Lubricating device of motor bearing

A technology for lubricating devices and motor bearings, applied in the directions of electromechanical devices, casings/covers/supports, electrical components, etc., can solve problems such as excessive use of grease, discharge of waste grease, narrow cavity, etc., to ensure cleanliness, thickness, etc. Thin, easy-to-process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the drawings and embodiments.

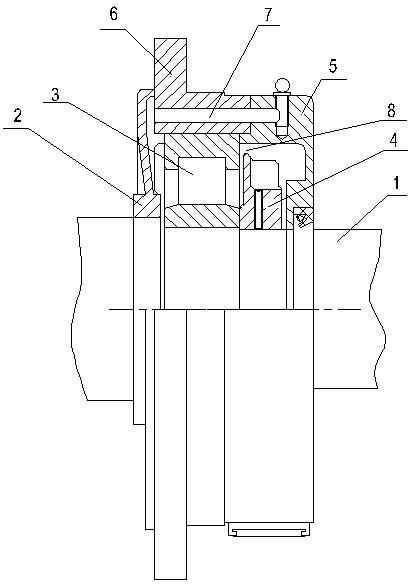

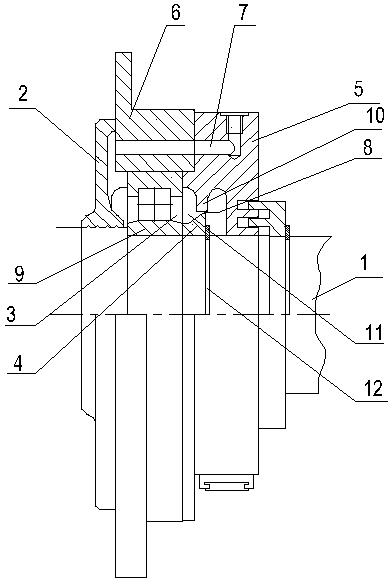

[0020] Such as figure 2 As shown, a lubricating device for a motor bearing includes a motor shaft 1, a bearing 3 installed on the bearing stand of the motor shaft 1, an oil slinger 4 installed on the motor shaft outside the bearing 3, and two sides of the bearing respectively The bearing inner cover 2 and the bearing outer cover 5 fixed by the bearing outer cover 6 are provided with an oil injection channel 7 that penetrates the cavity of the bearing inner cover 2 inside the bearing outer cover 5 and the bearing outer cover 6.

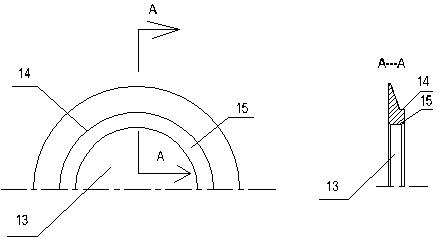

[0021] Such as image 3 As shown, the oil slinger 4 in the lubricating device is a disc with an inner hole 13, combined image 3 It can be seen from the AA cross-sectional view in the middle that the thickness of the slinger body 15 is divided into two parts. The surface of the disc is bounded by the contact contour circle 14 with the bearing inn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com