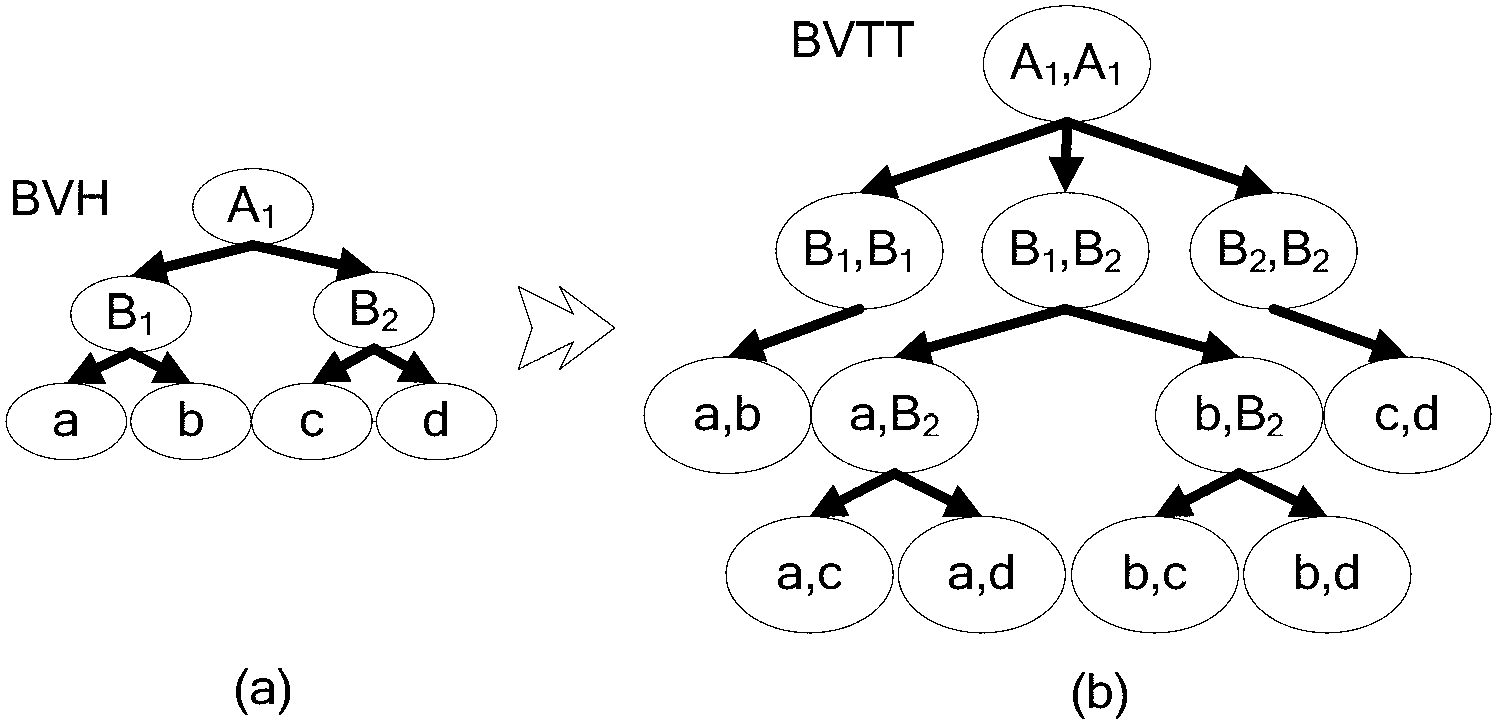

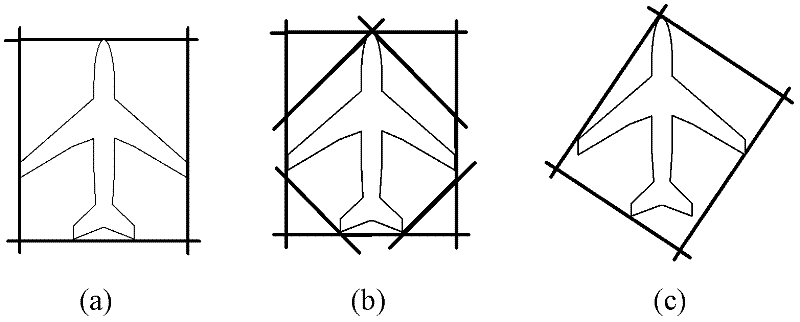

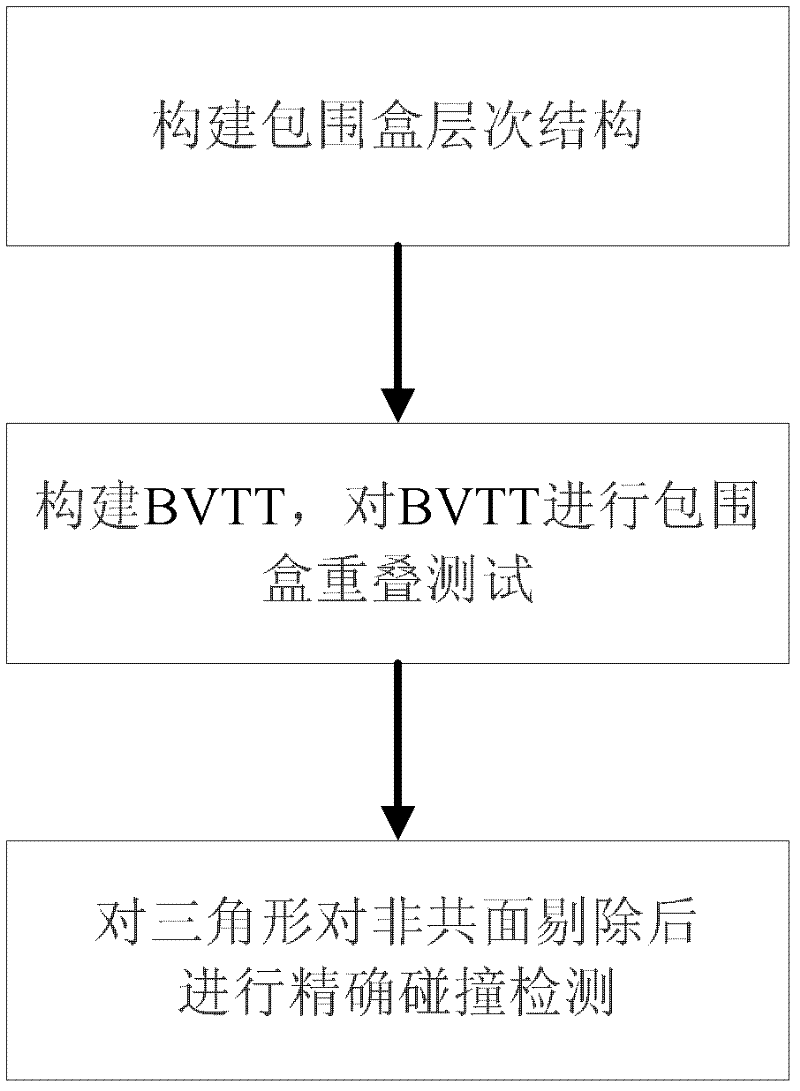

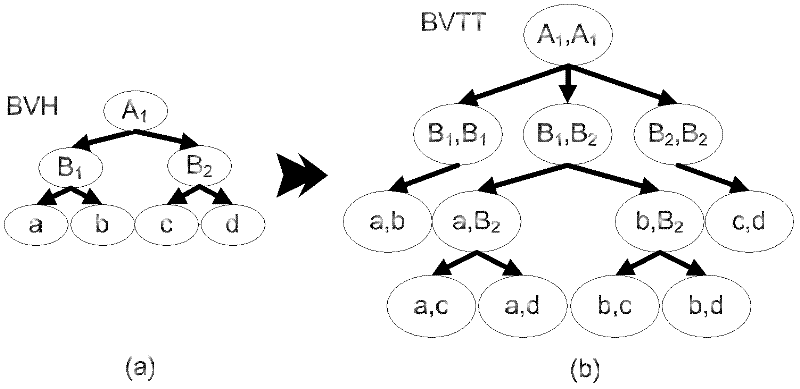

Non-collinear-elimination-based detection method for continuous collision in flexible scene

InactiveCN102708017AImprove culling efficiencyThe detection process is fastError detection/correctionComputer scienceBounding volume

The invention discloses a non-collinear-elimination-based detection method for continuous collision in a flexible scene. The method comprises the following steps: (1) establishing a hierarchical structure of a bounding volume; (2) establishing a BVTT (bounding volume test tree), and performing the overlap test of the bounding volume for the BVTT; and (3) performing the accurate collision detection to the triangle after the non-collinear elimination. According to the invention, the corresponding collisions are eliminated in a non-collinearly manner in the accurate collision detection phase, the efficiency of the continuous collision detection is improved due to the high elimination efficiency of the non-collinear elimination detection and fast detection speed, and the times of the accurate collision detection are greatly reduced, so that the coverall speed of the continuous collision detection is greatly increased with very good compatibility.

