Patents

Literature

30results about How to "Improve silk yield" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cooking method for fresh cocoons

InactiveCN104894655AEasy to cleanGood relaxing effectAnimal materialSilk filament obtainingEngineeringCooking methods

The invention discloses a cooking method for fresh cocoons. The cooking method is characterized by including the technological steps of cocoon selection, tea bran water soaking, permeation, enzymolysis, cocoon cooking and cocoon picking. The cooking method for the fresh cocoons has the advantages that the method is simple in technology, convenient to operate and low in production cost; after the method is used for cooking the cocoons, silk yielding rate and quality of obtained cooked cocoons are high; quality index level of the cooked cocoons is improved greatly, and cleanness, spotlessness, strength and cohesion indexes are improved by above one grade.

Owner:广西立盛茧丝绸有限公司

Method for preparing high grade sexual silk

InactiveCN101054731AImprove silk yieldSilk reelingSilk cocoons cleaning/classifyingFiberUltraviolet lights

The present invention discloses a process for preparing high-quality gender cocoon fibre. Said process comprises the following steps: adopting breeded fluorescent cocoon color to judge breed variety of gender silkworm under ultraviolet light source, respectively measuring sizes of female / male silkworm cocoon and thickness of cocoon layer after separating female silkworm cocoon from male silkworm cocoon, adjusting the cocoon drying technological conditions according to determination of conventional technological condition for cocoon drying and cocoon boiling, wherein for female cocoon, the reducing dry temperature is adjusted to 3-10 DEG C and the shortening reduced speed dry time is adjusted to 0.5-.5 hours, for male cocoon, the prolonging reduced speed dry time is adjusted to 0.5-.5 hours; regulating the technological conditions for cocoon boiling, for female cocoon, the prolonging boiling setting time is 1-3 minutes, for male cocoon, the shortening boiling debug time is 1-3 minutes; then, reeling silks at an auto cocoon cooking machine or an auto fiber-fixed reeling machine to manufacture male silkworm bast silk with a gradation of 6A and female silkworm bast silk with a gradation of 5A-6A. The obtained bast silks is one or two gradations higher than the male / female mixing bast silk, and then realizes the batch silk reeling of cocoon fibre, with high quality.

Owner:SUZHOU UNIV

Method of storaging and treating fresh silkworm cocoon

The method for storing-treatment of the fresh silkworm cocoons incldues such steps as loading fresh silkworm cocoons in baskets, antistaling transporting in air-permeable coach without sunshining, stacking the baskets on the pallet far from ground, and storing in cold storage at -4-10 deg.C. Before the cocoons are used, they are defrozen at ordinary temp., and equilibrium treatment in cool wind. Its advantages are high cocoon quality and high silk output rate.

Owner:CHENGDU TIANCHUANG BIO TECH

Cleaning agent of circulating water for washing recycled plastics

InactiveCN104016425AImprove qualityNo pollution in the processWater/sewage treatmentNicotiana tabacumWater quality

The invention discloses a cleaning agent of circulating water for washing recycled plastics, relating to the technical field of water treatment. The cleaning agent is composed of the following components in parts by weight: 100 parts of lucid ganoderma, 250 parts of tobacco, 100 parts of Chinese gall, 100 parts of melia azedarach, 100 parts of cypress, 100 parts of rhubarb or lime, 100 parts of garlic, 100 parts of rhizoma atractylodis, 100 parts of folium artemisiae argyim, 500 parts of honeysuckle, 500 parts of herba houttuyniae, 500 parts of cyrtomium fortunei, 500 parts of isatic roots, 100 parts of gardenia, 400 parts of scutellaria baicalensis, 100 parts of coptis chinensis, 250 parts of golden cypress, 300 parts of officinal magnolia barks, 500 parts of white paeony roots, 200 parts of clove, 100 parts of logwood, 80 parts of semen cassiae, 500 parts of galanga, 100 parts of pepper, 500 parts of astragalus, 500 parts of rhizoma curcumae, 500 parts of perilla leaves, 300 parts of radix saposhnikoviae, 250 parts of radix angelicae, 250 parts of asarum, 100 parts of cinnamon and 100 parts of anise. The cleaning agent is simple in component and low in preparation cost, the water purified by using the cleaning agent is good in quality and capable of realizing circular washing, and no wastewater is discharged; in addition, due to the adoption of the cleaning agent disclosed by the invention, the quality of the plastics can be improved, the silk yield can be increased, and the prepared modified plastics are nontoxic, pollution-free and incapable of generating any injury to human bodies.

Owner:王磊

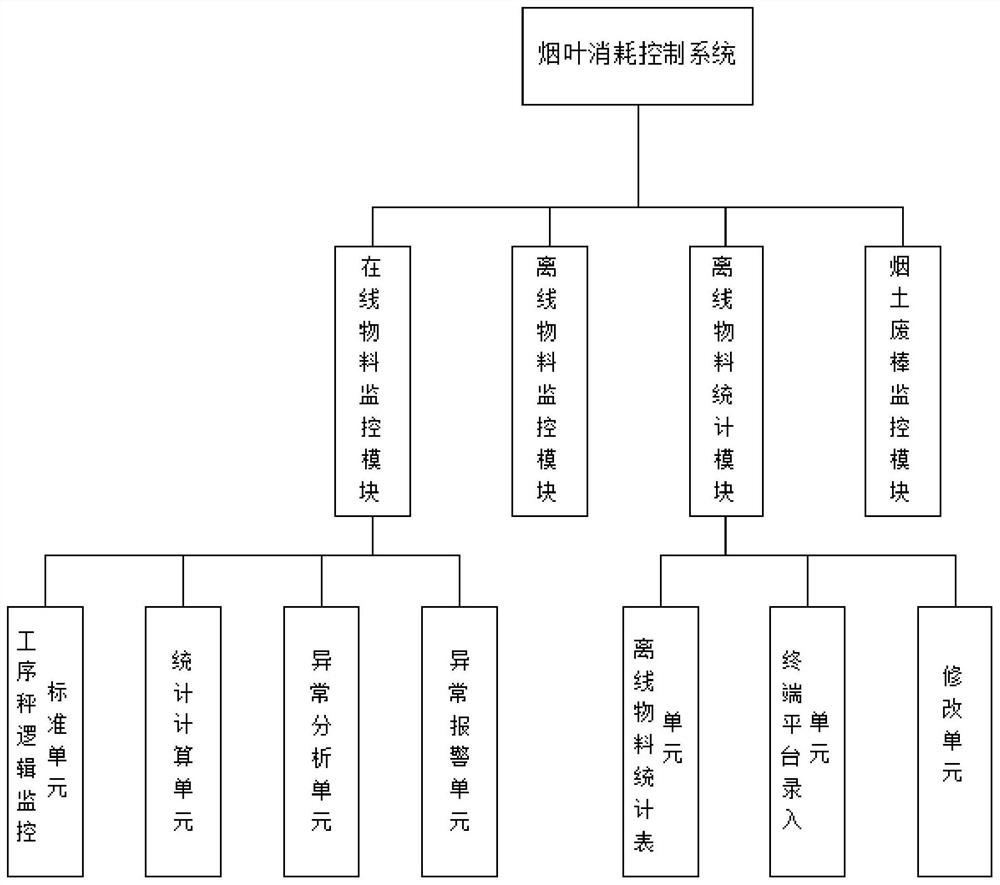

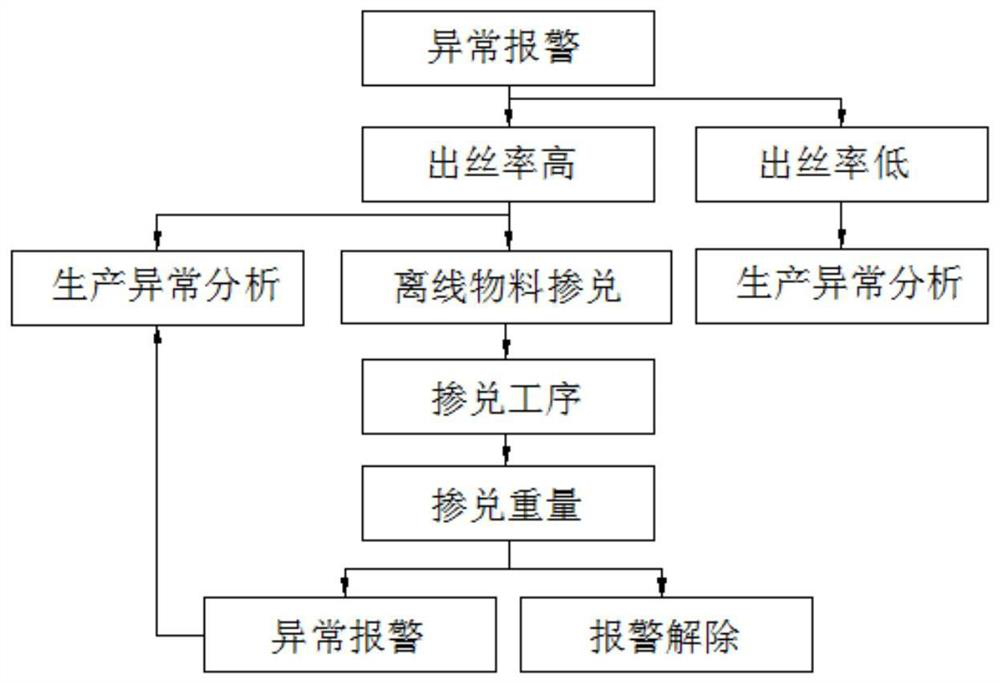

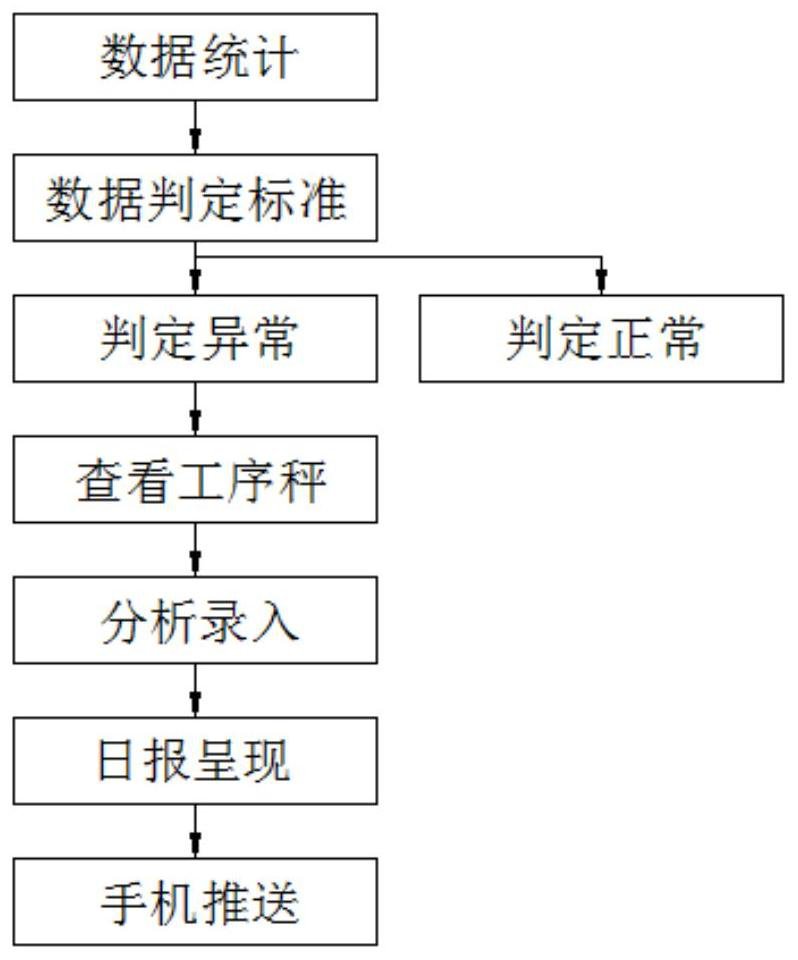

Tobacco consumption control system and method

InactiveCN111638686ARealize monitoringEffective data monitoringTotal factory controlProgramme total factory controlAgricultural scienceStatistical analysis

The invention discloses a tobacco consumption control system and method. The system comprises a database, and an online material monitoring module, an offline material monitoring module, an offline material statistics module and a tobacco soil waste rod monitoring module which are built in the database. According to the invention, a workshop informatization system is used as support; full-staff and comprehensive benchmarking is used as a promotion; consumption reduction research is taken as a means; the method includes establishing a real-time monitoring, abnormal alarming and statistical analysis system for the cut tobacco yield of the leaf / stem line, the waste tobacco rods, the process materials and the off-line materials; immediate discovery, immediate feedback, immediate analysis and immediate solution mechanisms of tobacco leaf consumption problems are realized, thus improving tobacco consumption management and control level.

Owner:ZHANGJIAKOU CIGARETTE FACTORY

Treatment method of tobacco leaf slices

The invention discloses a treatment method of tobacco leaf slices.The treatment method includes hexagonally slicing tobacco slices.Through slicing rules of big tobacco slices, slicing uniformity is improved and broken powder and broken slices in the slicing process are reduced.

