Deslagging type tea leaf grading screening device

A technology for grading and screening tea, which is applied in the fields of sieving, solid separation, tea treatment before extraction, etc. It can solve the problems of untreated impurities, waste, and easily damaged equipment, and achieve the effect of speeding up screening and improving safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

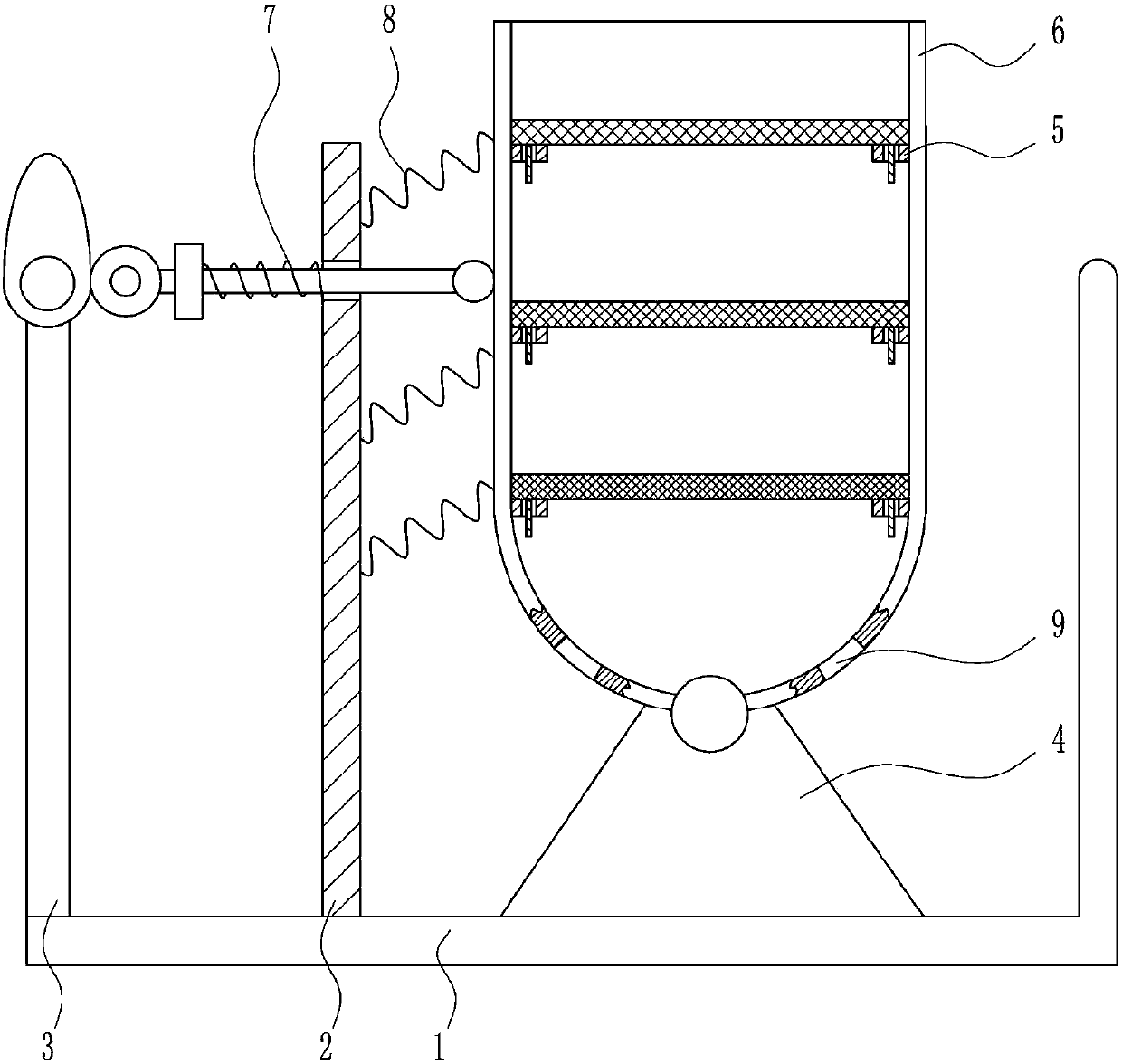

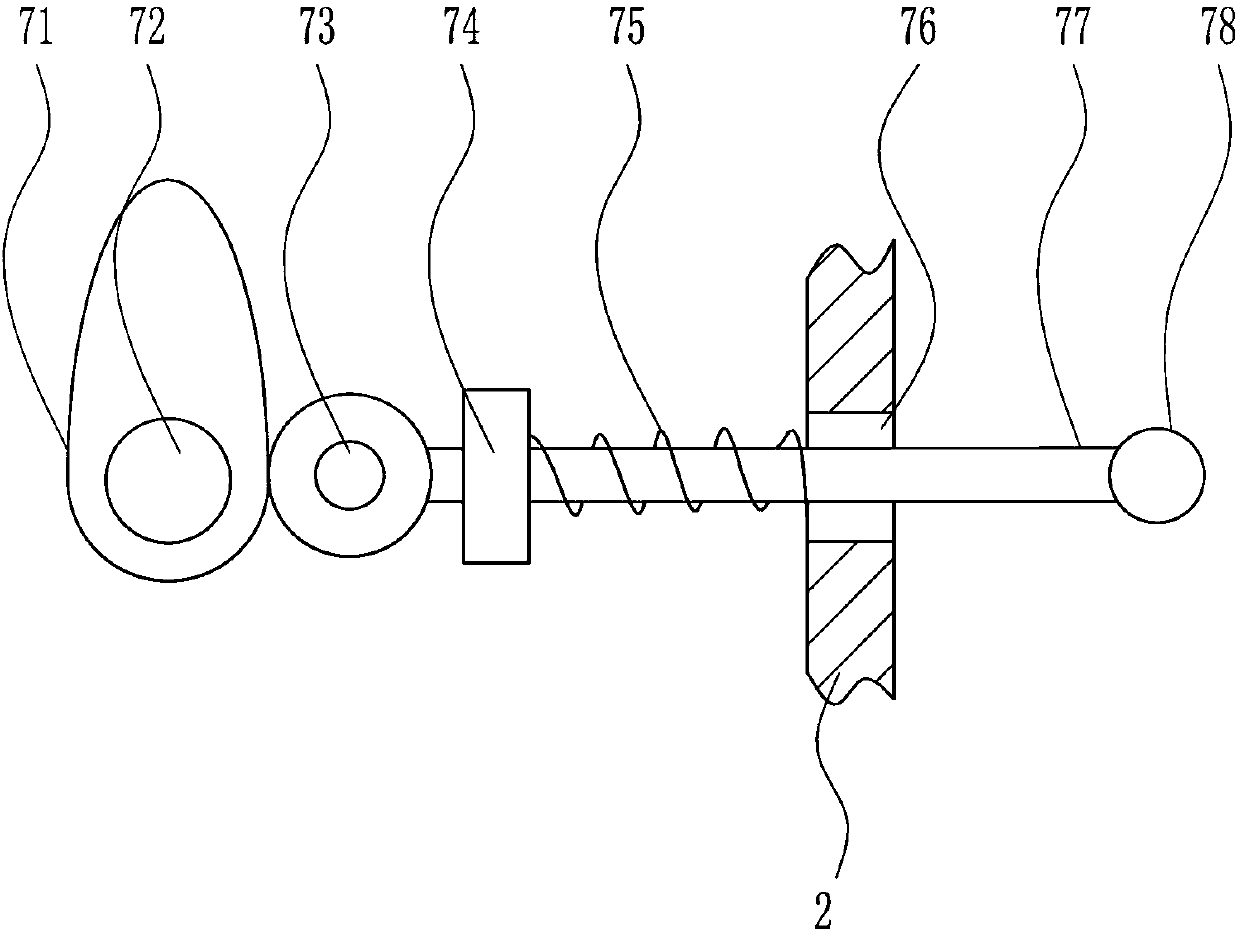

[0029] A slag-removing type tea grading and screening device, such as Figure 1-5 As shown, it includes a bracket 1, a guide plate 2, a pole 3, a support 4, a grading mechanism 5, a screening tank 6, a screening mechanism 7 and a first elastic member 8, and the top of the bracket 1 is arranged in turn from left to right. The pole 3, the guide plate 2 and the support 4, the top of the pole 3 is provided with a screening mechanism 7, the top of the support 4 is connected to the screening tank 6 in a rotating manner, the left wall of the screening tank 6 and the right wall of the guide plate 2 The first elastic member 8 is connected between them, and the left and right sides of the bottom front side of the screening tank 6 are symmetrically opened with slag outlets 9, and the screening tank 6 is equipped with a classification mechanism 5 inside.

Embodiment 2

[0031] A slag-removing type tea grading and screening device, such as Figure 1-5 As shown, it includes a bracket 1, a guide plate 2, a pole 3, a support 4, a grading mechanism 5, a screening tank 6, a screening mechanism 7 and a first elastic member 8, and the top of the bracket 1 is arranged in turn from left to right. The pole 3, the guide plate 2 and the support 4, the top of the pole 3 is provided with a screening mechanism 7, the top of the support 4 is connected to the screening tank 6 in a rotating manner, the left wall of the screening tank 6 and the right wall of the guide plate 2 The first elastic member 8 is connected between them, and the left and right sides of the bottom front side of the screening tank 6 are symmetrically opened with slag outlets 9, and the screening tank 6 is equipped with a classification mechanism 5 inside.