Owner:ZHEJIANG UNIV

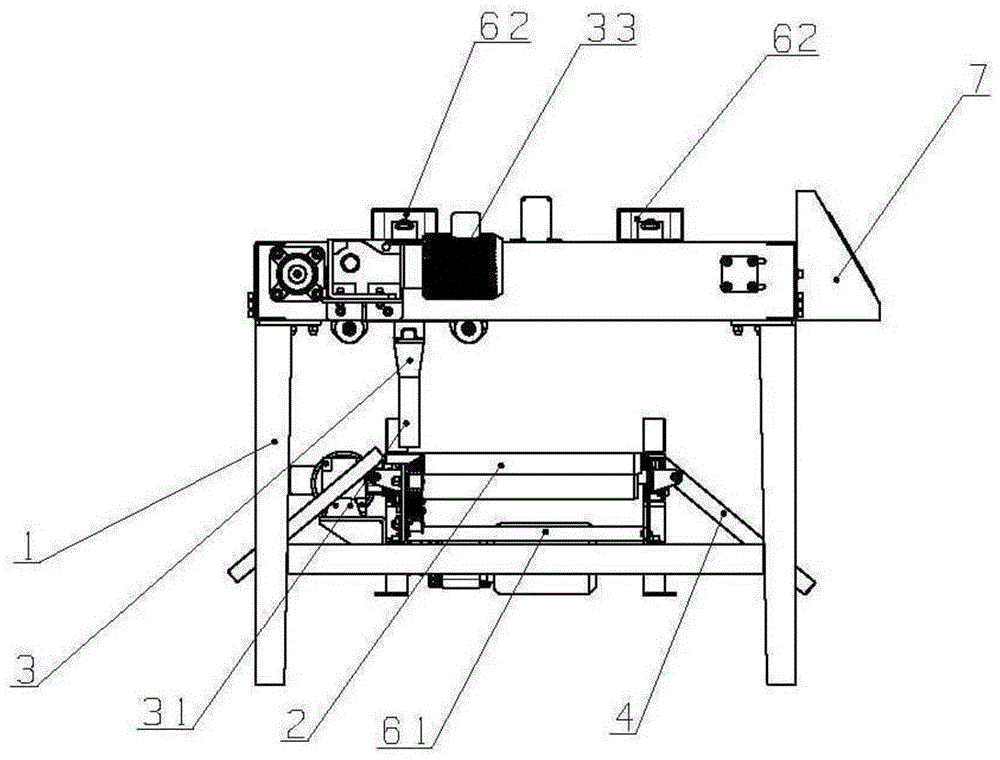

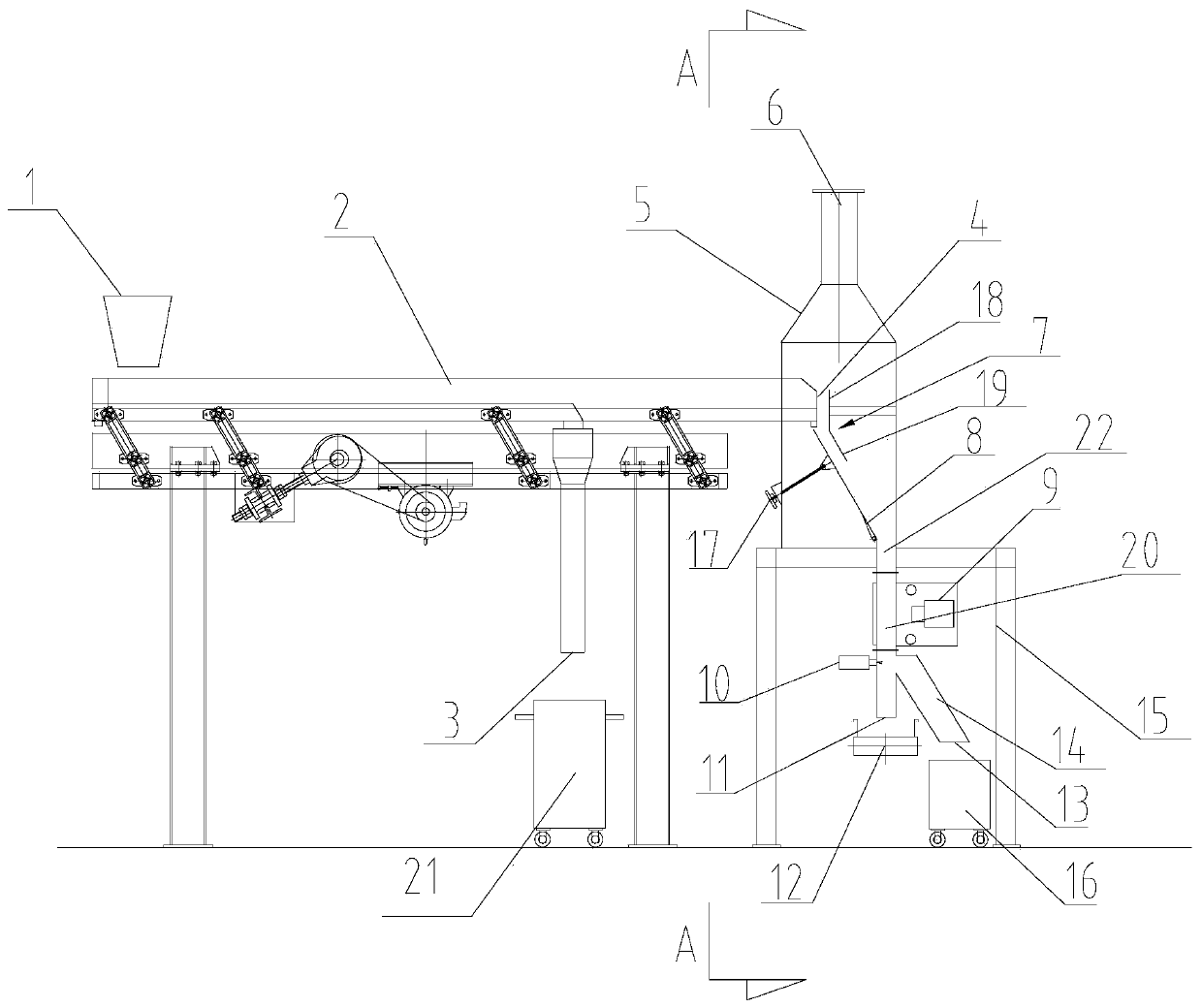

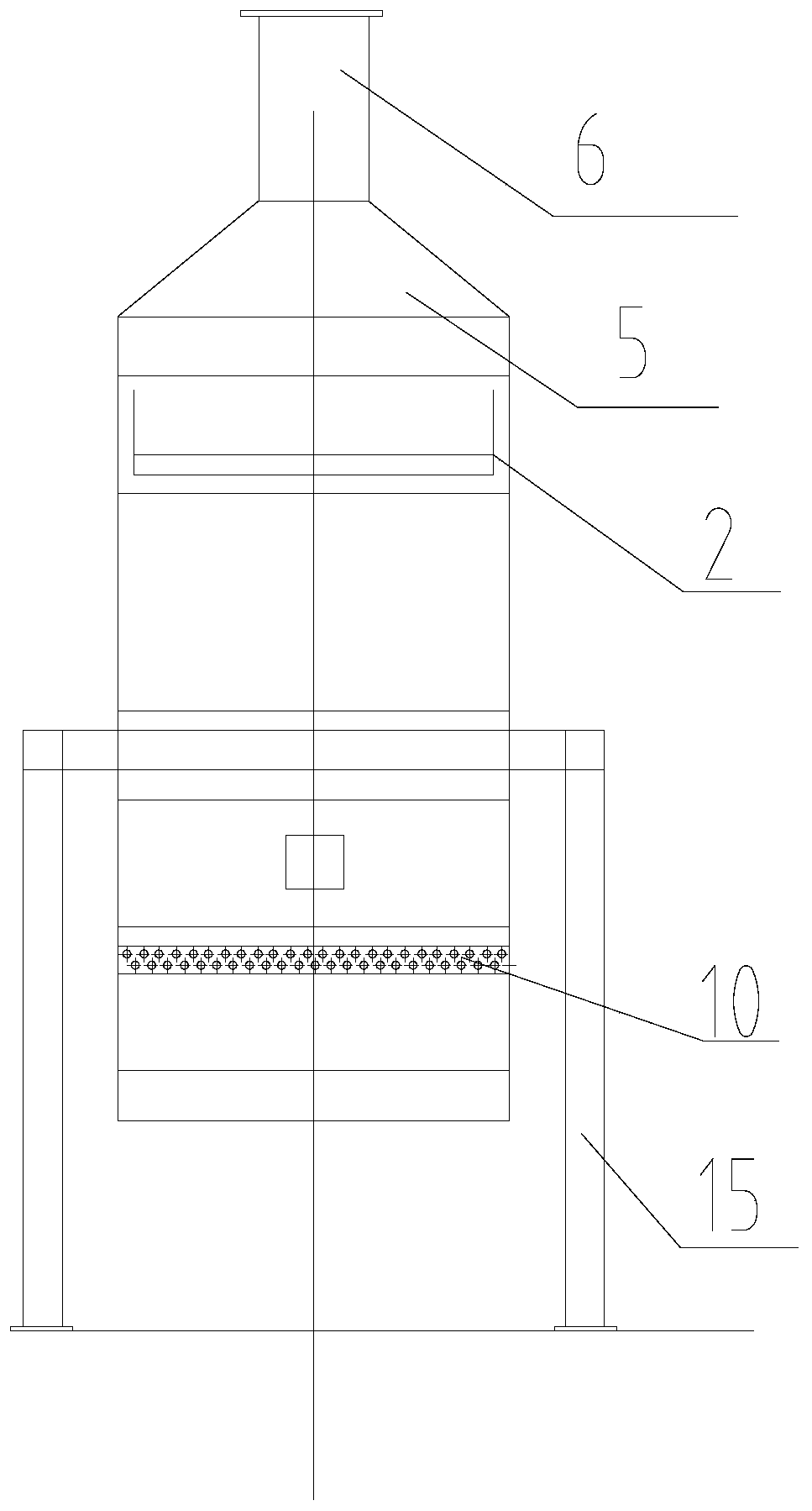

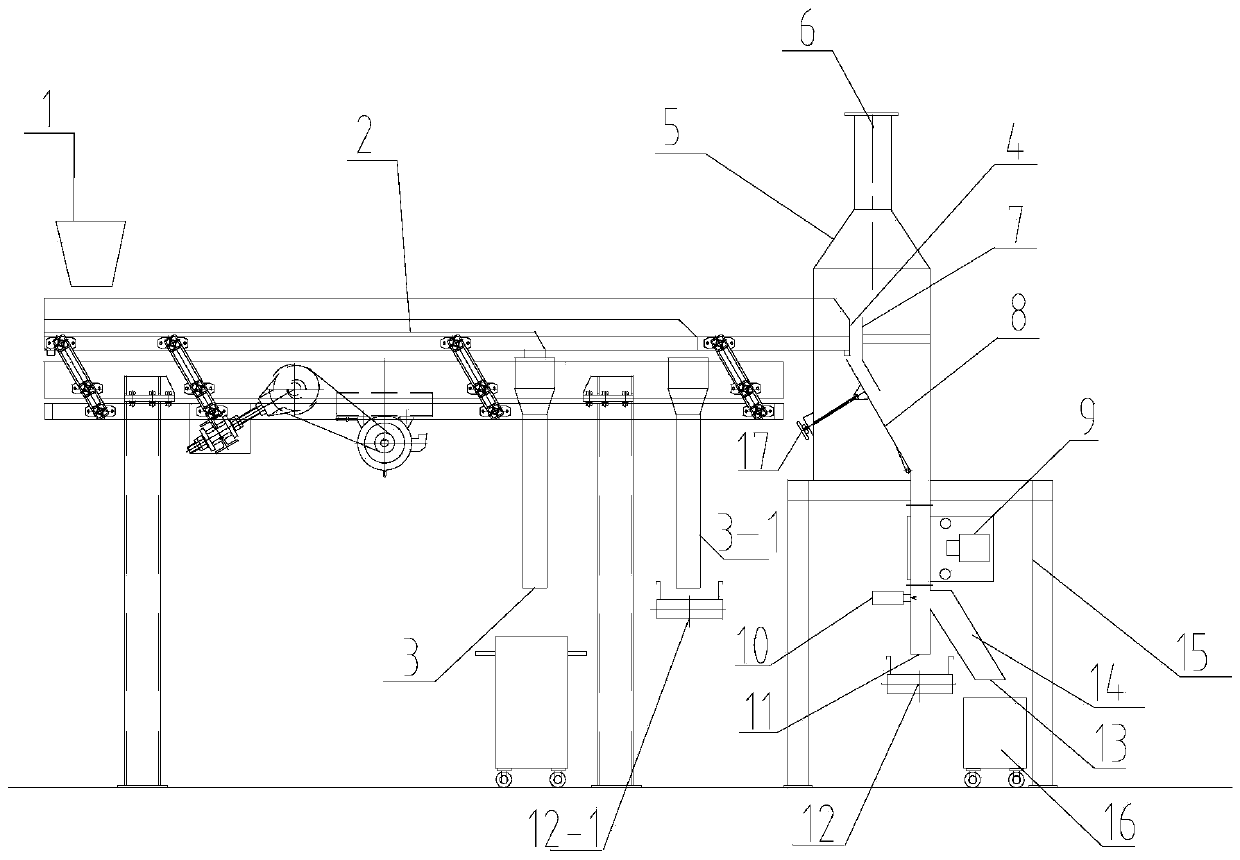

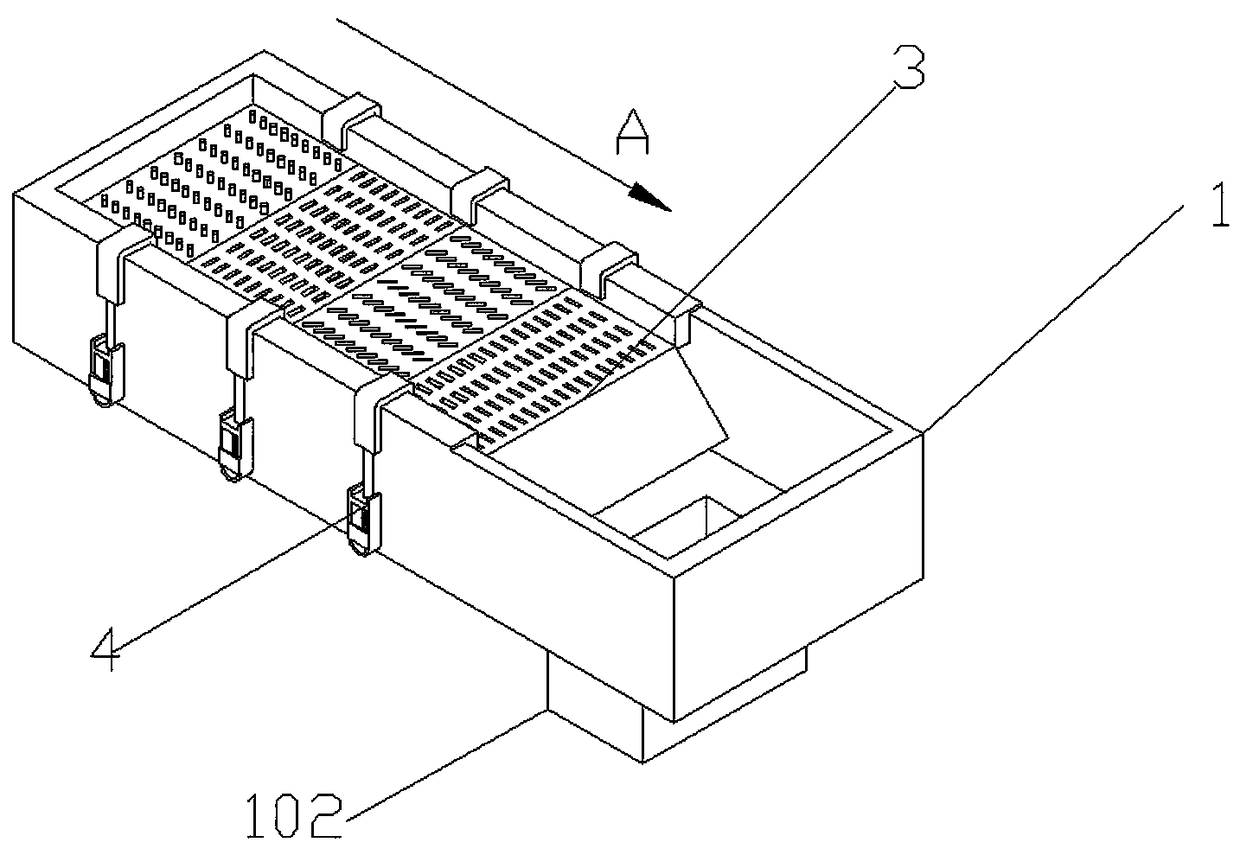

High-speed intelligent plastic bag arranging and bundling mechanism

ActiveCN108545237AHigh-speed automatic strappingImprove bundling efficiencyPaper article packagingPlastic recyclingEngineeringPlastic bag

The invention discloses a high-speed intelligent plastic bag arranging and bundling mechanism. The high-speed intelligent plastic bag arranging and bundling mechanism comprises a whole rack, a feedingconveying module, a guiding module, a falling groove module, a reciprocating pushing blocking rod module, a transferring module and a bundling module, and the feeding conveying module, the guiding module, a way-separation baffle module, the falling groove module, the reciprocating pushing blocking rod module, the transferring module and the bundling module are all arranged on the whole rack. Plastic bags can be automatically bundled, the bundling efficiency is high, and the labor cost is low; the high-speed intelligent plastic bag arranging and bundling mechanism can be adjusted to adapt to automatic bundling of the plastic bags of different widths, lengths and thicknesses, and the application range is wide; and unqualified products can be detected and removed, and the removing efficiencyis high.

