Riveting press with automatic feeding function

An automatic feeding and riveting machine technology, which is applied in the field of riveting machines, can solve the problems of slow feeding speed, crushed products, and inability to guarantee directionality, etc., and achieve the effect of preventing throwing out or deviating from the working position, and tight connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

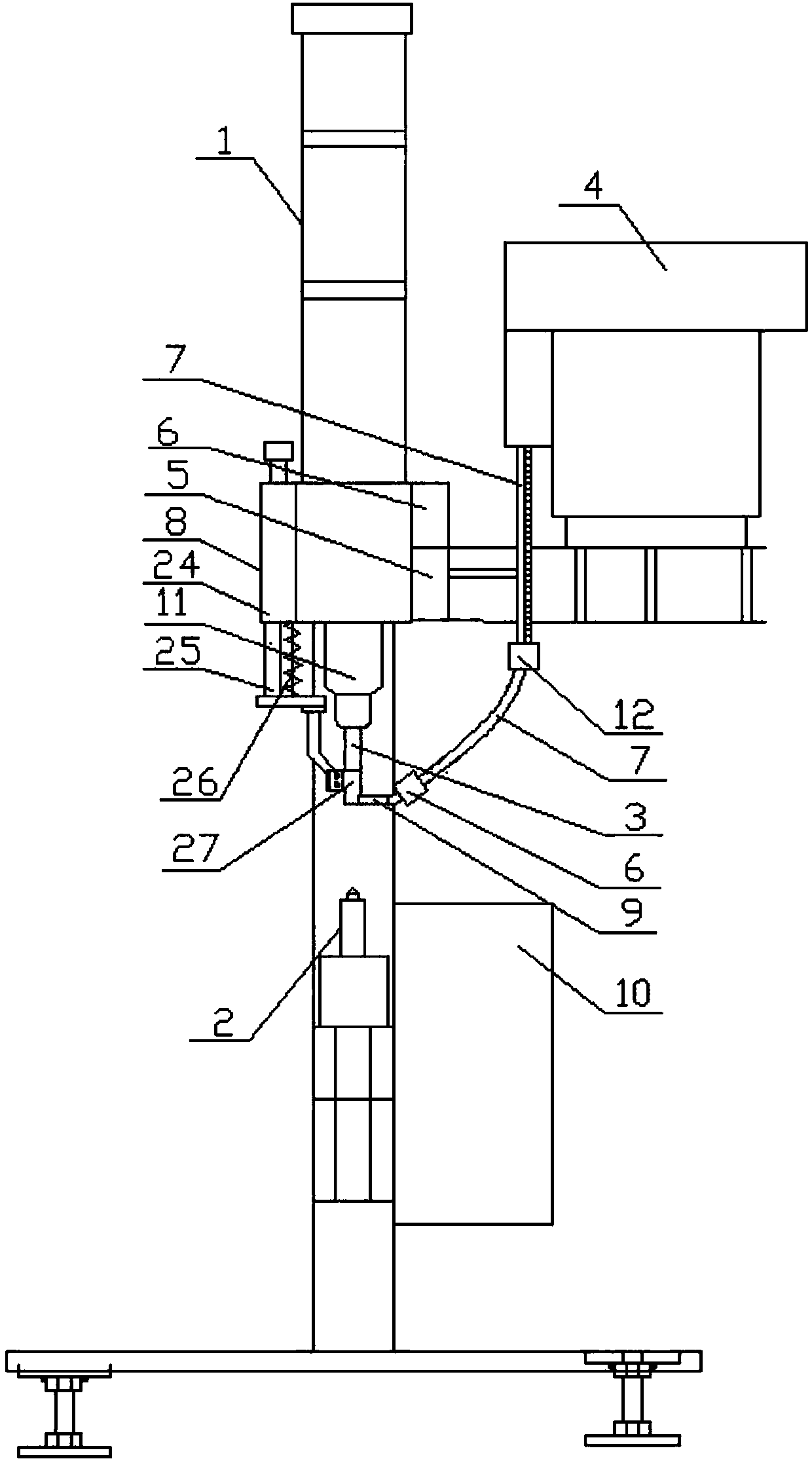

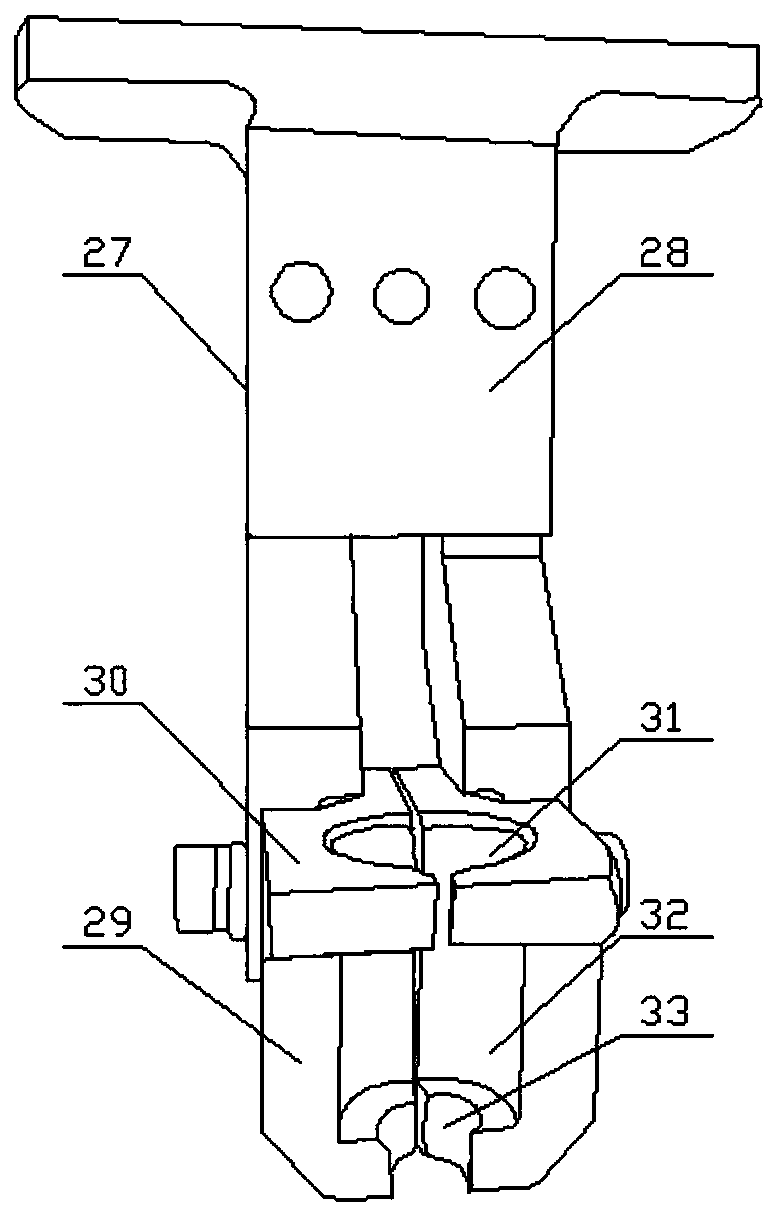

[0037] Such as Figure 1~5 As shown, an automatic feeding riveting machine includes a body 1, a vibrating plate 4, a feeding track controller 5, a feeding track 7, a lower die 2, an upper die that can move up and down along the body 1, and a clamp for clamping the upper die The auxiliary clamping mechanism 8, the auxiliary clamping mechanism 8, the vibrating plate 4 and the feeding track controller 5 are all installed on the body 1, the upper mold is slidably connected with the body 1, and the lower mold 2 is fixedly installed on the workbench of the body 1 and located at Directly below the upper die, the discharge port of the vibrating plate 4 communicates with the feed end of the feeding track 7, and the feeding track controller 5 is provided with a driving mechanism connected to the feeding track 7, and the feeding track controller 5 is connected to the driving mechanism electronically. Connected, the driving mechanism drives the feeding track 7 to approach or stay away from ...