Owner:HONGYUN HONGHE TOBACCO (GRP) CO LTD

Top dressing of fire-cured tobacco as well as preparation method and use method thereof

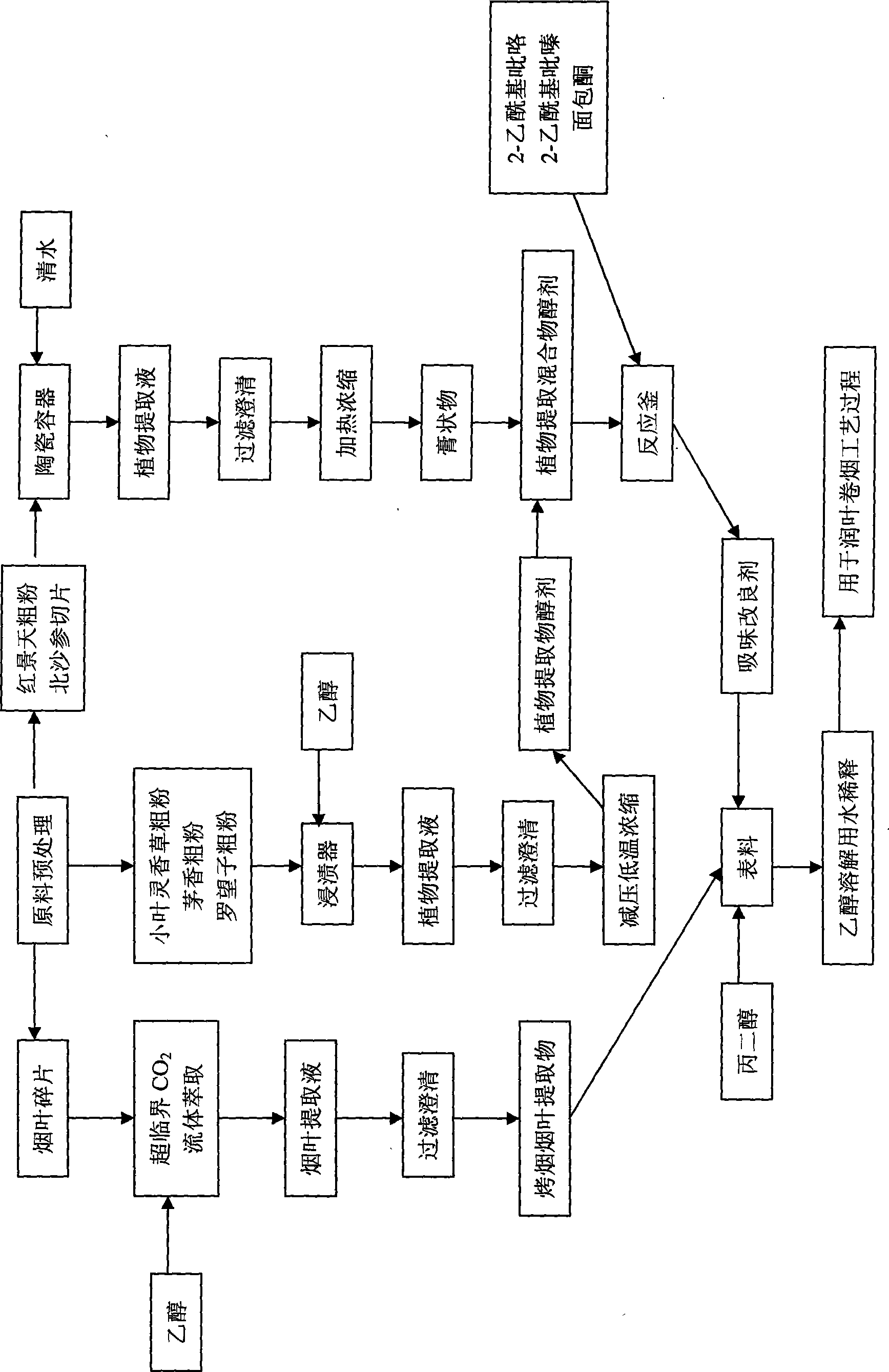

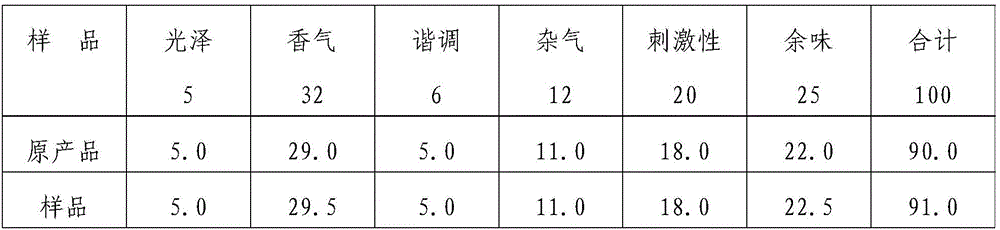

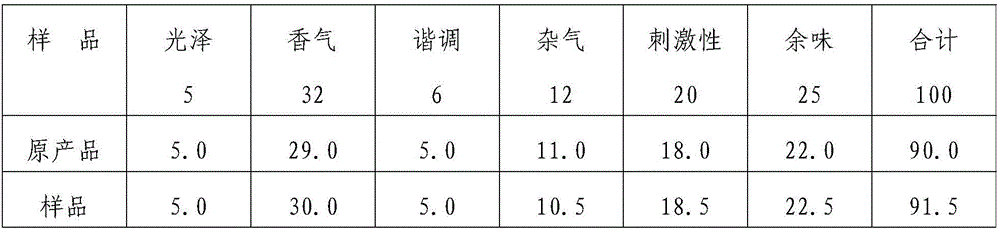

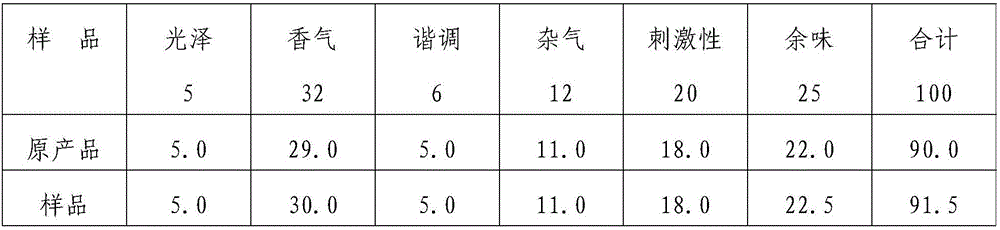

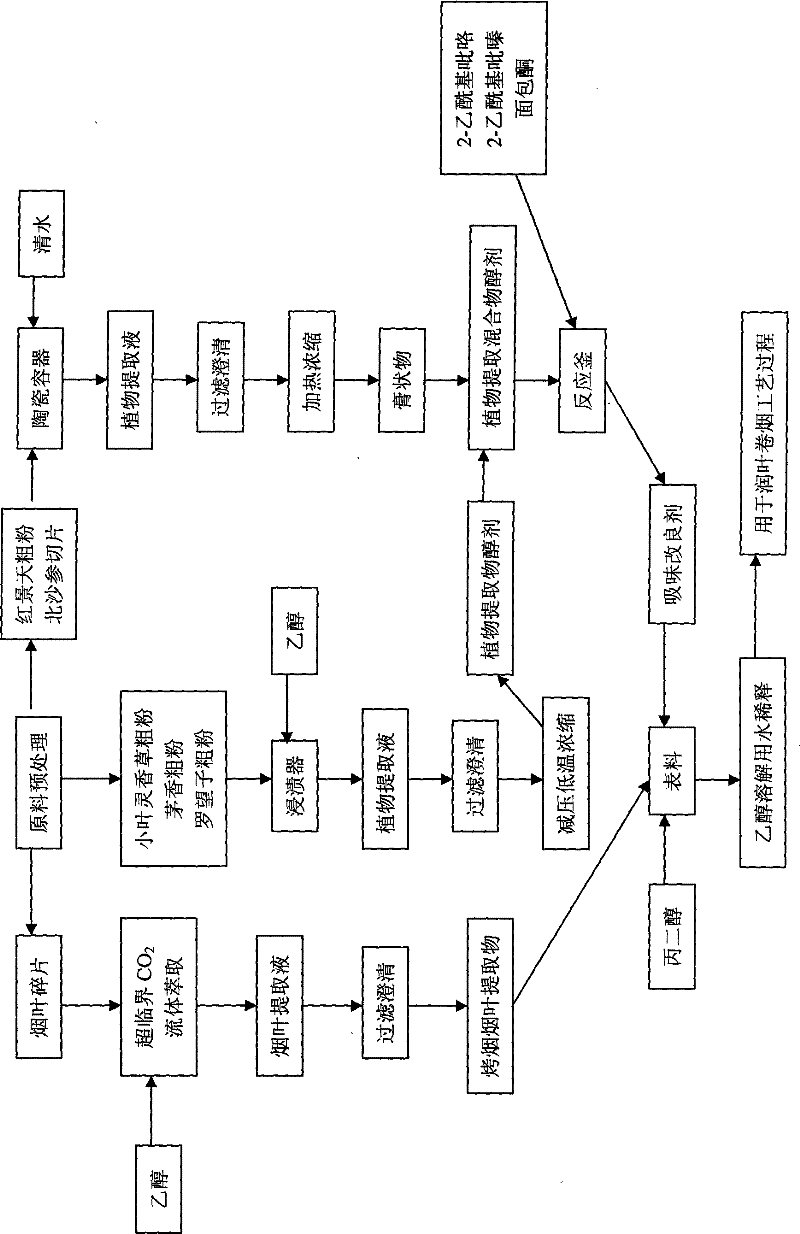

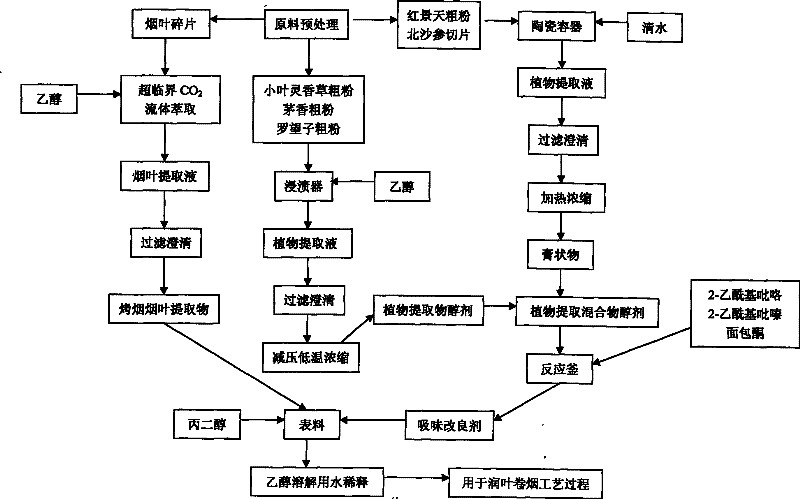

ActiveCN101461562ASimple processReduce manufacturing costTobacco preparationTobacco treatmentPolymer scienceAroma aroma

The invention discloses a surface material for cured tobacco leaf, preparation and use process thereof. An odor absorption improving agent in the surface material for cured tobacco leaf is capable of reducing impurity gas and coarse feeling in the fume, adding fragrance of intrinsic perfume of cured tobacco leaf. And the surface material includes propanediol, which is capable of enhancing moisture keeping performance of tobacco leaf, making leaf crushing in the cutting process uneasy, and yield high. The surface material for the cured tobacco leaf is simple in preparation, low in production cost, having wide market prospect.

Owner:延吉烟悦科技有限公司 +1

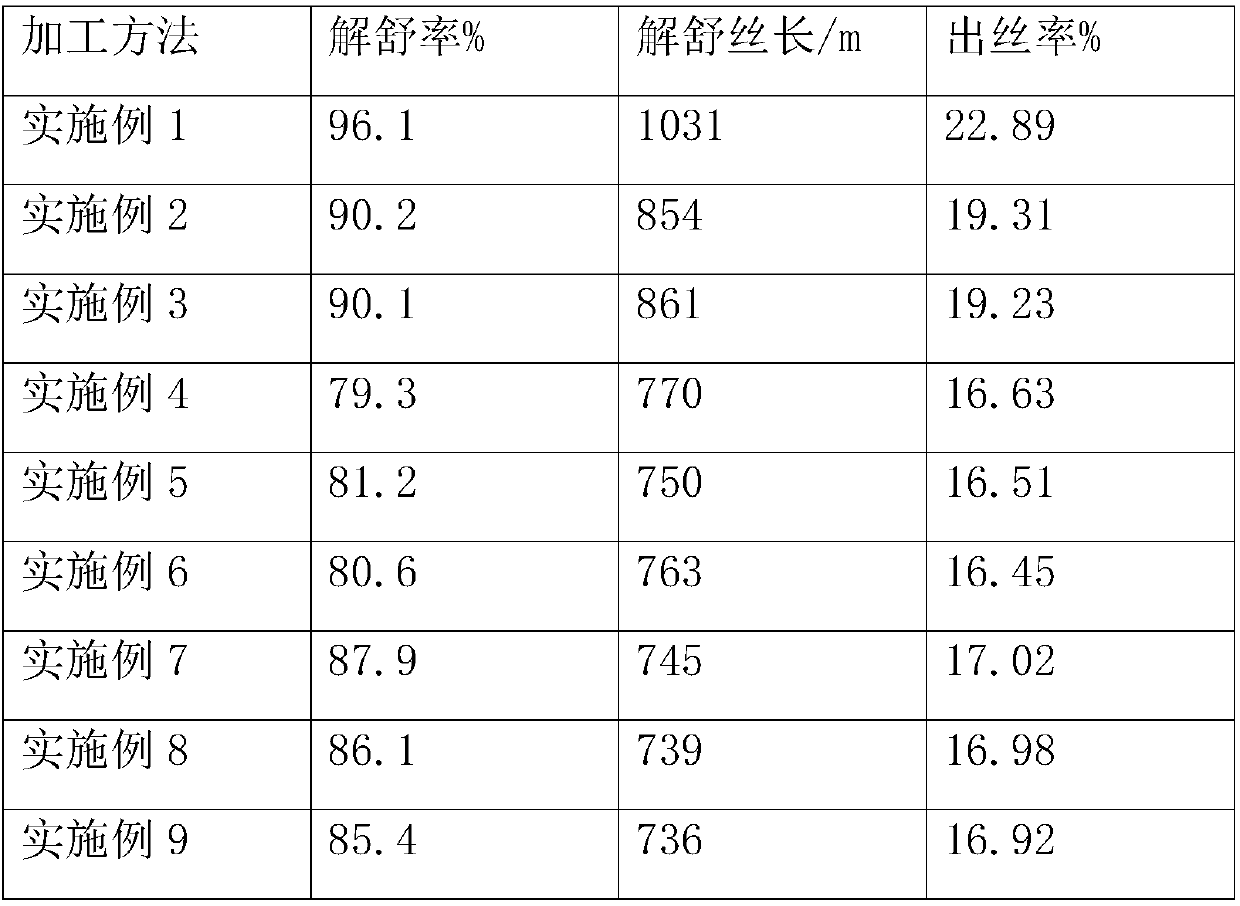

Silkworm cocoon processing method capable of increasing reelability percentage and silk yield of silkworm cocoons

InactiveCN108677249AImprove cocoon cooking effectPromote silk reeling performanceAnimal materialSilk filament obtainingEngineeringWarm water

The invention discloses a silkworm cocoon processing method capable of increasing reelability percentage and silk yield of silkworm cocoons. The processing method comprises the following steps: (1) selecting fresh silkworm cocoons under the condition that the illumination intensity is 2700 to 3100 lux, and removing light defective cocoons, double cocoons and rotten cocoons; (2) putting the silkworm cocoons in the step (1) into a vacuum pump, vacuumizing the vacuum pump until the vacuum degree is 0.0101 to 0.0102 Mpa, adding an aid I at the temperature of 32 to 35 DEG C, and enabling water to enter to be 6 to 8 cm higher than the cocoons, wherein the permeating and water absorbing time is 6 to 10 minutes; (3) cooking the silkworm cocoons in the step (2), and controlling the temperature of the cocoon cooking water to 55 to 65 DEG C, the time to 6 to 8 minutes and the PH to be 4.9 to 5.7 during cocoon cooking; (4) putting the silkworm cocoons in the step (3) into warm water at the temperature of 25 to 30 DEG C, adding an aid II in an amount which is 0.6 to 0.9 percent of the weight of the warm water and soaking for 30 to 60 minutes; and (5) cooling the silkworm cocoons obtained in thestep (4) to room temperature by using water at the temperature of 30 to 40 DEG C and reeling silk. By adopting the method, the development of silkworm cultivation and silk industries is promoted.