Owner:浙江创派智能科技有限公司

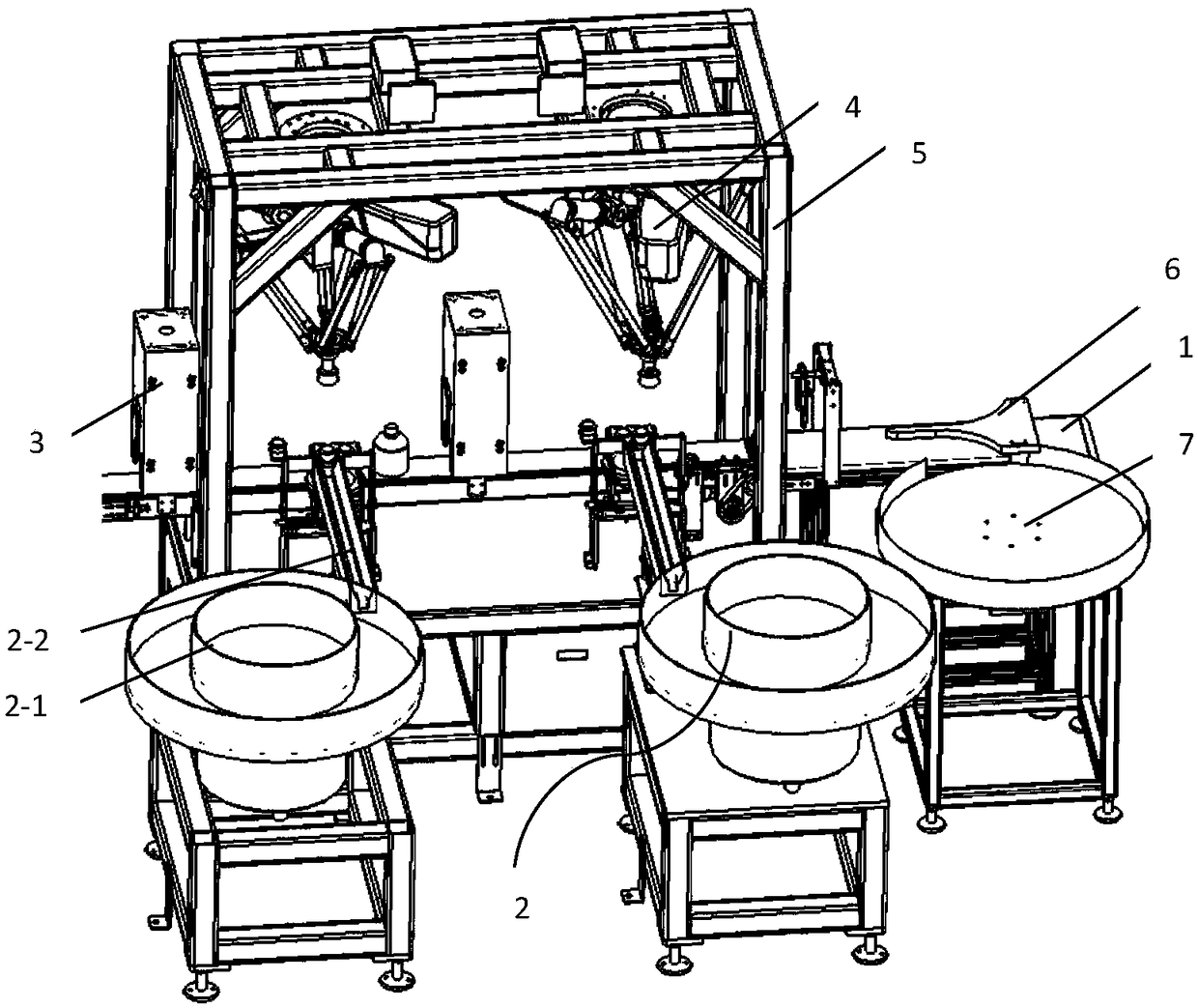

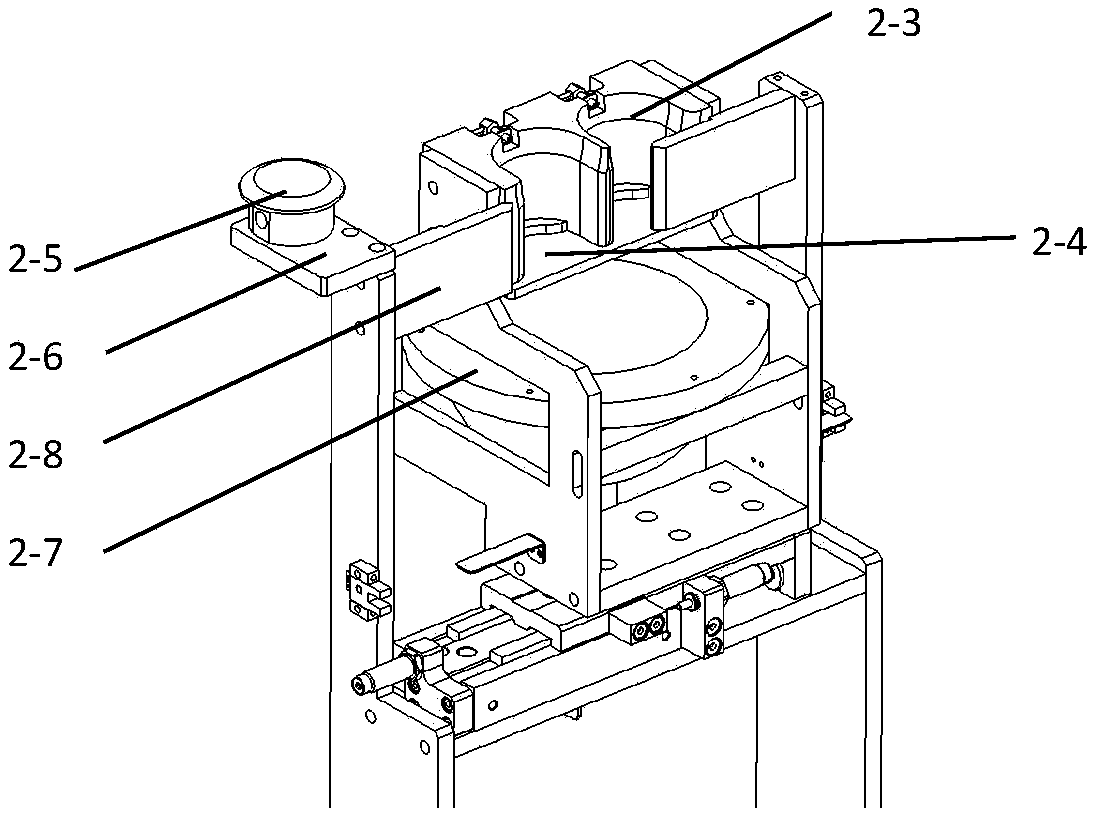

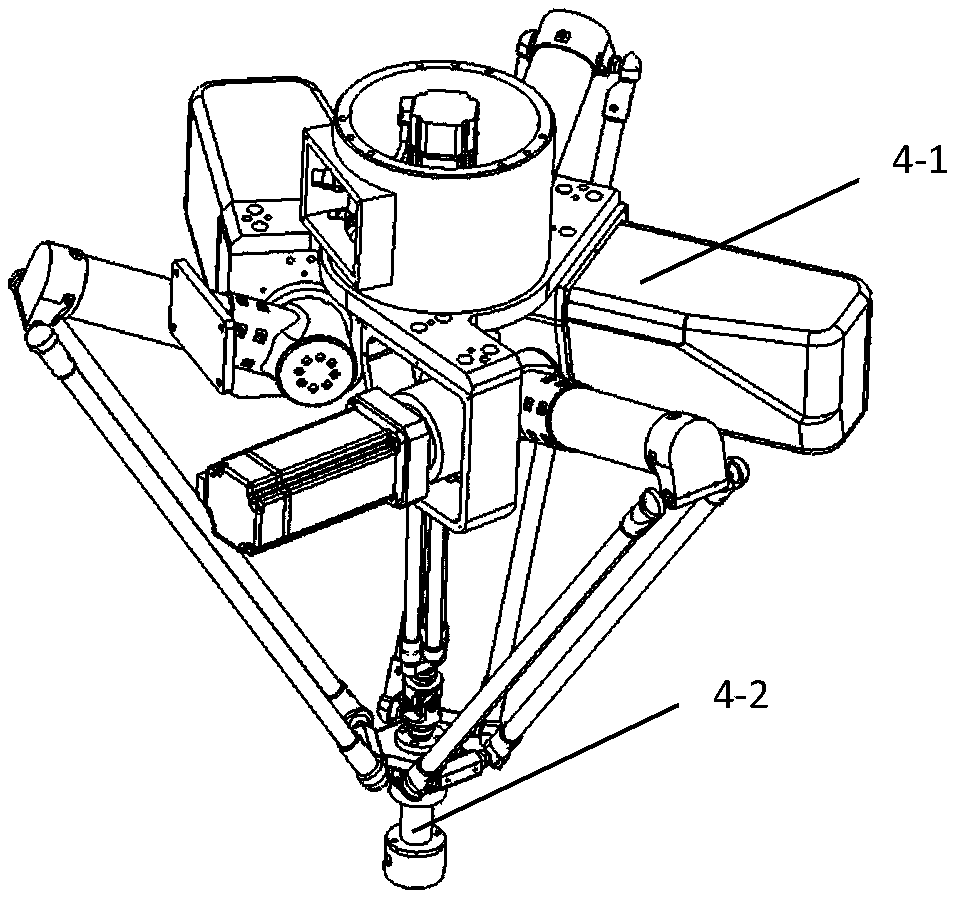

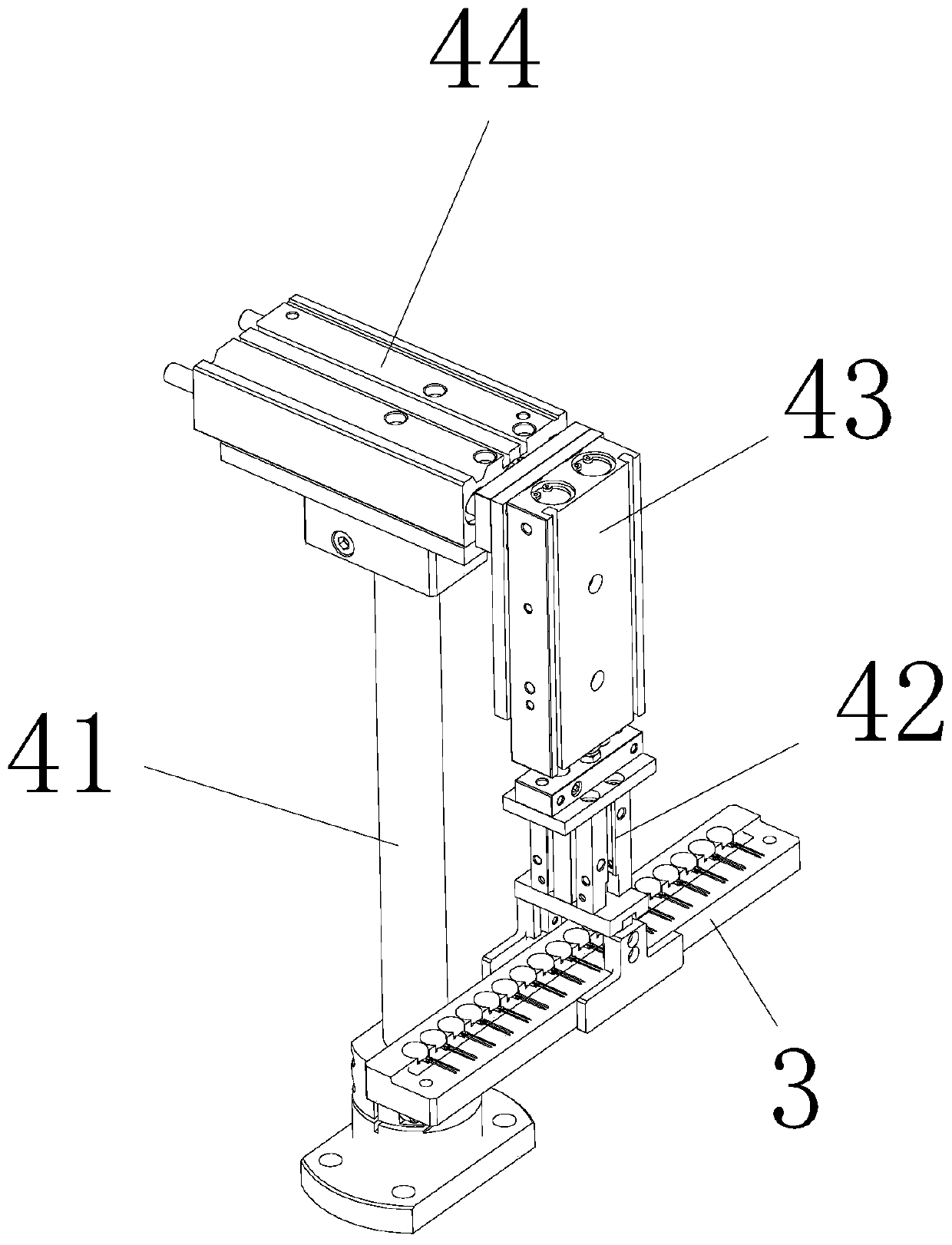

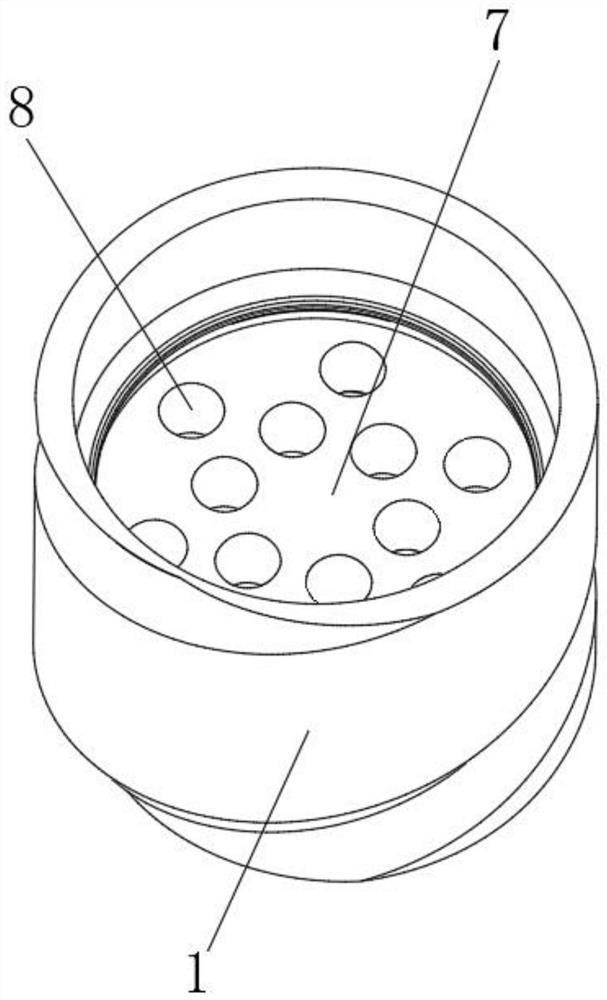

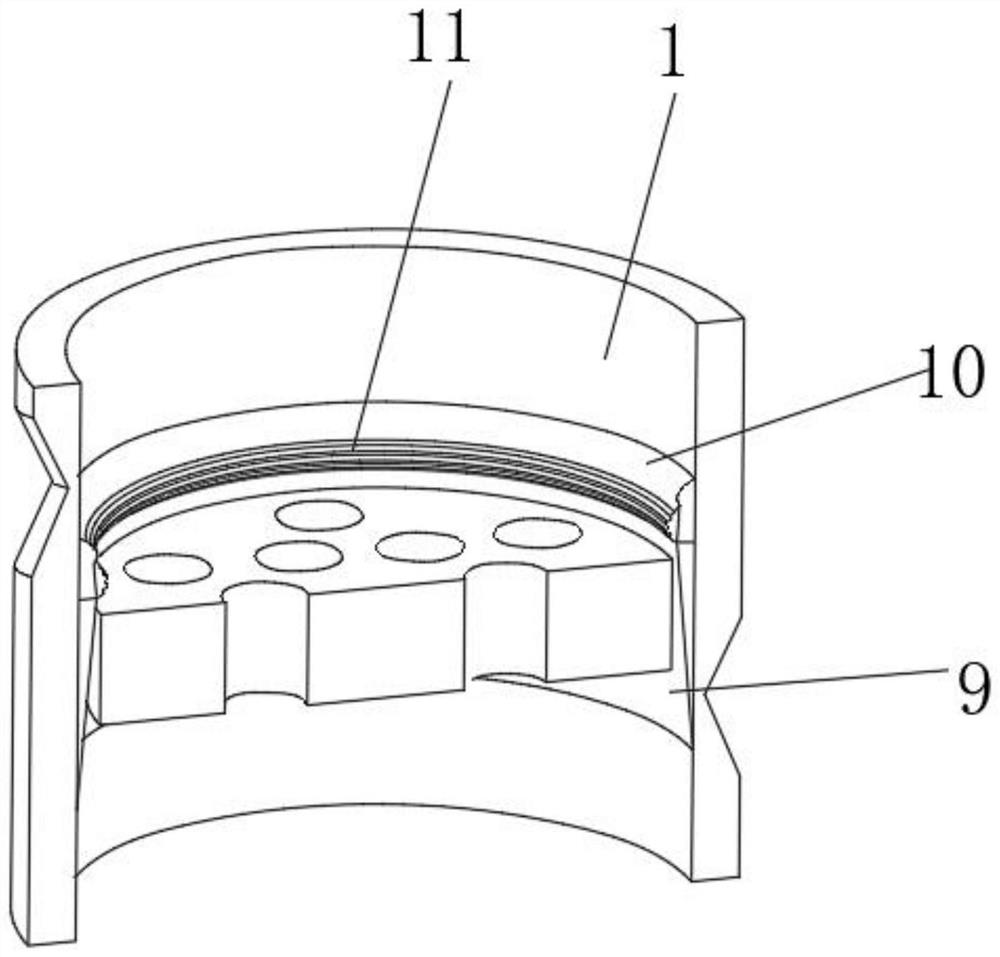

Automatic wine bottle cover putting device

PendingCN109179286AImprove production flexibilityIncrease the output speedConveyorsFlanged caps applicationWine bottleVisual inspection

The invention discloses an automatic wine bottle cover putting device, and belongs to the technical field of automatic white wine production equipment. The automatic wine bottle cover putting device comprises a first conveying line and a wine bottle cover putting unit; the wine bottle cover putting unit comprises a posture adjustment unit, a first visual inspection mechanism and a carrying robot;the first visual inspection mechanism and the carrying robot are sequentially arranged above the first conveying line in the movement direction of the first conveying line; the posture adjustment unitis arranged on one side of the carrying robot and comprises a vibration plate; the output end of the vibration plate is connected with the input end of a linear feeder; a receiving groove rightly faces the output end of the linear feeder; a wine bottle enters the receiving groove through the linear feeder; a light transmitting board is horizontally installed at the lower end of the receiving groove; a second visual inspection mechanism is arranged below the receiving groove and used for detecting the posture of a bottle cover in the receiving groove; and the carrying robot is used for carrying the bottle cover in the receiving groove to be put on a bottle mouth of the wine bottle. The automatic wine bottle cover putting device can put the special-shaped bottle cover on the wine bottle.

Owner:ANHUI HISEED ROBOT CO LTD

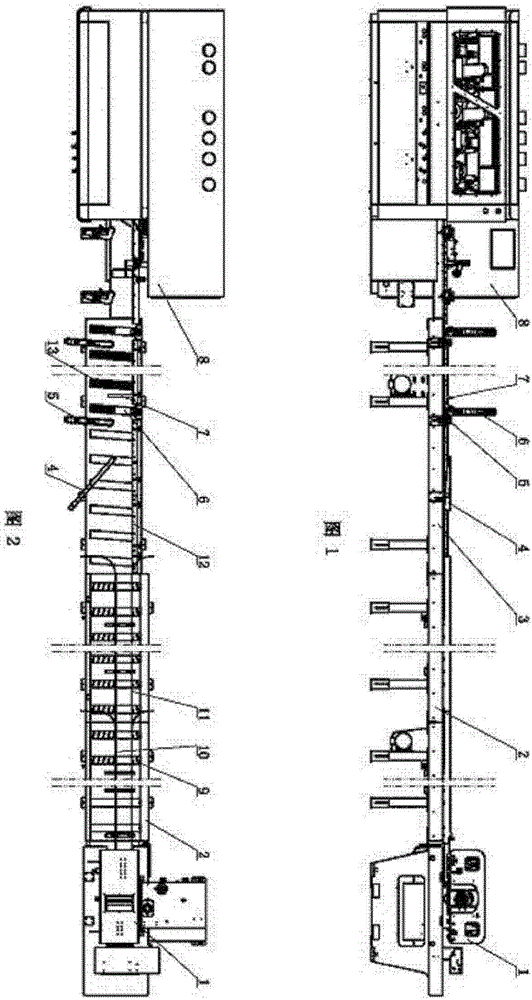

Substandard-product automatic-removal machine

ActiveCN104043601AImprove culling efficiencyThe stacking shape is neat and beautifulSortingElectric controlEngineering

The invention discloses a substandard-product automatic-removal machine. The substandard-product automatic-removal machine comprises a frame, a conveying device, a removal device, a sensor and an electric control cabinet. The conveying device and the removal device are installed on the frame. The removal device is located above the conveying device. In work, the removal device carries out side-to-side reciprocating rectilinear movement along a direction perpendicular to a conveying direction of the conveying device to push substandard products conveyed by the conveying device out of two sides of the conveying device so that substandard-product removal is realized. The substandard-product automatic-removal machine has very high substandard-product removal efficiency. Through the substandard-product automatic-removal machine, product shapes are tidy and shapes of stacks produced by a stacking device at a rear end are beautiful and the stacks are firm.

Owner:GUANGXI LIYUANBAO SCI & TECH

Woodworking saw shaving production line

InactiveCN105150294AReduce labor for cullingImprove processing speedMulti-purpose machinesCircular sawEngineering

The invention discloses a woodworking saw shaving production line. A rim charge removing frame is arranged between a circular saw and a milling machine; an inner picking roll spiral strip and an outer picking roll spiral strip with opposite spiral directions are arranged on a picking roll supported on the rim charge removing frame; an inner picking baffle and an outer picking baffle are arranged on the rim charge removing frame; the inner picking roll spiral strip is located on the outer side of the inner picking baffle; the outer picking roll spiral strip is located on the outer side of the outer picking baffle; an inner sawing picking baffle and an outer sawing picking baffle are arranged on the circular saw; the inner picking baffle and the outer picking baffle on the rim charge removing frame are respectively corresponding to the positions of the inner sawing picking baffle and the outer sawing picking baffle on the circular saw; a sawing material conveying frame is arranged between the rim charge removing frame and the circular saw; a sawing material conveying roll and an upper press roll are arranged on the sawing material conveying frame. The woodworking saw shaving production line not only can automatically sort and remove the rim charges but also is high in removing and processing efficiency.

Owner:JIANGSU JIANGJIA MACHINERY

Non-coplanar elimination based detecting method for continuous collision of flexible scene

ActiveCN102393825AImprove culling efficiencyThe detection process is fastError detection/correctionCollision detectionCollision test

The invention discloses a non-coplanar elimination based detecting method for continuous collision of a flexible scene, which comprises the following steps: (1) constructing a bonding box hierarchical structure; (2) constructing a BVTT (bonding box test tree) and performing a bonding box overlapping test on the BVTT; and (3) performing an accurate collision test after performing non-coplanar elimination on a triangle. According to the method, a collision situation corresponding to the non-coplanar elimination is utilized. The non-coplanar elimination is high in detecting and eliminating efficiency and is high in detecting speed, thereby promoting the efficiency of continuous collision detection, greatly reducing times of accurate collision detection, greatly increasing the whole speed of continuous collision detection, and achieving excellent compatibility.

