Stem removing machine

A technology of tobacco stems and skateboards, which is applied in tobacco, food science, tobacco processing, etc., can solve the problems of easy to remove by mistake or not, failure of removal, small area of tobacco stems, etc., achieve high automation level, reduce raw material consumption, The effect of improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

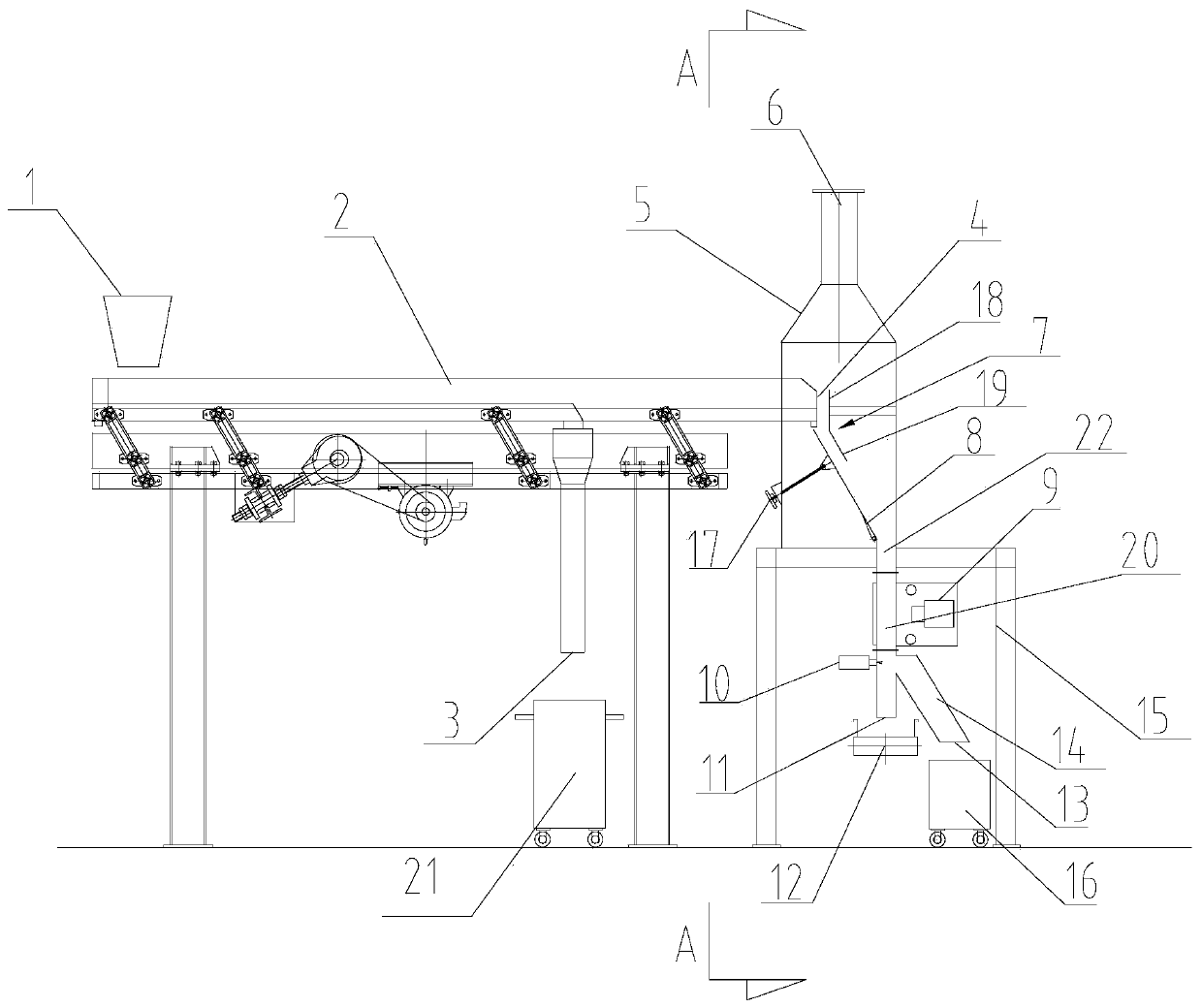

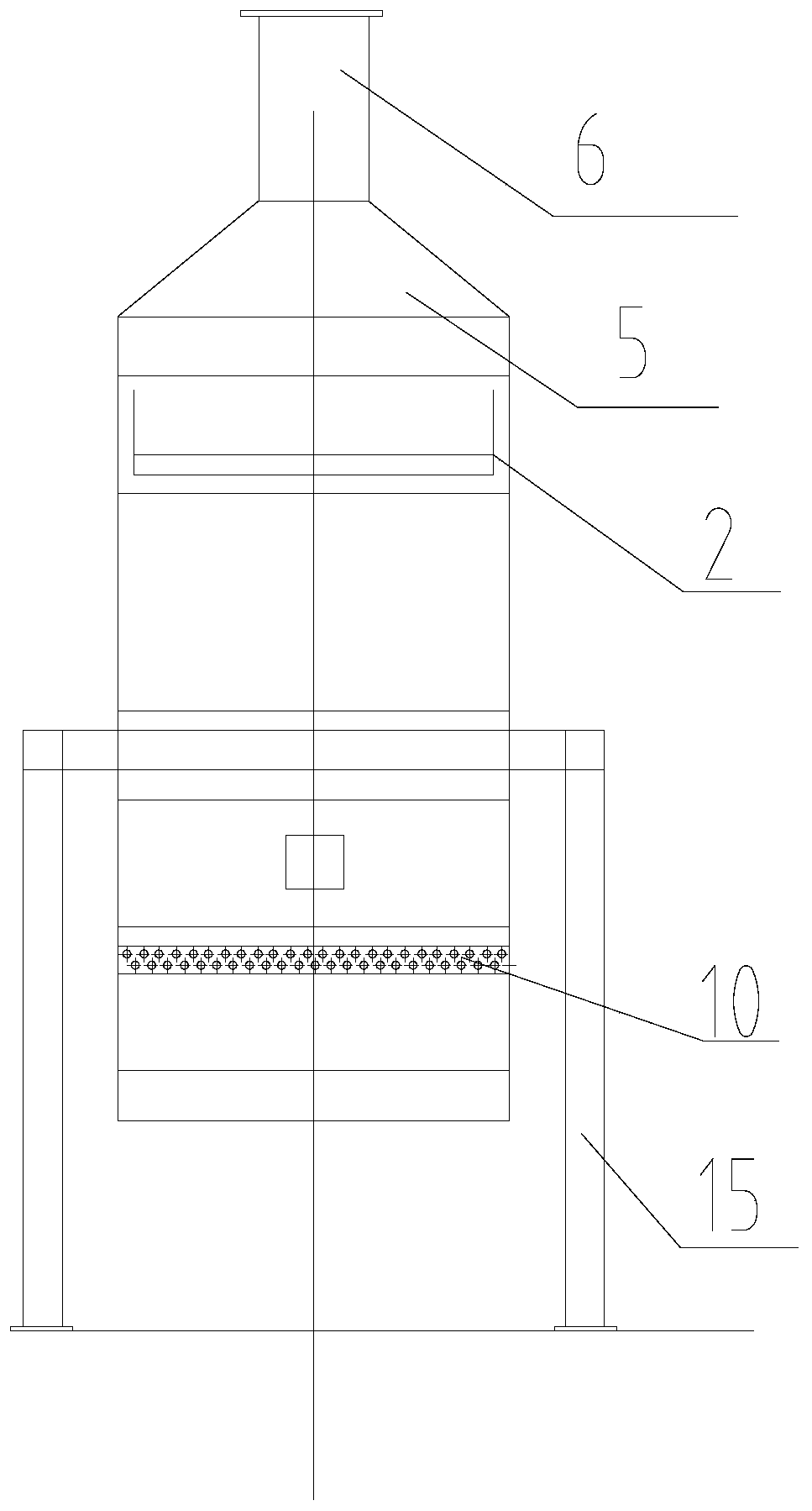

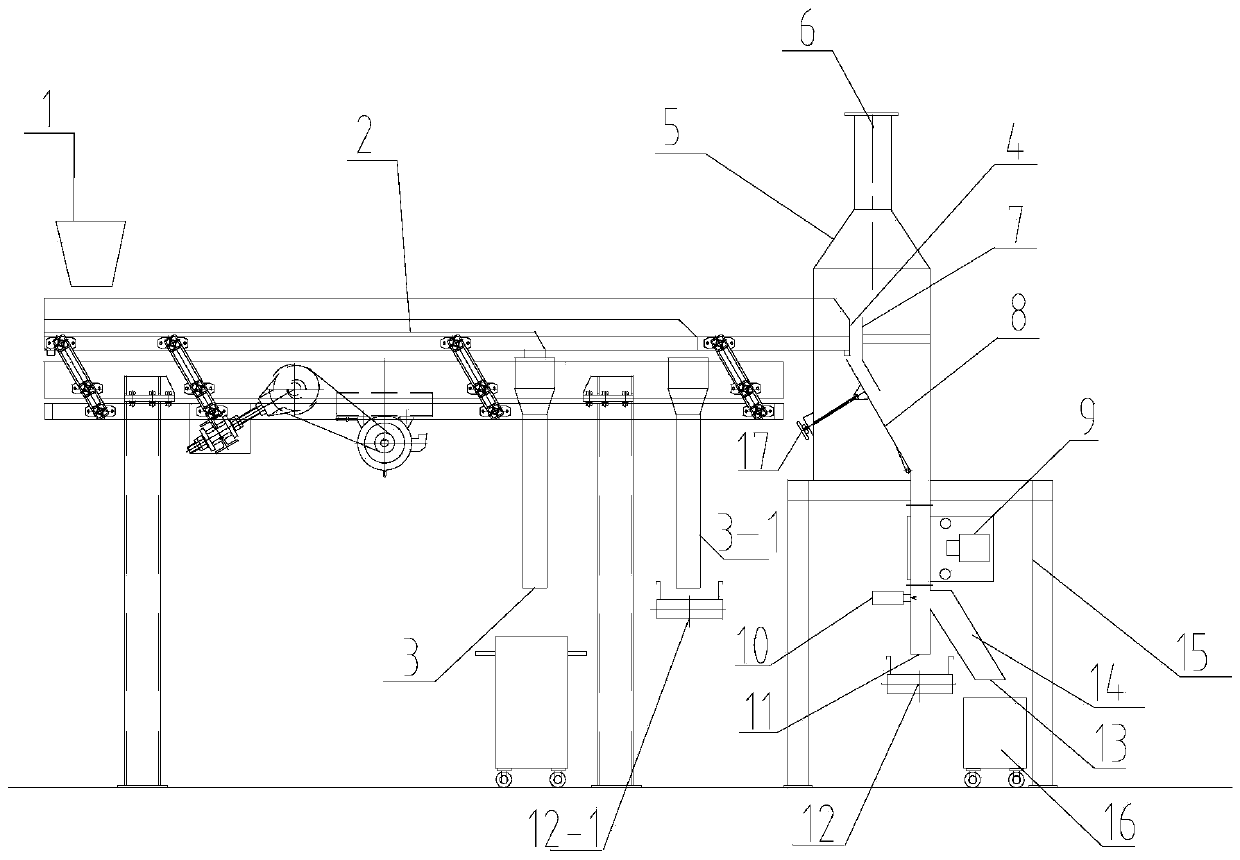

[0028] Such asfigure 1 , 2 Shown, the present invention comprises feeding hopper 1, vibrating screen 2, frame 15, tobacco stem slide box 5. Feed hopper 1 is arranged on the top of the feeding port of vibrating screen 2, and vibrating screen 2 has broken stem outlet 3, and the below of broken stem outlet 3 is provided with broken stem