Embodiment 2

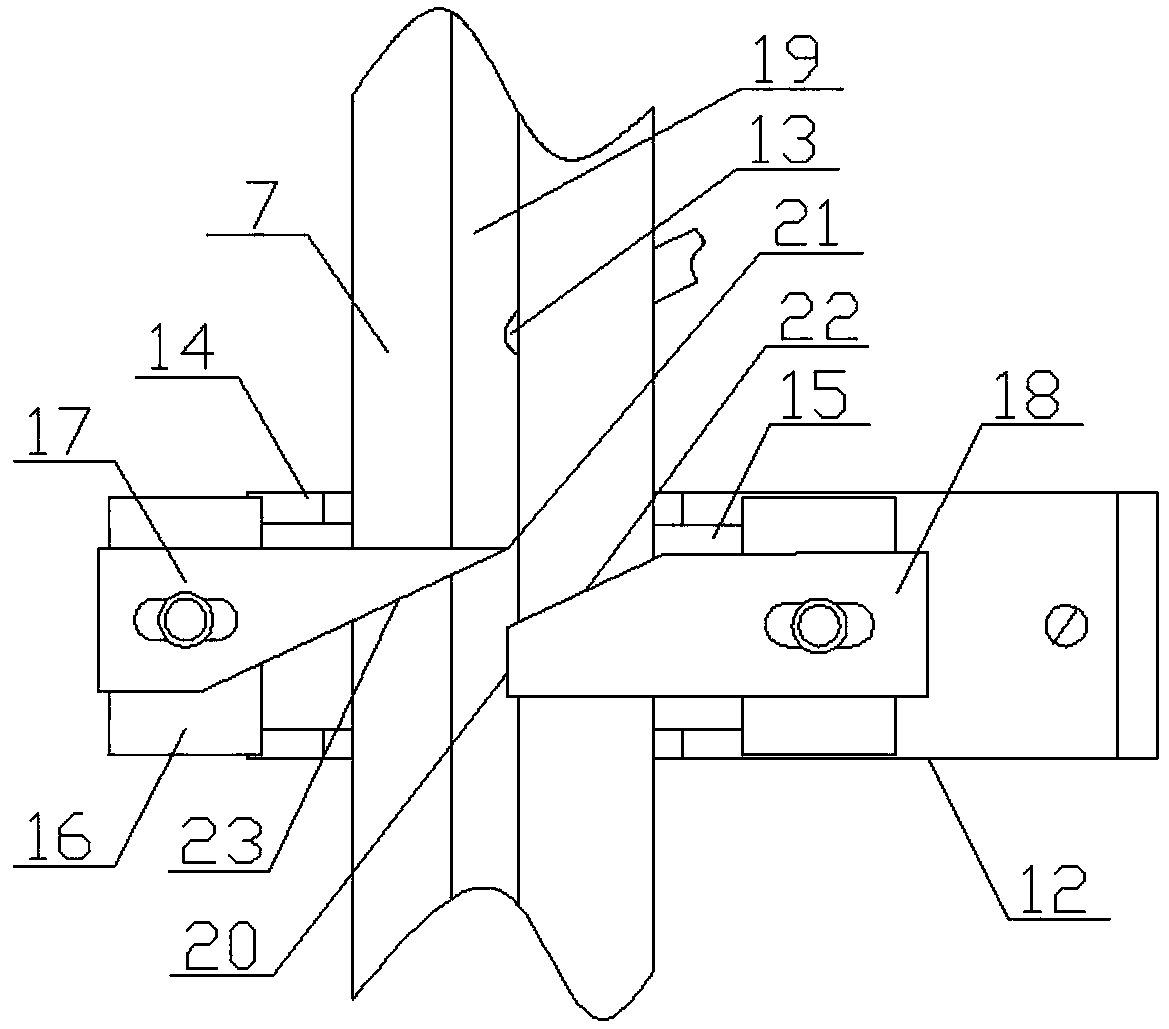

[0049] Such as Figure 1-7 As shown, the difference between embodiment 2 and embodiment 1 is that a lock door A12 is installed near the end of the vibrating plate 4 on the feeding track 7, and a lock door B38 is installed near the end of the duckbill head 9 on the feed track 7, and the lock door B38 includes Pressure cylinder 36 and push rod 37, pressure cylinder 36 is fixedly installed on the feeding track 7, the piston rod of pressure cylinder 36 is fixedly connected with push rod 37, and protrusion 35 and push rod 37 are respectively positioned at the upper and lower ends of guide groove 34, guide Both the groove 34 and the feeding groove 19 are vertically arranged with the push rod 37 . When the parts flowed to the lock door B38 through the lock door A12, the pressure cylinder 36 worked, and the parts were cut into the opening by the action of the push rod 37. There is an inclined surface C39 under the push rod 37, and the distance between one end of the inclined surface ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com