Patents

Literature

84results about How to "Save processing fee" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

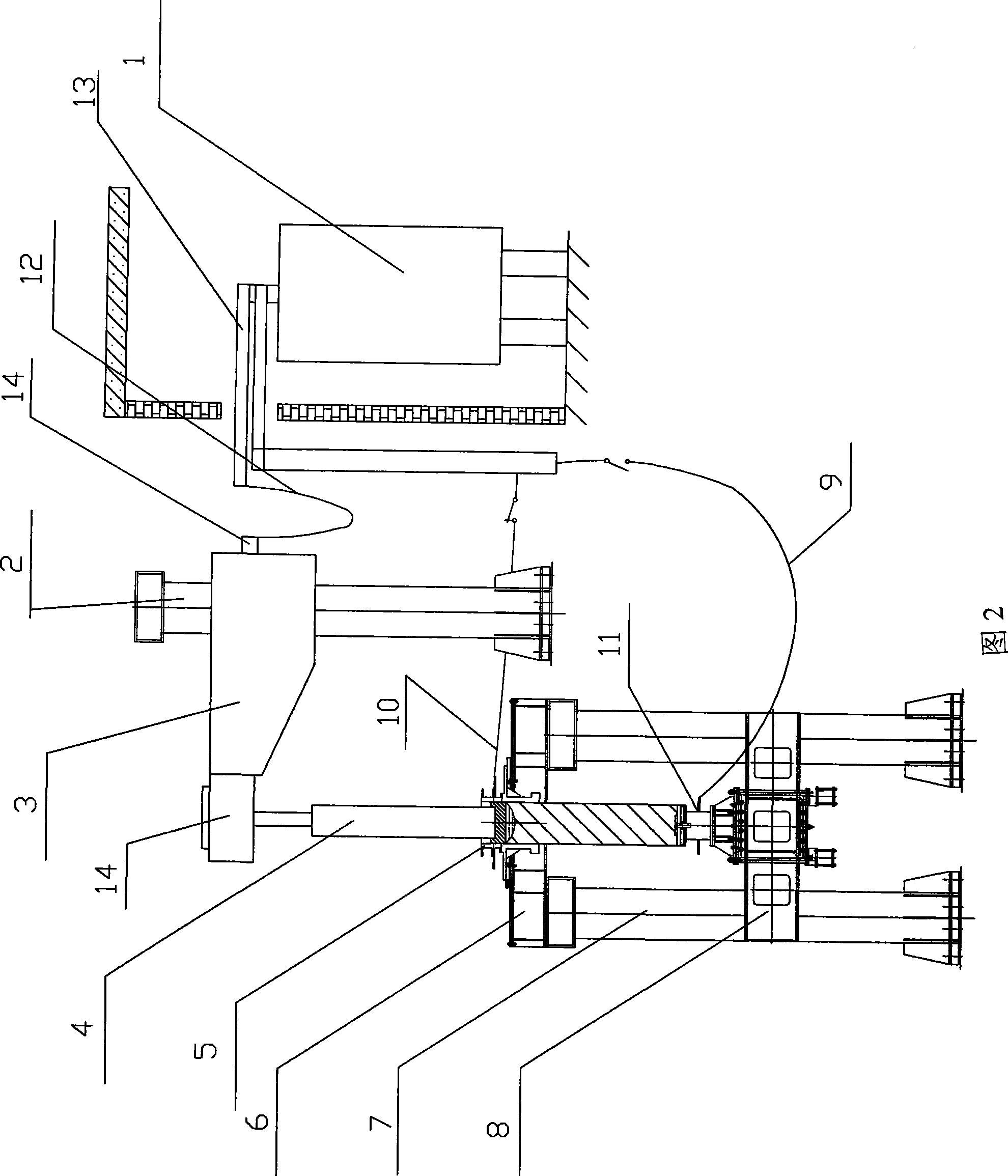

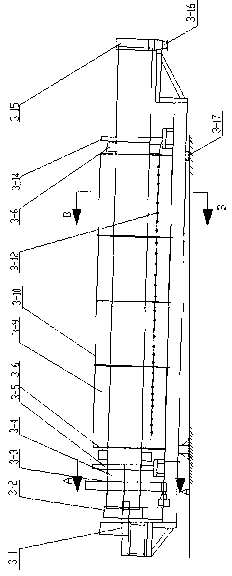

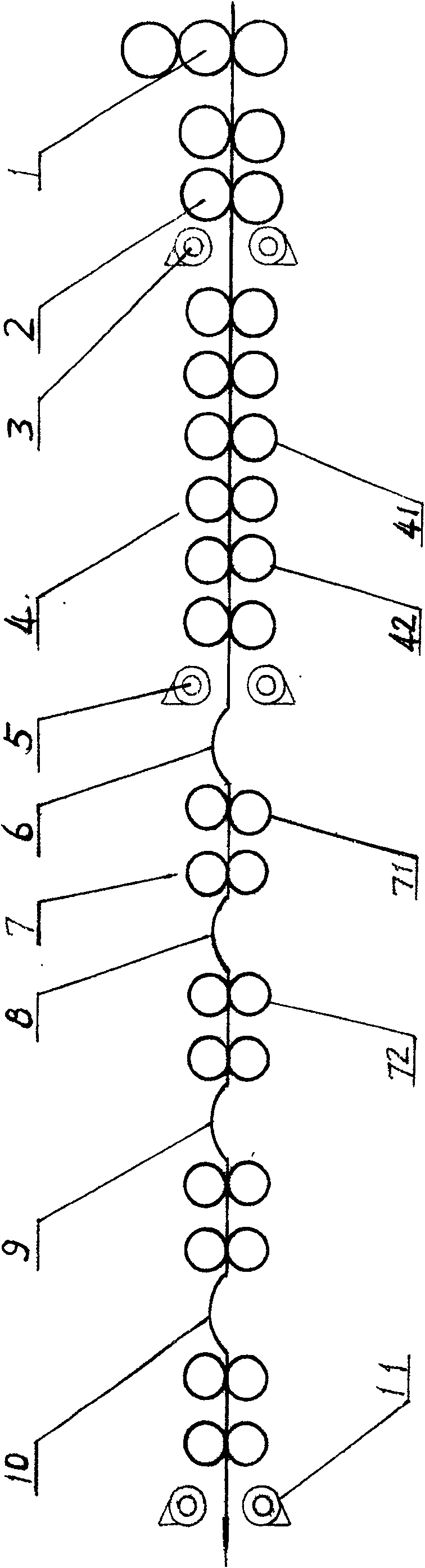

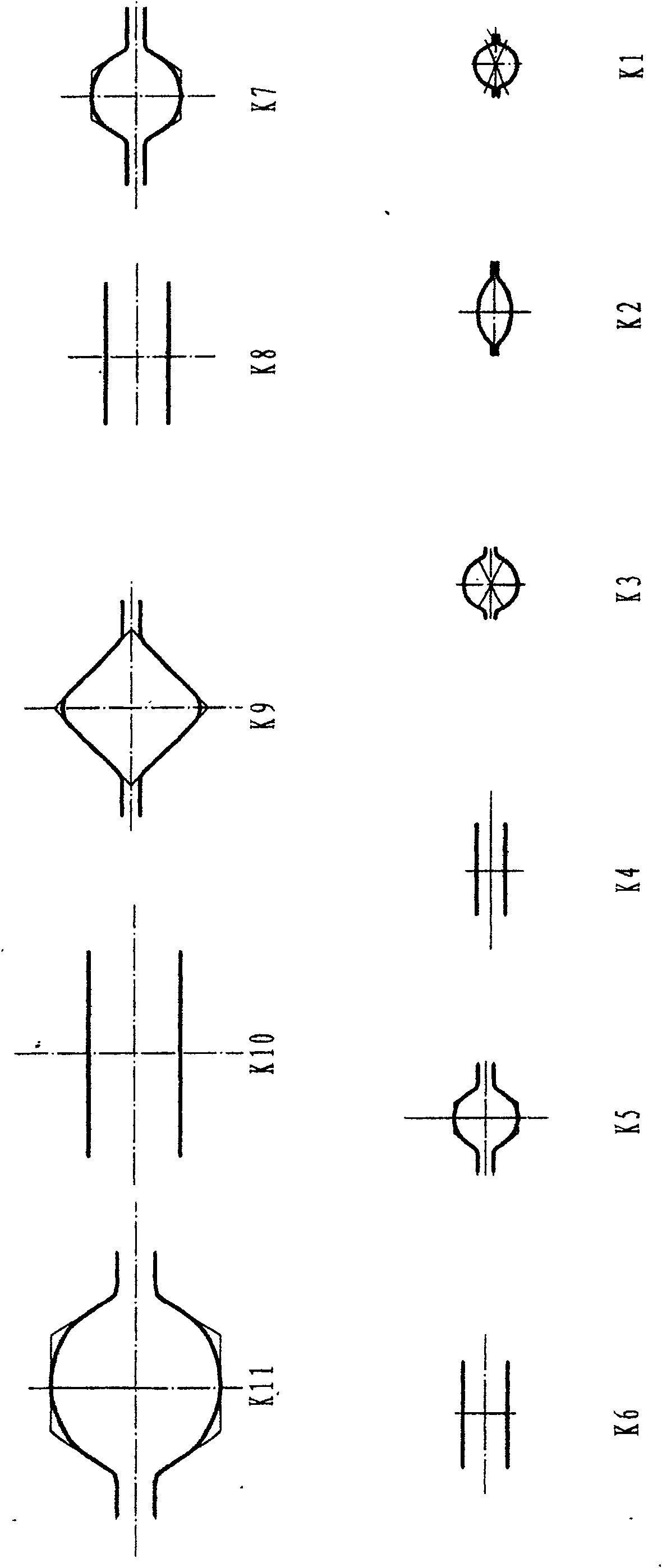

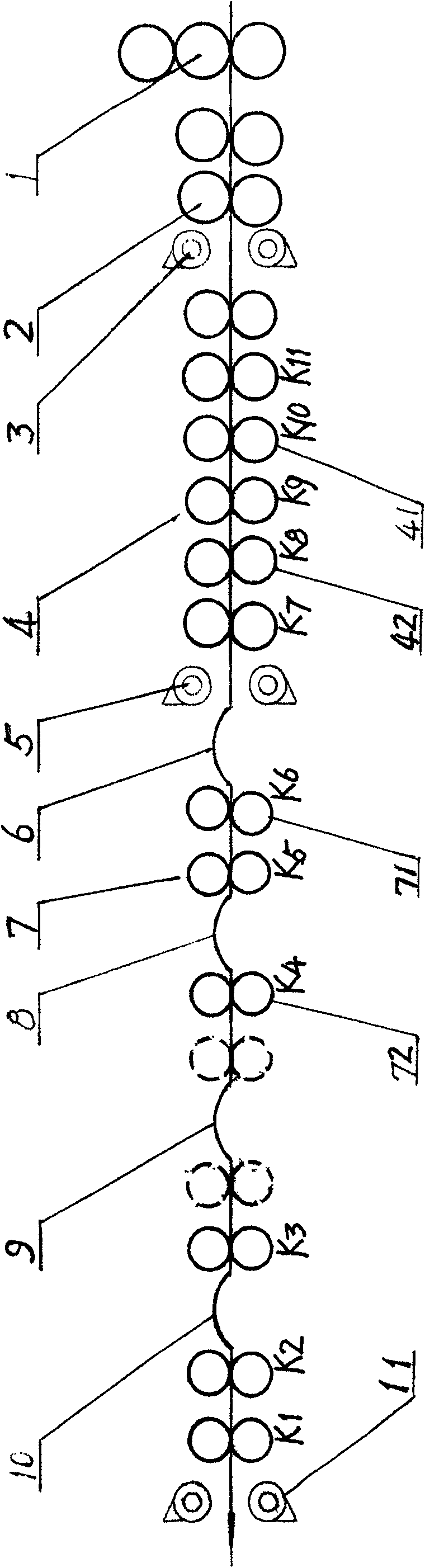

Non-groove rolling technology of horizontal mill