Owner:宁南县南丝路集团有限公司

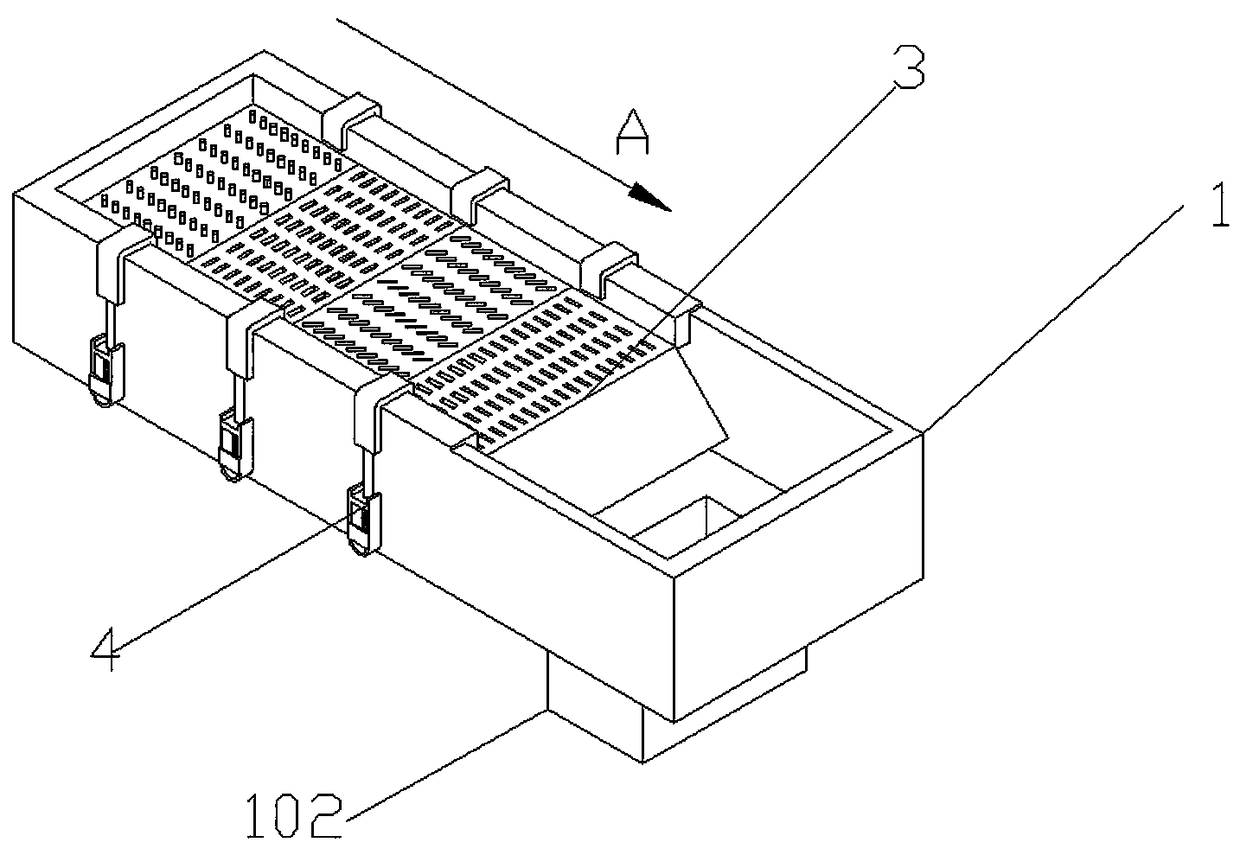

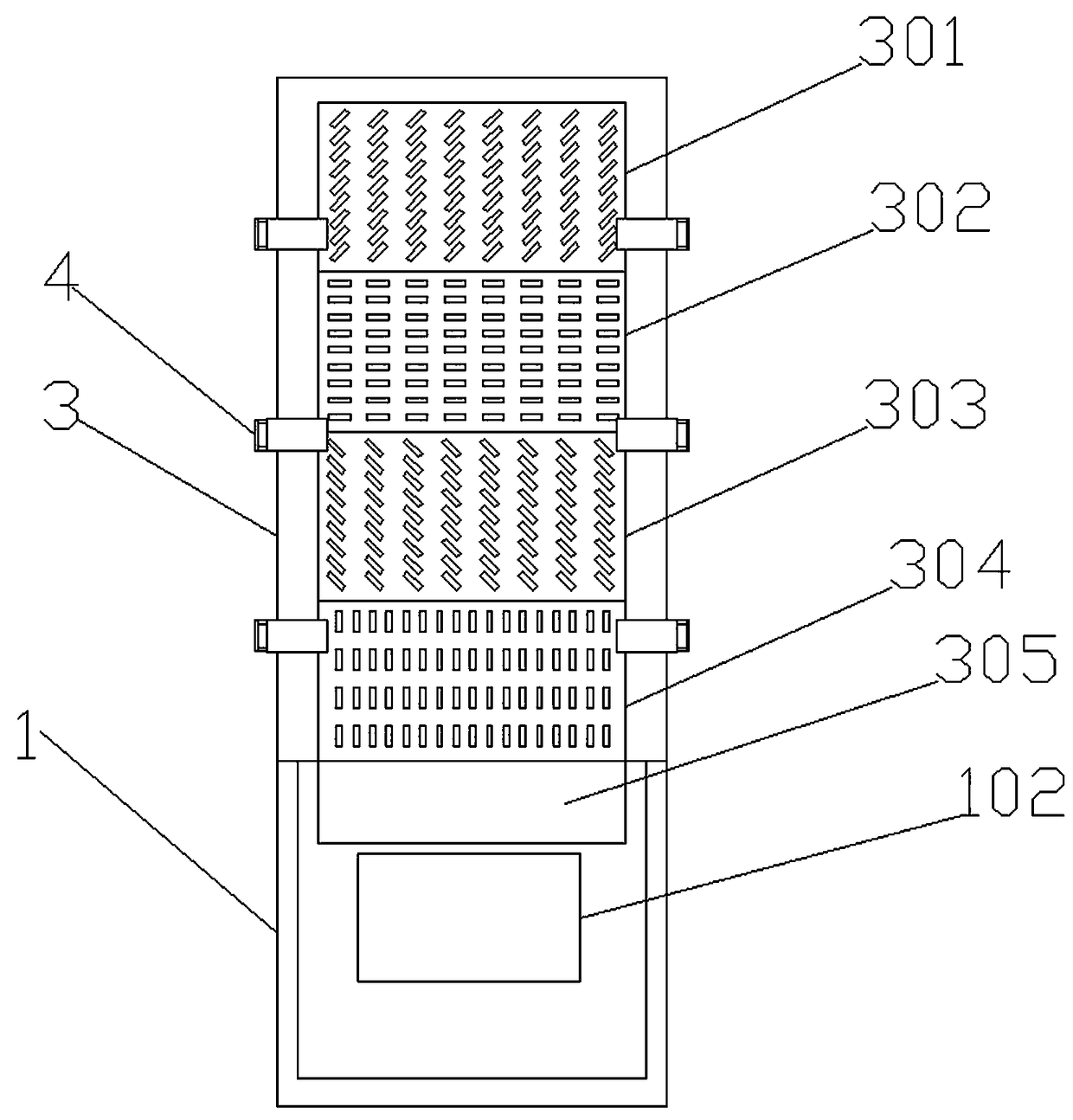

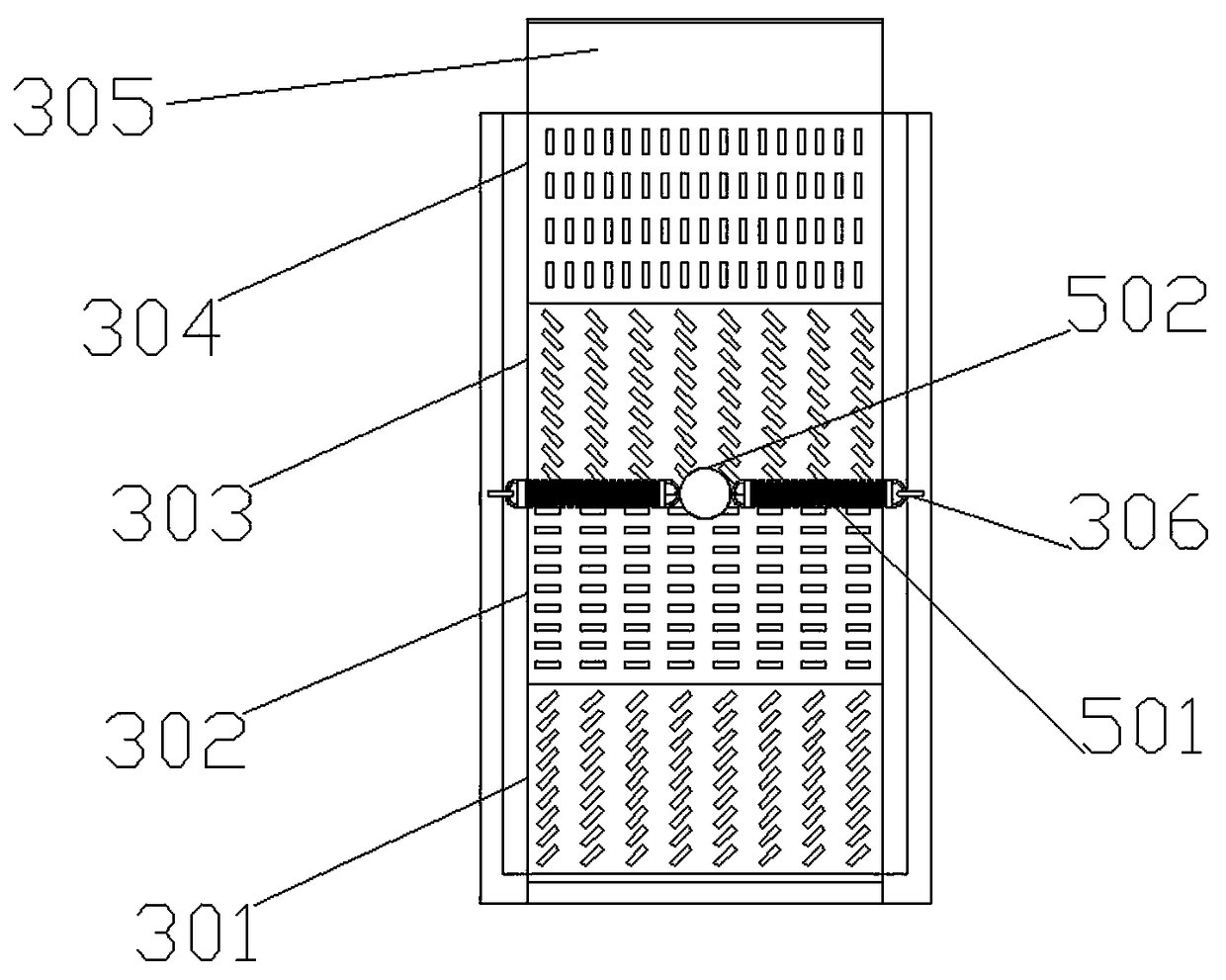

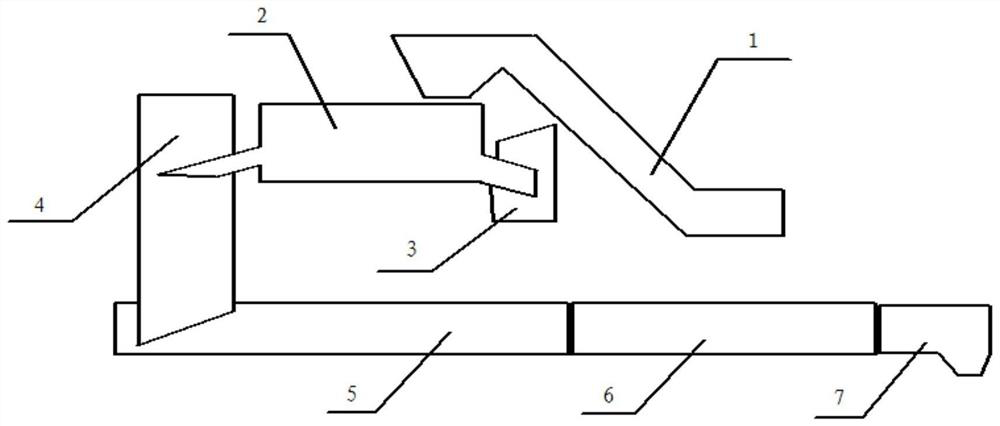

Scattered tobacco stem removing and sieving vibration trench

PendingCN109225834AImprove the quality of cut stems and silk yieldSatisfy the layoutSievingScreeningEngineeringSieve area

The invention relates to the technical field of tobacco processing, and particularly discloses a scattered tobacco stem removing and sieving vibration trench. The scattered tobacco stem removing and sieving shocking trench comprises a trench body, a vibration sieve, locking devices and a self-cleaning device, wherein the locking devices are used for fixing the vibration sieve on the trench body, and the self-cleaning device is connected with the bottom of the vibration sieve; folded edges for being erected on the trench body are arranged on the left and right sides of the vibration sieve, thevibration sieve is divided into multiple sieving areas in the front direction, and the inclinations of sieving net holes in each sieving area are different. By the adoption of the scattered tobacco stem removing and sieving vibration trench, scattered tobacco stems with the length of 15 mm and the diameter of 3 mm can be effectively removed, the cut stem tobacco quality is improved, the cut tobacco generating rate is increased, the labor intensity is greatly reduced, no tools are needed, the vibration sieve can be easily and rapidly mounted and dismounted simply by an operator, and the scattered tobacco stem removing and sieving vibration trench is convenient for the operator to maintain.