Owner:ZHEJIANG UNIV

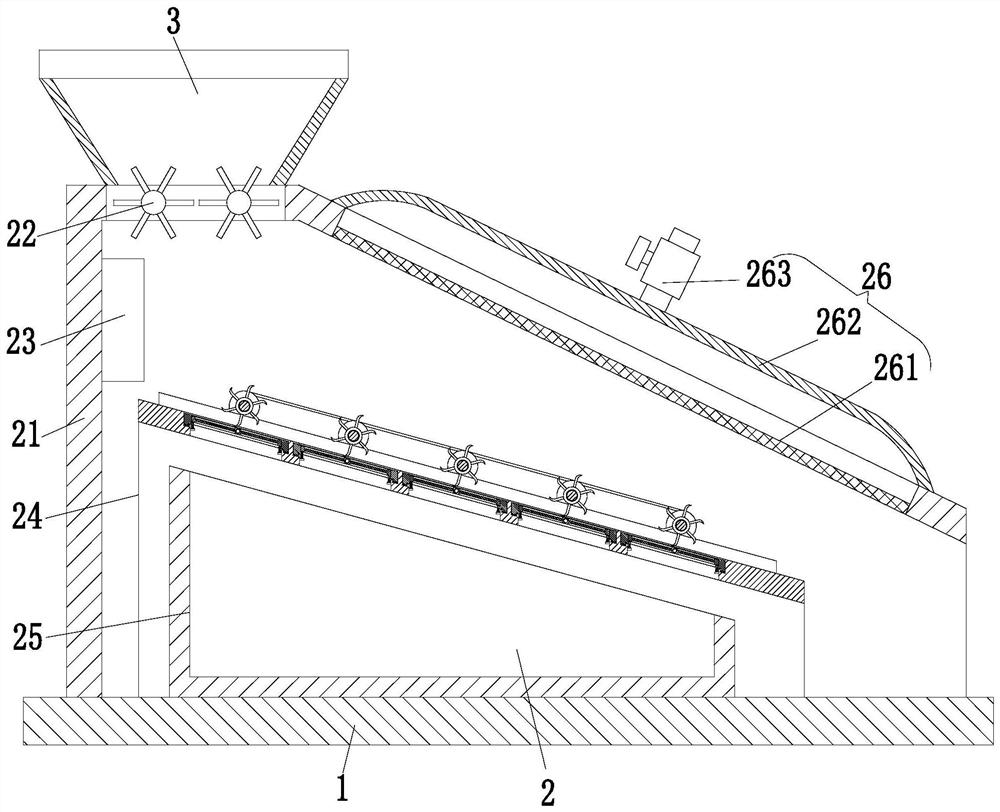

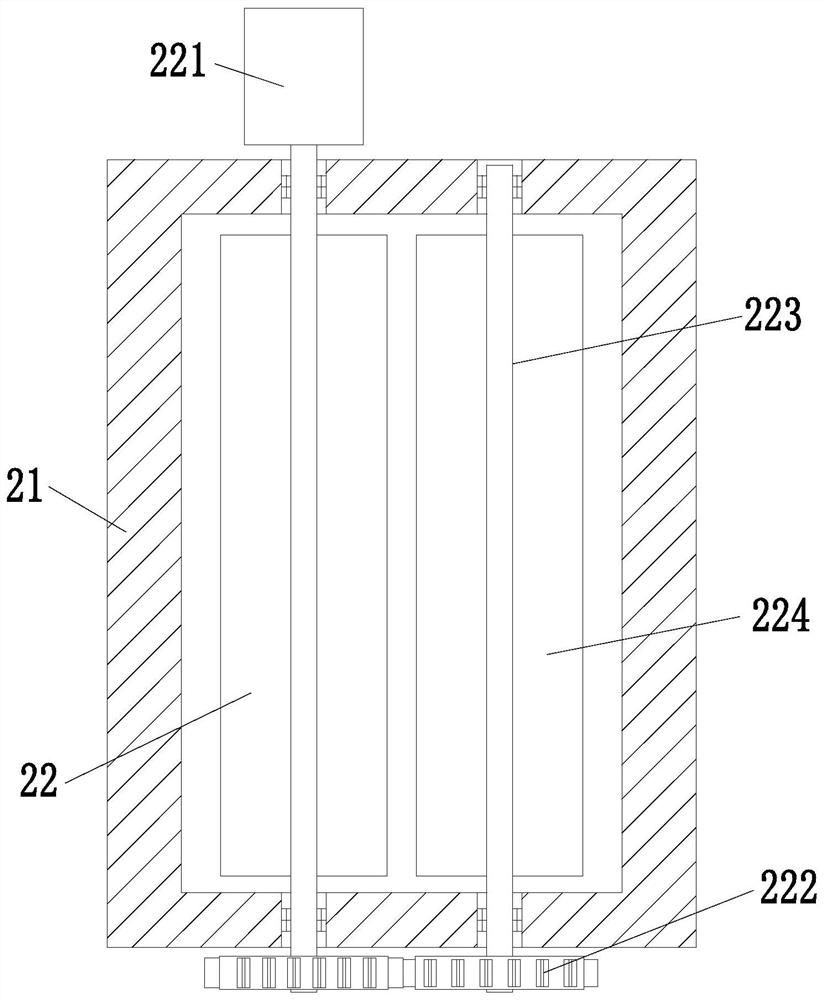

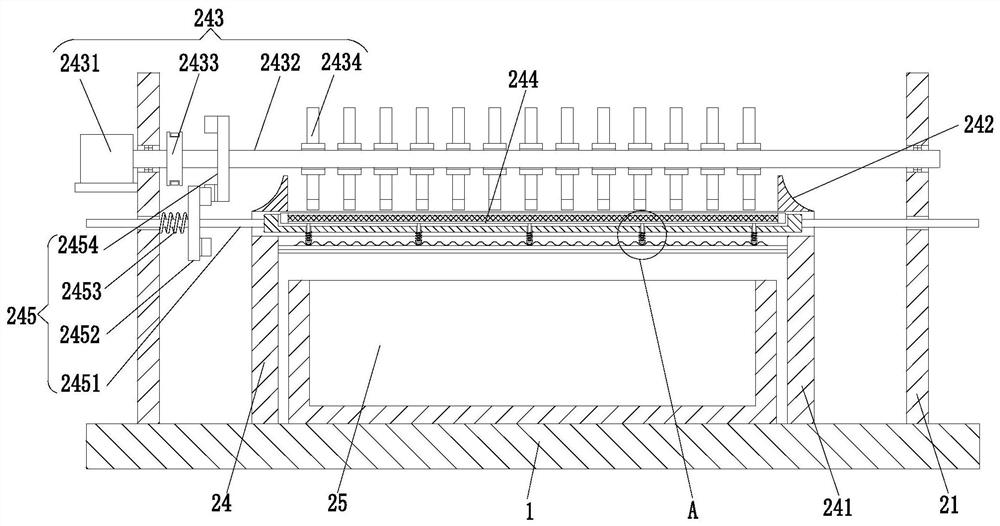

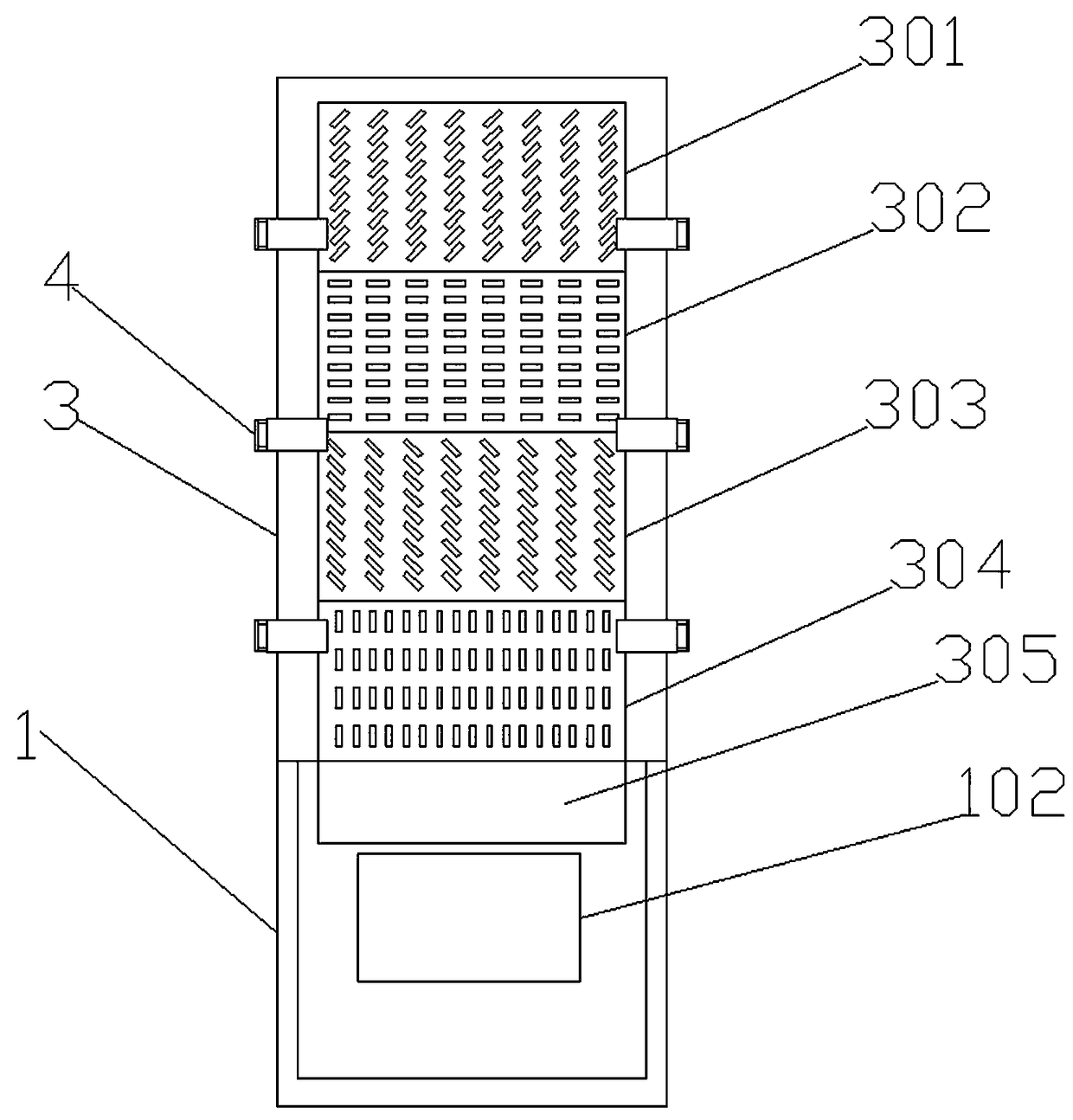

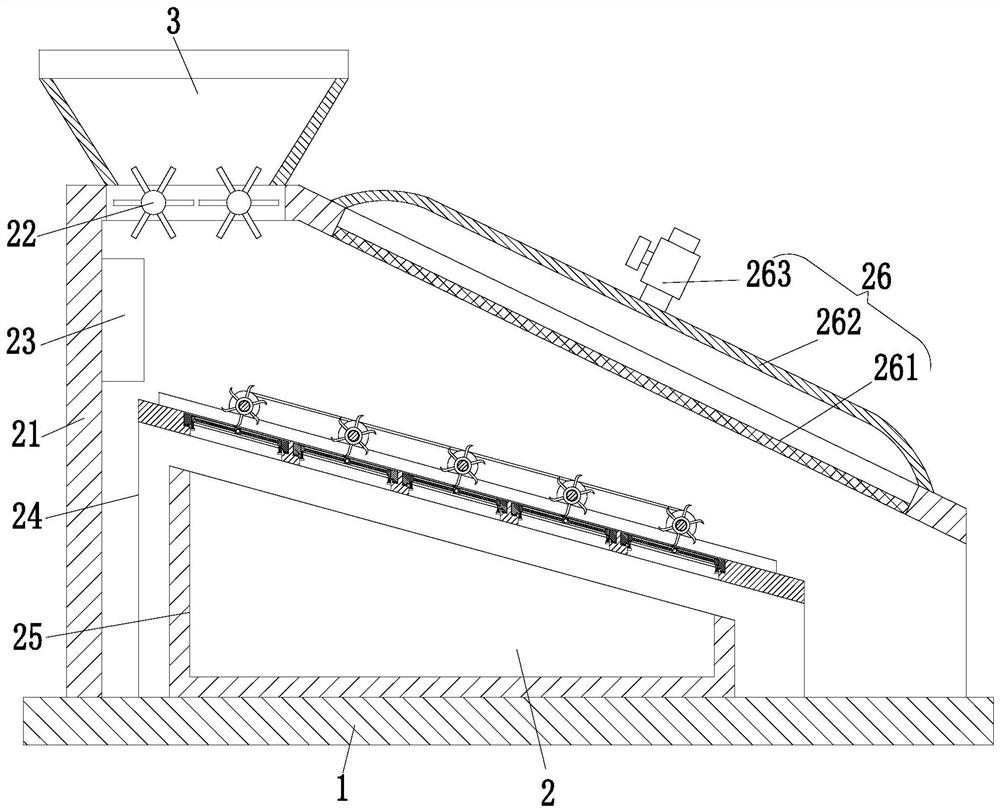

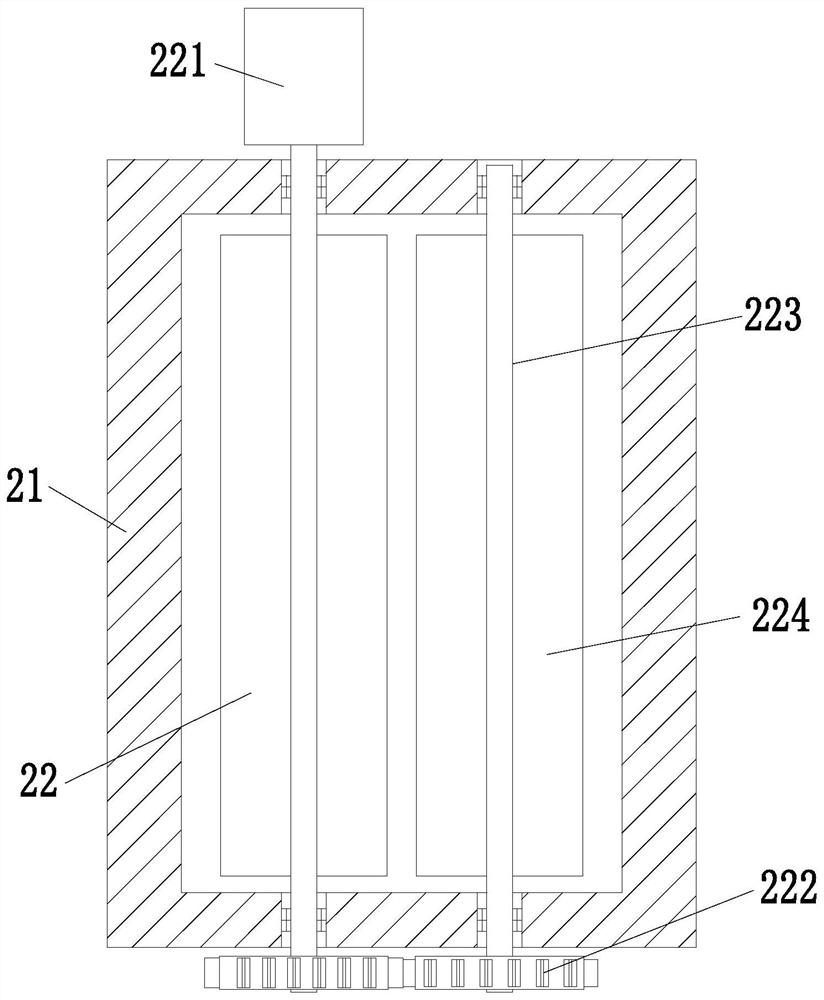

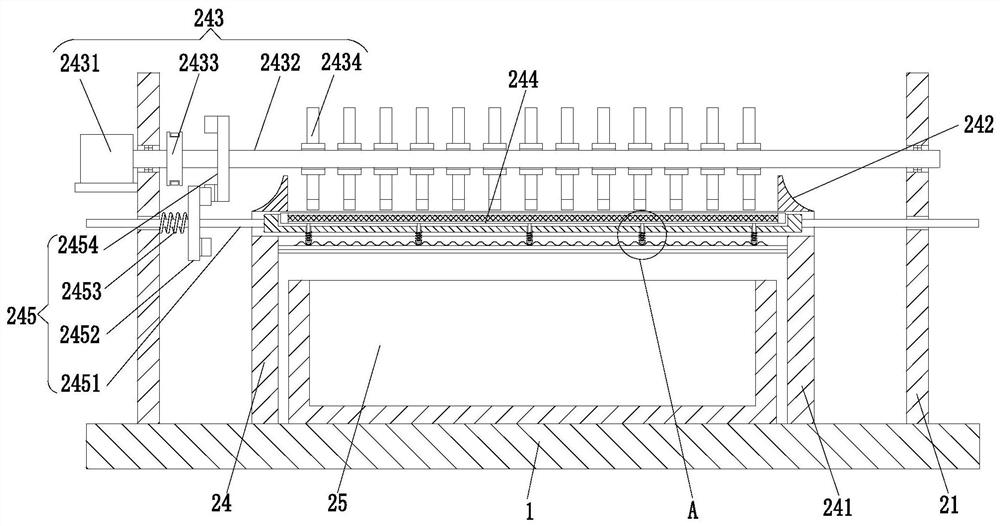

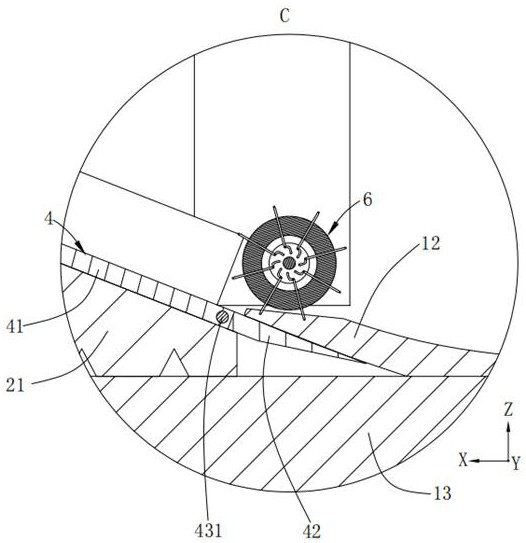

Wheat seed selection equipment capable of rejecting deteriorated grains

ActiveCN111699780AGood selectionImprove culling efficiencySievingGas current separationEnvironmental geologyBotany

The invention relates to wheat seed selection equipment capable of rejecting deteriorated grains. The wheat seed selection equipment comprises a bottom plate, a sorting device and a feeding frame, wherein the sorting device is mounted at the upper end of the bottom plate, an opening groove is formed in the upper end of the sorting device, and the feeding frame is mounted at the opening groove andadopts a trapezoid structure. The wheat seed selection equipment can solve the problems that when selecting and processing wheat seeds, existing equipment has poor selection effects on the wheat seedsand is unable to effectively reject and filter out the deteriorated grains in the wheat seeds, as a result, a larger quantity of impurities are still mixed in the wheat seeds and the survival rate ofthe wheat seeds is affected, and besides, when selecting and processing the wheat seeds, the existing equipment is unable to reject lighter impurities in the wheat seeds and rejected dust and impurities diffuse in the environment easily to affect the environmental quality.

