Scattered tobacco stem removing and sieving vibration trench

A technology for screening and crushing tobacco, which is applied in the direction of sieve, solid separation, grille, etc., can solve the problems of long disassembly and installation process, lower removal rate of broken tobacco stems, lower screening effect, etc. The effect of labor intensity, improving the quality and yield of cut stems, and facilitating maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

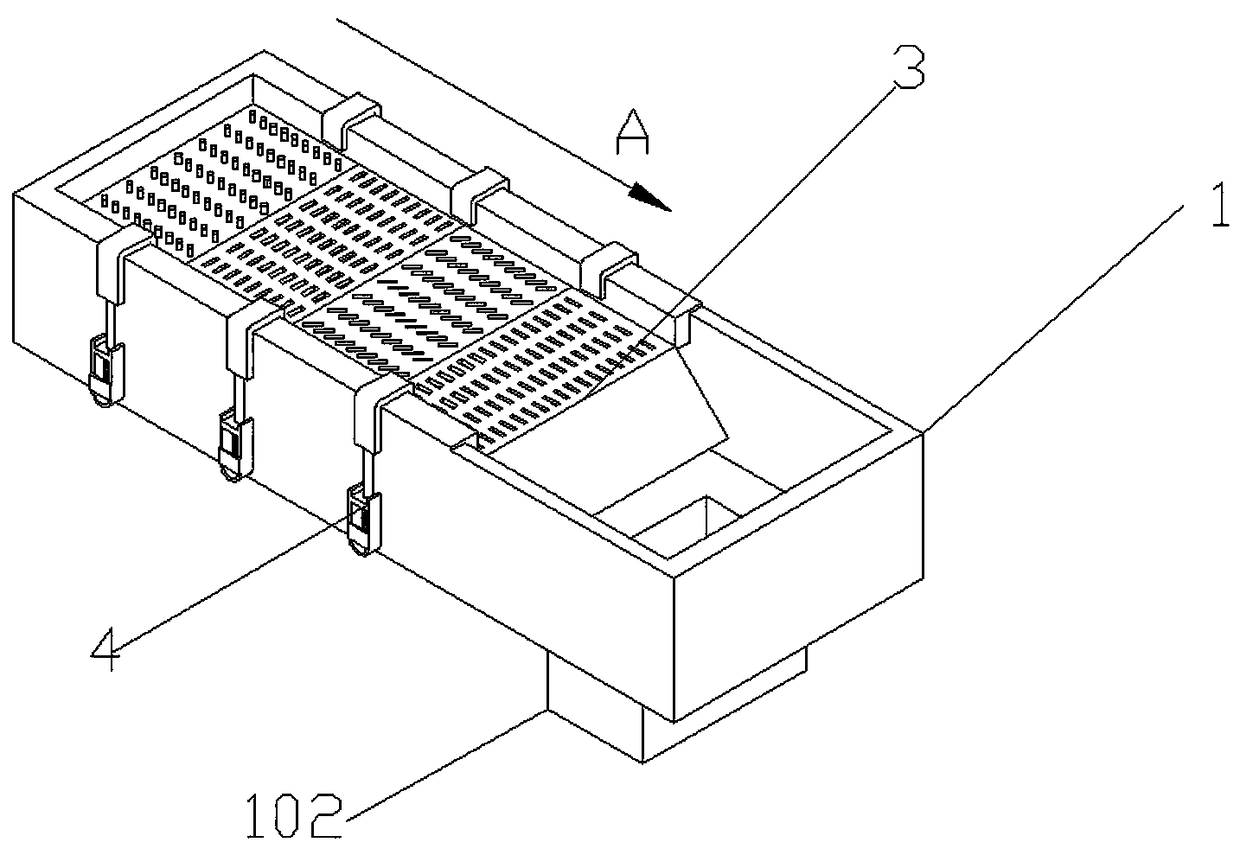

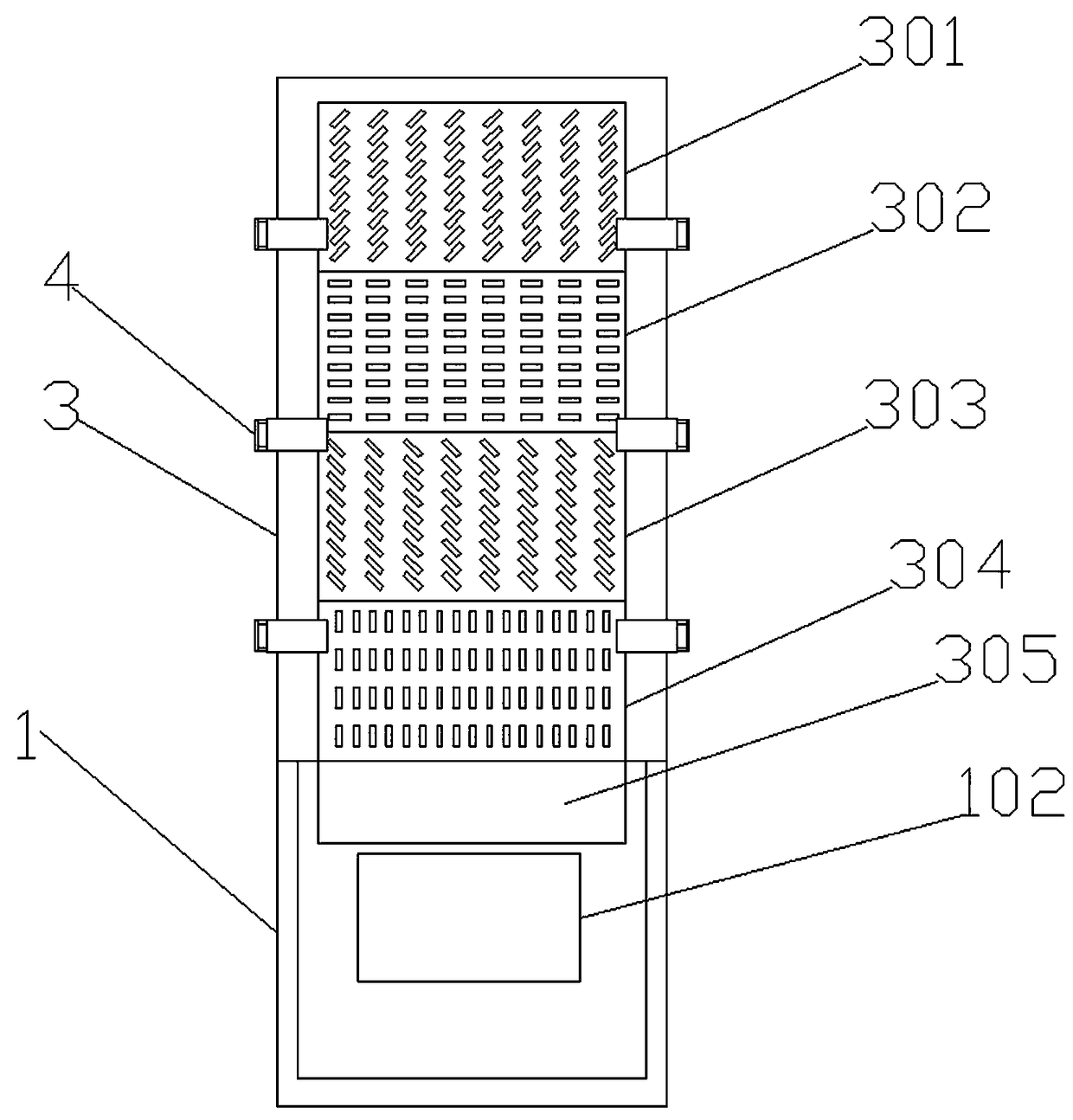

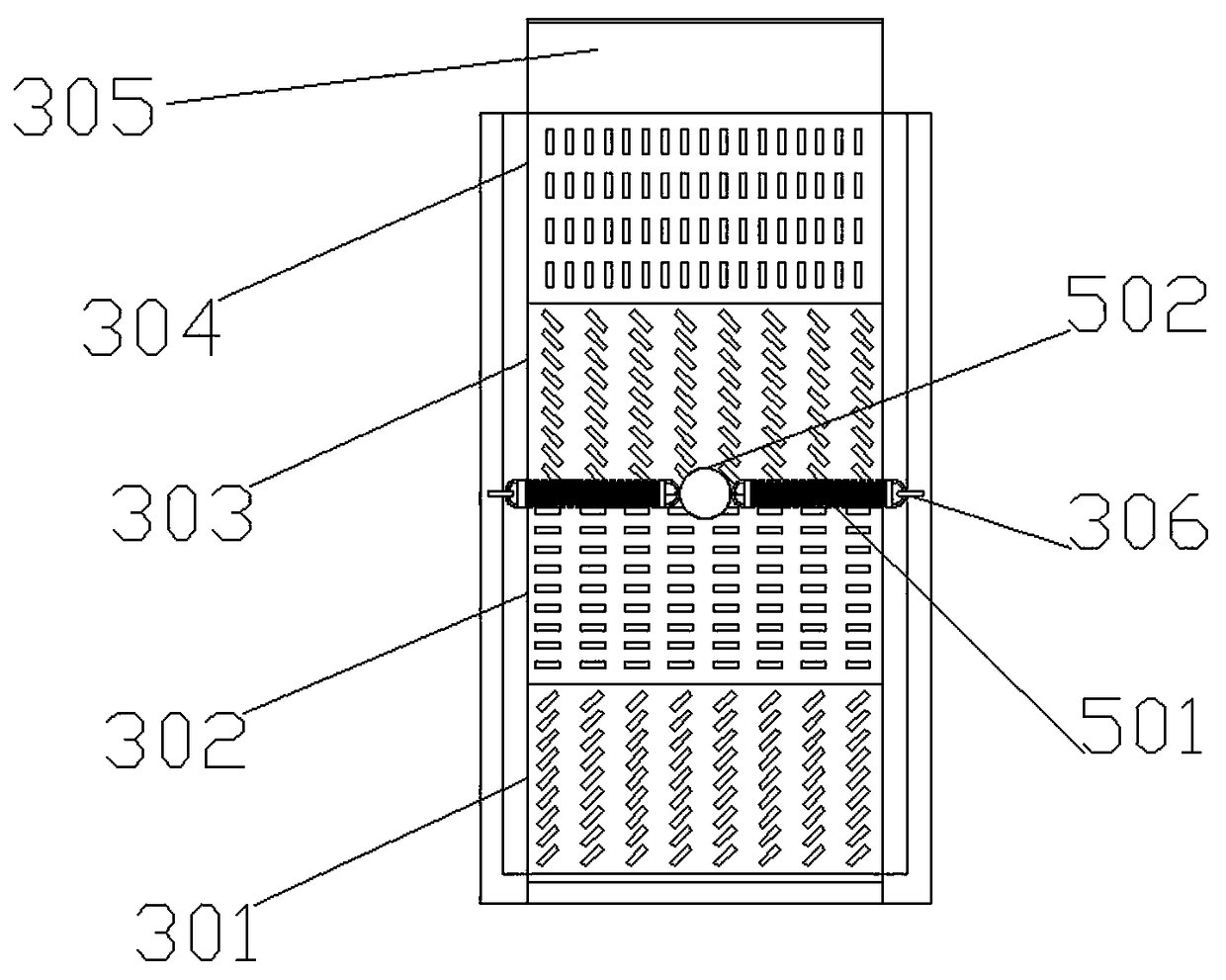

[0027] Such as Figure 1 to Figure 5 As shown, taking the material transportation direction as the front direction, that is, the direction A, a vibrating tank for removing and screening broken tobacco stems includes a tank body 1, a vibrating screen 3, and a vibrating screen 3 for fixing the vibrating screen 3 on the tank body 1. The locking device 4 and the self-cleaning device 5 connected to the bottom of the vibrating screen 3,

[0028] The width of the vibrating screen 3 matches the width of the tank body 1, and the left and right sides of the vibrating screen 3 are provided with flanges for erecting on the tank body 1, and the vibrating screen 3 is fixed by a locking device 4 connected to the flanges on both sides of the tank body 1,

[0029] Such as image 3 As shown, the vibrating screen 3 is divided into four screenin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com