Owner:CHINA TOBACCO HENAN IND

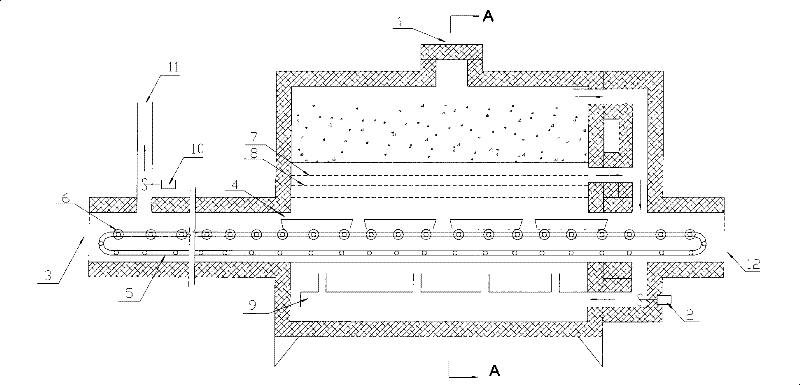

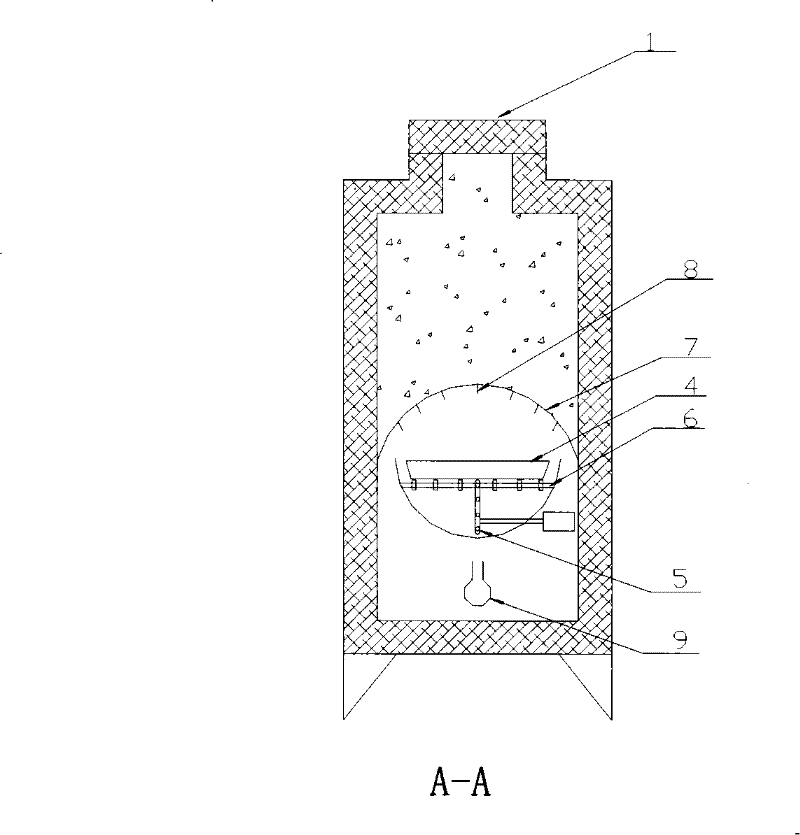

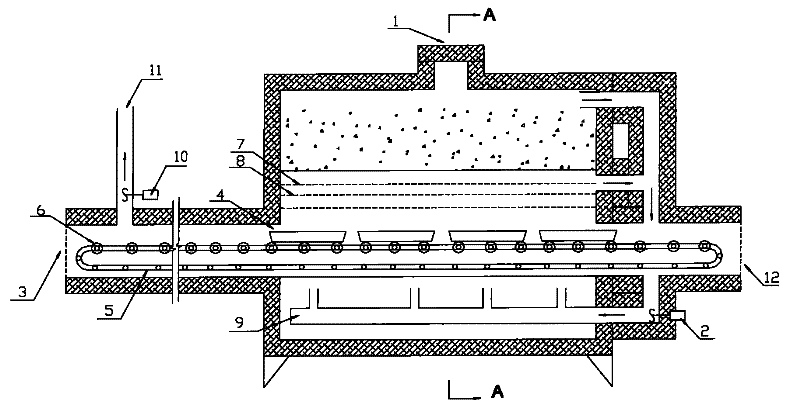

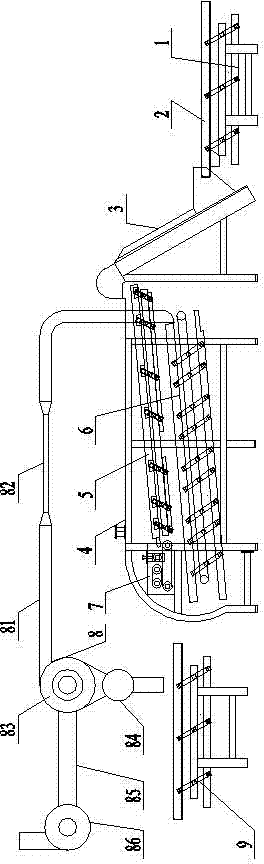

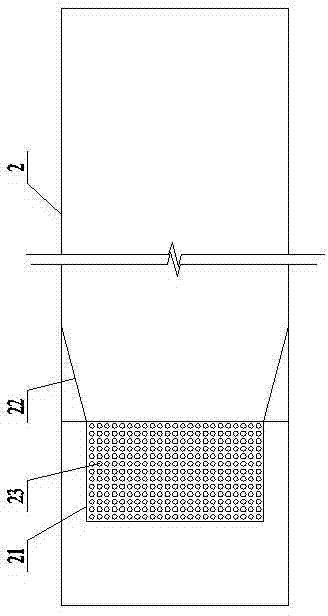

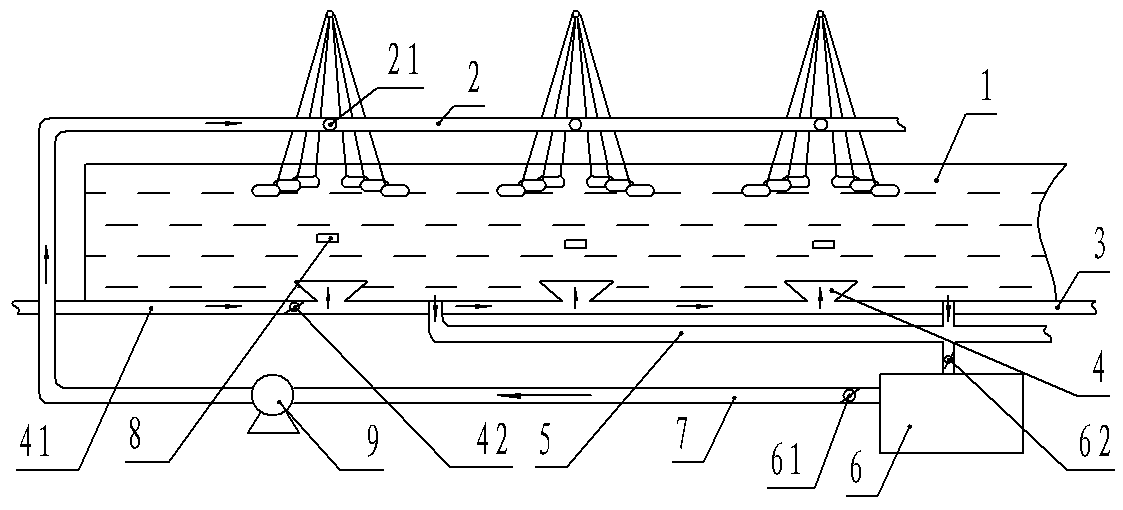

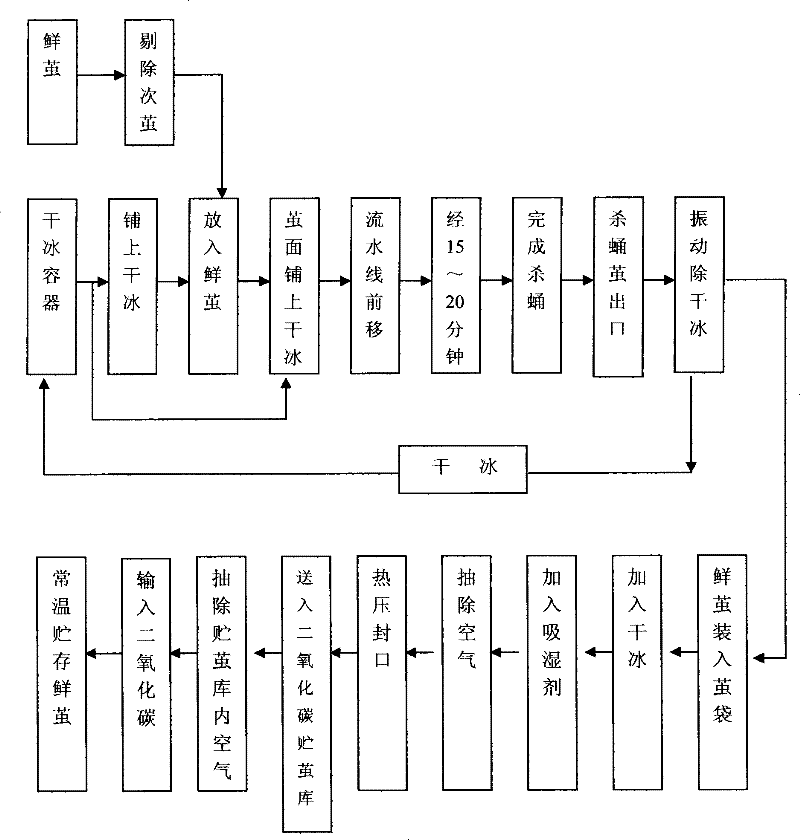

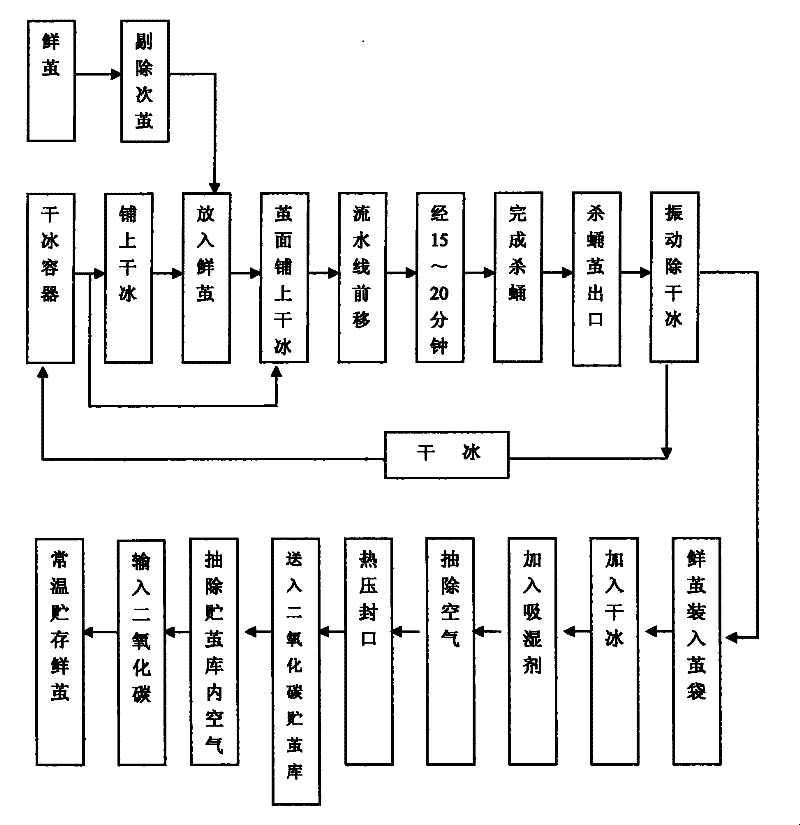

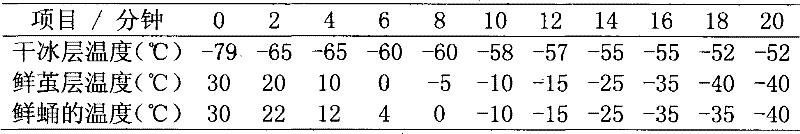

Method and equipment of cultivated silkworm fresh cocoon quick-freezing for cocoon suffocation

ActiveCN101328617BLittle impact on qualityImprove qualitySilk cocoons cleaning/classifyingNatural stateDry ice

The invention provides a quick freezing pupa killing method for fresh silkworm cocoons, particularly comprising the following steps that: solid dry ice is taken as a cold source to absorb heat of the fresh silkworm cocoons, and simultaneously carbon dioxide obtained through sublimation of the dry ice is taken as the cold source to blow over the fresh silkworm cocoons and exchange heat with the fresh silkworm cocoons so as to make the temperature of the fresh silkworm cocoons reduced to below a given temperature and maintain for a period of time. The invention simultaneously provides a device for realizing the method, comprising an insulated cabinet body and an endless apron, wherein, a cold source cabinet body is arranged on the upper part of the insulated cabinet body, and the solid dry ice is arranged inside the cabinet body; the bottom of the cold source cabinet body is provided with a heat exchange plate; a cold blast pipe is arranged on the lower side of the endless apron, and anopening of the cold blast pipe faces to the endless apron; the cold blast pipe is communicated with the cold source cabinet body; and a fan is arranged on an inlet end of the cold blast pipe. By adoption of the method and the device, the pupa killing production cycle can be obviously shortened and the labor efficiency can be obviously improved; moreover, because pupae are killed at a low temperature, fresh cocoon shells and pupal cells maintain natural state, thereby the quality of the fresh cocoon shells and the pupal cells is slightly influenced and good-quality raw materials are provided for the silk reeling technique and deep-processing of fresh pupae.