Owner:安徽永民种业有限责任公司

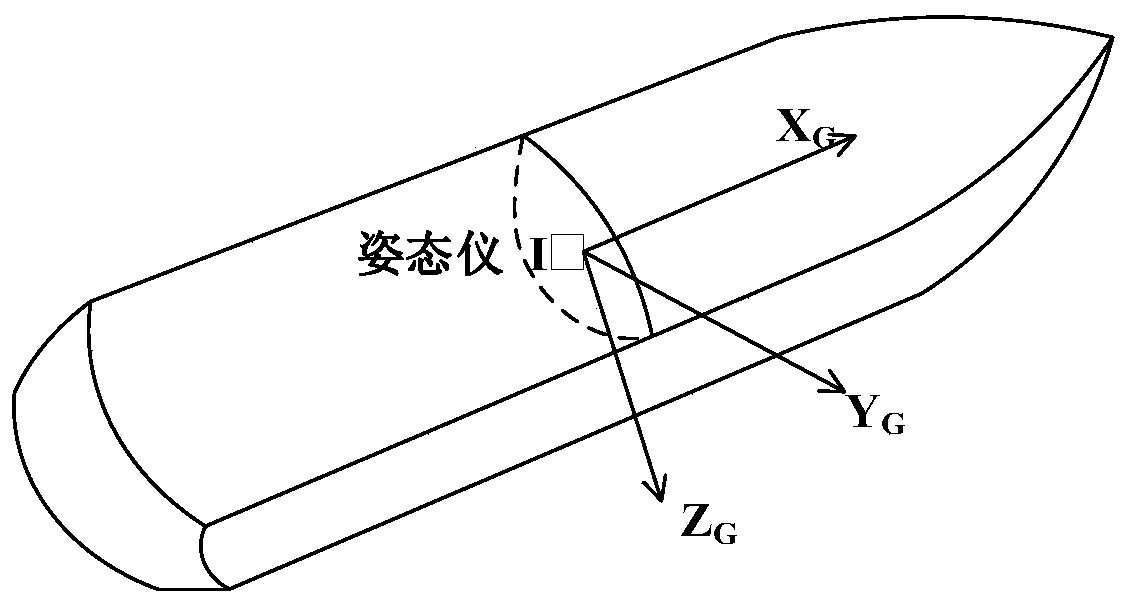

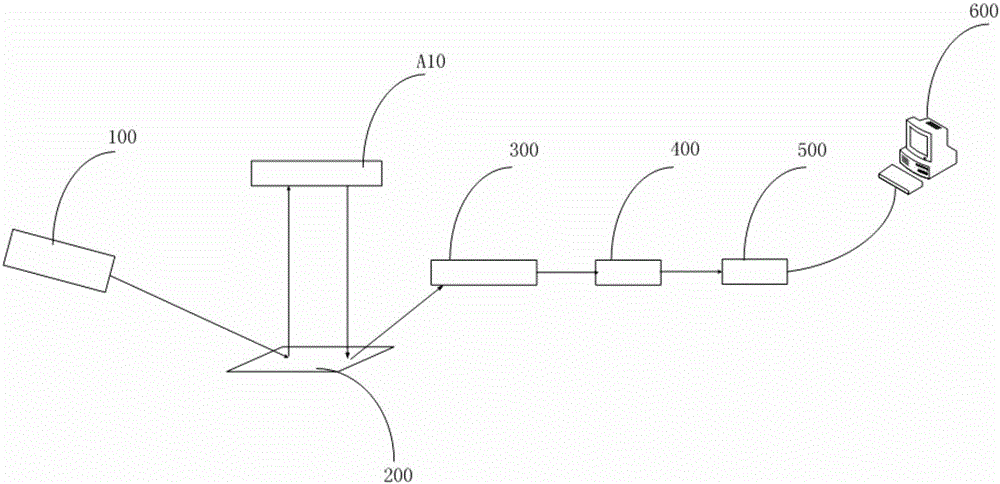

Automatic data processing method based on multi-beam sounding system

InactiveCN110297248AFast decodingImprove detection efficiencyAngle measurementSatellite radio beaconingOcean bottomTerrain

The invention relates to the technical field of seabed terrain observation, in particular to an automatic data processing method based on a multi-beam sounding system, wherein the data automatic dataprocessing method comprises the following steps of 1 data collection and original data analysis, wherein data collection is carried out by a measuring system designed in the method, and the original measurement data are decoded; 2, coordinate conversion, wherein the attitude information obtained through an attitude instrument is used for correcting the sounding data obtained under a carrier coordinate system G system to obtain the position of a sounding point in a geographic coordinate system P system; and 3, abnormal data detection and removal, wherein the abnormal data are automatically identified and removed according to the algorithm designed in the method. According to the method, the efficiency of abnormal data detection and removal is improved, the operation process is simplified, the operation cost is lowered, and the reliability of multi-beam sounding data is improved.

Owner:TIANJIN UNIV

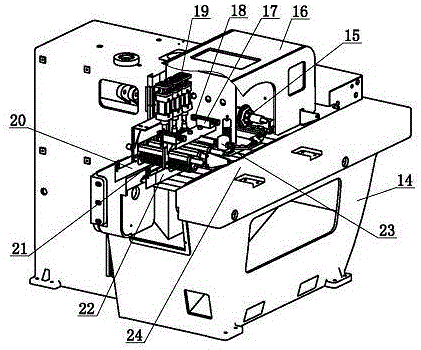

Device suitable for defect detection of mobile-phone flat motors and achievement method thereof

PendingCN109759342AHigh degree of automationAccelerate the efficiency of loading inspectionOptically investigating flaws/contaminationSortingEngineeringMobile phone

The invention discloses a device suitable for the defect detection of mobile-phone flat motors and an achievement method thereof, and belongs to the technical field of mobile-phone hardware detection.The device includes a frame, wherein the upward side of the frame is correspondingly connected with a feeding positioning mechanism, a transplanting mechanism, a step shifting mechanism, a CCD photographing detecting mechanism, a transplant removing mechanism, a defective-product collection mechanism and a second conveying mechanism. According to the device, the automatic feeding of the motors and the automatic detection of appearance defects are achieved, so that the factory quality of the motors is better, the detection speed is fast, the detection result is accurate, and the production efficiency is greatly improved.

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

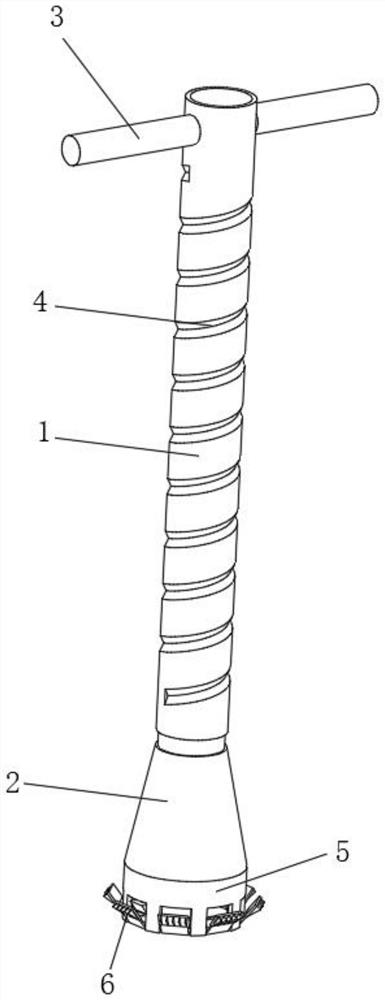

Stem removing machine

PendingCN110404798APrevent throwingLittle change in the downward trajectoryTobacco treatmentSortingSlide plateEngineering

Owner:ZHISI HLDG GRP

High speed continuous plastic bag strapping machine

ActiveCN108945577AHigh-speed automatic strappingImprove bundling efficiencyPaper article packagingBundling machine detailsPlastic bagEngineering

The invention discloses a high speed continuous plastic bag strapping machine. The high speed continuous plastic bag strapping machine comprises an integral rack, a supporting bottom plate at the discharge port of a bag maker, a separated baffle plate module, a blanking slot module, a reciprocating material pushing pin module, a transfer module and a strapping module. The supporting bottom plate at the discharge port of the bag maker, the separated baffle plate module, the blanking slot module, the reciprocating material pushing pin module, the transfer module and the strapping module are arranged on the integral rack. The high speed continuous plastic bag strapping machine disclosed by the invention can strap plastic bags automatically, is high in strapping efficiency and low in labor cost, and can be adjusted to be suitable for strapping the plastic bags different in width, length and thickness automatically, so that the high speed continuous plastic bag strapping machine is wide inapplication range; the high speed continuous plastic bag strapping machine can detect and remove unqualified products, and is high in removal efficiency. The high speed continuous plastic bag strapping machine disclosed by the invention can directly fit the outlet of the bag maker. The plastic bags at the outlet of the bag maker enter into a blanking slot to be accumulated, conveyed and strapped,so that the integral strapping step is canceled.

Owner:浙江创派智能科技有限公司

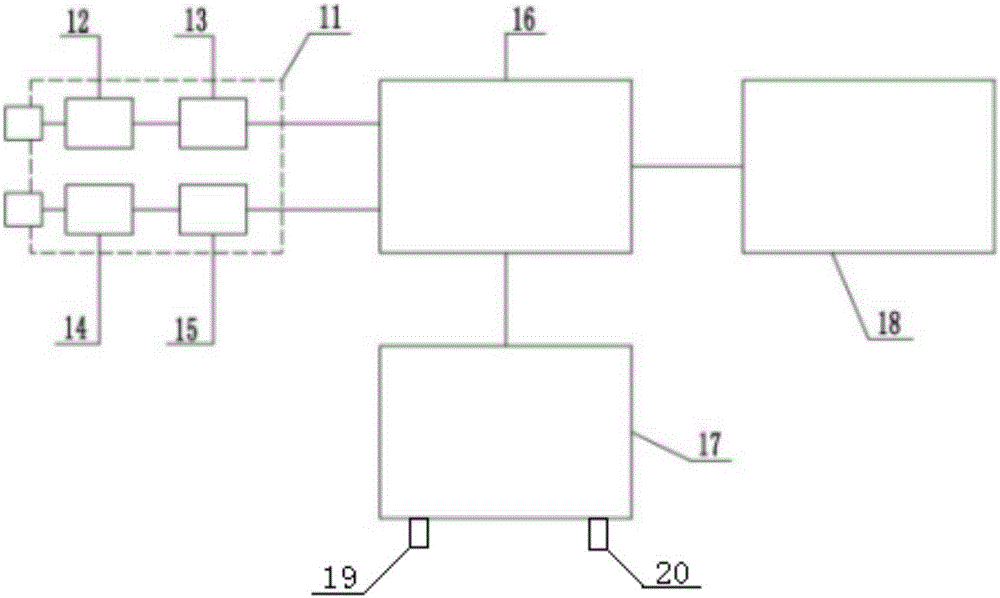

Tobacco foreign body removing device

ActiveCN106820245AImprove culling efficiencyAvoid product qualityTobacco preparationConveyorsEngineeringForeign matter

The invention discloses a tobacco foreign body removing device. The tobacco foreign body removing device comprises a support assembly; the support assembly is provided with a primary sorting device, a conveyer belt A, a secondary sorting device, a conveyer belt B, a finished product conveyer belt and a control device, wherein the primary sorting device, the secondary sorting device and the finished product conveyer belt are arranged in a step mode from top to bottom; the conveyer belt A is arranged between the primary sorting device and the secondary sorting device and under the secondary sorting device; the conveyer belt B is arranged between the secondary sorting device and the finished product conveyer belt and under the finished product conveyer belt; the primary sorting device, the secondary sorting device, the conveyer belt A, the conveyer belt B and the finished product conveyer belt are electrically connected with the control device. The tobacco foreign body removing device can automatically remove foreign bodies or defective products from tobacco materials at high speed and precision, reduce influence of the foreign bodies on product quality, ensure product quality, reduce production cost and improve the production efficiency.

Owner:HONGTA TOBACCO GRP

Scattered tobacco stem removing and sieving vibration trench

PendingCN109225834AImprove the quality of cut stems and silk yieldSatisfy the layoutSievingScreeningEngineeringSieve area

The invention relates to the technical field of tobacco processing, and particularly discloses a scattered tobacco stem removing and sieving vibration trench. The scattered tobacco stem removing and sieving shocking trench comprises a trench body, a vibration sieve, locking devices and a self-cleaning device, wherein the locking devices are used for fixing the vibration sieve on the trench body, and the self-cleaning device is connected with the bottom of the vibration sieve; folded edges for being erected on the trench body are arranged on the left and right sides of the vibration sieve, thevibration sieve is divided into multiple sieving areas in the front direction, and the inclinations of sieving net holes in each sieving area are different. By the adoption of the scattered tobacco stem removing and sieving vibration trench, scattered tobacco stems with the length of 15 mm and the diameter of 3 mm can be effectively removed, the cut stem tobacco quality is improved, the cut tobacco generating rate is increased, the labor intensity is greatly reduced, no tools are needed, the vibration sieve can be easily and rapidly mounted and dismounted simply by an operator, and the scattered tobacco stem removing and sieving vibration trench is convenient for the operator to maintain.

Owner:CHINA TOBACCO HENAN IND

Damage-prevention type inferior-quality product removing device for automatic boxing machine

InactiveCN112660517AImprove culling efficiencyAvoid damagePackaging automatic controlStructural engineeringFan blade

The invention discloses a damage-prevention type inferior-quality product removing device for an automatic boxing machine, and belongs to the technical field of automatic boxing machines. The damage-prevention type inferior-quality product removing device comprises an automatic boxing machine body and two groups of transverse plates with the same structure, the right side of the automatic boxing machine body is fixedly connected with the two groups of transverse plates, and conveying belts are arranged on the two groups of transverse plates; the right sides of the two transverse plates are fixedly connected with a baffle, the bottom of the baffle is connected with a vertical rod, the right sides of the conveying belts are connected with guide plates in an attached mode, the bottom of each guide plate is connected with a removing mechanism, and a containing mechanism is arranged at the position, below the removing mechanism, of the right side of the automatic boxing machine body. Through rotating a movable rod, a sliding block drives a swing rod to swing, so that fan blades can blow air back and forth on the rear side of the inferior-quality product, the inferior-quality product removing efficiency can be improved, the inferior-quality product is not contacted, and the inferior-quality product is prevented from being damaged.

Owner:蒋柏成

Tire rubber sheet foreign matter removing device

ActiveCN112718583AIncrease productivityImprove culling efficiencySortingMaterial analysis by transmitting radiationForeign matterRobot hand

Owner:SBT ULTRASONIC TECH CO LTD

A wheat seed selection device for removing spoiled grains

ActiveCN111699780BEffective filtration and sievingGuaranteed survival rateSievingGas current separationAgricultural engineeringHorticulture

The invention relates to a wheat seed selection device for removing metamorphic particles, which comprises a bottom plate, a sorting device and a feeding frame. The feeding rack is in a trapezoidal structure. The present invention can solve the problem that when the existing equipment selects and processes wheat seeds, the selection effect of wheat seeds is poor, and the deteriorating particles in wheat seeds cannot be effectively removed and filtered, resulting in the inclusion of a large amount of impurities in wheat seeds , affecting the survival rate of wheat seeds, and the existing equipment cannot effectively remove the lighter impurities in wheat seeds when selecting and processing wheat seeds, and the dust impurities after removal are easy to diffuse into the environment, affecting environmental quality issues.