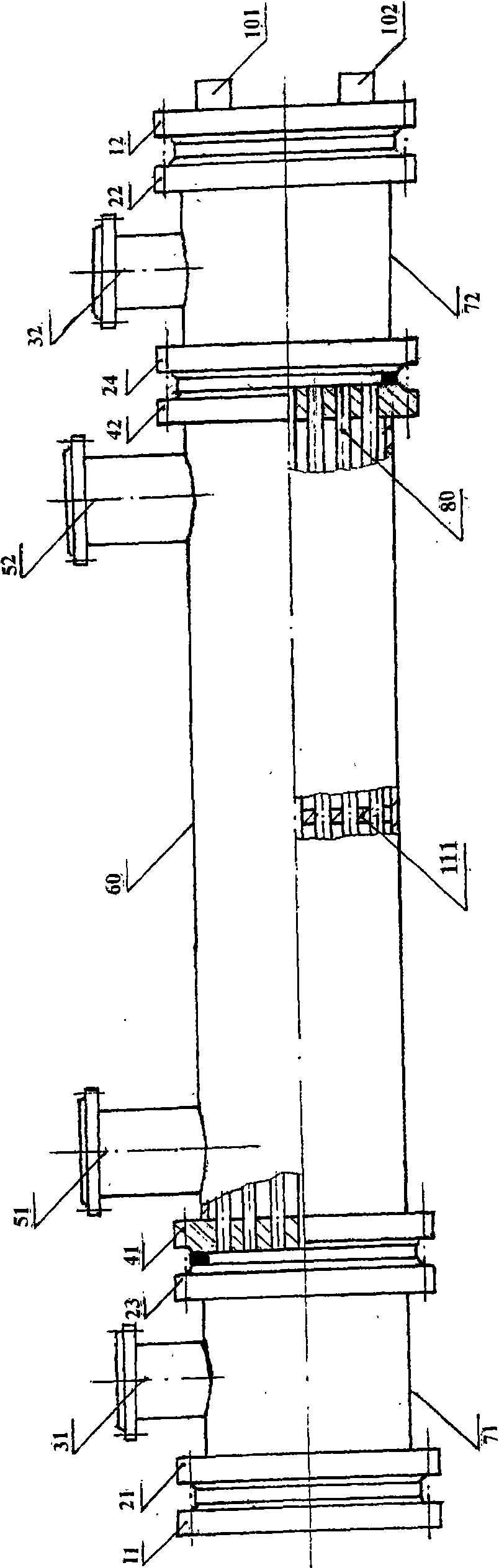

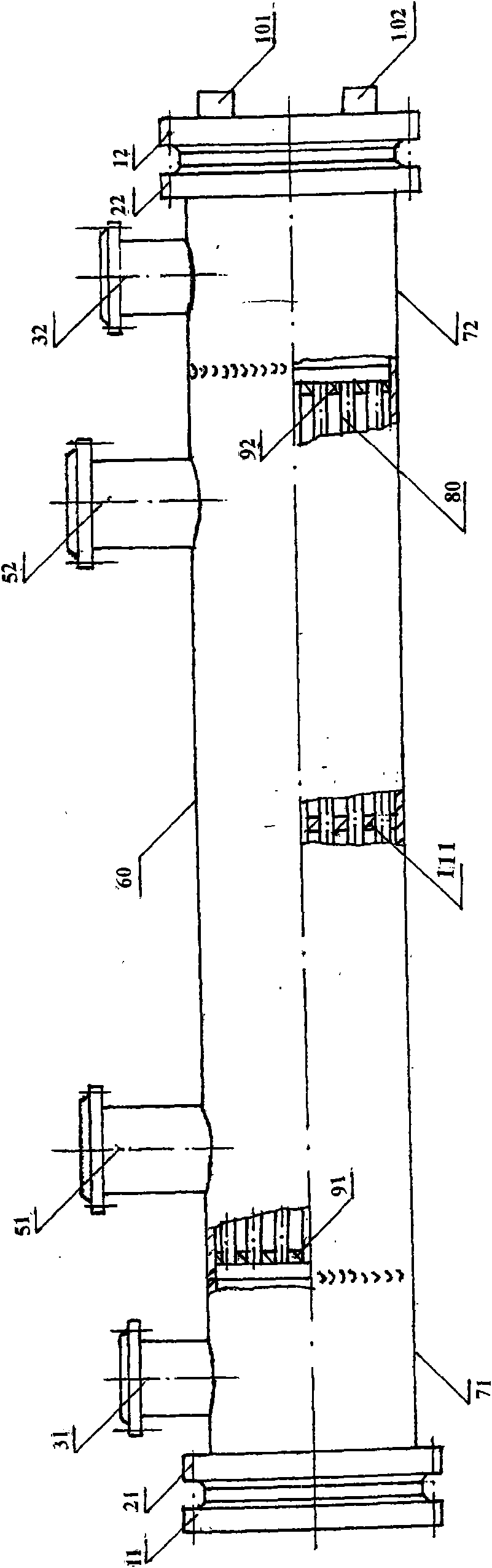

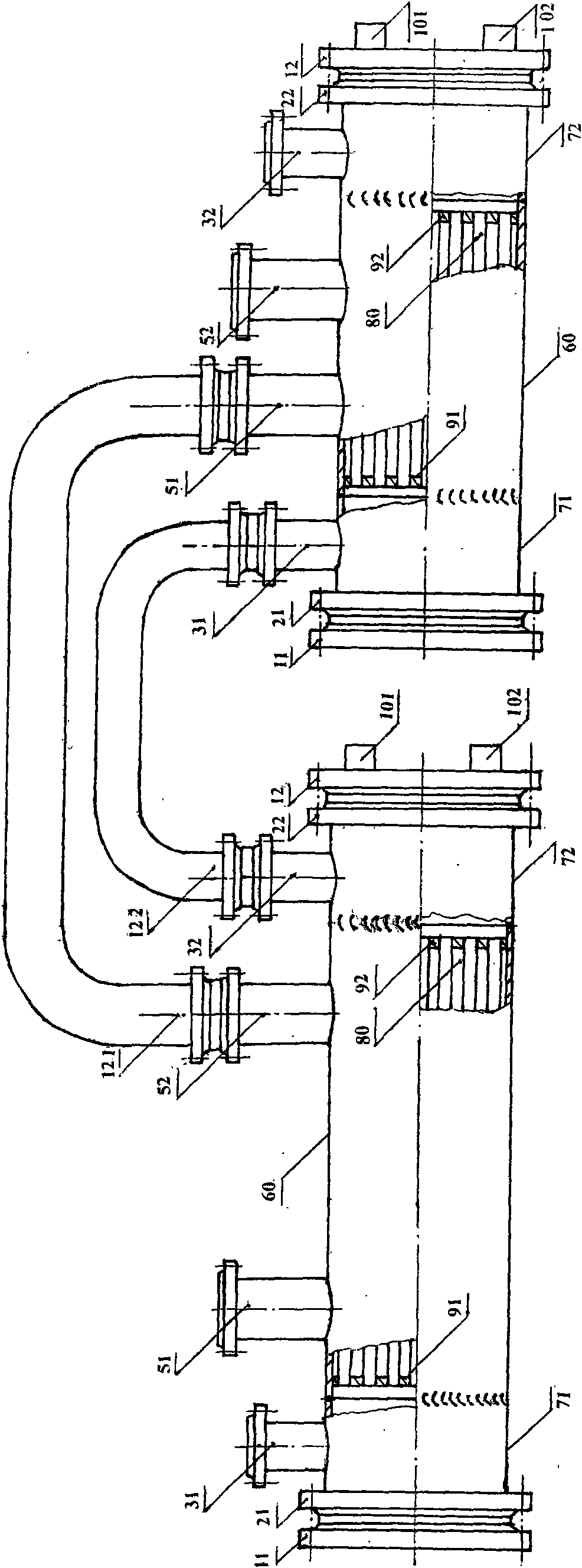

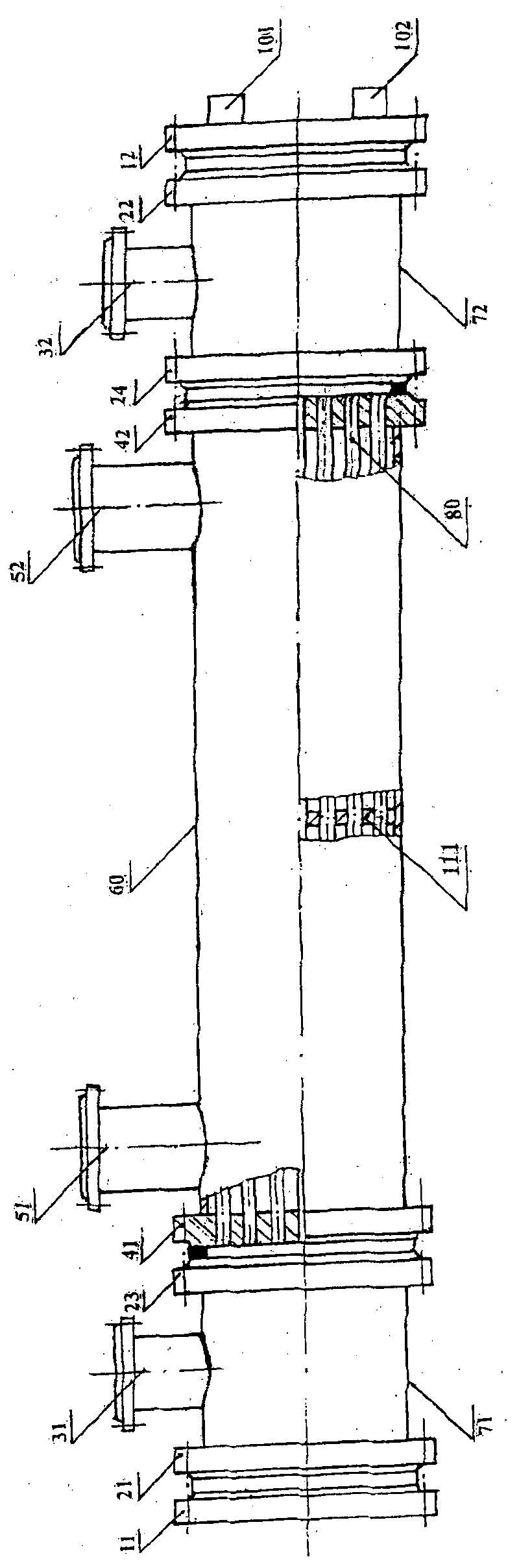

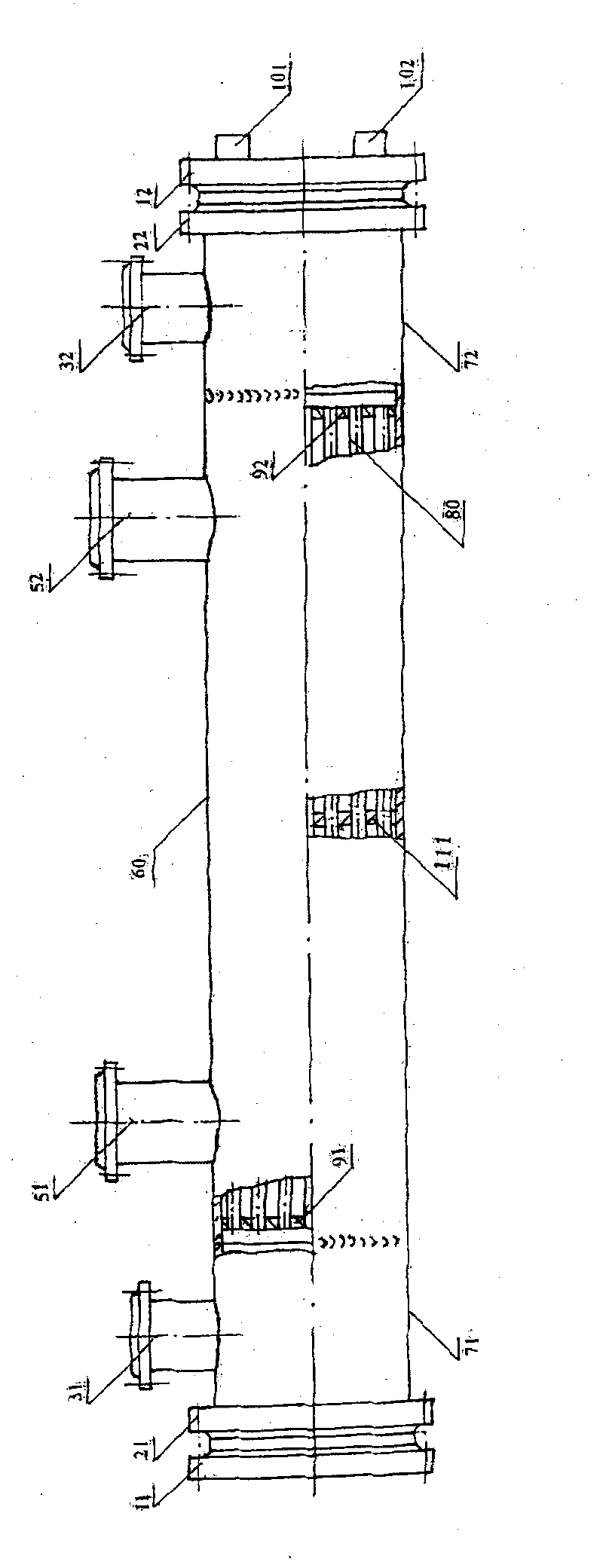

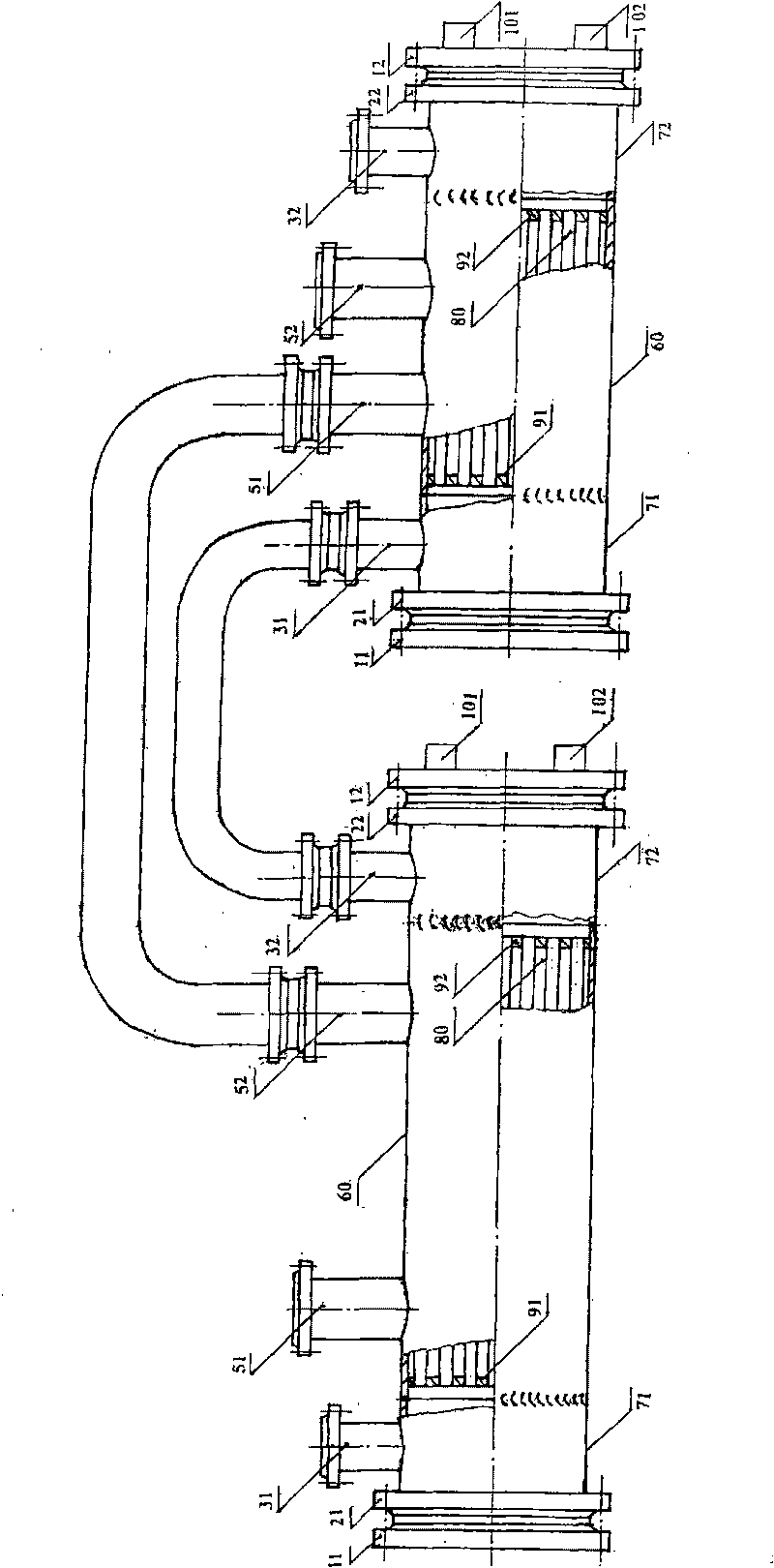

ActiveCN101007315AReduce rolling accidentsReduce intermediate rolling wasteRollsMetal rolling arrangementsStrip millRound bar