Owner:广东省蚕业技术推广中心 +3

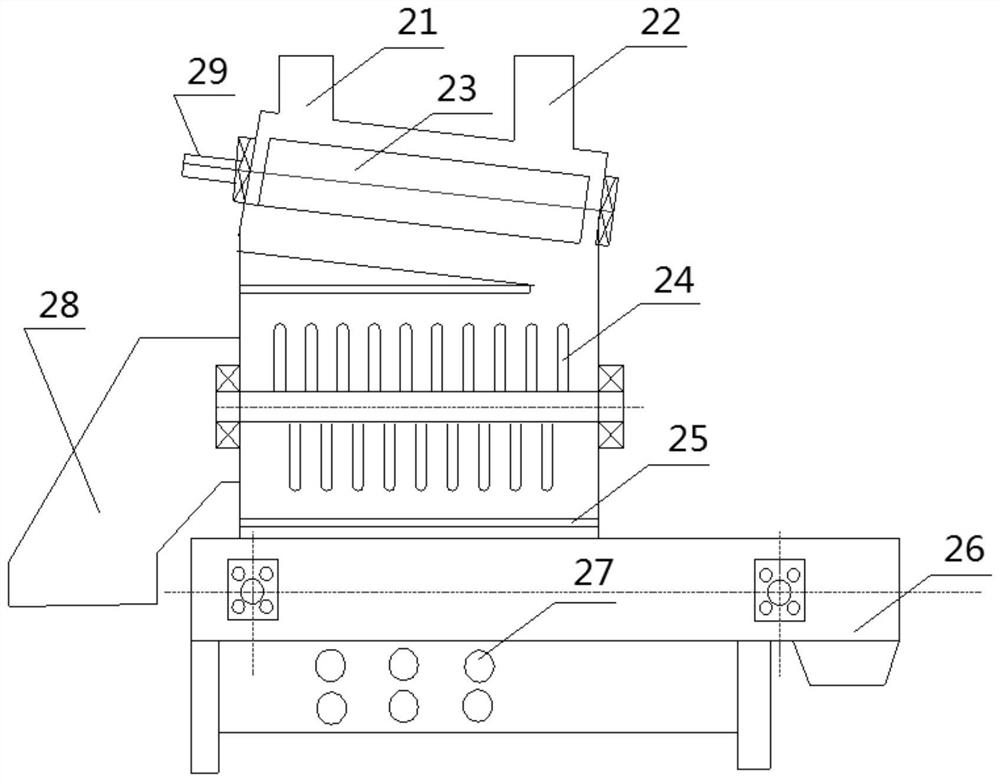

A flexible treatment system for residual cigarettes

Provided is a flexible processing system for defective tobacco rods. The system comprises a rack and a carding dilution vibration trough arranged on the rack. A flexible rolling mechanism is arranged at the discharging end of the carding dilution vibration trough. A primary grade screening vibration sieve is arranged under the carding dilution vibration trough and the flexible rolling mechanism. A hoister and a charging vibrator are arranged at back of the rack and to be adjacent to each other. The material channel of the hoister corresponds to the material catching end of the carding dilution vibration trough. A sedimentation trough is arranged at the front end of the charging vibration trough of the upper part of the charging vibrator. Trough holes are arranged in the bottom and the side walls of the sedimentation trough. The upper end of the sedimentation trough is flushed with the bottom surface of the charging vibration trough. A wind power separating mechanism corresponding to the primary grade screening vibration sieve is arranged at one side of the rack. A second grade screening vibration sieve is arranged under the wind power separating mechanism. The flexible processing system is simple in structure, and has simple operation. Defective tobacco rods are subjected to flexible processing, The shred yield and the tobacco shred purity degree of defective tobacco rod processing can be raised greatly, smash of tobacco shred and damage of tobacco paper are reduced, and the purposes of raising tobacco shred recovery utilization rate and purity degree can be achieved finally.

Owner:CHINA TOBACCO HENAN IND

Method of storaging and treating fresh silkworm cocoon

The method for storing-treatment of the fresh silkworm cocoons incldues such steps as loading fresh silkworm cocoons in baskets, antistaling transporting in air-permeable coach without sunshining, stacking the baskets on the pallet far from ground, and storing in cold storage at -4-10 deg.C. Before the cocoons are used, they are defrozen at ordinary temp., and equilibrium treatment in cool wind. Its advantages are high cocoon quality and high silk output rate.

Owner:CHENGDU TIANCHUANG BIO TECH

Method for preparing palm fiber by utilizing processed palm plates

InactiveCN107201550ALoose structureNo damageMechanical fibre separationTextile cablesEnvironmental resistanceEngineering

The invention discloses a method for preparing palm fiber by utilizing processed palm plates. The method comprises the steps that 1 separation is performed, wherein fresh palm plates, palm sheets and palm leaves are cut and separated; 2, bundling is performed, wherein the palm plates are bundled into bundles according to a certain sequence; 3, soaking and softening are performed, wherein the palm plates are soaked and softened at high temperature and are taken out and rapidly cooled to remove water soluble matter; 4, flattening and fiber extraction are performed, wherein the palm plates soaked and softened at high temperature are processed by selecting a flattening and fiber extraction machine to extract palm fiber in the palm sheets; 5, carding is performed, wherein the extracted palm fiber is carded, and long palm fiber, short palm fiber and palm chaff ash in the palm fiber are separated; 6, air-drying and impurity removal are performed, wherein the obtained palm fiber are bundled and air-dried, and impurities are removed to obtain a palm fiber product, the palm fiber is made into ropes by using a rope stranding machine, and the ropes are stored for usage. The method for preparing the palm fiber by utilizing the processed palm plates is simple in process, convenient to operate, novel in making, efficient, environmentally friendly and feasible.

Owner:杨柳福 +2

Method of using liquorice root for cigarette generation after liquorice root primary processing

InactiveCN106666815ASimple structureAvoid discomfort such as coughing and phlegmTobacco treatmentAlcoholLiquorices

The invention discloses a method of using liquorice root for cigarette generation after liquorice root primary processing. The method includes the steps that 100 parts of liquorice root pieces are taken, 400 parts of 70% ethyl alcohol are added to carry out extraction once at the temperature of 90 DEG C, then solid and liquid are separated, the solid obtained after solid-liquid separation namely the liquorice root pieces obtained after primary extraction is aired until the water content is 40+ / -3%, the liquorice root pieces are tableted through a tablet press, liquorice root tablets are collected, baked until the water content is 20+ / -3% and cut into shreds through a tobacco cutter, a 30-mesh screen is used for removing particles and powdery matter, and the shreds are bake until the water content is 12+ / -3% to obtain the needed shred product finally. The shred product is mixed uniformly with a tobacco shred set and accounts for 5%-1%the mass of the tobacco shred set, and the usage amount is determined according to the smoking quality needing to meet. The product is high in shred yield and has remarkable effects of reducing cigarette harm, making smoke mellow and full and improving smoke taste. The production method is simple and remarkable in effect and has good application and popularization prospects.

Owner:CHINA TOBACCO YUNAN NEW MATERIAL

Method for improving silk production rate of silkworm cocoons

InactiveCN107815738AChange complianceChange resilienceAnimal materialSilk filament obtainingSodium bicarbonateProduction rate

The invention discloses a method for improving a silk production rate of silkworm cocoons and belongs to the technical field of silk production of silkworm cocoons. The method disclosed by the invention comprises the following steps: soaking silkworm cocoons in brine for 1-5 hours before silk reeling of the silkworm cocoons; taking out the silkworm cocoons, and rinsing the residual brine on the surfaces of the silkworm cocoons; adding the silkworm cocoons treated in the step A into a soaking solution prepared from sodium bicarbonate, polyethylene wax, sodium stearate, perfiuoro-sodium sulfonate, sodium borate, sodium pyrophosphate, sodium tripolyphosphate, polyether and water, and soaking for 2-6 hours; and taking the silkworm cocoons out, and rinsing the residual soaking solution on the surfaces of the silkworm cocoons. According to the method disclosed by the invention, the silkworm cocoons are added into the brine at the specific temperature and concentration before silk reeling, sothat the surface tension is changed; and the silkworm cocoons are added into the soaking solution prepared from the sodium bicarbonate, polyethylene wax, sodium stearate, perfiuoro-sodium sulfonate,sodium borate, sodium pyrophosphate, sodium tripolyphosphate, polyether and water, so that the smoothness and toughness of silk in the silkworm cocoons are changed, and the silk production rate of thesilkworm cocoons in the silk reeling process is effectively improved.

Owner:LUZHAI GUISHENG COCOON SILK IND & TRADE

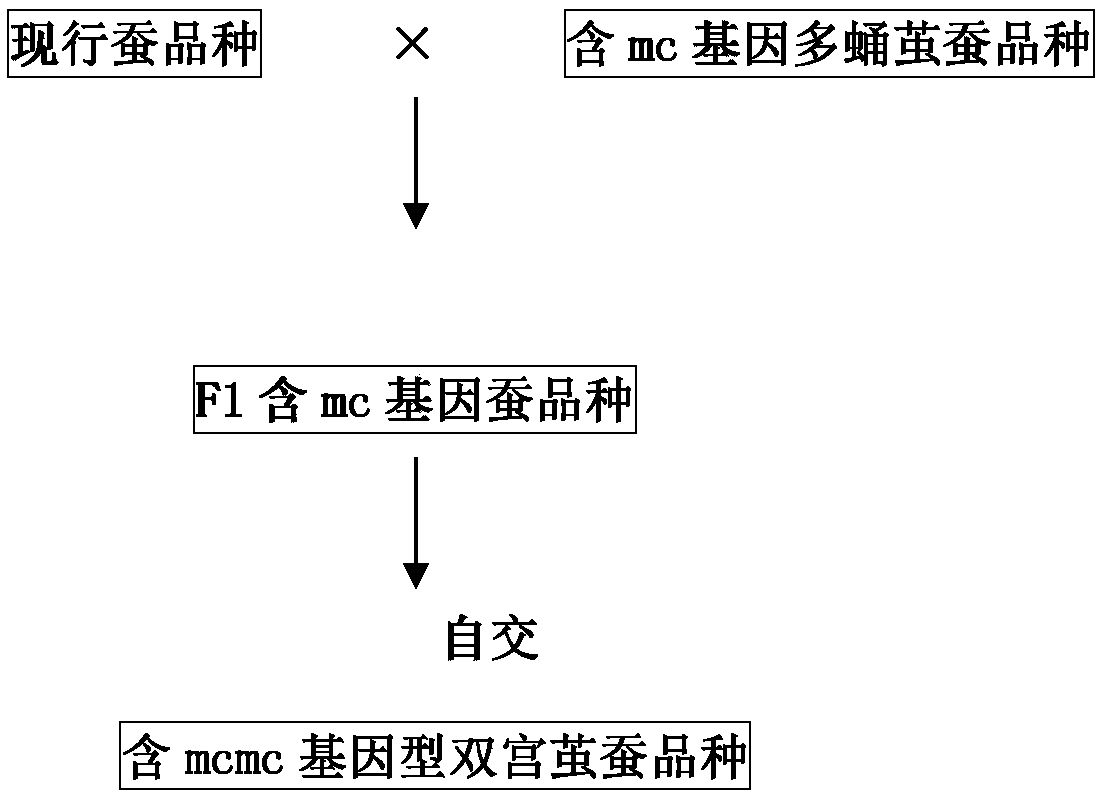

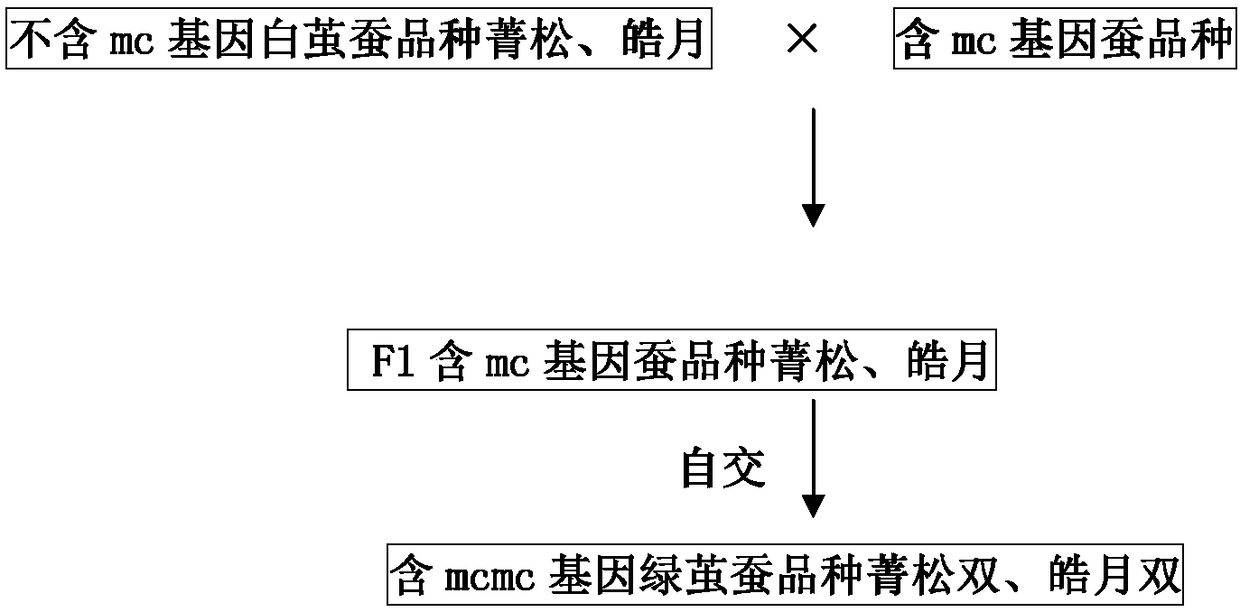

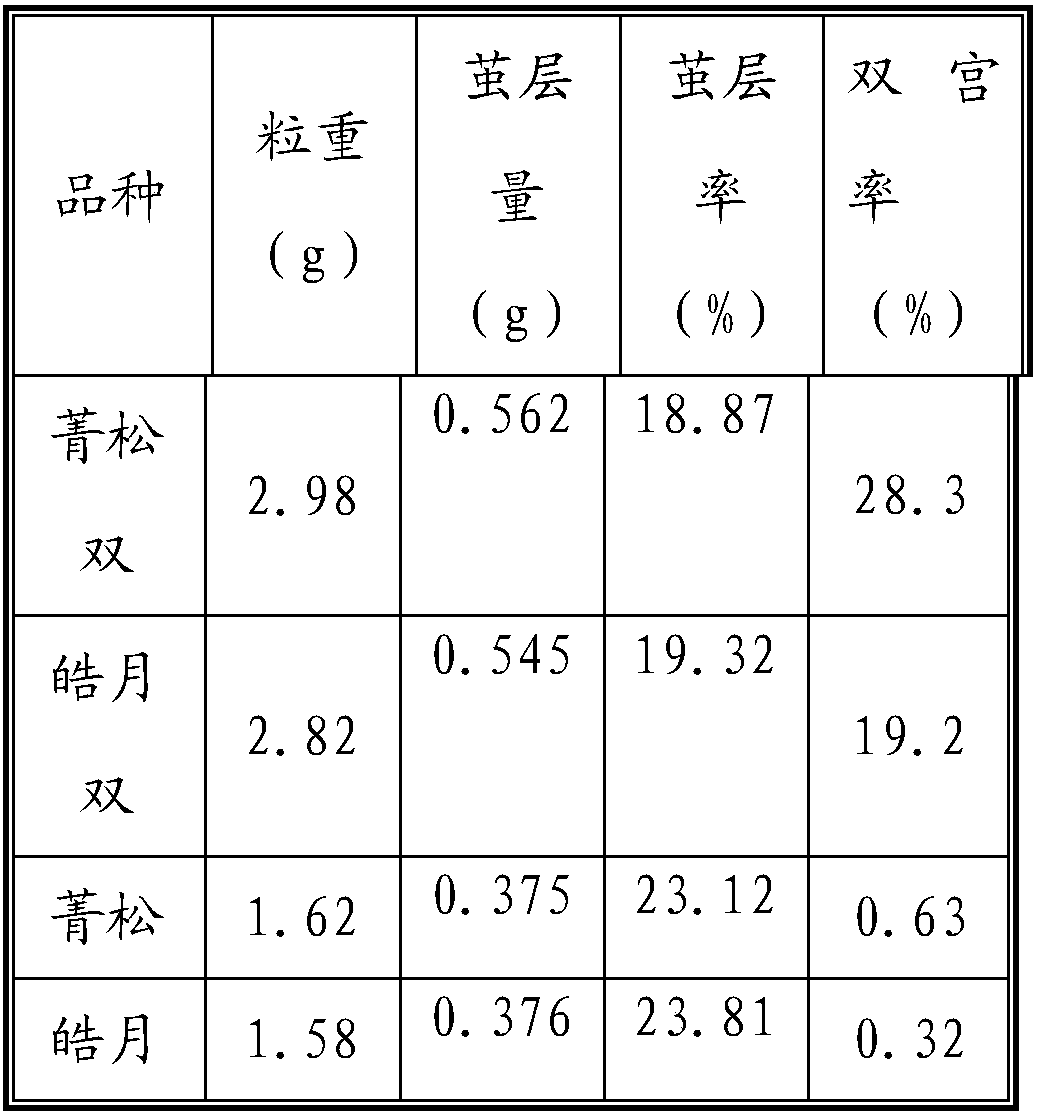

A kind of cultivation method of double palace cocoon silkworm variety

ActiveCN108142383BExcellent cocoon silkExcellent cocoon silk propertiesAnimal husbandryBiotechnologyGene