Owner:安徽永民种业有限责任公司

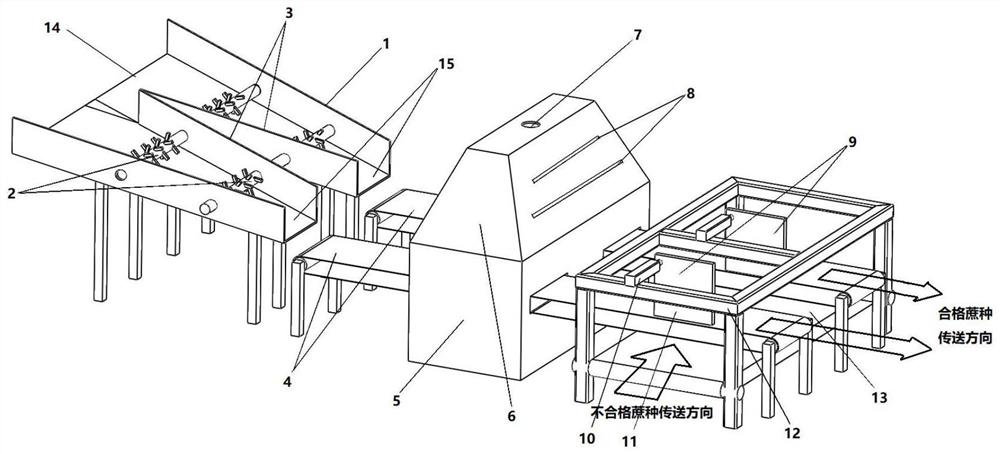

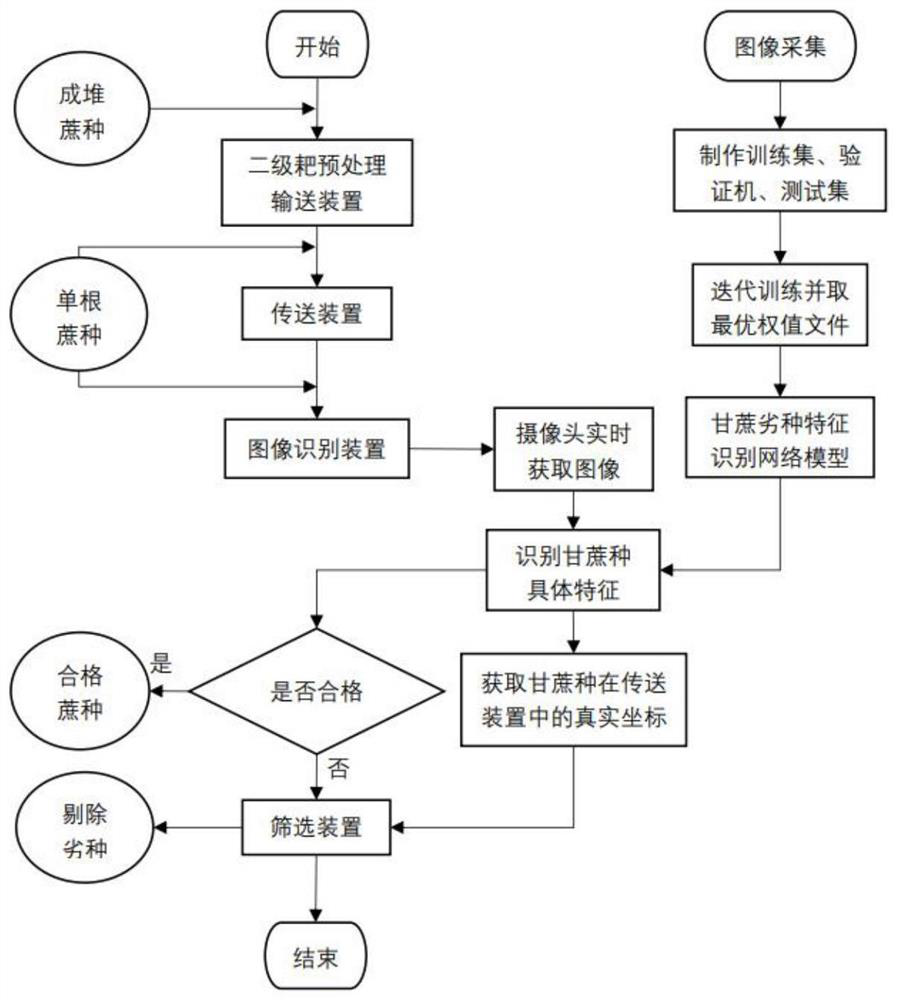

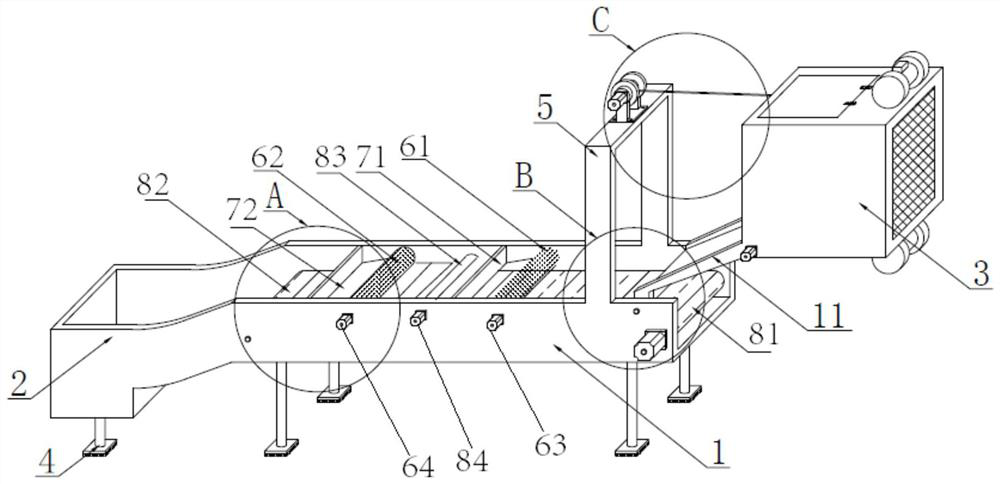

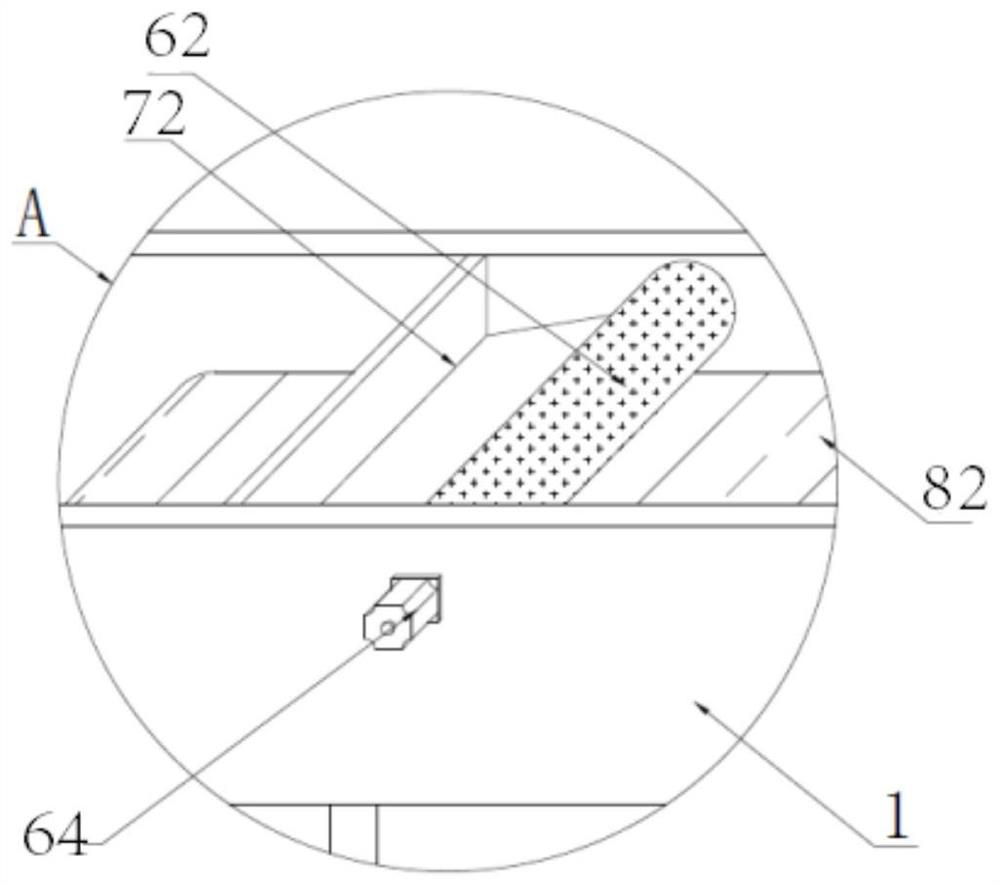

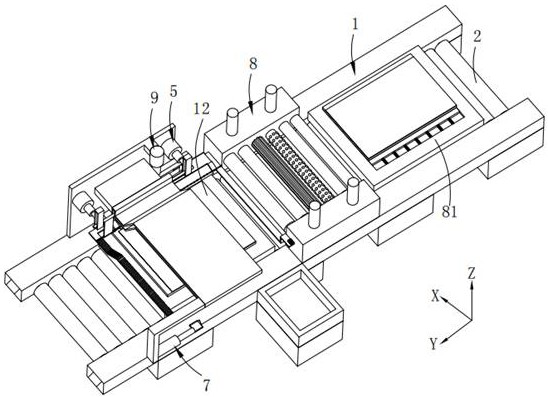

Sugarcane seed screening system and method based on deep learning

PendingCN114140675AImprove recognition rateFast recognitionImage analysisCharacter and pattern recognitionHorticultureEngineering

The invention discloses a sugarcane seed screening system based on deep learning, which comprises a pretreatment conveying device, a qualified sugarcane seed conveying device, an image recognition device, a screening device and an unqualified sugarcane seed conveying device, the pretreatment conveying device arranges piled sugarcane seeds into a single conveying state to enter the qualified sugarcane seed conveying device, so that the image recognition device recognizes the sugarcane seeds conveniently, and the screening device removes inferior sugarcane seeds conveniently; the invention also discloses a method for screening sugarcane seeds by using the system, and the inferior seed feature recognition system is constructed based on a deep learning convolutional neural network, so that surface features which are not beneficial to sugarcane growth, such as too close incision to sugarcane buds, incision damage, too long sugarcane buds, wormholes, cracks and the like, can be recognized and detected; an effective mode is provided for screening sugarcane seeds in a sugarcane segment form generated by a pre-cutting type sugarcane cutting machine, a segment cutting type sugarcane harvesting machine and the like, the sugarcane inferior seed screening rate can be effectively increased, and the sugarcane planting cost and the manual labor intensity are reduced.

Owner:GUANGXI UNIV FOR NATITIES

Online foreign matter removing device for tobacco primary processing

InactiveCN111957435AReduce manufacturing costLow failure rateSievingScreeningForeign matterElectric machinery

The invention relates to an online foreign matter removing device for tobacco primary processing. The device comprises a frame body, one end of the frame body is provided with a material receiving box, and the other end of the frame body is rotatably provided with a material screening component; a supporting plate is arranged at the position, close to the screening component, of the upper surfaceof the frame body, and a winch assembly is arranged on the upper surface of the supporting plate and connected with the screening component; a conveying belt assembly is mounted in the frame body; a metal suction roller is rotationally installed on the frame body above the conveying belt assembly, a magnetic suction layer is arranged on the outer surface of the metal suction roller, and a suctionroller motor provides power for the metal suction roller; and a metal slag collecting box is arranged at one side of the metal suction roller and matched with the metal suction roller. According to the technical scheme, the whole tobacco leaves can be screened out, the removing positions are not distinguished, the manufacturing cost of the device is reduced, materials are turned over through the conveying belt assembly, and the removing efficiency is improved.

Owner:CHINA TOBACCO GUIZHOU IND

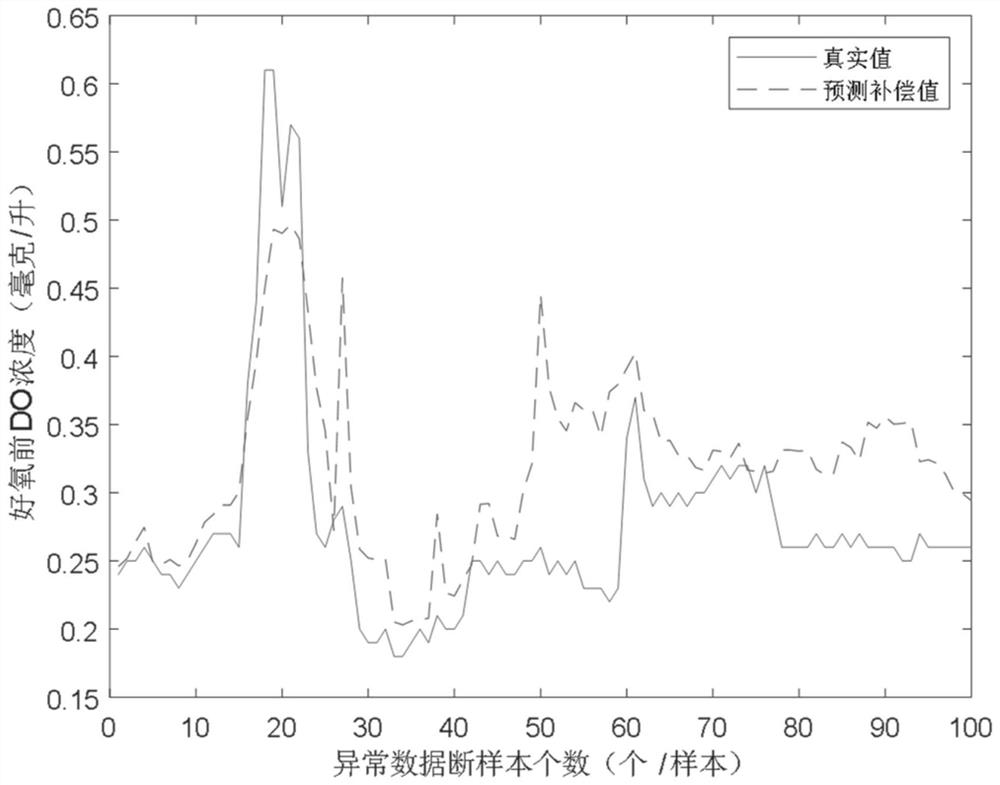

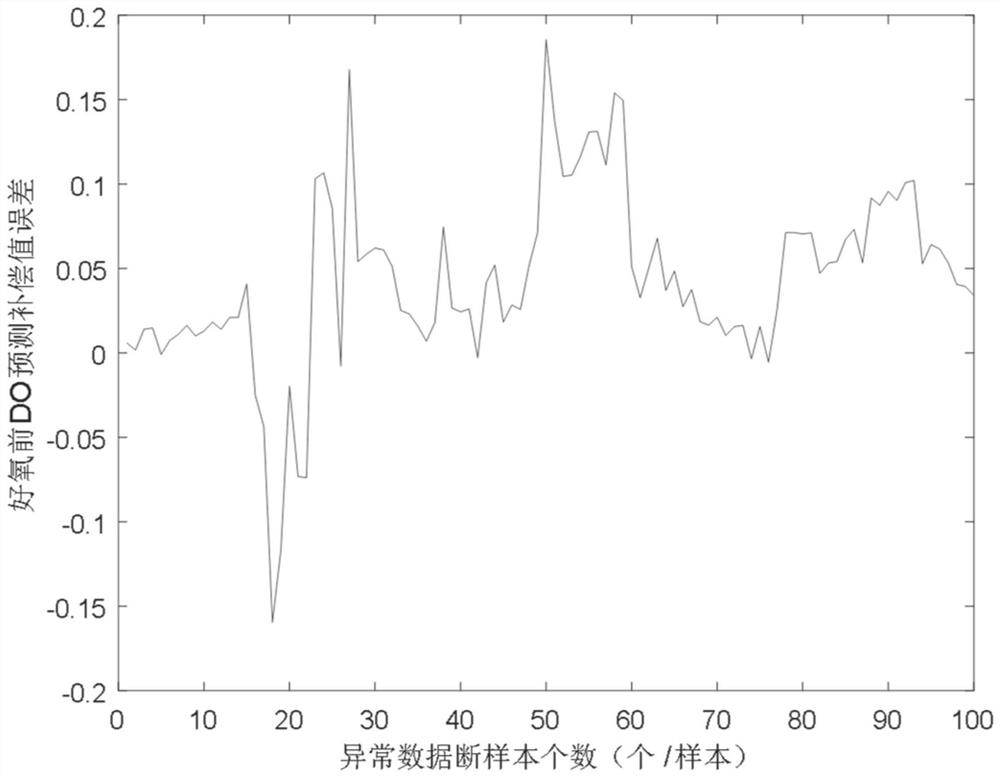

Urban sewage treatment process data cleaning method based on dynamic interpolation

PendingCN113157674AImprove accuracyImprove culling efficiencyDigital data information retrievalCharacter and pattern recognitionMissing dataMunicipal sewage

The invention discloses a dynamic interpolation-based urban sewage treatment process data cleaning method, belongs to the field of sewage treatment, and aims to solve the problem of poor data quality caused by mixing of outliers and continuous repetitive values in urban sewage treatment process data. According to the dynamic interpolation method, data segments are segmented through a sliding window, abnormal factor coefficients of the segmented data segments are calculated, abnormal conditions of the data segments are judged, outliers and continuous abnormal values in the abnormal data segments are removed, missing data are compensated by adopting a random forest regression model, and the quality of the data in the urban sewage treatment process is improved. Experimental results show that the method improves the precision of data compensation, guarantees the data quality of a database in the urban sewage treatment industry, and improves the credibility of the research of a sewage treatment plant.

Owner:BEIJING UNIV OF TECH

Road waste asphalt removing and regenerating construction integrated device

The invention discloses a road waste asphalt removing and regenerating construction integrated device, which comprises a base, wherein the upper end of the base is provided with a cab, wheels are mounted at the lower end of the base, two removing devices are mounted on the front side of the wheels at the lower end of the base, the two removing devices get close to each other, each removing devicecomprises an oil cylinder, a first mounting plate, a second mounting plate, a first motor, a rotating shaft, an inner rotating drum, an outer rotating drum, a first removing blade, a second removing blade and a cutting blade, the fixed end of the oil cylinder is vertically mounted at the lower end of the base, the first mounting plate is fixed at the movable end of the oil cylinder, and the secondmounting plate is in bolted connection with the lower end of the first mounting plate. The road waste asphalt removing and regenerating construction integrated device is easy to operate and high in removing efficiency, the time consumed for removing is shortened, the removing and regenerating are integrated, waste asphalt mixtures of a fine grain layer and a coarse grain layer can be classified,removed and smashed, and screening does not need to be conducted again in the removing process.

Owner:胡拴紧

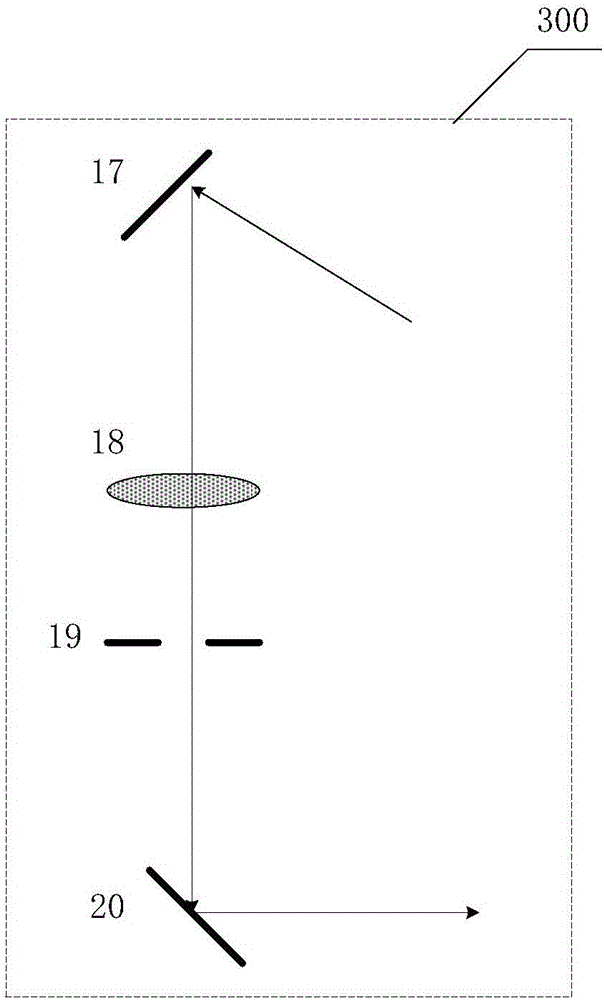

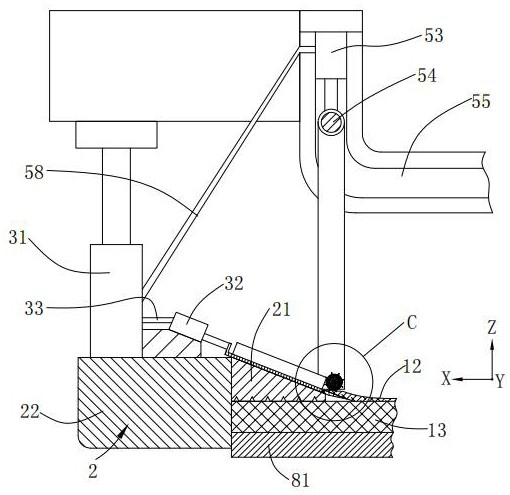

Recognition device for tobacco impurities and removing device for tobacco impurities

ActiveCN105911068AImprove accuracyTo achieve the purpose of detecting moldy tobacco leavesMaterial analysis by optical meansSortingLength waveImpurity

The invention discloses a recognition device for tobacco impurities and a removing device for tobacco impurities and belongs to the technical field of recognition and removing of tobacco impurities. The recognition device for tobacco impurities comprises a laser generating module, a scanning module, an aligning module, a light splitting module, a conversion module and a processing module. The three-primary color principle or the characteristic wavelength of unqualified tobaccos is utilized to accurately restore the color information of the surface of a sample to be recognized without the influence of the features of the sample to be recognized and the detection environment, so that the accuracy of recognizing the tobacco impurities and unqualified tobaccos is increased. The removing device for tobacco impurities comprises a vibration device, a guide chute, a recognition device, a gas spraying device, an impurity slot, a qualified slot and a fixing bracket. After being vibrated, scattered and separated by the vibration device, the tobaccos to be sorted pass through the guide chute, the detecting area and the qualified slot (or the impurity slot) in turn from a discharging port of the vibration device, so that the purpose of automatically removing the tobacco impurities of the tobaccos to be sorted is achieved, the efficiency of removing the tobacco impurities is increased, and the labor cost is lowered.