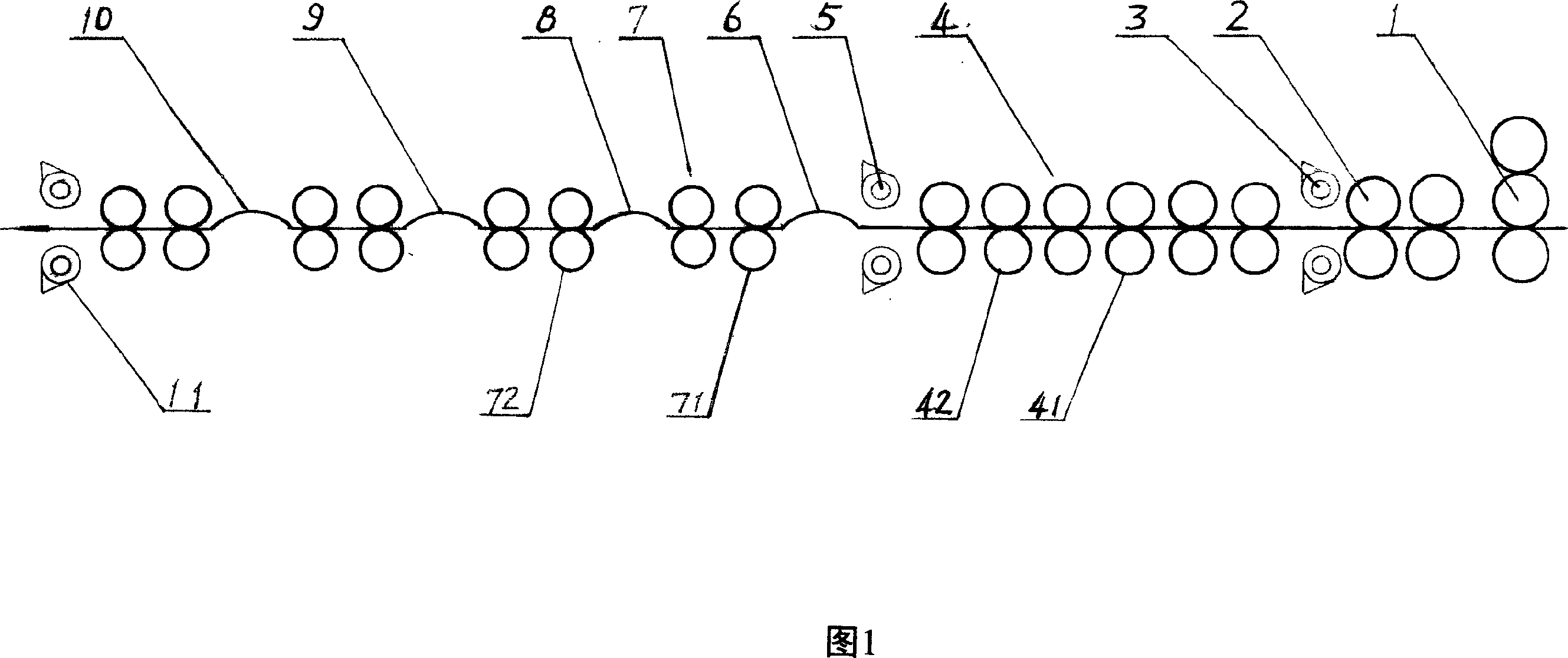

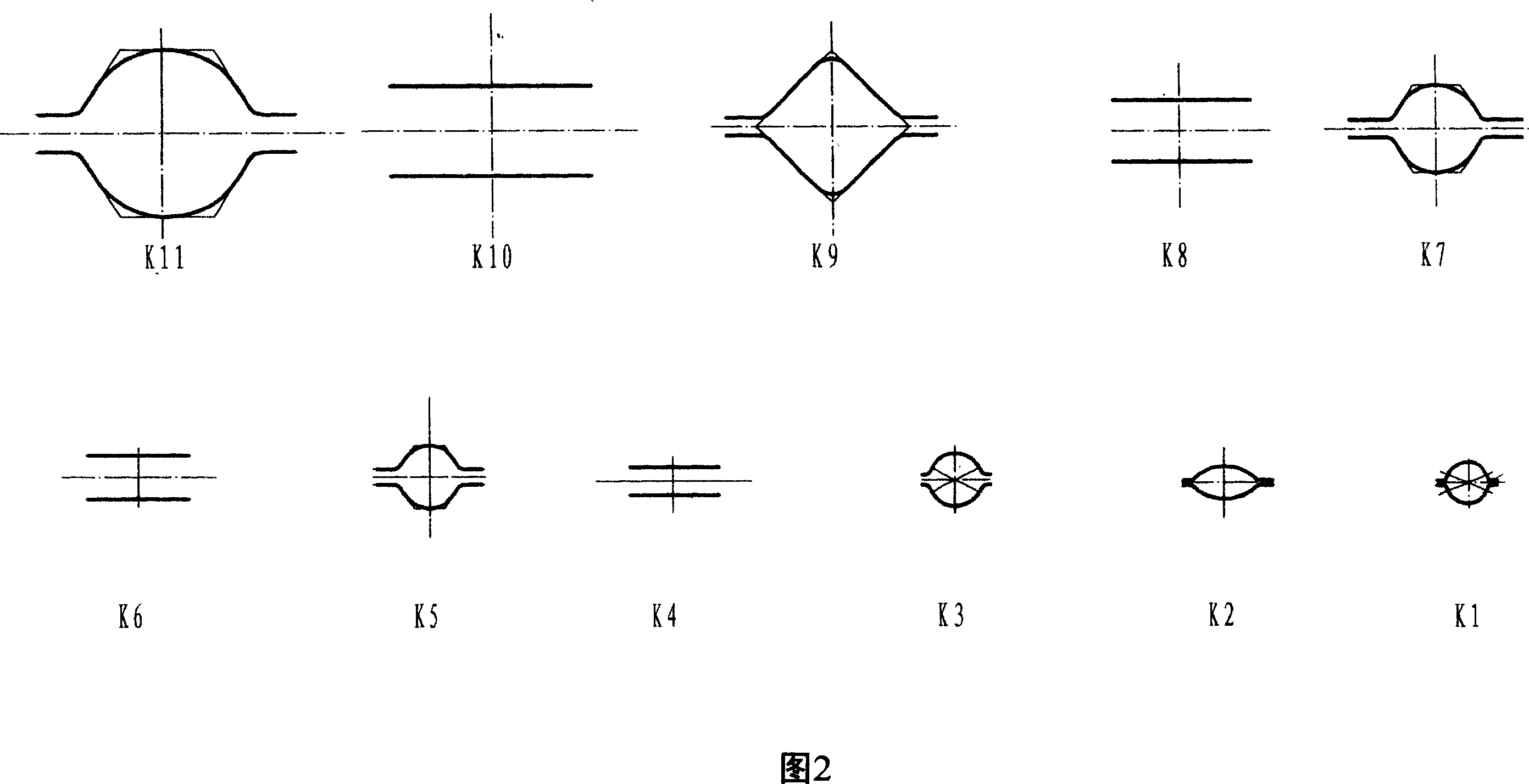

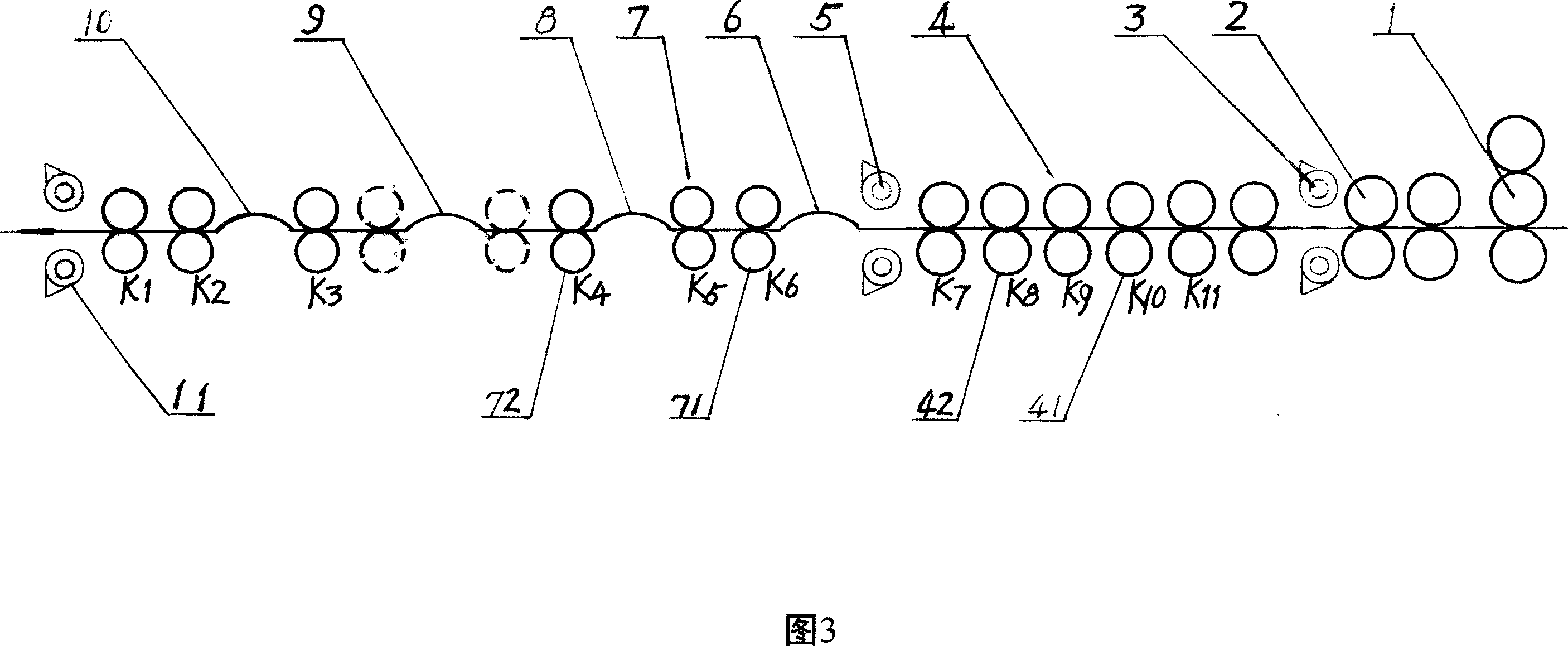

The invention discloses a slotless rolling art for all-horizontal rolling mill which rolls round bar and screw-thread steel on semi-continuous rolling process online. It arranges junior mill 2, crop flying shear 3, junior mills group 4, crop and crop end flying shear 5, loop 6 or 8 or 9 or 10, finishing mills group 7 and times ruler flying shear 11 after blooming mill 1 consecutively; installs plain-barreled roll 41 or 42 and 71 or 72 on the third or fifth rolling mill frames of junior mills group 4 and the first and third rolling mill frames of finishing mills group 7, the plain-barreled rolls need not be processed hole-type groove, the rolling pressure is decreased significantly. The plain-barreled rolling mills does not have wrong rollers in whole rolling process, does not generate ears, decreases central waste rollers, saves changing roller time, increases rolling mill efficiency. The plain-barreled roll slotless rolling art not only can be used in flat alternative continuous rolling process line, but has a bright prospect in development and application of all-horizontal rolling mill process line.