Owner:江苏苏豪蚕种有限公司

Cocoon cooking method for fresh cocoons

InactiveCN104894655BEasy to cleanGood relaxing effectAnimal materialSilk filament obtainingEngineeringCooking methods

The invention discloses a cooking method for fresh cocoons. The cooking method is characterized by including the technological steps of cocoon selection, tea bran water soaking, permeation, enzymolysis, cocoon cooking and cocoon picking. The cooking method for the fresh cocoons has the advantages that the method is simple in technology, convenient to operate and low in production cost; after the method is used for cooking the cocoons, silk yielding rate and quality of obtained cooked cocoons are high; quality index level of the cooked cocoons is improved greatly, and cleanness, spotlessness, strength and cohesion indexes are improved by above one grade.

Owner:广西立盛茧丝绸有限公司

Top dressing of fire-cured tobacco as well as preparation method and use method thereof

ActiveCN101461562BSimple processReduce manufacturing costTobacco preparationTobacco treatmentMoisturePropanediol

The invention discloses a surface material for cured tobacco leaf, preparation and use process thereof. An odor absorption improving agent in the surface material for cured tobacco leaf is capable of reducing impurity gas and coarse feeling in the fume, adding fragrance of intrinsic perfume of cured tobacco leaf. And the surface material includes propanediol, which is capable of enhancing moisture keeping performance of tobacco leaf, making leaf crushing in the cutting process uneasy, and yield high. The surface material for the cured tobacco leaf is simple in preparation, low in production cost, having wide market prospect.

Owner:延吉烟悦科技有限公司 +1

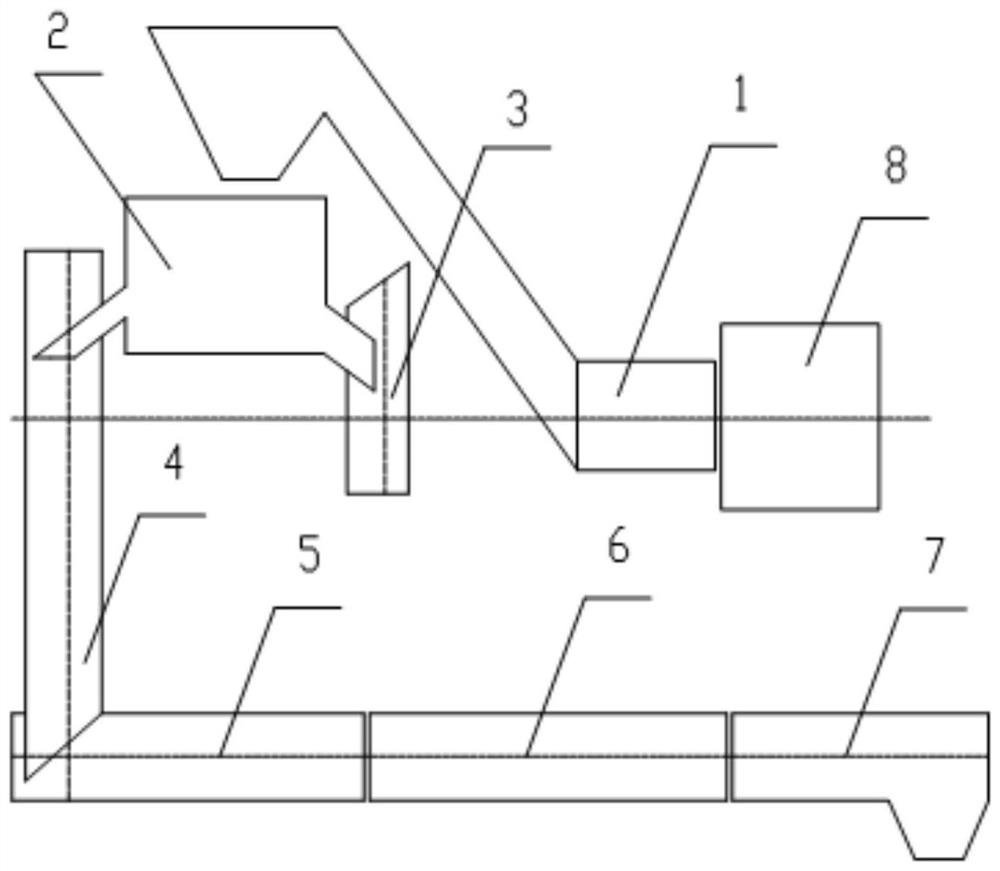

A device and method for stripping fine cigarettes containing explosive beads

ActiveCN109602078BAchieve separate processingEliminate breaksCigarette manufactureProcess engineeringConveyor belt

The invention provides a device for stripping fine cigarettes containing explosive beads, which includes a quantitative feeder, a FY37 type waste cigarette processing machine, a paper vibrating tank, a screening device, a conveyor belt, a vibrating tank, and a spectrum cleaner. There is also a sorting mechanism for fine cigarettes containing explosive beads in front of the quantitative feeding machine. The sorting mechanism for fine cigarettes containing explosive beads is used to sort and straighten the fine cigarettes containing explosive beads. The lowered cigarettes enter the quantitative feeding machine, and then enter the FY37 waste cigarette processing machine, the separated cigarette paper and filter tip enter the paper vibrating groove, and the shredded tobacco enters the screening device through the bottom belt of the FY37 waste cigarette processing machine , and then filtered and separated by conveyor belts, vibrating tanks, and spectral cleaners to finally become qualified shredded tobacco. The invention can solve the quality problem that the filter tip containing the popping beads is damaged in the process of stripping the slim cigarettes containing the popping beads, which causes the taste of shredded tobacco stripped back to change.

Owner:HUBEI CHINA TOBACCO IND

Cleaning agent of circulating water for washing recycled plastics

InactiveCN104016425BImprove qualityNo pollution in the processWater/sewage treatmentWater qualityCleansing Agents

The invention discloses a cleaning agent of circulating water for washing recycled plastics, relating to the technical field of water treatment. The cleaning agent is composed of the following components in parts by weight: 100 parts of lucid ganoderma, 250 parts of tobacco, 100 parts of Chinese gall, 100 parts of melia azedarach, 100 parts of cypress, 100 parts of rhubarb or lime, 100 parts of garlic, 100 parts of rhizoma atractylodis, 100 parts of folium artemisiae argyim, 500 parts of honeysuckle, 500 parts of herba houttuyniae, 500 parts of cyrtomium fortunei, 500 parts of isatic roots, 100 parts of gardenia, 400 parts of scutellaria baicalensis, 100 parts of coptis chinensis, 250 parts of golden cypress, 300 parts of officinal magnolia barks, 500 parts of white paeony roots, 200 parts of clove, 100 parts of logwood, 80 parts of semen cassiae, 500 parts of galanga, 100 parts of pepper, 500 parts of astragalus, 500 parts of rhizoma curcumae, 500 parts of perilla leaves, 300 parts of radix saposhnikoviae, 250 parts of radix angelicae, 250 parts of asarum, 100 parts of cinnamon and 100 parts of anise. The cleaning agent is simple in component and low in preparation cost, the water purified by using the cleaning agent is good in quality and capable of realizing circular washing, and no wastewater is discharged; in addition, due to the adoption of the cleaning agent disclosed by the invention, the quality of the plastics can be improved, the silk yield can be increased, and the prepared modified plastics are nontoxic, pollution-free and incapable of generating any injury to human bodies.

Owner:王磊

A stem washing method of a temperature gradient type stem washing equipment

ActiveCN106820246BIncrease moistureReduce contentTobacco treatmentCleaning using liquidsUltrasonic sensorTemperature difference

Owner:CHINA TOBACCO YUNNAN IND

Cultivation method of double-cocoon silkworm variety

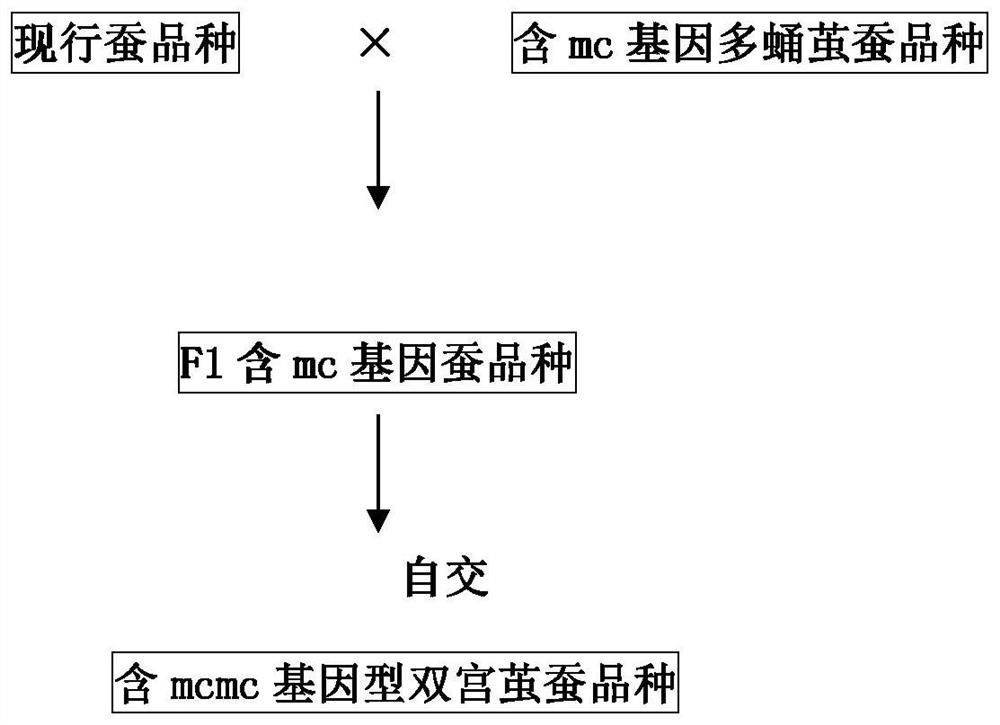

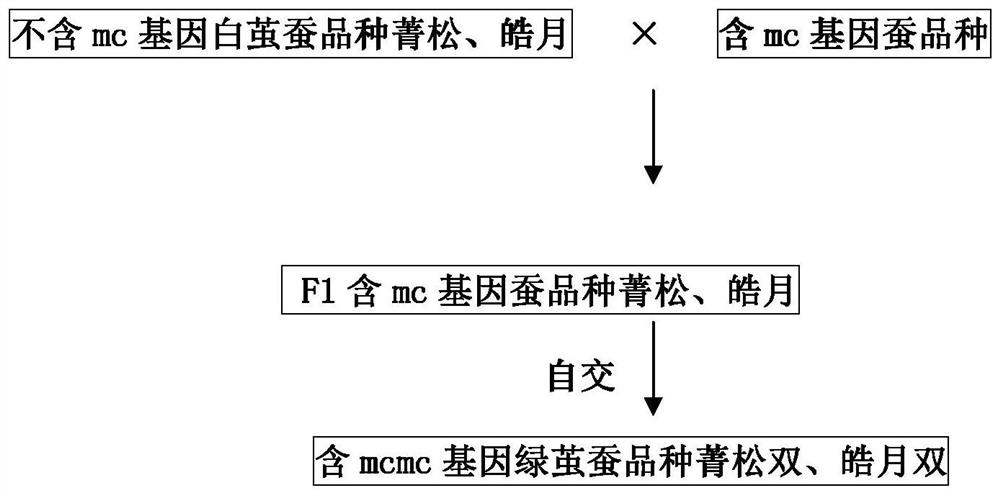

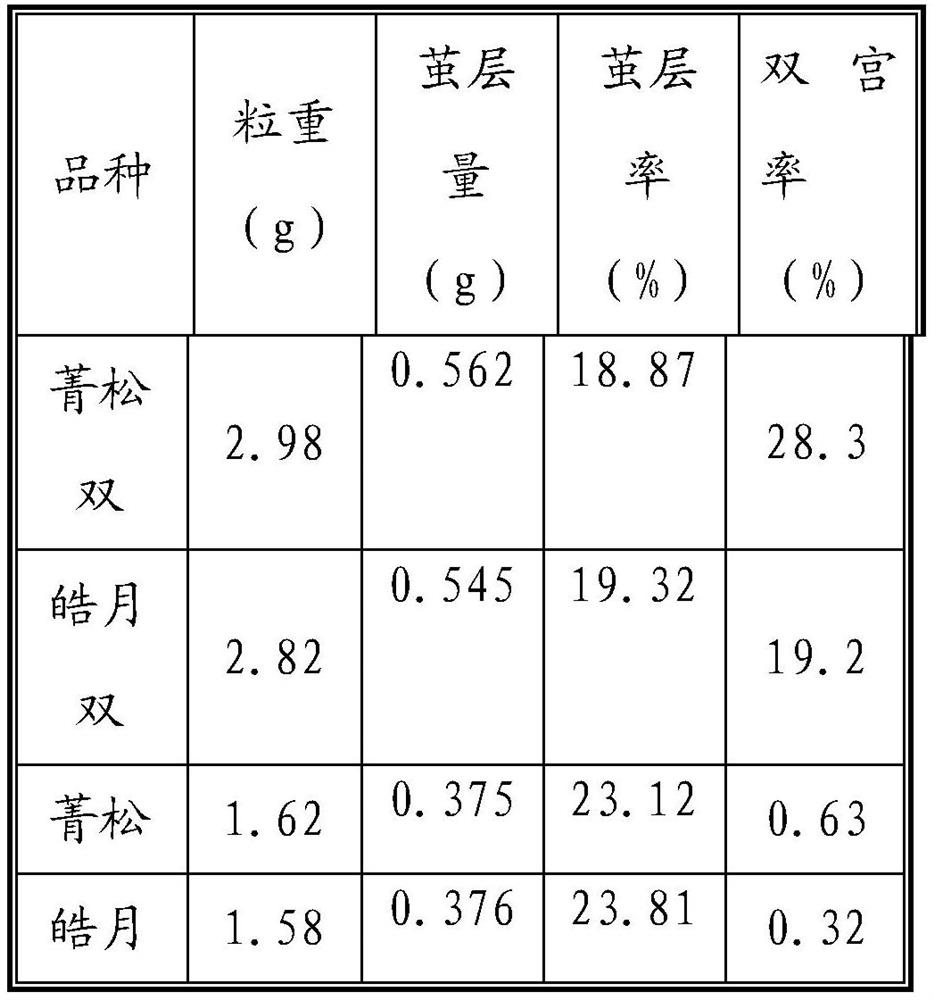

ActiveCN108142383AExcellent cocoon silkExcellent cocoon silk propertiesAnimal husbandryBombyx moriBiology

