A method for online classification and collection of threshing and redrying tobacco stems

A technology of threshing and re-curing and re-curing tobacco, which is applied in the fields of tobacco, tobacco preparation, application, etc. It can solve the problems of not considering the reasonable distribution of cut stem structure, complicated process technology, and inability to classify tobacco stems, so as to ensure consistency and stability Sexuality, broaden the scope of application, the effect of simple design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

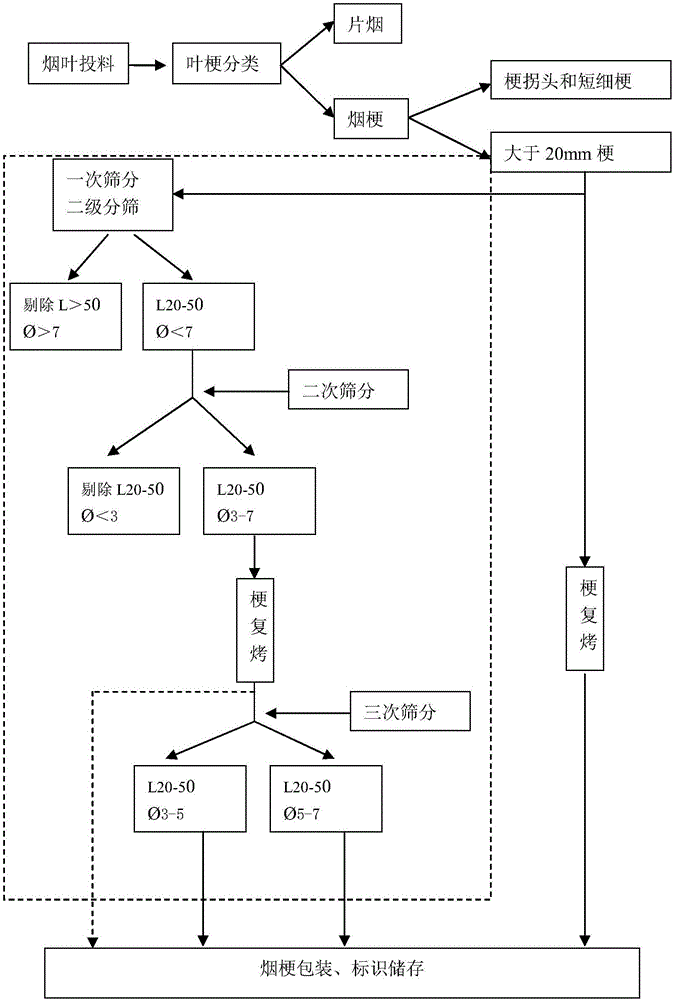

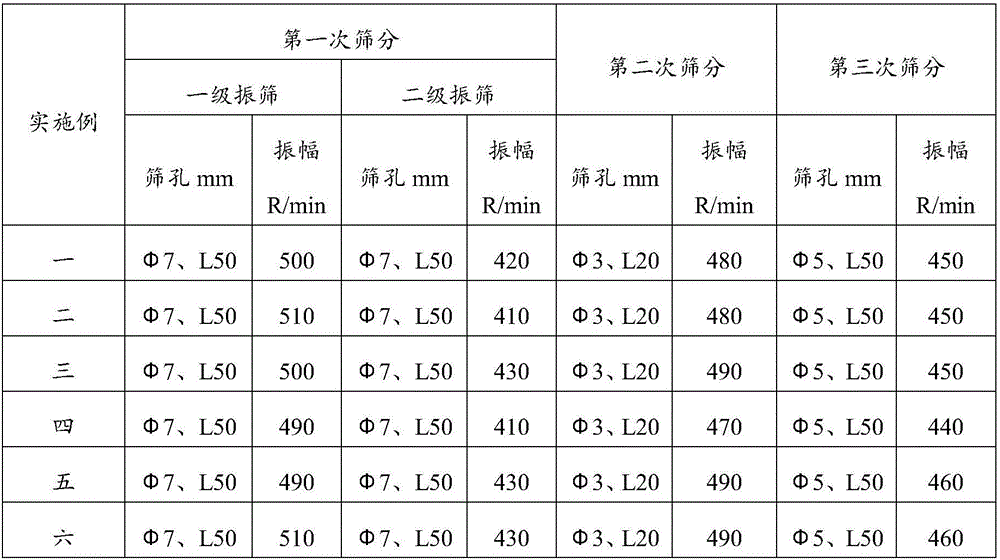

Method used

Image

Examples

Embodiment Construction

[0018] The existing tobacco stems in stock were manually classified according to the factors of length and diameter, and the statistical results are shown in Table 2 and Table 3.

[0019] Table 2 Distribution ratio of different lengths of conventional tobacco stems

[0020] Length (mm)

Average percentage (%)

accumulation(%)

≤10

3.24

0.24

10-20

7.3

10.54

20-30

15.6

26.14

30-40

20

46.14

40-50

25.3

71.44

50-60

8.1

79.54

60-70

6.6

86.14

70-80

5.9

92.04

80-90

4.6

96.64

90-100

2.7

99.34

>100

0.66

100

[0021] It can be seen from the statistical results in Table 2 that tobacco stems with length L≤20mm accounted for 10.54%; tobacco stems with length L≤20mm accounted for 60.90%; tobacco stems >50mm accounted for 28.56%. Therefore, nearly two-thirds of the tobacco stems are between 20-50mm in length.

[0022] Table 3 Distribution rati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com