Owner:湖南华菱涟源钢铁有限公司

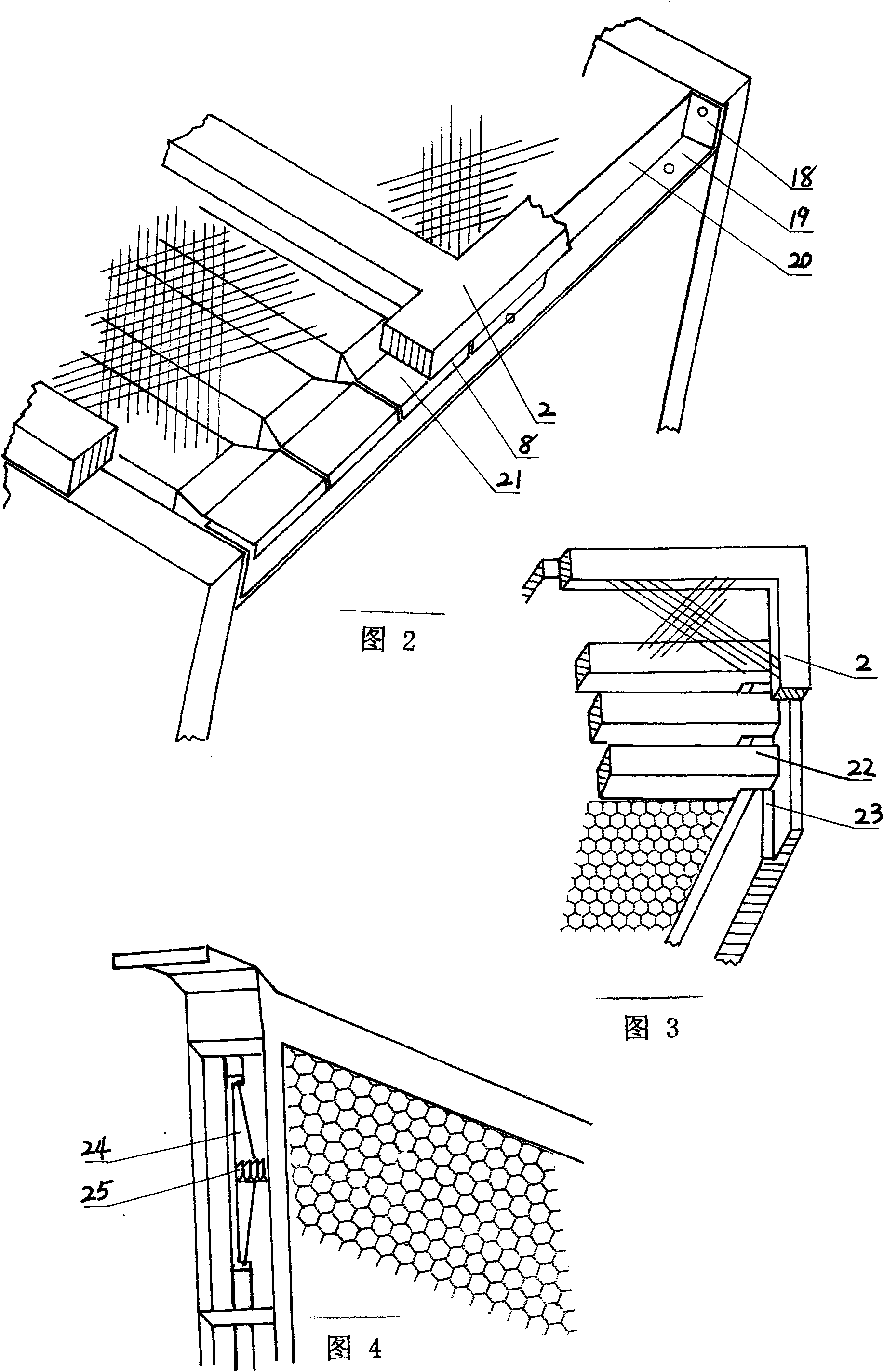

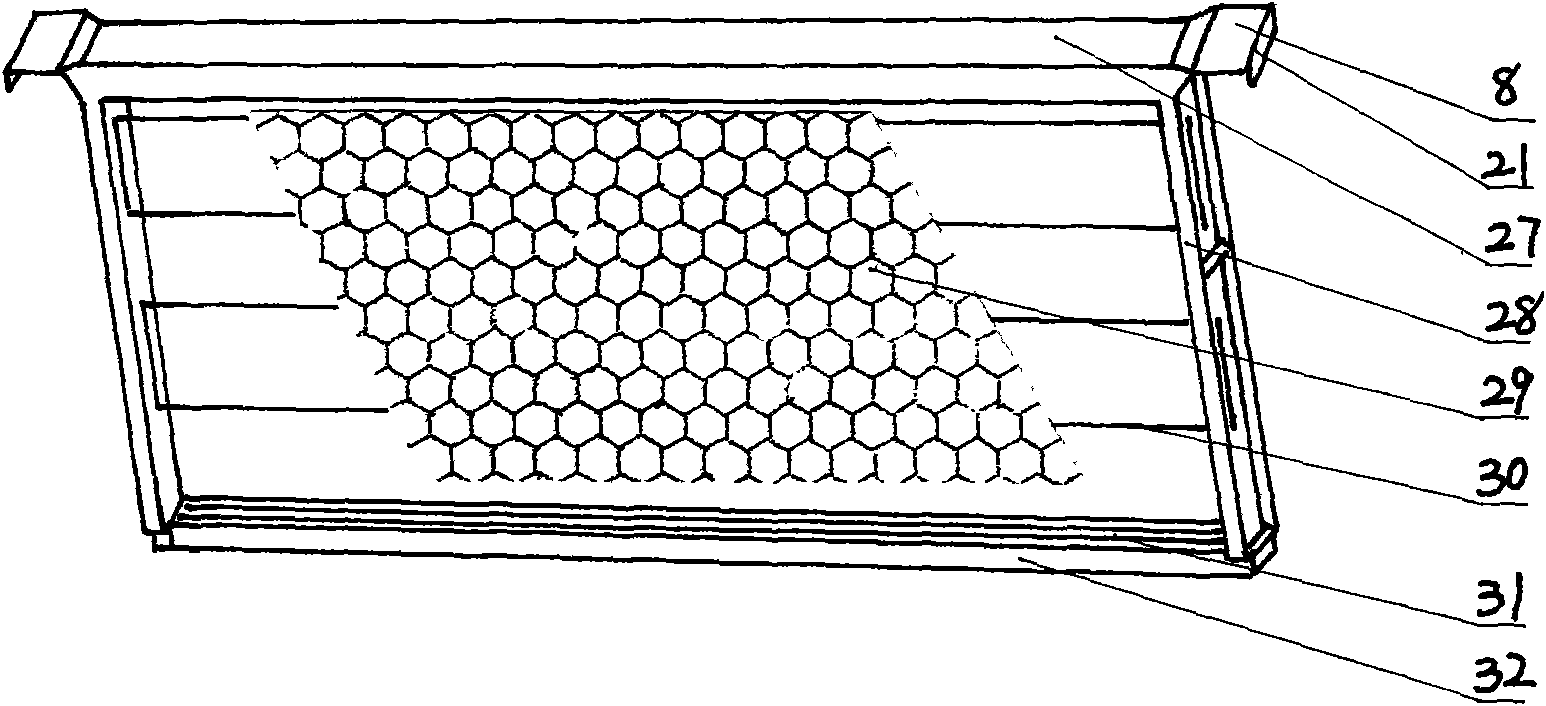

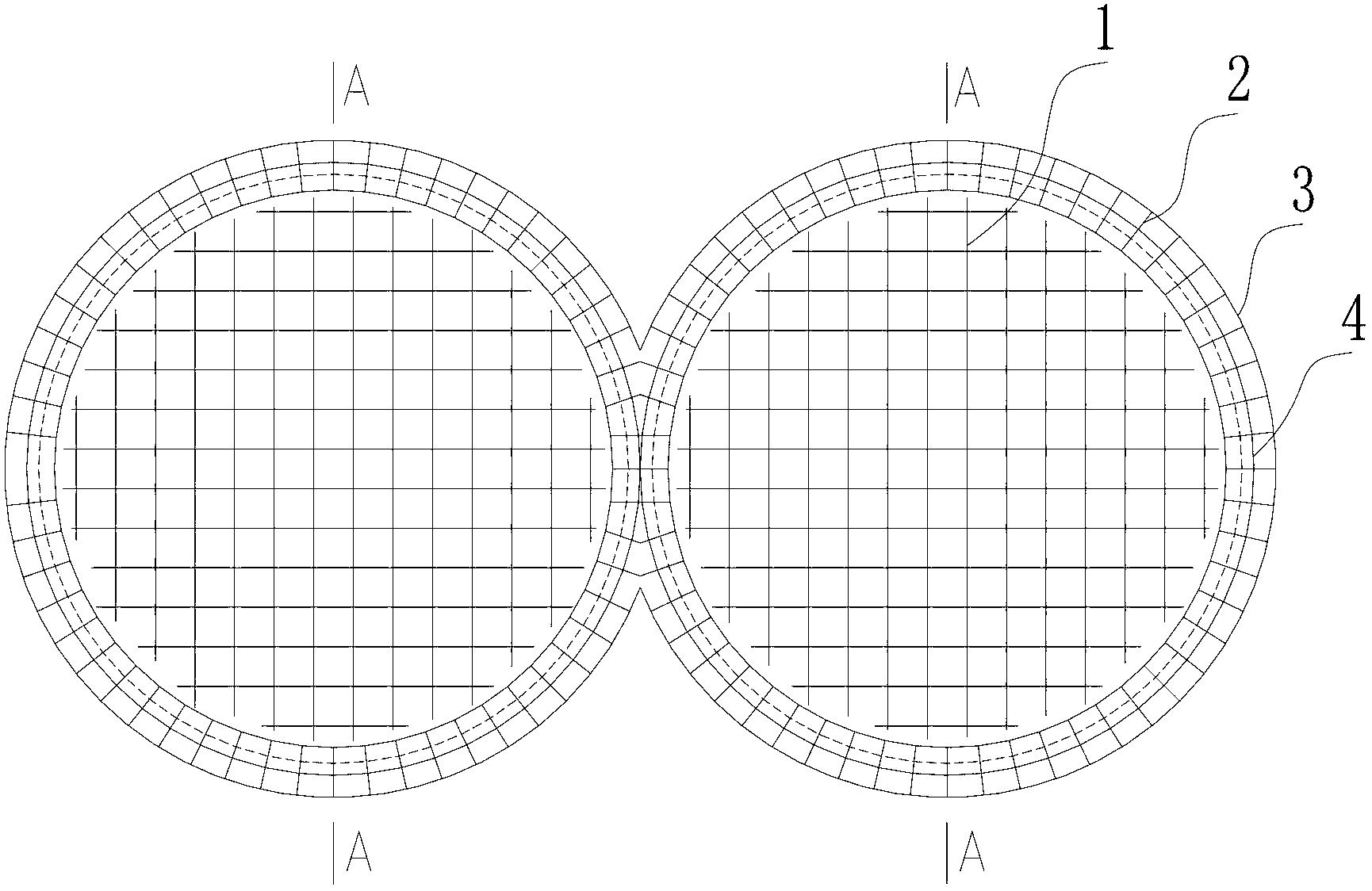

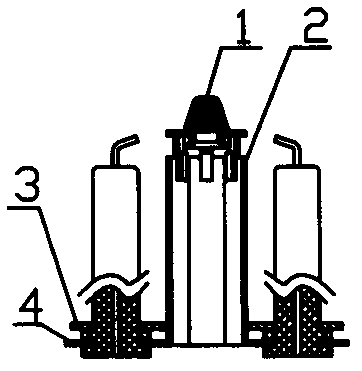

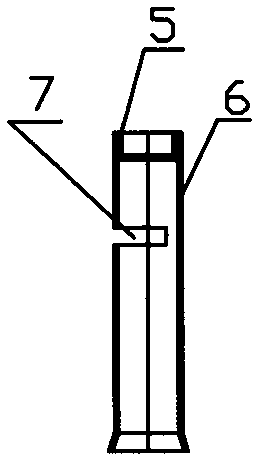

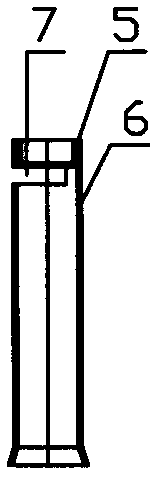

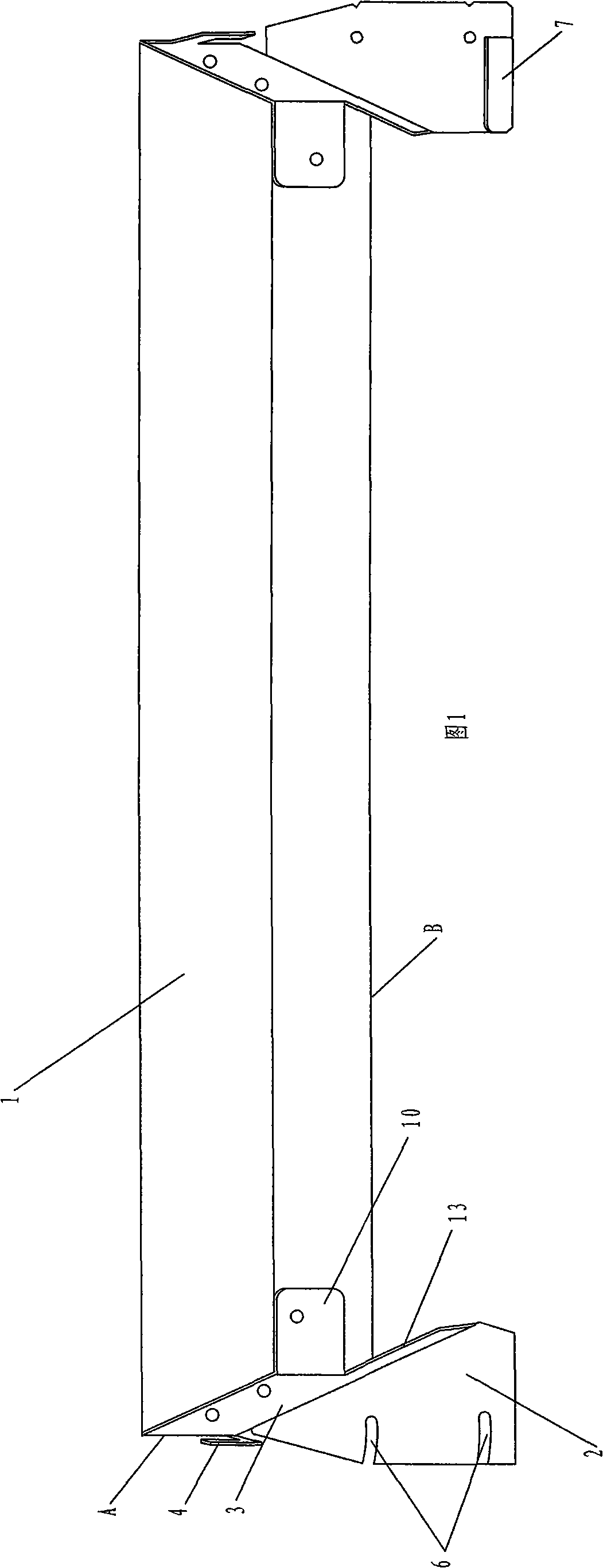

Horizontal and super combined beehive

InactiveCN101897300AImprove work efficiencyIncrease productionBeehivesHoney collectionWaxEngineering

A horizontal and super combined beehive comprises a wide-comb box, a frame support, a powder-releasing cover, a pollen box, a connector, a degummed drape, an inserted frame, an integrated frame and a wax comb foundation with suspension loops. The wide-comb box is characterized in that the both ends of the box are used as the breeding areas for two swarms of bees, a super is supported above the middle production area, frame queen excluders are used to form a working bee centralized production area, the areas are covered; the powder-releasing cover is bottomless, pollens and honey on a powder-leaking railing pedal with anti-theft gantry boxes on both sides directly leak in the pollen box at the bottom; the connected box is coarsely adjusted by a multi-teeth hook and finely adjusted and connected firmly by a screw crow bar through screws; the laps and edgings of the inserted frame are integrated, an upper beam and a lower beam are inserted in the upper and lower grooves of two edgings to integrate, the upper beam is thin, the lower beam and the edgings are provided with grooves to be inserted in the comb foundation; a wide hook with the same width and an adjuster are hung on the wax comb foundation for tightening; the laps are integrated with a frame-distance clip and connected with the upper beam through a downward slope, the tops of comb-forming frame supports are butted to each other and are tightly pressed by the degummed drape and the inner frame of the box cover, the distance of the frames is standard so that people can not stung by bees; and the top of each lap is provided with a handle, thus the laps can be fast gripped outside the box. The wide-comb box can be used to multiply the efficiency, thus being suitable to be used for beekeeping around the world.