Owner:廖鲁昕

Beef fascia removing equipment for beef product processing

ActiveCN114451440AReduce lossRealize automatic eliminationMeat holding apparatusEngineeringMechanical engineering

The invention relates to the technical field of beef production, in particular to beef fascia removing equipment for beef product processing. The pressing assembly is used for pressing one side edge of the beef cubes, and the pressing assembly is arranged on the rack; the cutter assembly which obliquely cuts into the beef cubes below the fascia is arranged beside the pressing assembly; needle bodies used for picking up fascia are evenly arranged on the surface of the film winding roller, and the film winding roller which cuts into beef and abuts against the upper surface of the cutter assembly at first and then rotates to pick up and wind up the fascia on the surface of the beef is arranged beside the cutter assembly; according to the beef fascia removing device, after the cutter assembly cuts into beef, the film winding roller makes contact with and abuts against the upper surface of the cutter assembly, then the film winding roller rotates to pick up and wind up the fascia on the surface of the beef, the fascia is removed in a cutting mode by pulling the fascia, and the technical problems that the fascia on the beef is difficult to remove, and the beef waste amount is large in the fascia removing process are solved.

Owner:福建佳客来食品股份有限公司

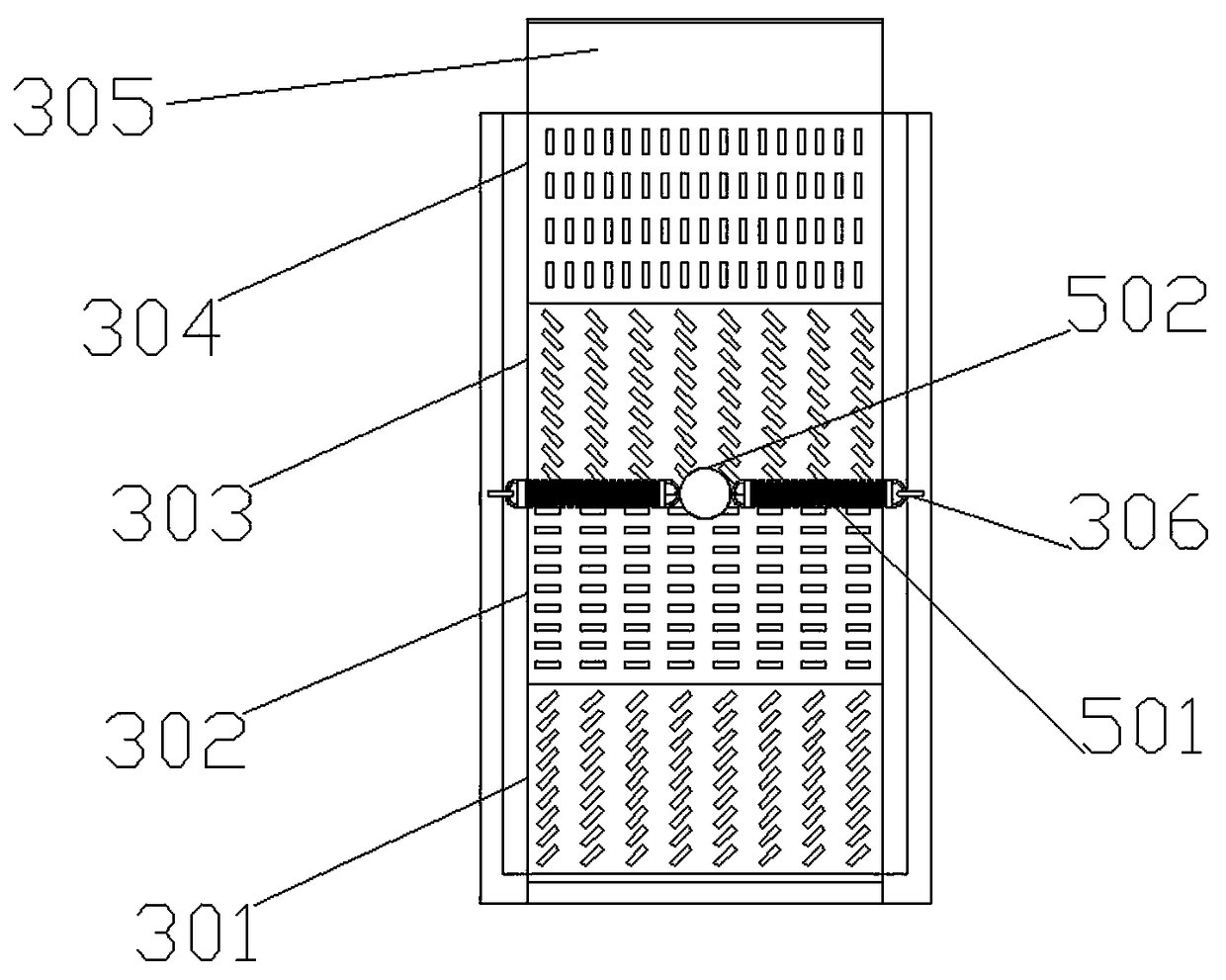

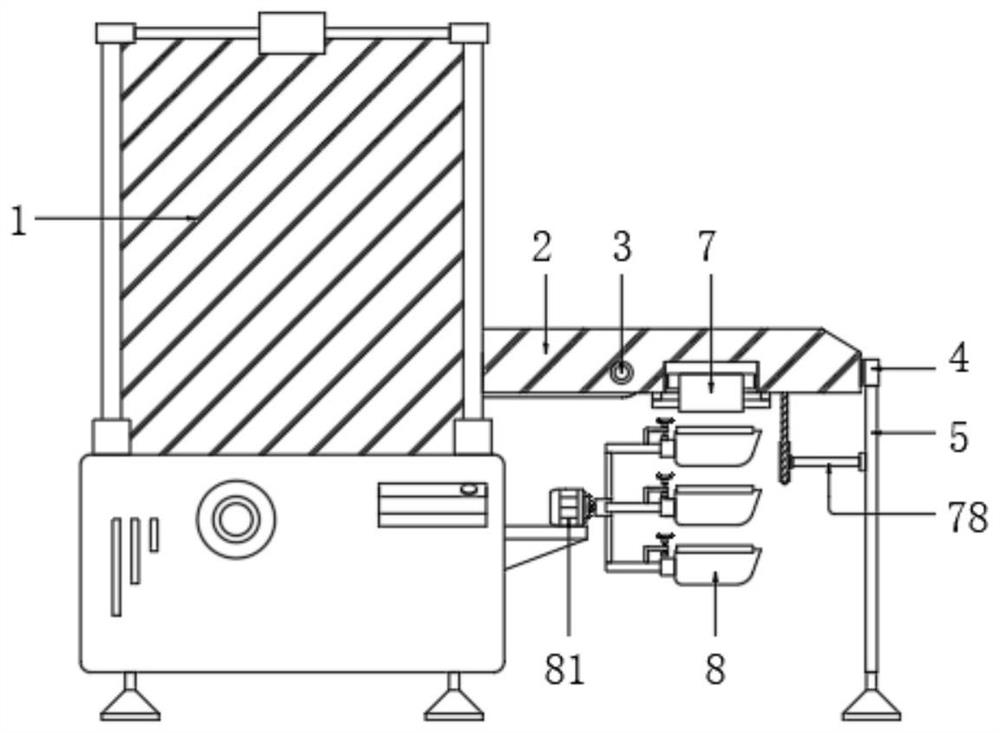

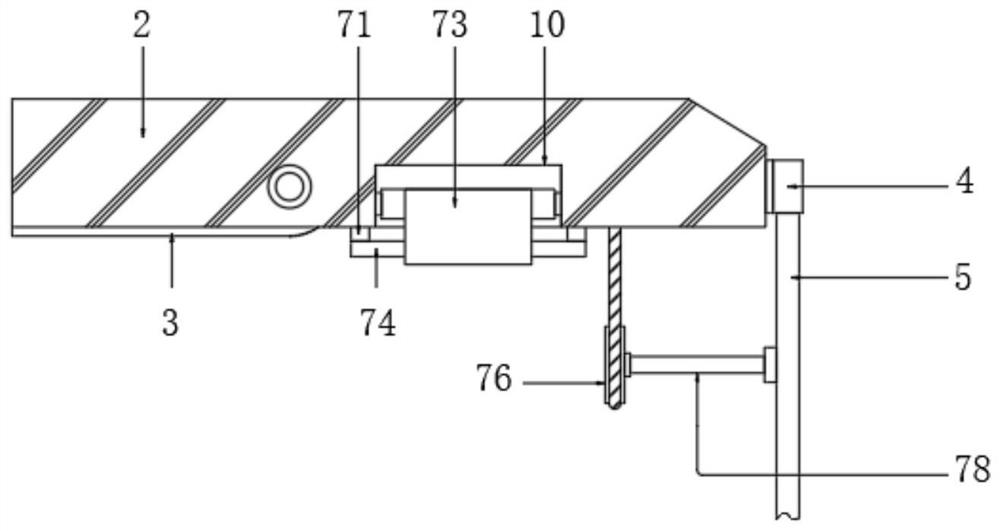

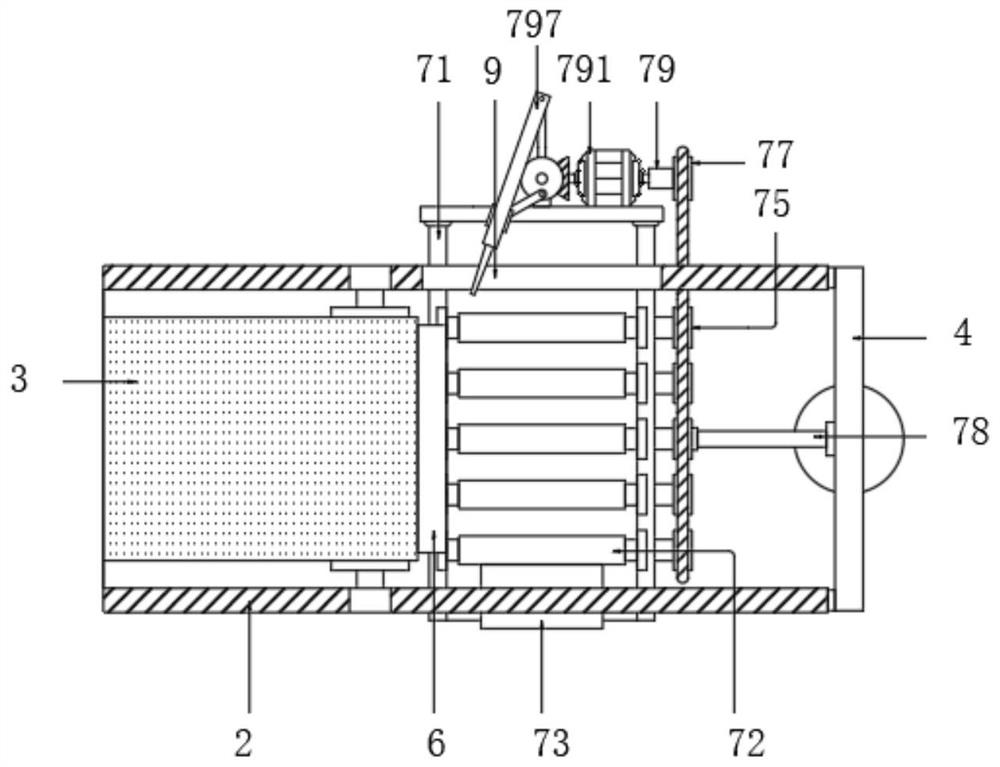

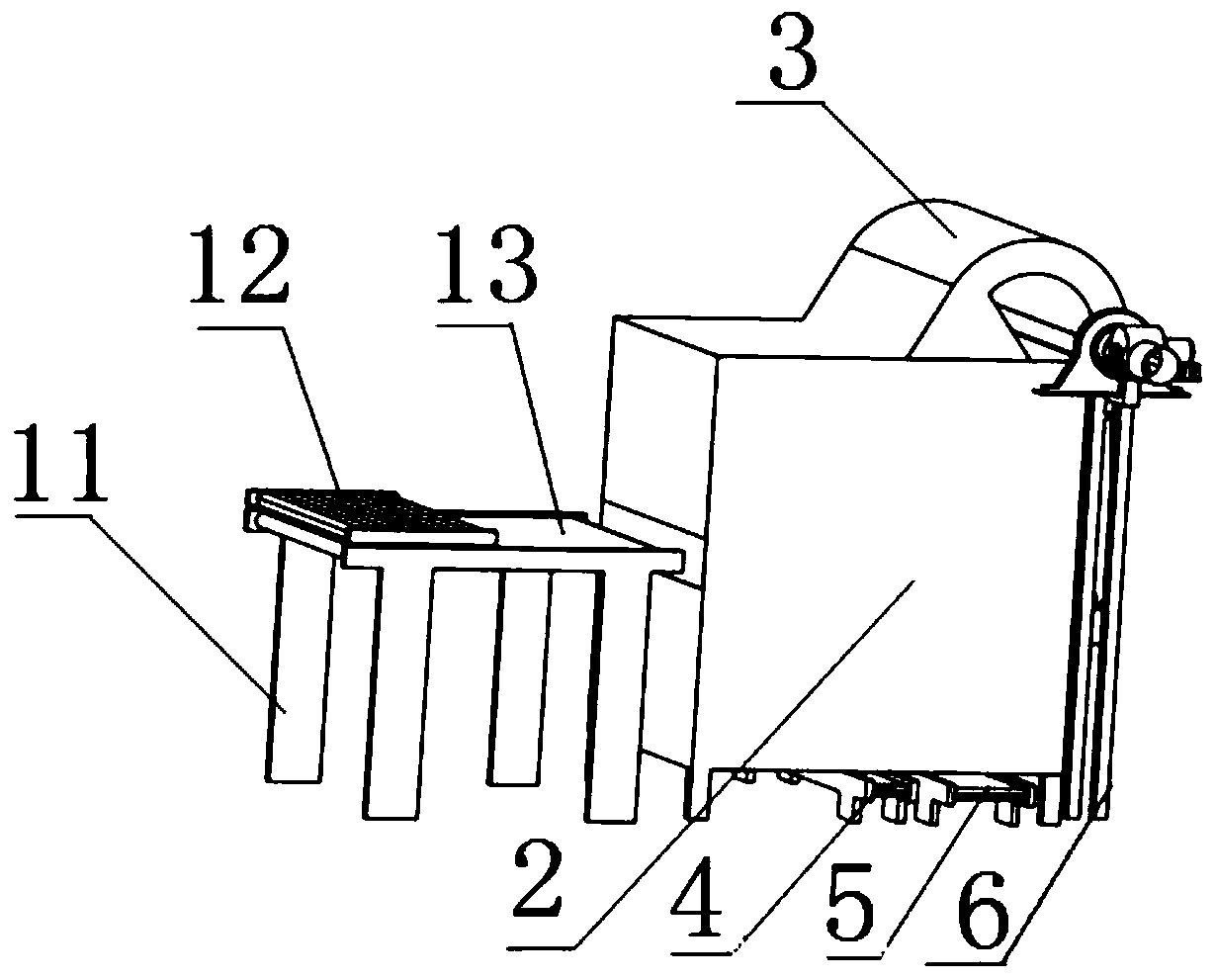

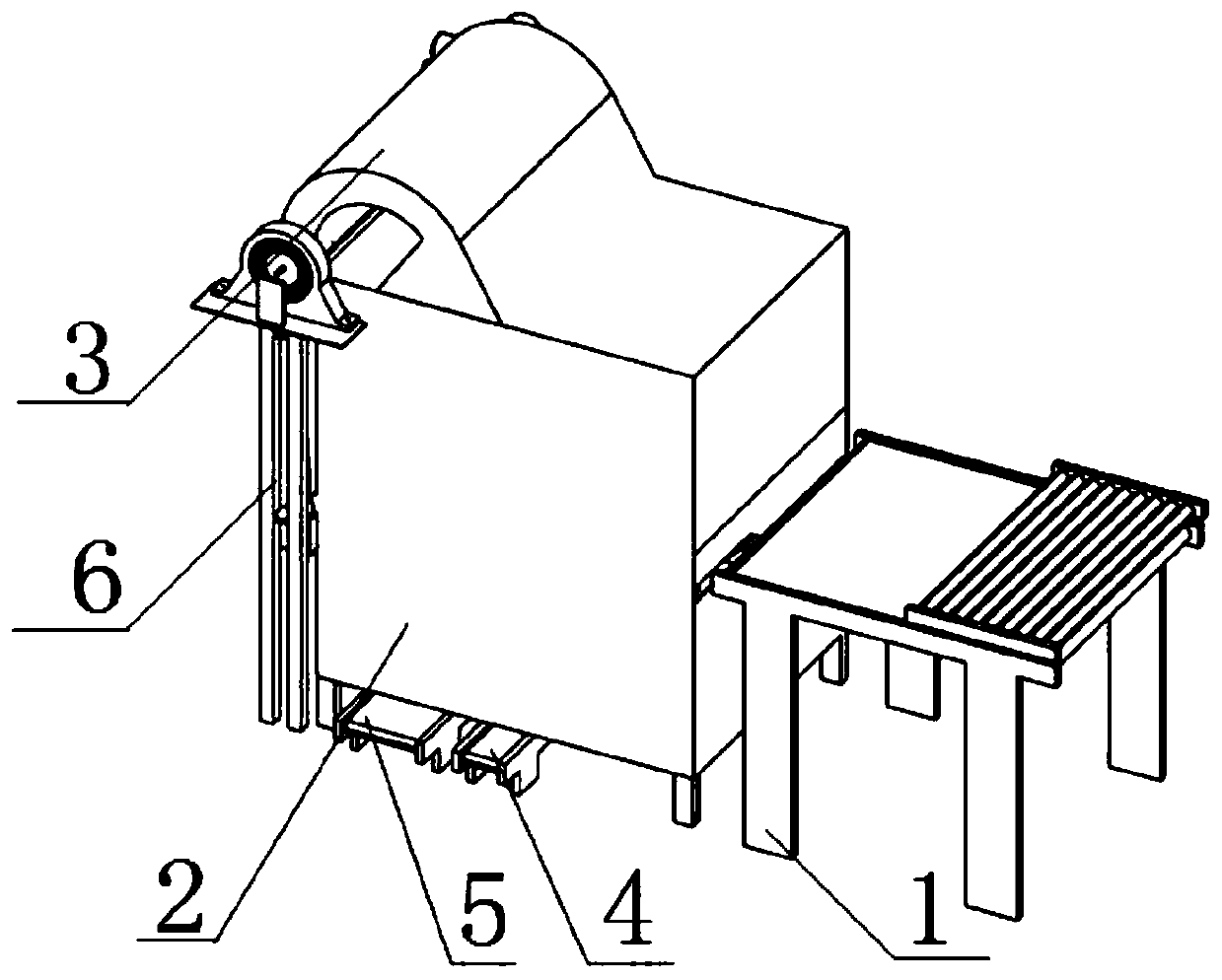

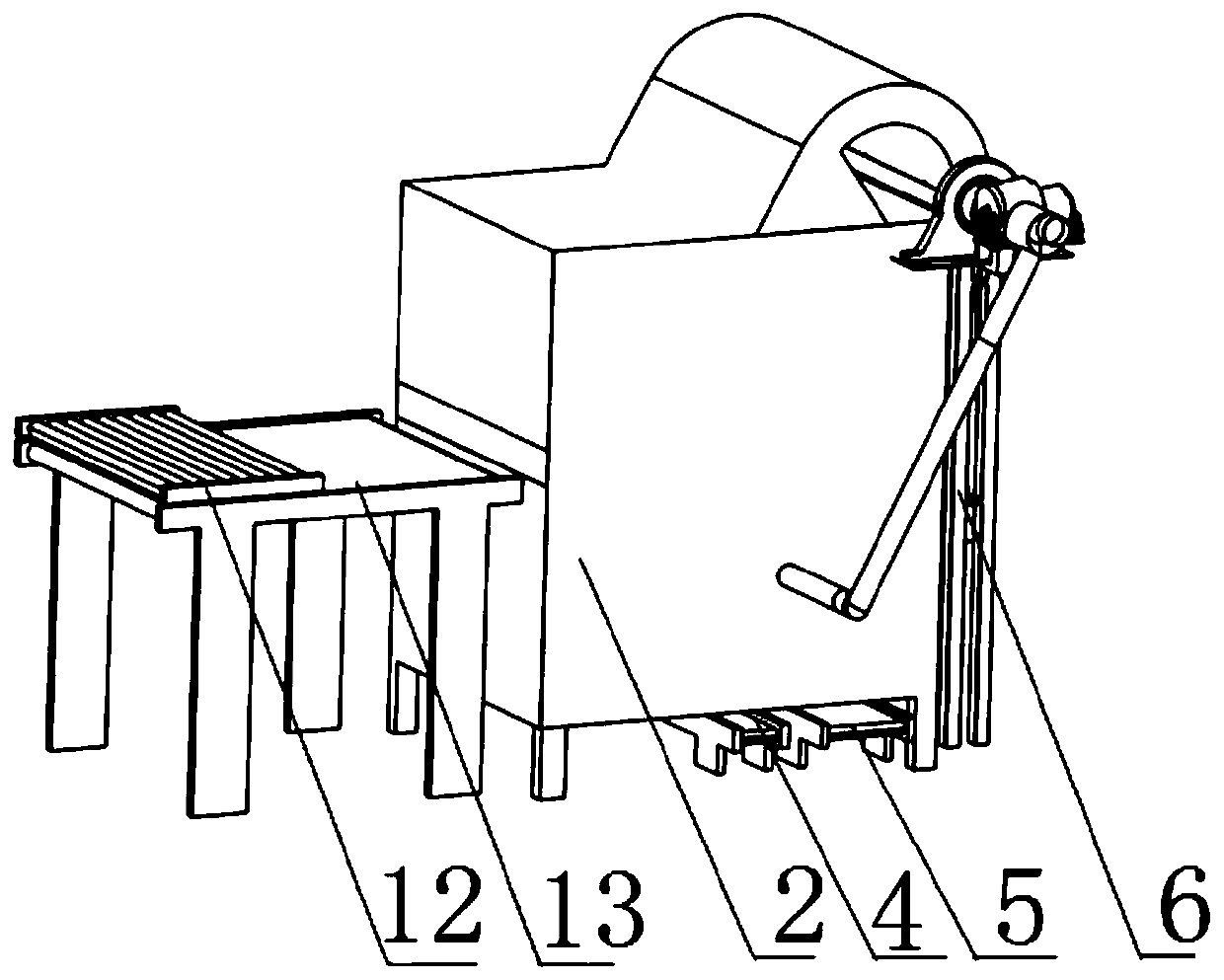

Photoelectric wind separation and impurity removal integrated device based on photoelectric impurity removal machine

PendingCN111085467AReal-time clearAccurate removalTobacco preparationSortingForeign matterDust control

The invention discloses a photoelectric wind separation and impurity removal integrated device based on a photoelectric impurity removal machine. The photoelectric wind separation and impurity removalintegrated device comprises a conveying device (1), the photoelectric impurity removal machine (2), a wind separation and impurity removal device (3), an unqualified material conveying device (4) anda qualified material conveying device (5), wherein the conveying device (1) is arranged on one end of the photoelectric impurity removal machine (2), and the conveying device (1) is engaged with thephotoelectric impurity removal machine (2); a dust removal port is formed in the top of the other end of the photoelectric impurity removal machine (2), the wind separation and impurity removal device(3) is installed at the dust removal port, and the wind separation and impurity removal device (3) is installed on a bracket (6). The photoelectric wind separation and impurity removal integrated device has the advantages of the simple structure and novel design, non-smoke foreign matter or defective goods in tobacco materials can be automatically removed for many times at high speed and high precision, the removal efficiency of the non-smoke foreign matter or the defective goods is further improved, the product quality problem caused by materials is greatly reduced in a production process, the product quality is effectively guaranteed, the production cost is reduced, and the production efficiency is improved.