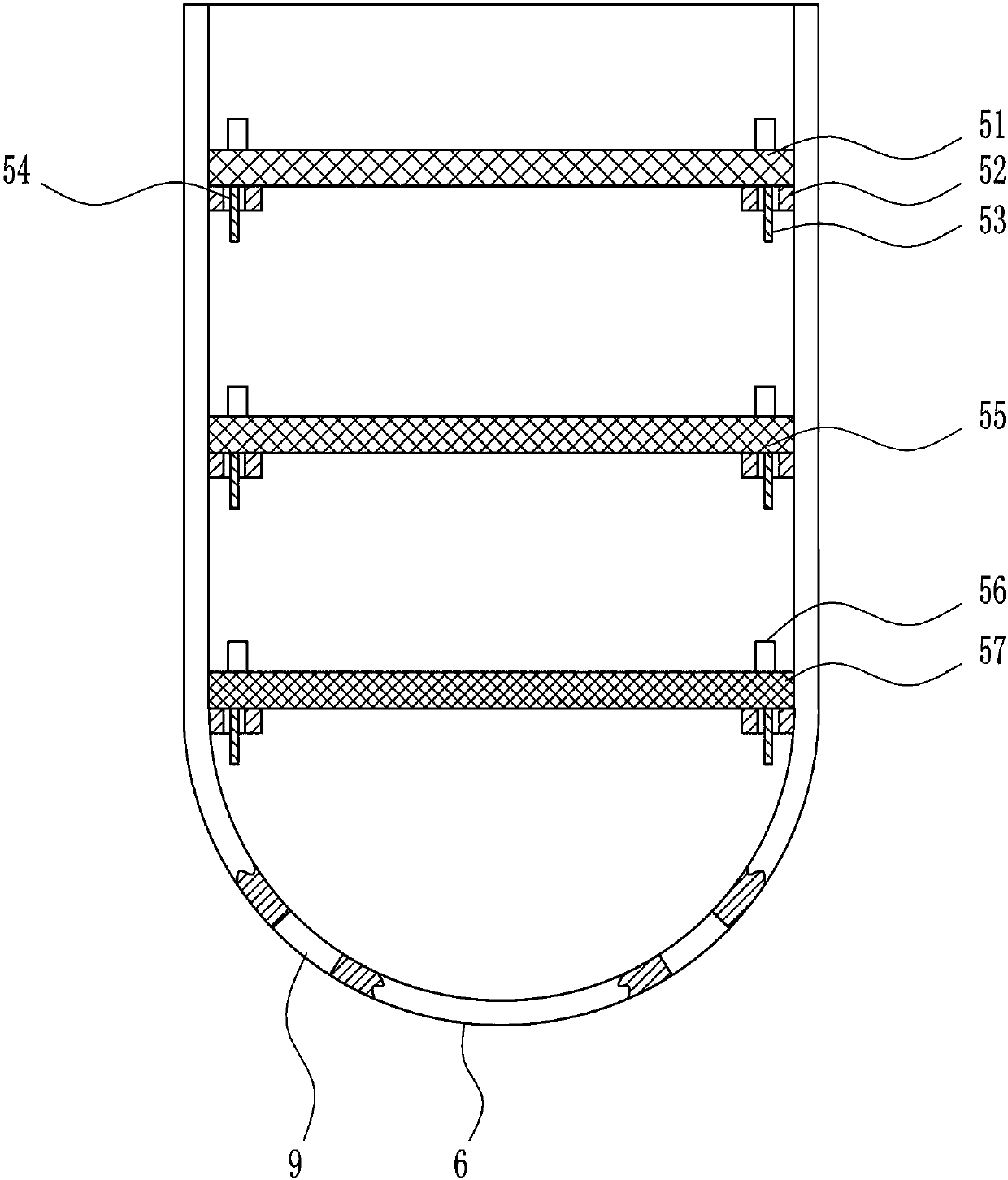

[0032] Grading mechanism 5 comprises large screen 51, fixed plate 52, inserting rod 53, middle screen 55, handle 56 and small screen 5...

Embodiment 3

[0034] A slag-removing type tea grading and screening device, such as Figure 1-5As shown, it includes a bracket 1, a guide plate 2, a pole 3, a support 4, a grading mechanism 5, a screening tank 6, a sieve moving mechanism 7 and a first elastic member 8, and the top of the bracket 1 is arranged in sequence from left to right The pole 3, the guide plate 2 and the support 4, the top of the pole 3 is provided with a screening mechanism 7, the top of the support 4 is connected with the screening tank 6 in a rotating manner, the left wall of the screening tank 6 is connected with the right wall of the guide plate 2 The first elastic member 8 is connected between them, and the left and right sides of the bottom front side of the screening tank 6 are symmetrically opened with slag outlets 9, and the screening tank 6 is equipped with a classification mechanism 5 inside.

[0035] Grading mechanism 5 includes large screen 51, fixed plate 52, inserting rod 53, middle screen 55, handle 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com