Owner:汪修建

Blast furnace smelting method by using vanadium-titanium two-phase sintering ore

ActiveCN104673951AReduce ironmaking costsImprove utilization factorBlast furnace detailsIronstoneBlast furnace smelting

The invention belongs to the technical field of iron and steel metallurgy, in particular relates to a blast furnace smelting method by using a vanadium-titanium two-phase sintering ore. The blast furnace smelting method by using vanadium-titanium two-phase sintering ore is characterized in that the blast furnace burden structure is as follows: 70-100wt% of vanadium-titanium two-phase sintering ore, 0-30wt% of vanadium titanium magnetite pellet and 0-10wt% of common iron ore, wherein the common iron ore is an iron ore containing no vanadium or titanium. The invention provides the blast furnace smelting method by using vanadium-titanium two-phase sintering ore, and the method is low in cost; vanadium-titanium titanic magnetite for blast furnace smelting is provided by the vanadium-titanium two-phase sintering ore, so as to optimize the blast furnace burden structure, improve the breathability of the blast furnace burden structure and perfect the technical-economic indicator of blast furnace smelting.

Owner:攀钢集团西昌钢钒有限公司

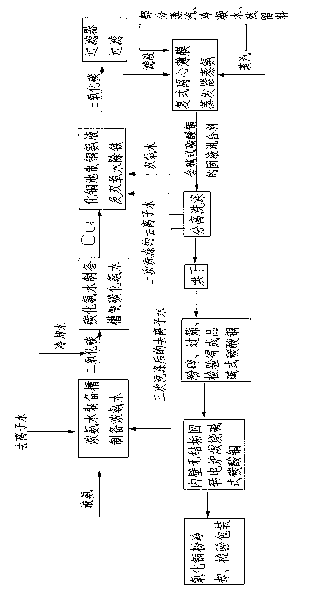

Method for preparing high-activity electroplating grade copper oxide from basic cupric carbonate

InactiveCN103101958AGuaranteed purityOvercoming the disadvantages of static calcinationCopper oxides/halidesBASIC CUPRIC CARBONATEBasic copper carbonate

The invention discloses a method for preparing high-activity electroplating grade copper oxide from basic cupric carbonate. According to the method, pure copper, liquid nitrogen and high-purity carbon dioxide are taken as materials to prepare the high-purity basic cupric carbonate through a centrifugal film evaporator or a scraper reaction kettle; the problem of impurities such as chlorine which may be caused by production of the basic cupric carbonate material by the traditional method is avoided; the purity of the basic cupric carbonate is improved; the high-purity low-chorine electroplating grade copper oxide is burnt from the high-purity basic cupric carbonate through a rotary kiln; the defects of inactivation, a plurality of impurities, large labor intensity, un-continuous production, long period, high energy consumption, large cost and the like due to the fact that the basic cupric carbonate at the low-temperature part is not burnt thoroughly and the content is not enough when a pushed slab kiln statically burns while copper oxide at the high-temperature part is burnt to death are overcome; the product activity is ensured; and the method is high in product quality, less in energy consumption, small in cost and more environment-friendly.

Owner:TAIXING SMELTING PLANT

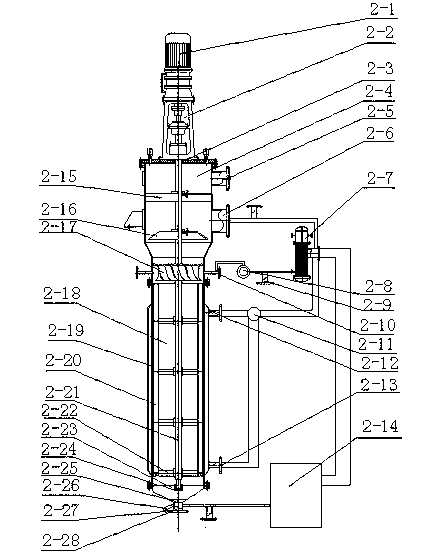

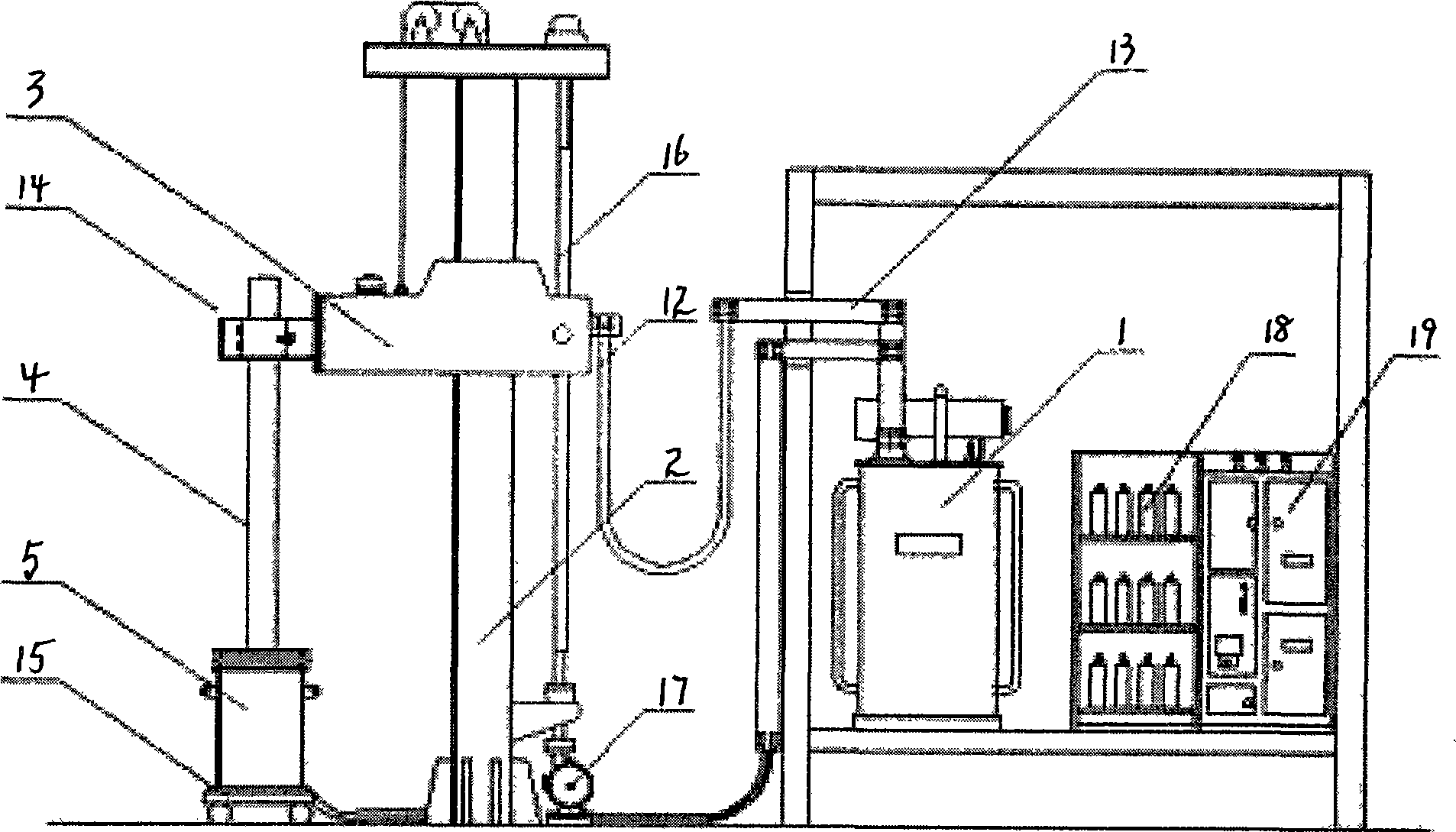

Conductive and continuous casting type electroslag remelting furnace for crystallizer

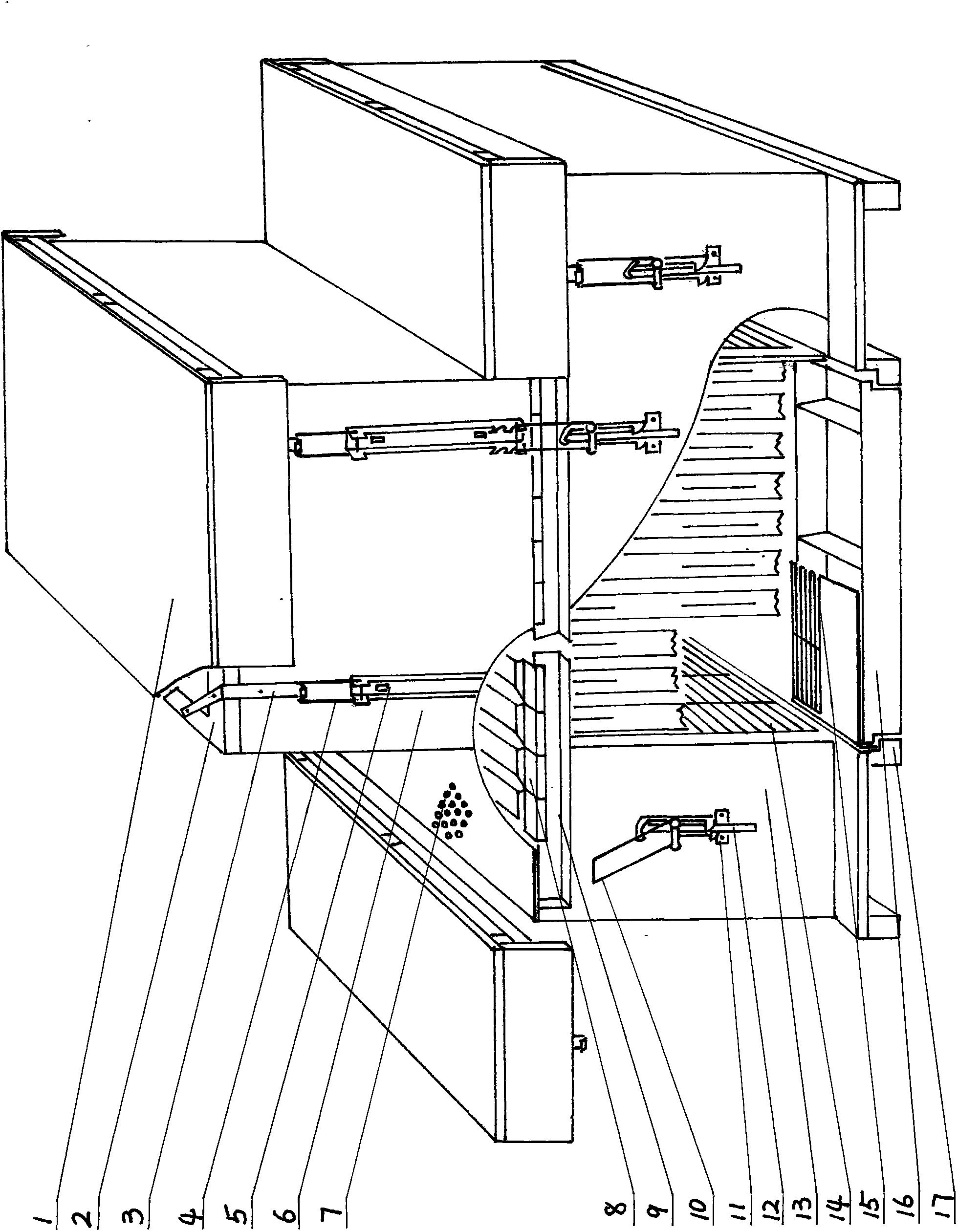

The invention relates to a crystallizer conducting continuous casting type electroslag remelting furnace which comprises a stripping system, a crystallizer system, an electrode, an electrode elevating system and a power supply system. The stripping system comprises a stripping upright column (7), a stripping platform (8) and a bottom water tank (10). The crystallizer system comprises a crystallizer platform (6) and a crystallizer (5). The electrode elevating system adopts two independent cross arm upright columns (2) and cross arms (3). The power supply system comprises a transformer (1), a short network (13), a cross arm cable (12), a crystallizer cable (11) and a bottom water tank cable (9), wherein one end of the cross arm cable (12) is connected with an electrode holder (14) through the short network (13), the other end of the cross arm cable (12) is connected with the transformer (1) through the short network (13), one end of the crystallizer cable (11) and one end of the bottom water tank cable (9) are connected with the crystallizer (5) and the bottom water tank (11) respectively, and the other end of the crystallizer cable (11) and the other end of the bottom water tank cable (9) are connected with the transformer (1). The crystallizer conducting continuous casting type electroslag remelting furnace has the advantages of low production electricity consumption, high production efficiency, simple production process, and higher yield than that of a continuous casting billet.