The invention relates to a cultivation method of a silkworm variety, in particular to a cultivation method of a double-cocoon silkworm variety, and belongs to the technical field of biology. On the basis of a genetic law of multi-pupal cocoon genes and a work principle of the environment condition, a popularized and applied breeding method for cultivating excellent silkworm varieties into the double-cocoon silkworm variety in current production is adopted. By adopting a hybridization introducing method and a generationally directional breeding method, on the premise of ensuring the excellent economic characteristic of existing cocoon varieties, the cocoon varieties are improved and selectively bred into the double-cocoon silkworm variety containing mcmc gene combinations, and the double-cocoon silkworm variety has the advantages that the cocoon color is pure, the cocoon silk property is excellent, and the practicability is high.

Owner:江苏苏豪蚕种有限公司

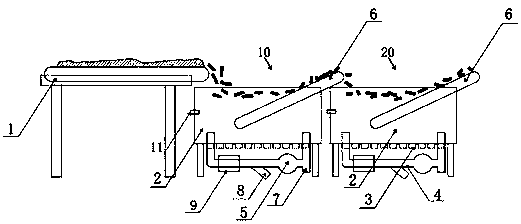

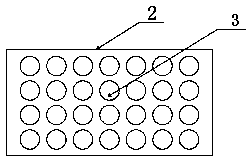

Water tank device for silk reeling and picking

The invention discloses an water tank device for silk reeling and picking, which belongs to the technical field of cocoon silk reeling equipment. The water tank device for silk reeling and picking comprises a tank body, the lower middle part of the wall of the tank body is provided with a water outlet which is controlled by a first electromagnetic valve to open or close and communicates with a purified water tank, and the water outlet of the purified water tank communicates with a water inlet tube of the tank body via a pump and a second electromagnetic valve; a liquid concentration sensor isarranged in the tank boy, and the liquid concentration sensor is respectively correspondingly connected to the first electromagnetic valve, the pump and the second electromagnetic valve though a controller. The picking water tank system for silk reeling can solve the problem existing in a picking water tank of an automatic silk reeling machine that the excessive thickness of the quality of pickingwater can easily cause picked silk breaking and difficult silk yielding, affecting silk yield.

Owner:LUZHAI GUISHENG COCOON SILK IND & TRADE

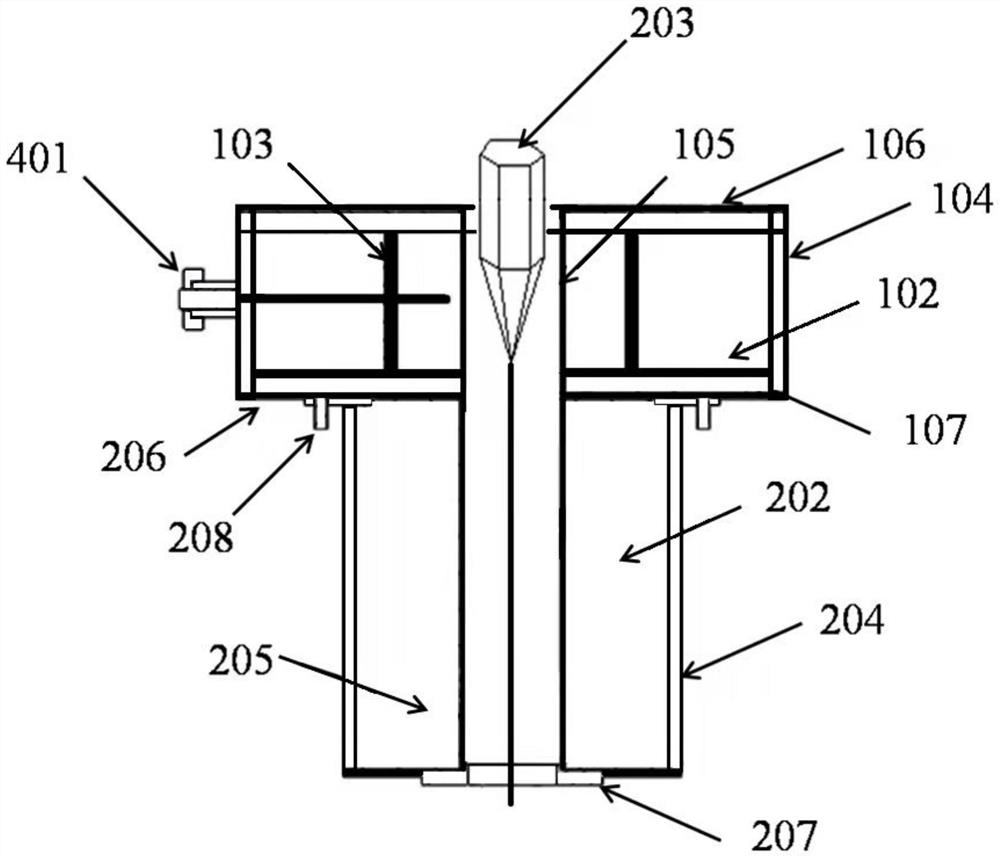

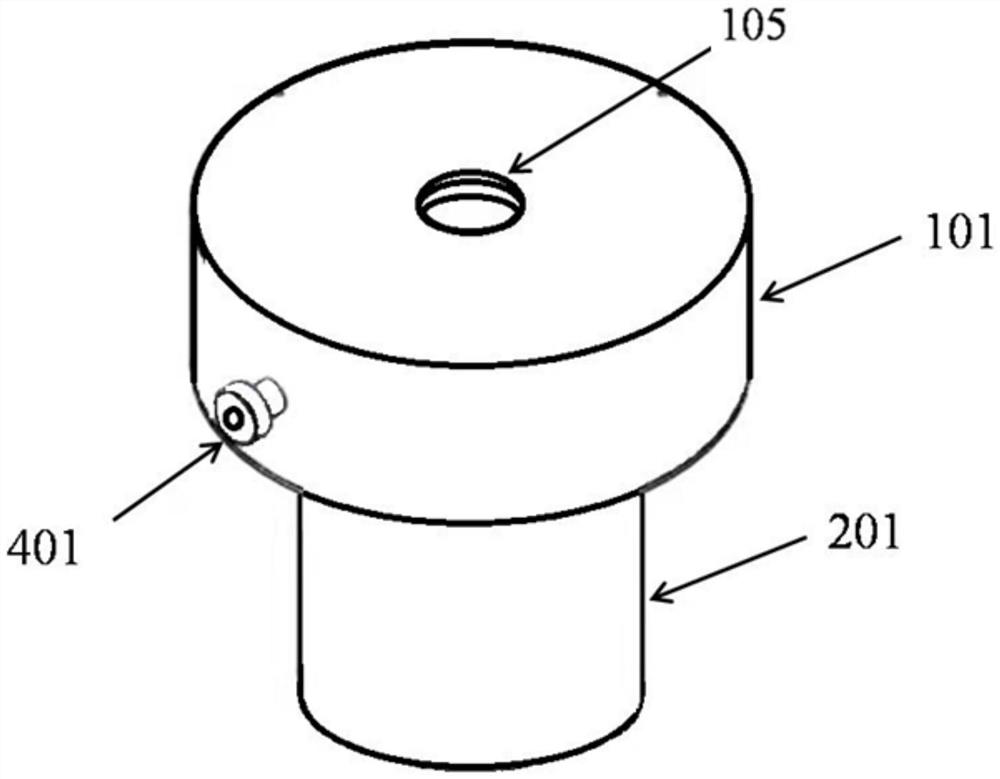

Optical fiber drawing furnace

ActiveCN114212990AExtended service lifeDrawing production process is stableGlass making apparatusGlass productionEngineeringFiber diameter

The invention discloses an optical fiber drawing furnace which comprises a heating furnace body and a supporting body arranged below the heating furnace body. The heating furnace body comprises a hollow hearth and a bottom plate, heating furnace wires are evenly arranged on the inner walls of the periphery of the hearth, the bottom plate is located at the bottom of the hearth, a hollow temperature equalizing body is arranged on the bottom plate and located in the hearth, and the center of a cavity of the temperature equalizing body coincides with the center of a cavity of the hearth. The supporting body comprises a wire drawing channel located in the middle, the wire drawing channel is communicated with the cavity of the temperature equalizing body, and the center of the cavity of the temperature equalizing body coincides with the center of the wire drawing channel. By designing the hearth with the narrow high-temperature area, the utilization rate of raw materials for wire drawing is increased, the structure is simple, disassembly and replacement are easy, the temperature field in the wire drawing hearth is stable and uniform, the heat preservation effect is good, energy is saved, environment friendliness is achieved, and drawn optical fibers are stable in fiber diameter and ovality, excellent in surface quality and few in surface defect.

Owner:CHINA BUILDING MATERIALS ACAD

Storage fresh-keeping method for fresh cocoon of cultivated silkworm

ActiveCN101317561BHigh quality raw materialShorten the production cycleDead animal preservationGeneration rateNatural state

The invention provides a storage fresh-keeping method for a silkworm fresh cocoon; silkworm chrysalis inside the fresh cocoons are killed by the quick freezing of dry ices; the fresh cocoons with the chrysalis killed are arranged in a closed article where the air is pumped out and the dry ices are added and the dry ices are converted into the CO2 gas under normal temperature; the fresh cocoons are hermetically stored under the anaerobic condition. The storage fresh-keeping method can keep the natural state of the cocoons better, has little effect on the silk quality, has simple, sanitary and convenient operation, quick disposal speed and low processing cost, can improve the silk generation rate and the silk generation quality; after reeling silk, the fresh cocoons can be taken as the raw material of the deep processing and is suitable for popularization and application in large scale.

Owner:广东省蚕业技术推广中心 +3

A method for treating silkworm cocoons by killing pupae with industrial salt for silk reeling in normal temperature water

The invention discloses a cocoon treating method for killing cocoons by industrial salt for normal-temperature water silk reeling. The method comprises the following steps of selecting high-quality raw materials of cocoons; preparing an industrial salt water solution with the concentration being 55 to 60 percent; soaking the cocoons into the industrial salt water solution; sealing the mixture for 30 to 40d at the temperature being 30 DEG C; fishing out the cocoons from the industrial salt water solution; pouring out the industrial salt solution; cleaning the fished cocoons by clean water; charging the fished cocoons into a 50-mesh nylon bag; sealing the opening; performing spin-drying for 3 to 4min in an ordinary spin-dry barrel of a washing machine; repeating the spin-drying operation for 4 to 5 times; pouring out the cocoons; spreading the cocoons at the temperature being 25 to 30 DEG C for drying the cocoons. The fresh cocoon raw materials are subjected to cocoon killing treatment by the circularly used industrial salt solution; the environment-friendly normal temperature silk reeling production is implemented; the reelability percentage and the silk yield of the cocoons are improved; the environment pollution is reduced; the health injury to silk reeling workers caused by severe work environment is reduced; the method is simple and convenient; the silk manufacturing technical flow process is simplified; the production cost of energy source labor and the like is reduced.