Owner:QILIN REDRYING FACTORY YUNNAN TOBACCO REDRYING

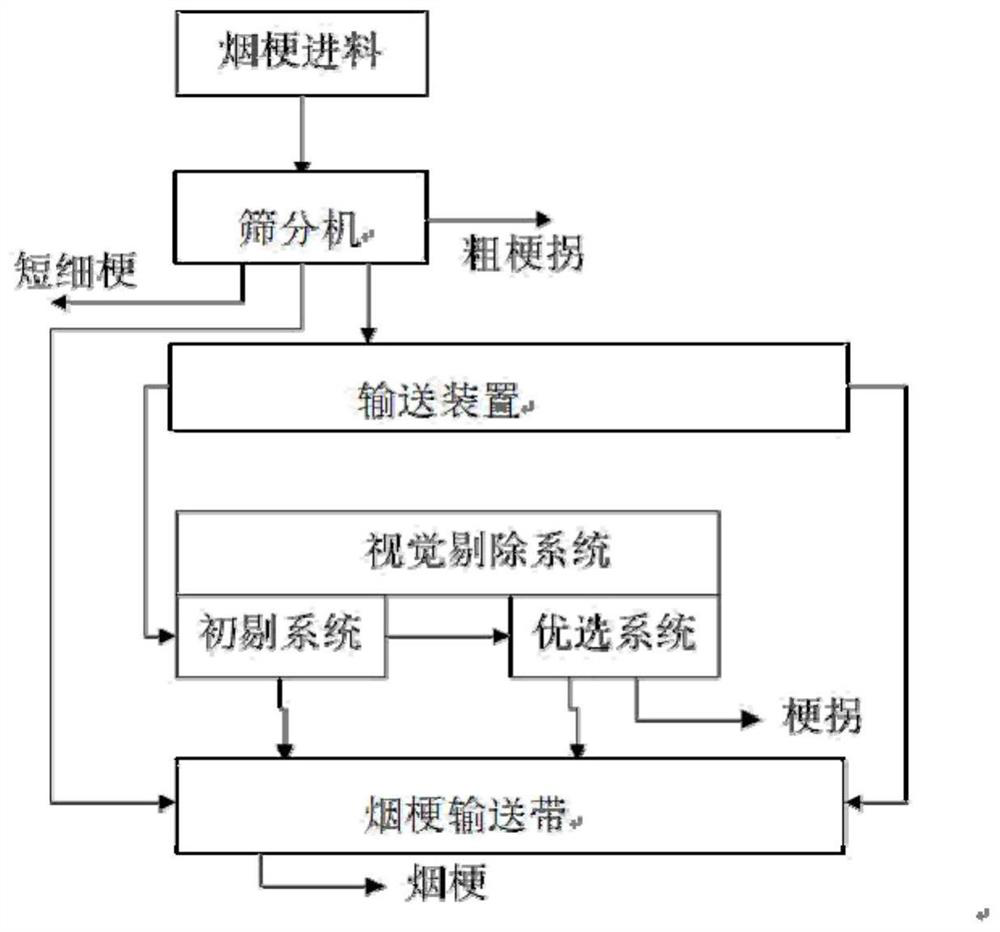

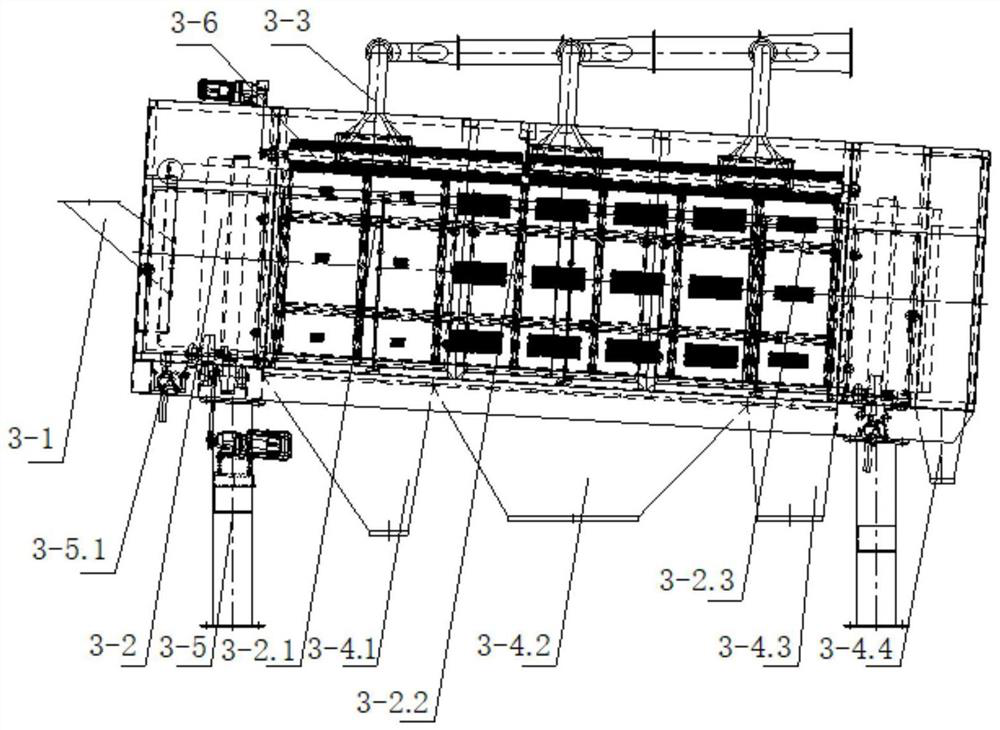

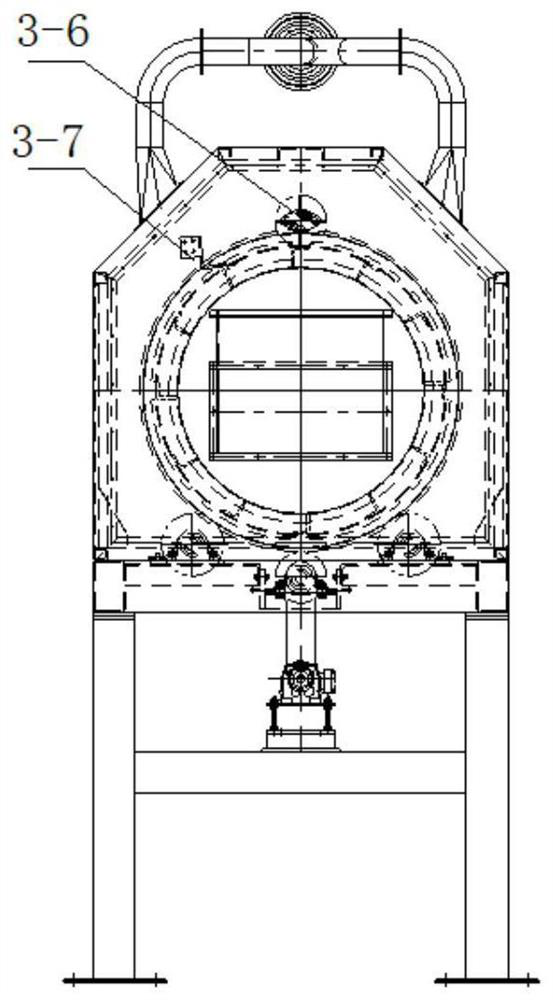

Stem crutch removing system

ActiveCN112056612AImprove culling efficiencyAdvanced technologyConveyorsTobacco treatmentPhysical medicine and rehabilitationVisual recognition

The invention provides a stem crutch removing system. The stem crutch removing system comprises a screening machine and a visual removing system; the visual removing system comprises a visual removingunit; the visual removing unit comprises a material dispersing mechanism, a material guiding mechanism, a visual identification and removing mechanism, a stem crutch outlet and a tobacco stem outlet;to-be-sorted materials sorted by the screening machine are fed into the material dispersing mechanism; the material guiding mechanism is obliquely arranged below an outlet of the material dispersingmechanism; the visual identification and removing mechanism is arranged close to an outlet of the material guiding mechanism; the visual identification and removing mechanism is used for removing stemcrutches in the to-be-sorted materials; the removed stem crutches are output from the stem crutch outlet; and other materials are output from the tobacco stem outlet. Compared with the prior art, thesystem has the advantages that multiple times of sorting of stem crutches and tobacco stems can be achieved through multiple methods, the stem crutch removing efficiency and technological indexes areimproved, and mistaken tobacco stem removing can be effectively avoided.

Owner:ZHISI HLDG GRP

Geotechnical engineering detection sampling device

ActiveCN112798329AImprove firmnessRealize automatic screeningWithdrawing sample devicesHandrailGeotechnical engineering

The invention relates to a geotechnical engineering detection sampling device. The device comprises a sampling insertion pipe; the bottom of the sampling insertion pipe is fixedly connected with a squeezing taper pipe; the outer side of the sampling insertion pipe and the two sides, close to the top, of the sampling insertion pipe are symmetrically and fixedly connected with rotating handrails; the outer surface of the sampling insertion pipe is uniformly provided with driving threads; an inserting and taking circular groove is fixedly connected to the bottom end of the exterior of the squeezing taper pipe; stone removing mechanisms are evenly arranged at the bottom of the inserting and taking circular groove; a compact pressing plate is slidably connected to the middle position of the interior of the sampling insertion pipe; and screening holes are evenly formed in the surface of the compact pressing plate; resistance-increasing taper plates are uniformly and fixedly connected to the surface of the interior of the sampling insertion pipe; and the inner side surfaces of the resistance-increasing taper plates are in corresponding contact with the outer side surface of the compact pressing plate. The invention relates to the technical field of engineering detection. According to the geotechnical engineering detection sampling device, rock soil on the inner side of the bottom of the device is removed outwards, blockage caused by accumulation of stones below the device is avoided, and the sampling precision is improved.

Owner:SHANDONG GUANGXIN ENG TESTING GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com