Owner:JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD

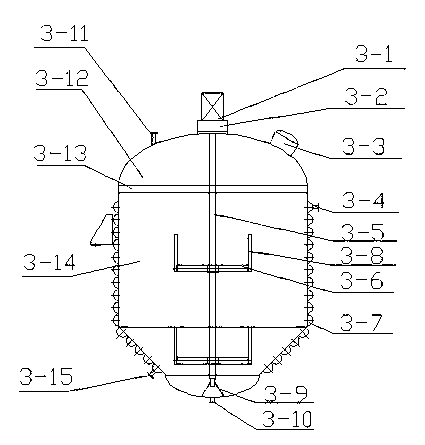

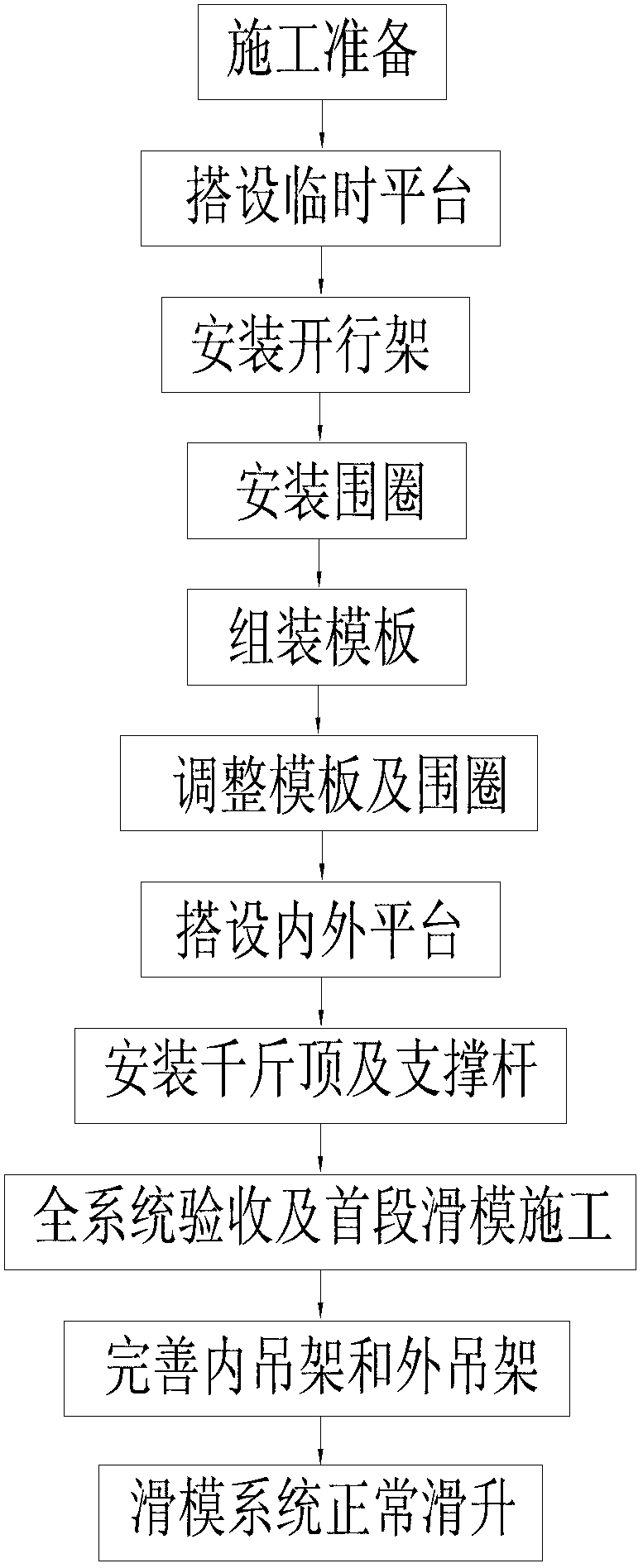

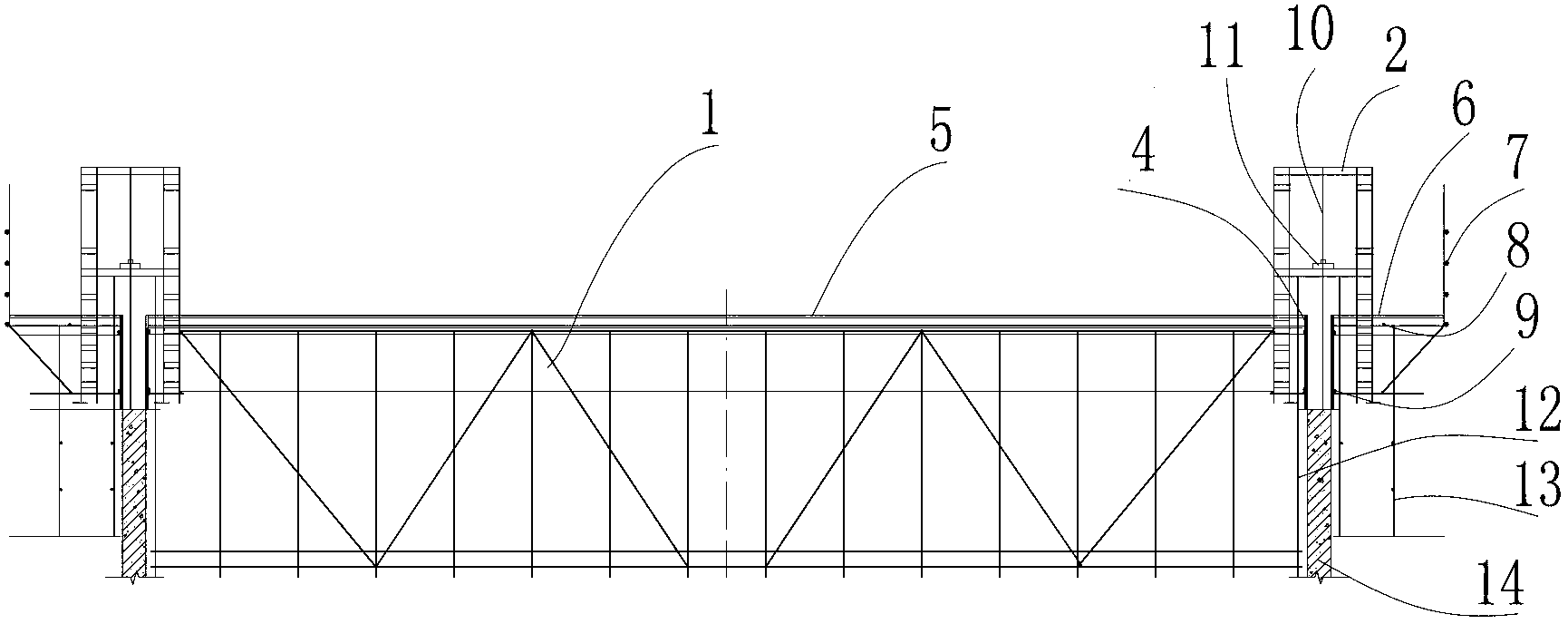

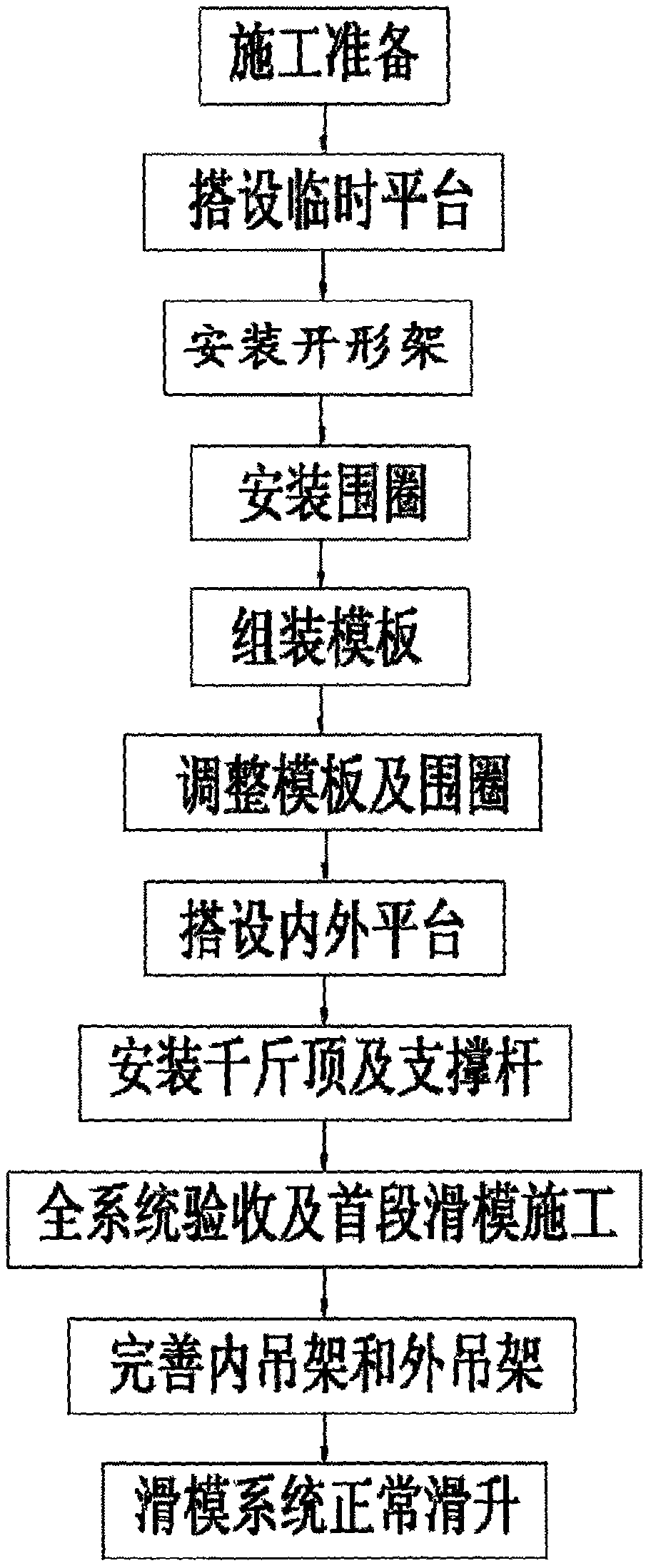

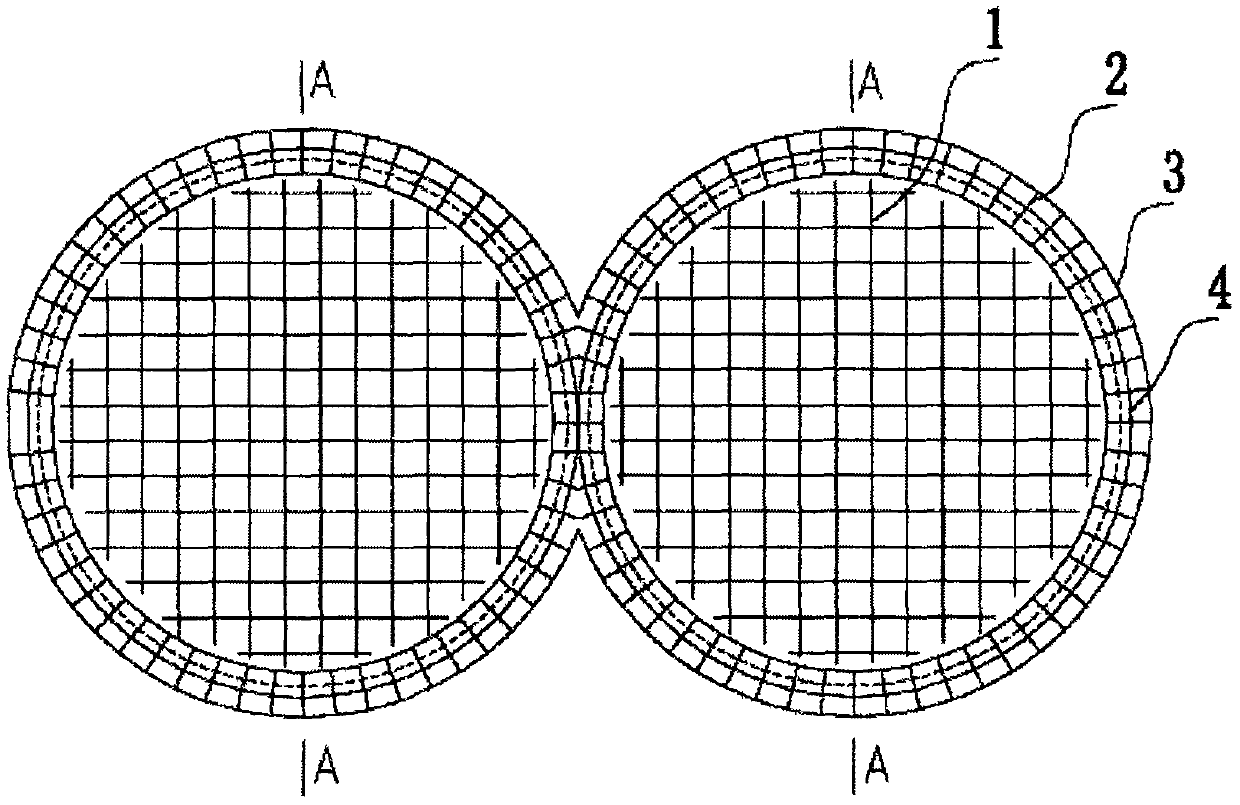

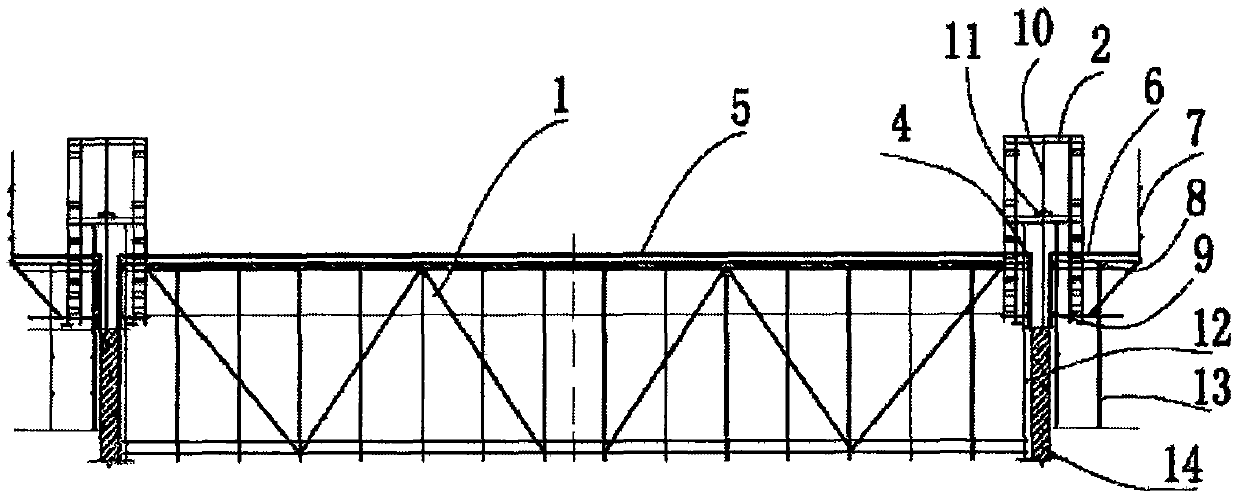

Hydraulic slip-form construction method of reinforced-concrete straight-drum high-rising building

InactiveCN102704681ASave processing feeSave on inactivity feesForms/shuttering/falseworksBuilding material handlingReinforced concreteArchitectural engineering

The invention discloses a hydraulic slip-form construction method of a reinforced-concrete straight-drum high-rising building. The hydraulic slip-form construction method specifically comprises the following steps of: a) building a temporary platform; b) installing an opened frame; c) installing enclosing rings; d) assembling a template; e) adjusting the template and the enclosing rings; f) installing an inner platform and an outer platform; g) installing jacks and supporting rods; h) inspecting the whole system and constructing a first-section slip form; i) improving an inner lifting frame and an outer lifting frame; and j) normally climbing a slip-form system. The hydraulic slip-form construction method has the advantages that the inner platform, the outer platform, the inner lifting frame, the outer lifting frame, the opened frame and the template enclosing rings of the slip form system adopt scaffold steel pipes and steel fasteners, simultaneously the connecting mode with the steel pipe fasteners is adopted between the template enclosing rings and the opened frame, between the opened frame and the inner and the outer platforms, and between the inner and the outer platforms and the inner and the outer lifting frames, thus the cost is low, the construction progress is high, the construction period of the engineering is shortened, simultaneously the processing and welding on site are reduced and further the environmental pollution is reduced.