collecting box 21. The sieve plate of the vibrating screen is a single layer, which is a steel wire mesh crossed horizontally and vertically. The diameter of the steel wire is 2mm to 3mm, and the efficiency of screening broken stems is high. The vibrating screen 2 also has a vibrating screen outlet 4, and the vibrating screen outlet 4 stretches into the tobacco stem sliding box 5, and the tobacco stem sliding box 5 is installed on the frame 15, and the top of the tobacco stem sliding box 5 is provided with a dust removal pipe 6.

[0029] Below the vibrating screen outlet 4, a slide plate 8 is provided, and the slide plate 8 is arranged obliquely....

Embodiment 2

[0034] The main difference between Embodiment 2 and Embodiment 1 is that the vibrating screen adopts a double-layer structure, the upper layer is a stainless steel perforated plate with a long hole size of 5mm×50mm, and the lower layer is a horizontally and vertically crossed steel wire mesh with a square hole size of 3mm×3mm. Tobacco stems with a diameter of ≤5mm and a length of ≤50mm fall from the upper sieve plate to the lower sieve plate. During the movement of the lower sieve plate, most of the tobacco stems will be sieved, and the broken stems under the sieve will move until The broken stem exit 3 falls into the broken stem collection box, and the other part of the tobacco stems that have not been removed by the lower sieve plate falls from the middle and thin stem exit 3-1 to the conveyor 12-1 to be transported, and merges with the normal stems behind. The tobacco stems removed by the upper sieve plate are conveyed by the upper sieve plate and enter the tobacco stem slid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com