Owner:SERICULTURAL RES INST ANHUI ACADEMY OF AGRI SCI

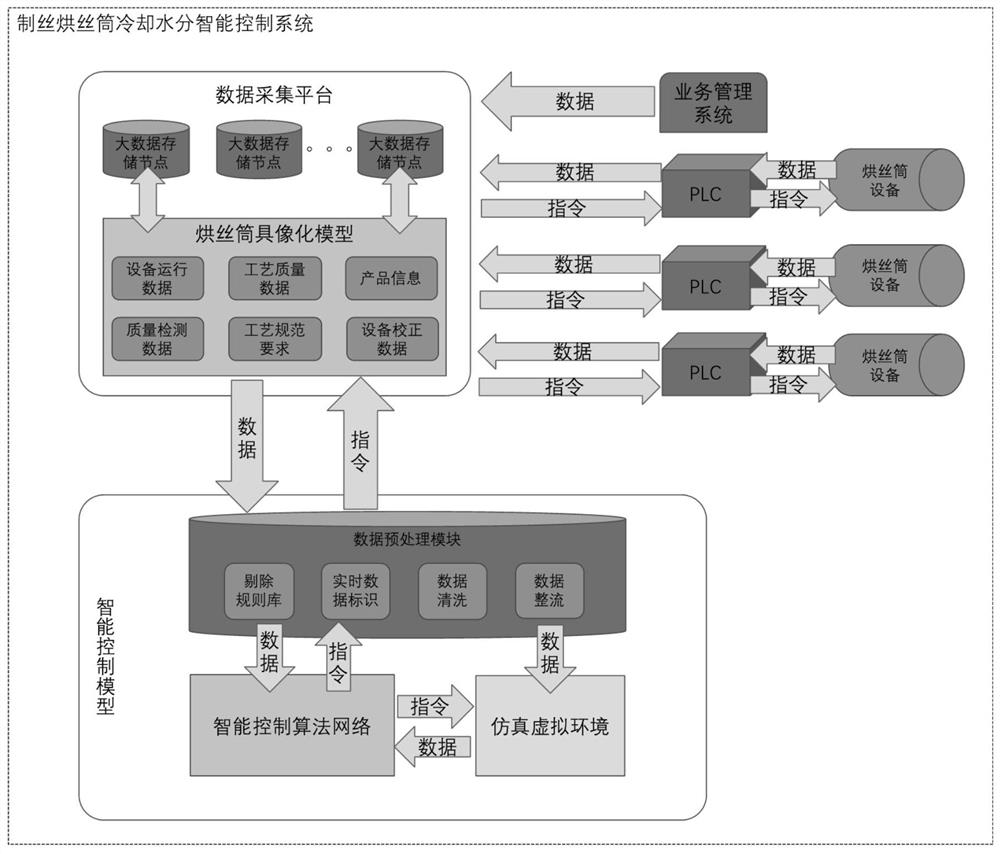

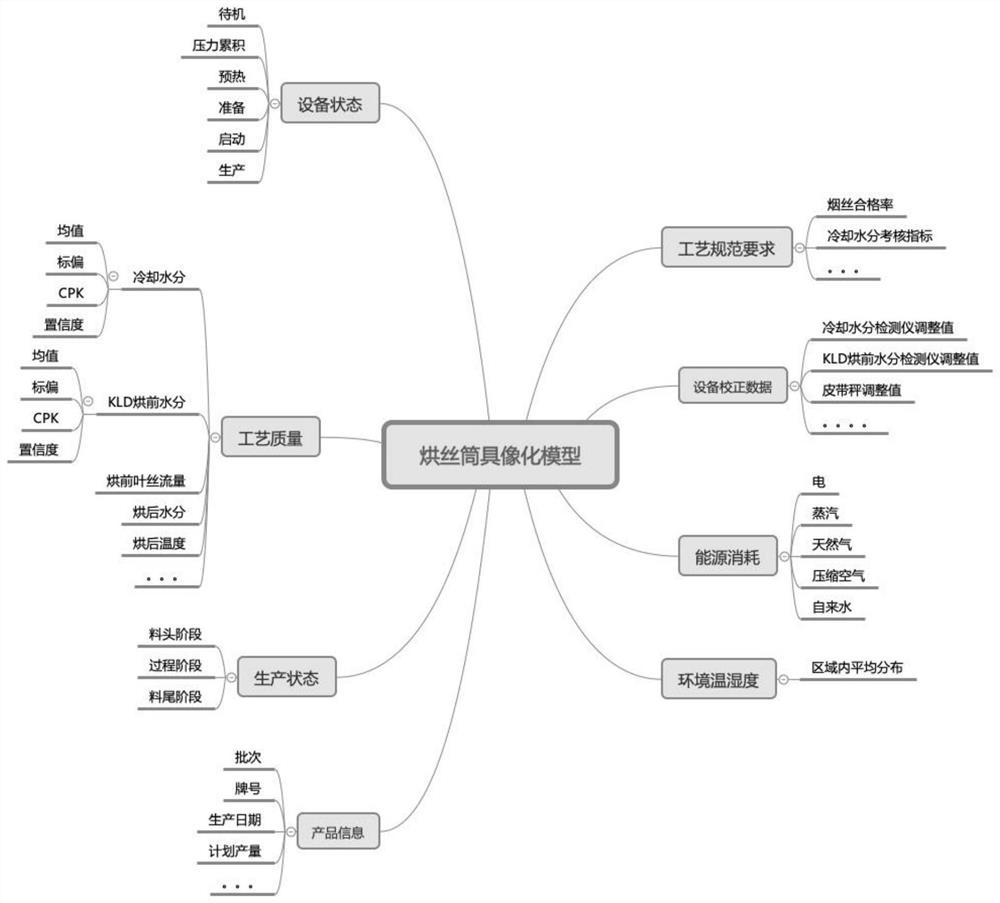

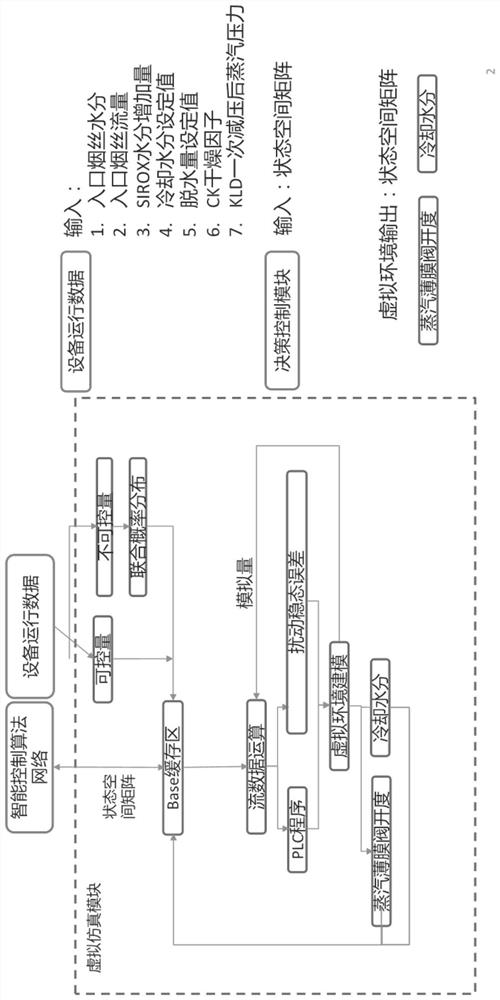

An Intelligent Control System of Cooling Moisture in Silk Drying Cylinder Based on Machine Learning Algorithm

ActiveCN111427322BReduce dependenceSolve the problem of intelligent transformationTotal factory controlProgramme total factory controlNetwork intelligenceData acquisition

Owner:CHINA TOBACCO ZHEJIANG IND

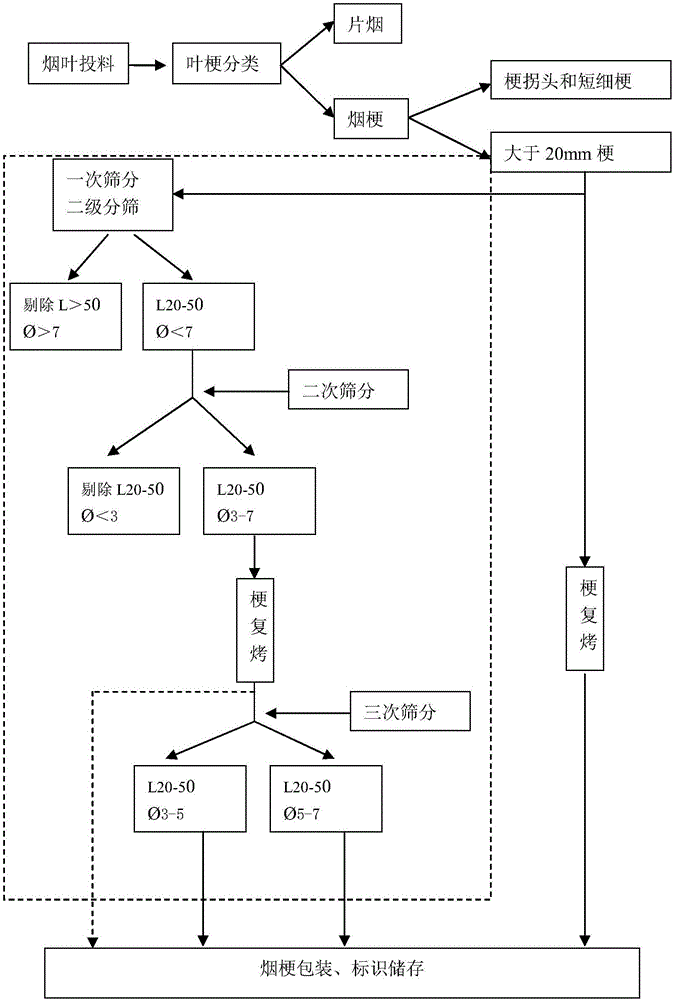

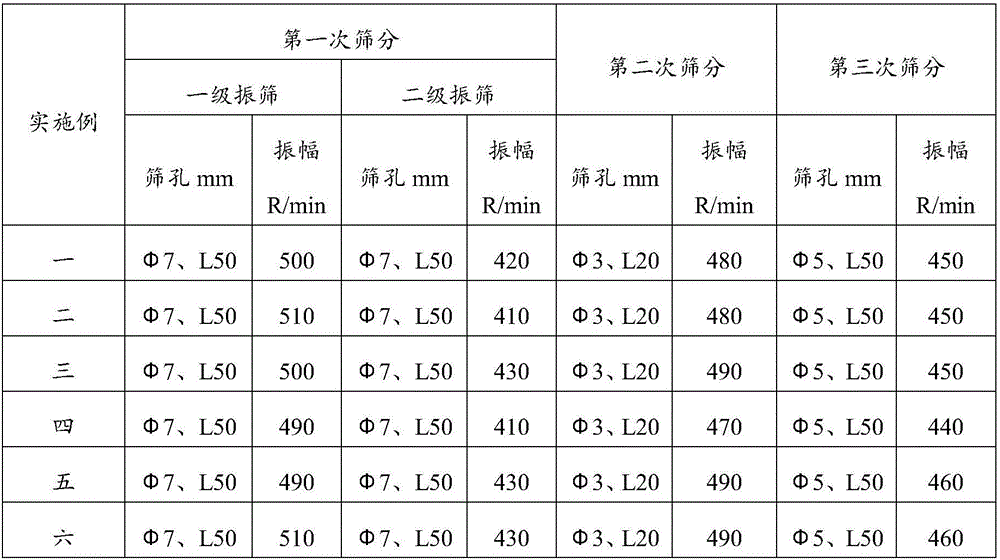

A method for online classification and collection of threshing and redrying tobacco stems

The invention provides a method for online screening of tobacco stems. The method comprises the steps of 1, separation of leaves and stems, and preliminary screening of tobacco stems; 2, primary screening, wherein two-stage screening is conducted on tobacco stems obtained after preliminary screening of step 1 by means of a two-stage vibration screening device; 3, secondary screening; wherein screening is conducted on tobacco stems obtained after two-stage primary vibration screening of step 2 by means of a one-stage vibration screening device; 4, redrying tobacco stems obtained in step 3 and then adding a one-stage screening device for screening; and 5, separately collecting tobacco stems with diameters between 3-5 mm and lengths between 20-50 mm and tobacco stems with diameters between 5-7 mm and lengths between 20-50 mm obtained in step 4, and conducting packaging, marking and storage. By the adoption of the method, tobacco stems with uniform and consistent physical characteristics can be provided for shredding, the application range of cut stems is widened after classification, the use ratio of cut stems is increased, and the quality of thin cigarettes is verified to be improved remarkably.

Owner:HUBEI CHINA TOBACCO IND

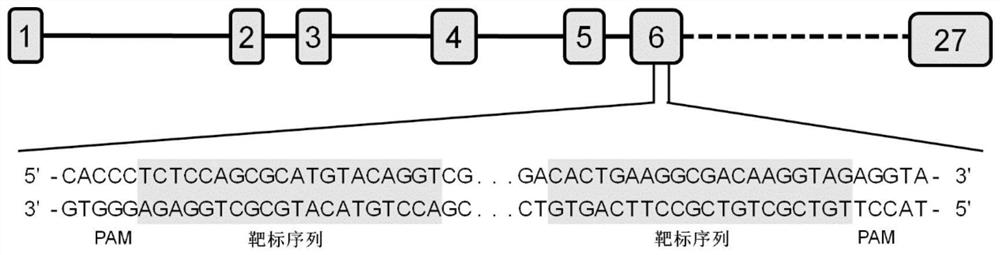

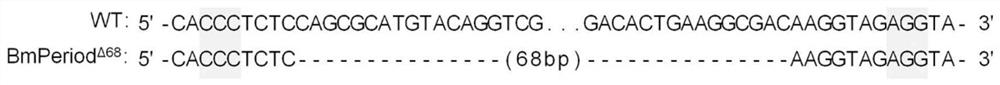

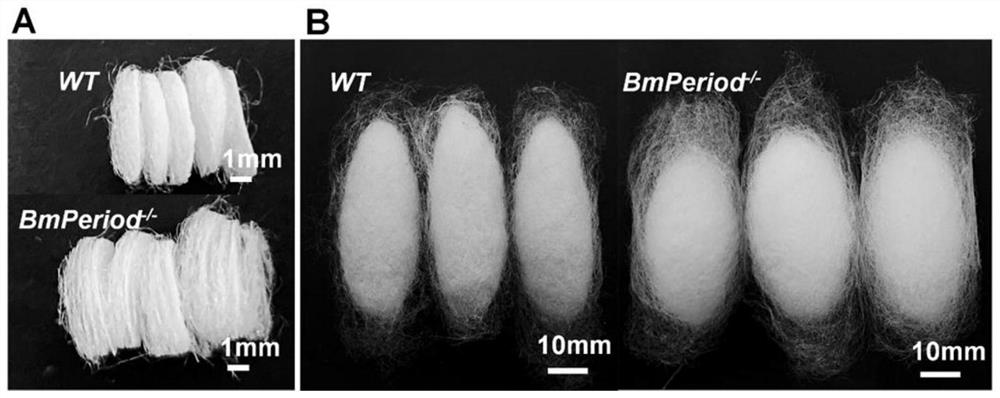

Application of silkworm Period gene or protein in silkworm breeding and silkworm cocoon production

The invention relates to application of a bombyx mori Period gene or protein in bombyx mori breeding and bombyx mori silkworm cocoon production, in particular to inhibition of expression of a gene shown in SEQ ID NO.1 or protein shown in SEQ ID NO.2 during bombyx mori breeding or bombyx mori silkworm cocoon production, cultivation of a special silkworm variety for silk floss production, improvement of the thickness of a silkworm cocoon layer and the total cocoon amount of the silkworm cocoon, improvement of the silk yield of the silkworm cocoon, and improvement of the yield of the silkworm cocoon. And the content of silk fibroin in the cocoon silk fibers is increased. According to the method, the development of posterior silk glands is remarkably promoted by inhibiting the expression of the silkworm Period gene, the content proportion of silk fibroin in cocoon silk fibers is remarkably increased while the yield of silkworm cocoons is increased, the silk yield of dried cocoons is effectively increased, and the cocoon forming shape of mature silkworm larvae can be stably changed.

Owner:NANTONG TEXTILE & SILK IND TECH RES INST +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com