Owner:GUIZHOU KAILIN CONSTR GRP CO LTD

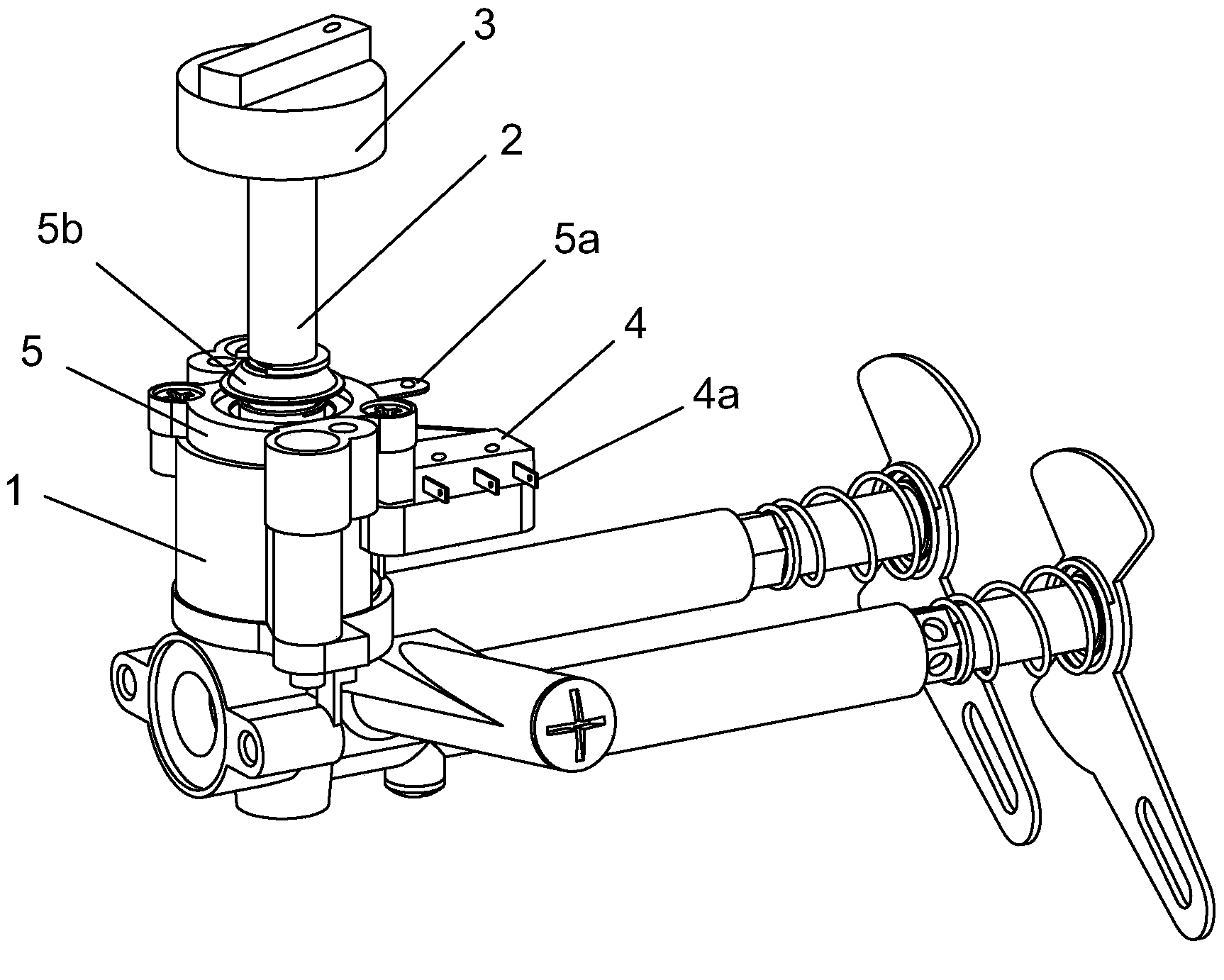

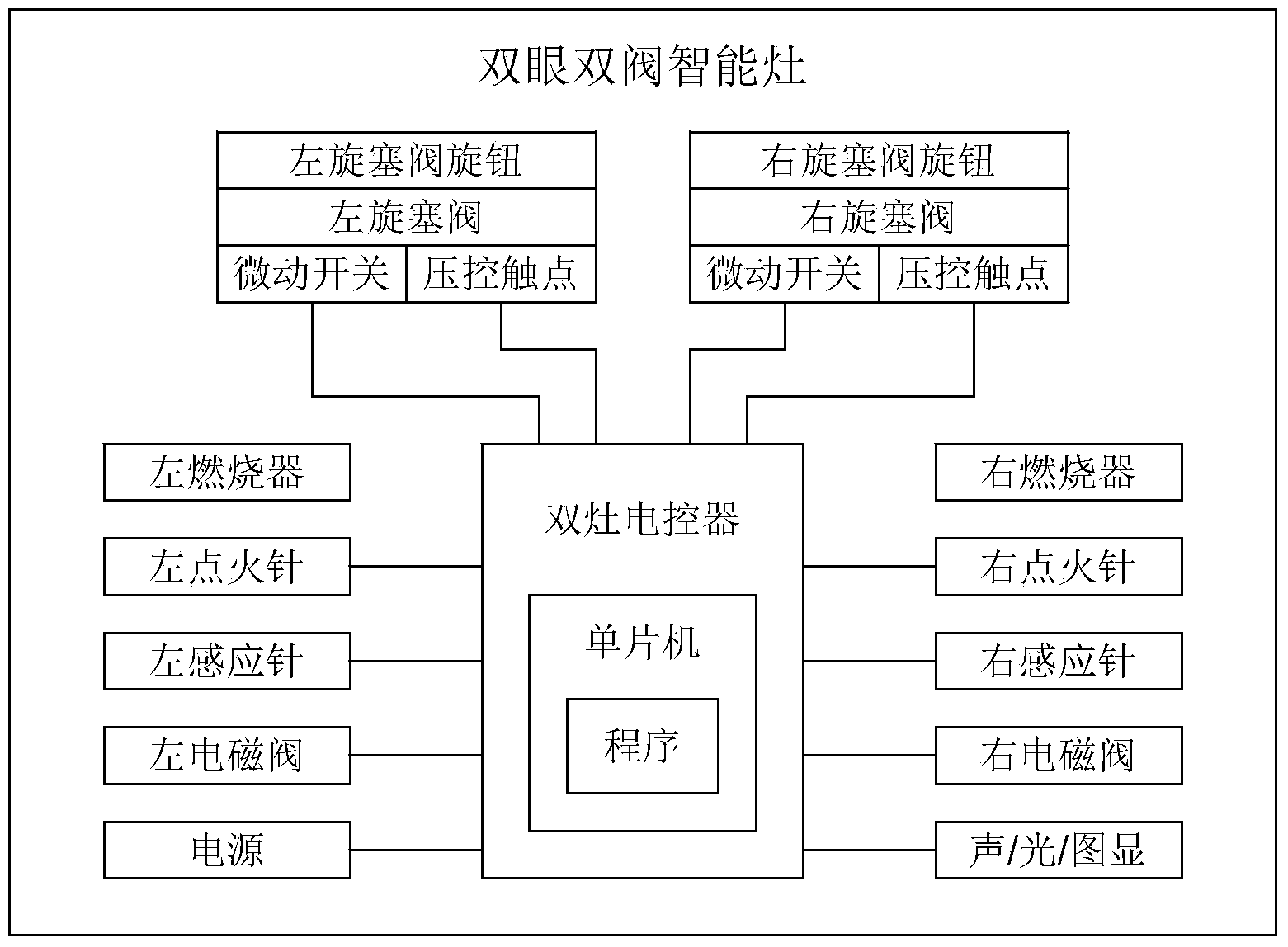

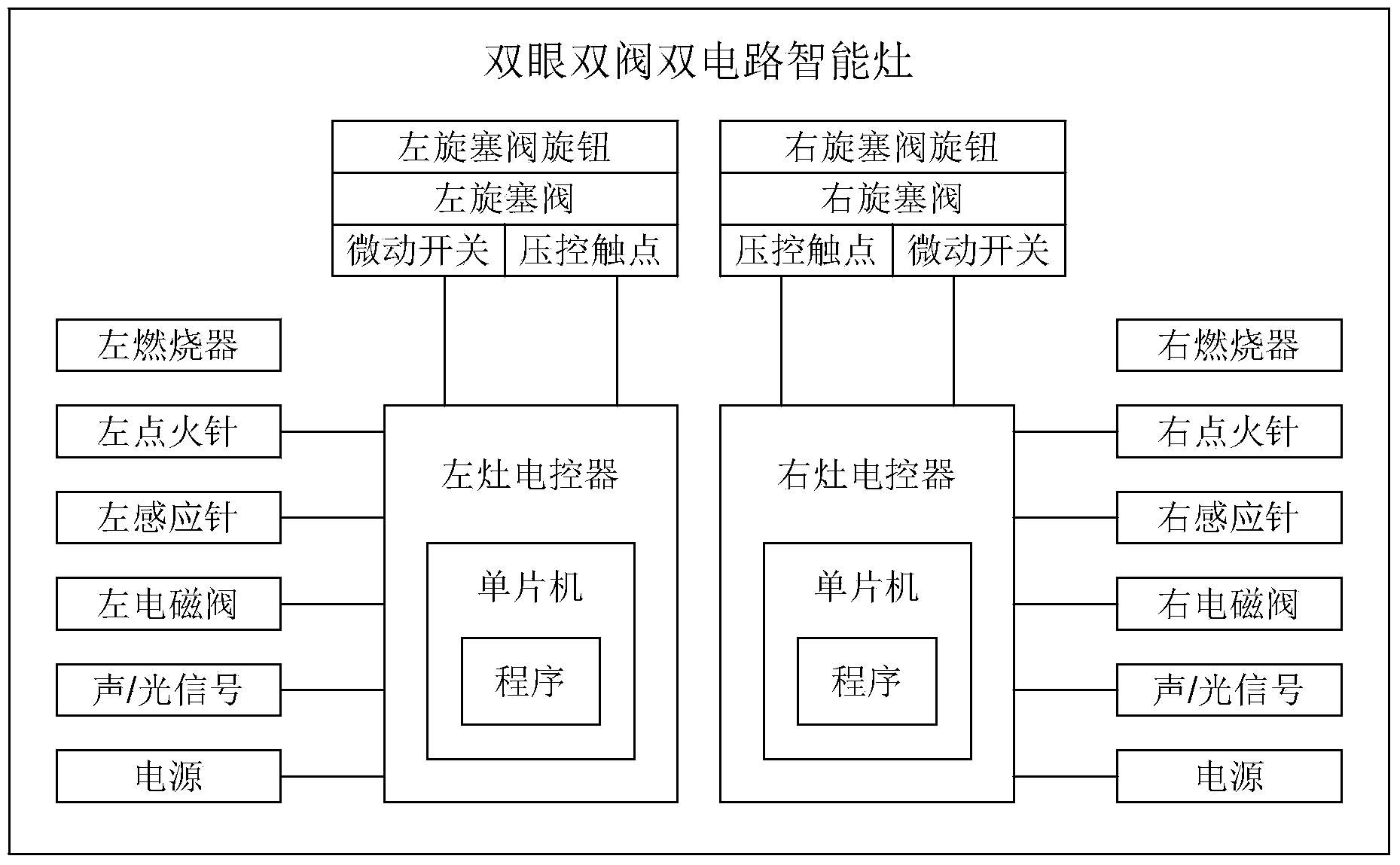

One-button operation system of gas stove and one-button intelligent gas stove

InactiveCN104165386AEasy to produceSave material costDomestic stoves or rangesOperating means/releasing devices for valvesMicrocontrollerControl engineering

The invention discloses a one-button operation system of a gas stove and the one-button intelligent gas stove, relating to a multifunctional one-button intelligent gas stove. The one-button operation system is technically characterized in that because a singlechip of the gas stove is equipped with a unique one-button operation system, the gas stove has unique strategies, neither support of multiple buttons nor control of complex gas electric control valves is needed, and functions such as child locking, temporary flame-out, timed flame-out, appointment, data checking and automatic report can be achieved by only ingeniously utilizing a plug valve assembly and a button of the plug valve assembly of a conventional gas stove. A microswitch and a voltage controlled contact on a plug valve are connected with an electric controller through leads so as to provide operation information of the knob for the singlechip, and programs relevant to novel functions of the knob are added into singlechip programs, so that a complete one-button operation system is formed, and function expansion and application of a single button are comprehensively supported. Functions of the gas stove are thoroughly upgraded by using software, and hardware does not need to be replaced, so that the operation is simple and feasible, and the cost performance is greatly improved.

Owner:李秋达 +1

Method for continuously preparing high-purity low-chloride electroplating copper oxide

InactiveCN103011251AHigh purityQuick responseCopper oxides/halidesBASIC CUPRIC CARBONATEBasic copper carbonate

Owner:TAIXING SMELTING PLANT

Method of storaging and treating fresh silkworm cocoon

The method for storing-treatment of the fresh silkworm cocoons incldues such steps as loading fresh silkworm cocoons in baskets, antistaling transporting in air-permeable coach without sunshining, stacking the baskets on the pallet far from ground, and storing in cold storage at -4-10 deg.C. Before the cocoons are used, they are defrozen at ordinary temp., and equilibrium treatment in cool wind. Its advantages are high cocoon quality and high silk output rate.

Owner:CHENGDU TIANCHUANG BIO TECH

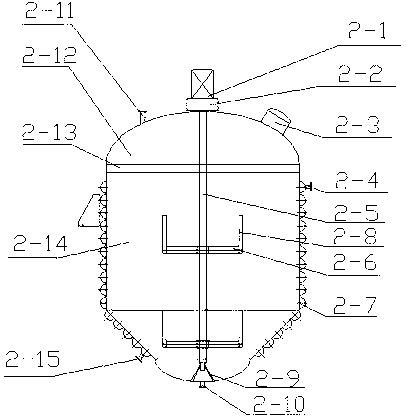

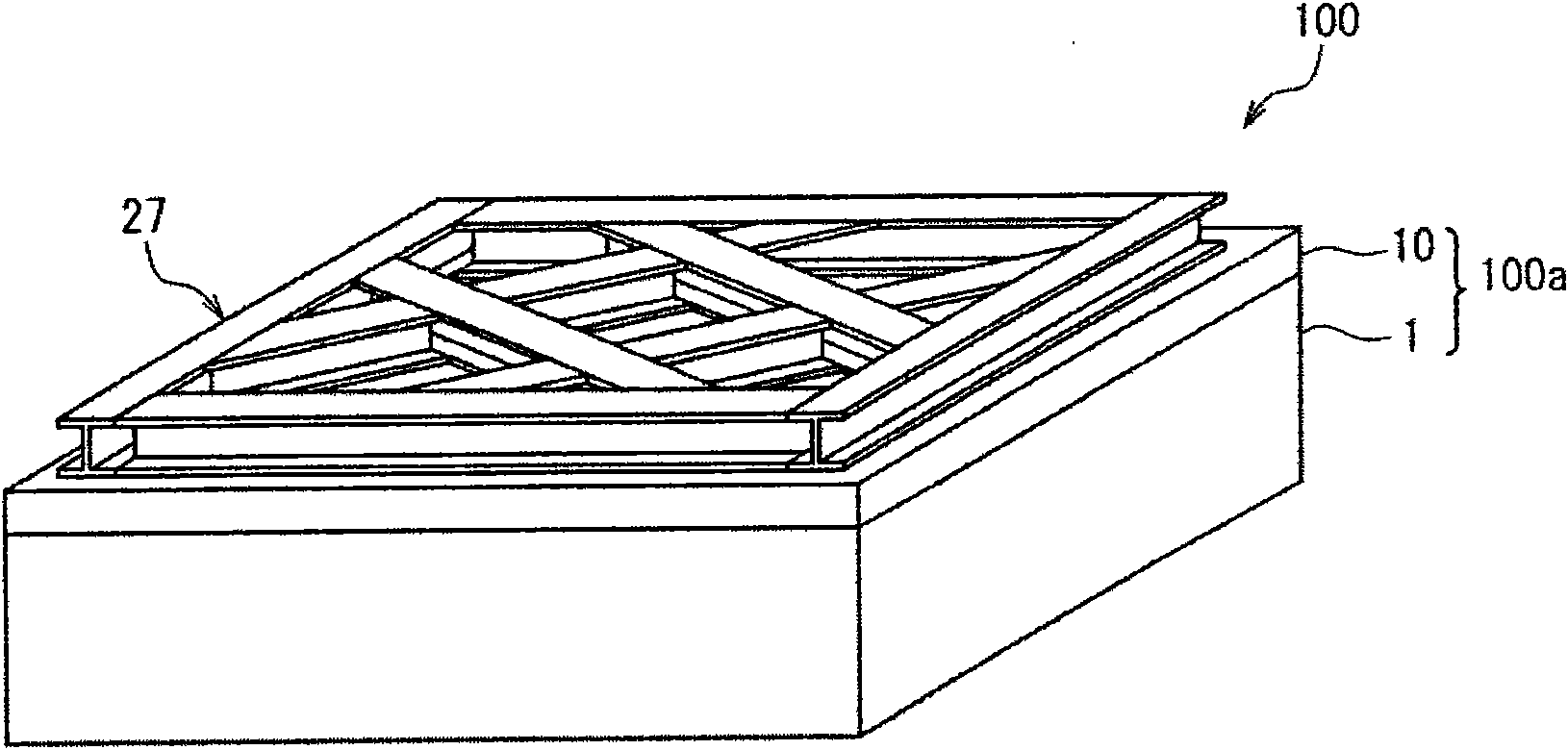

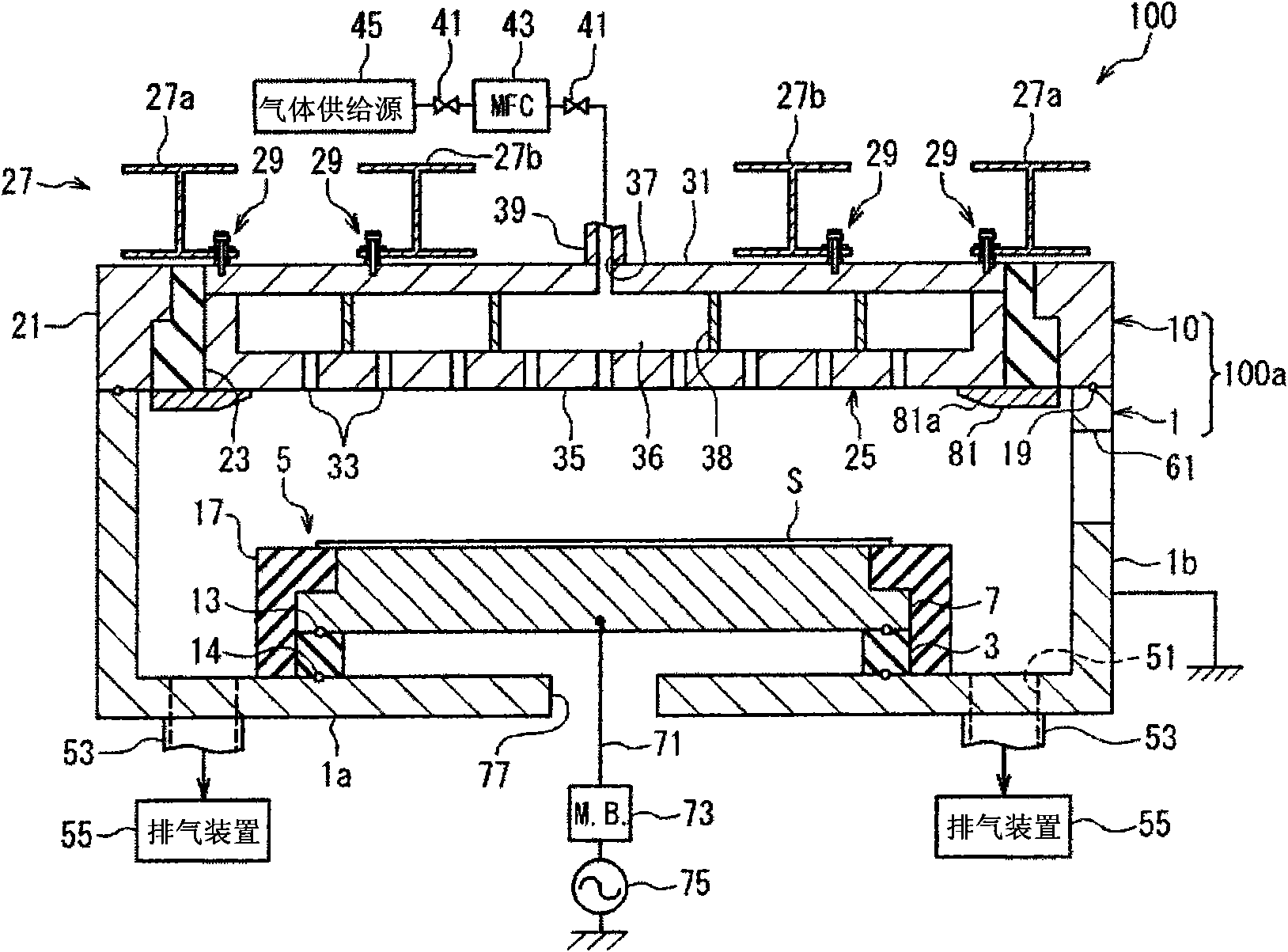

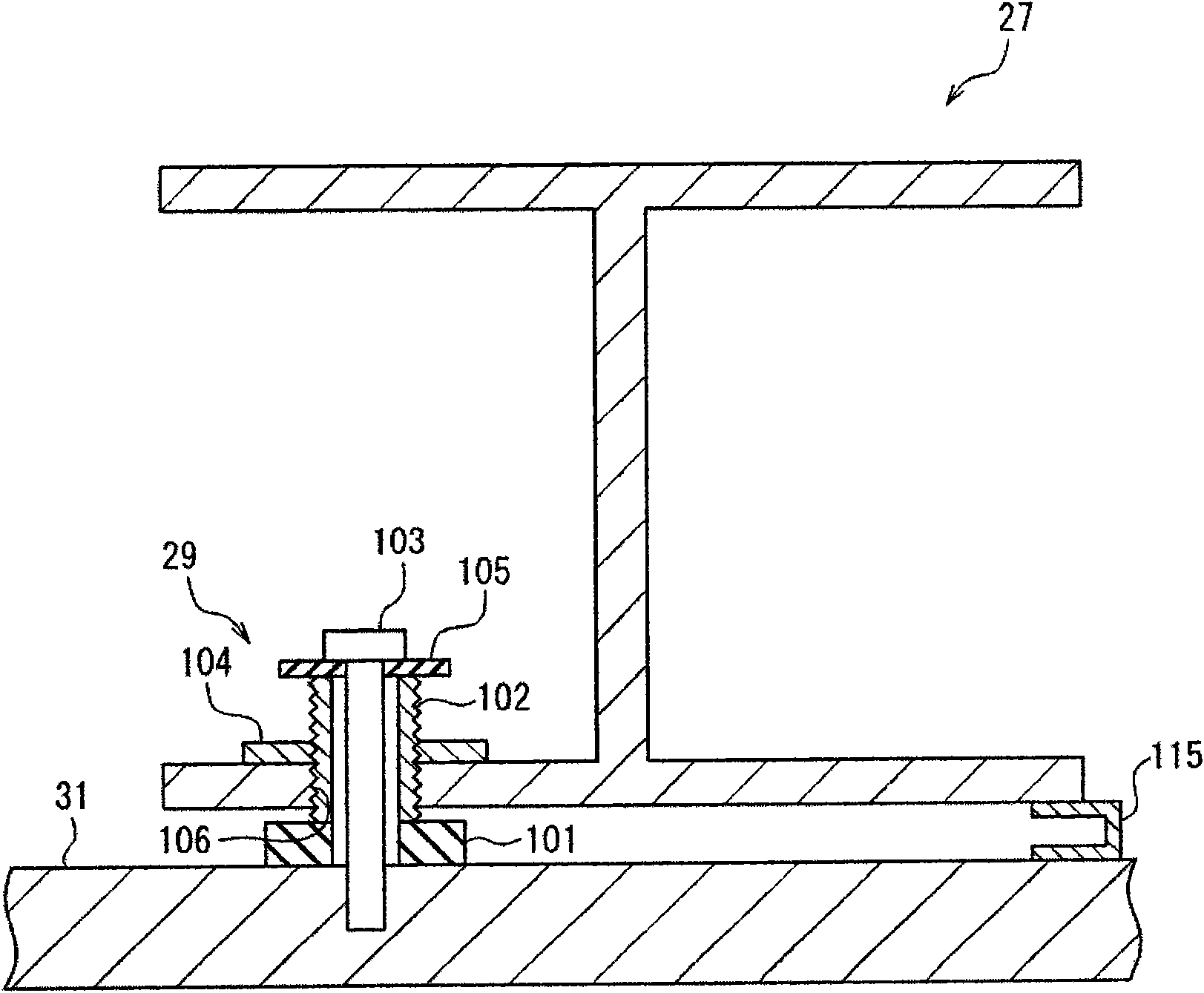

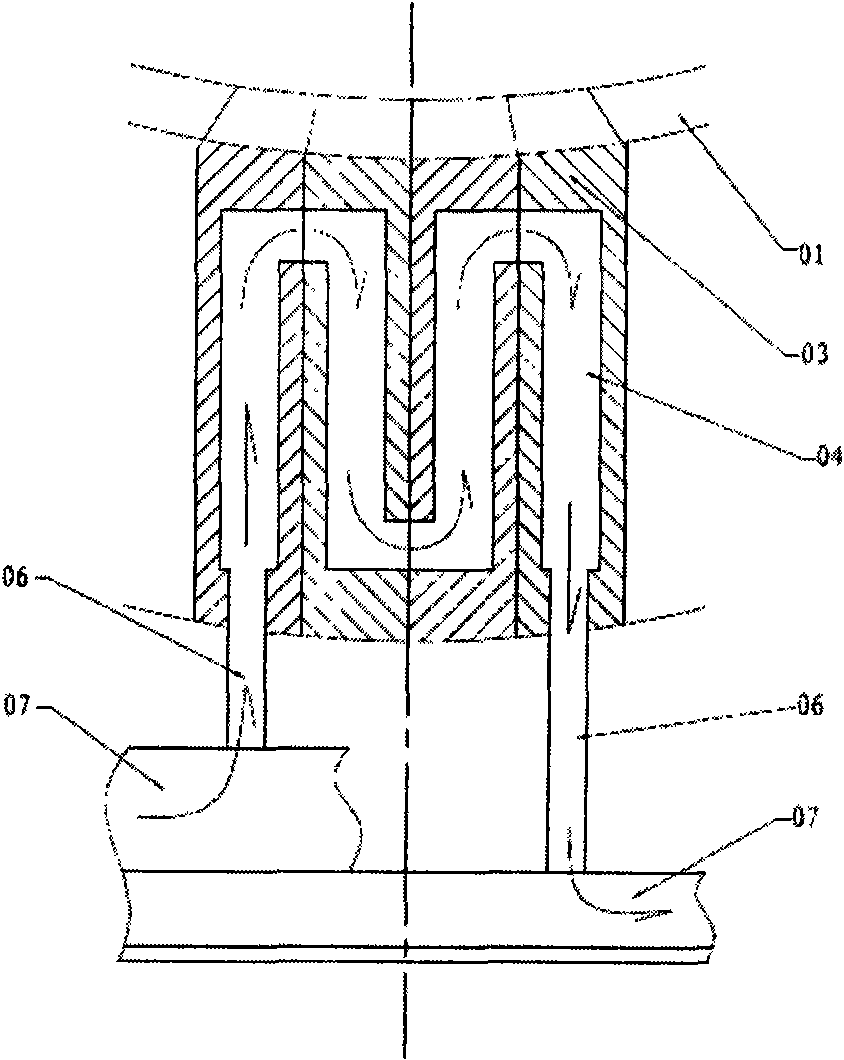

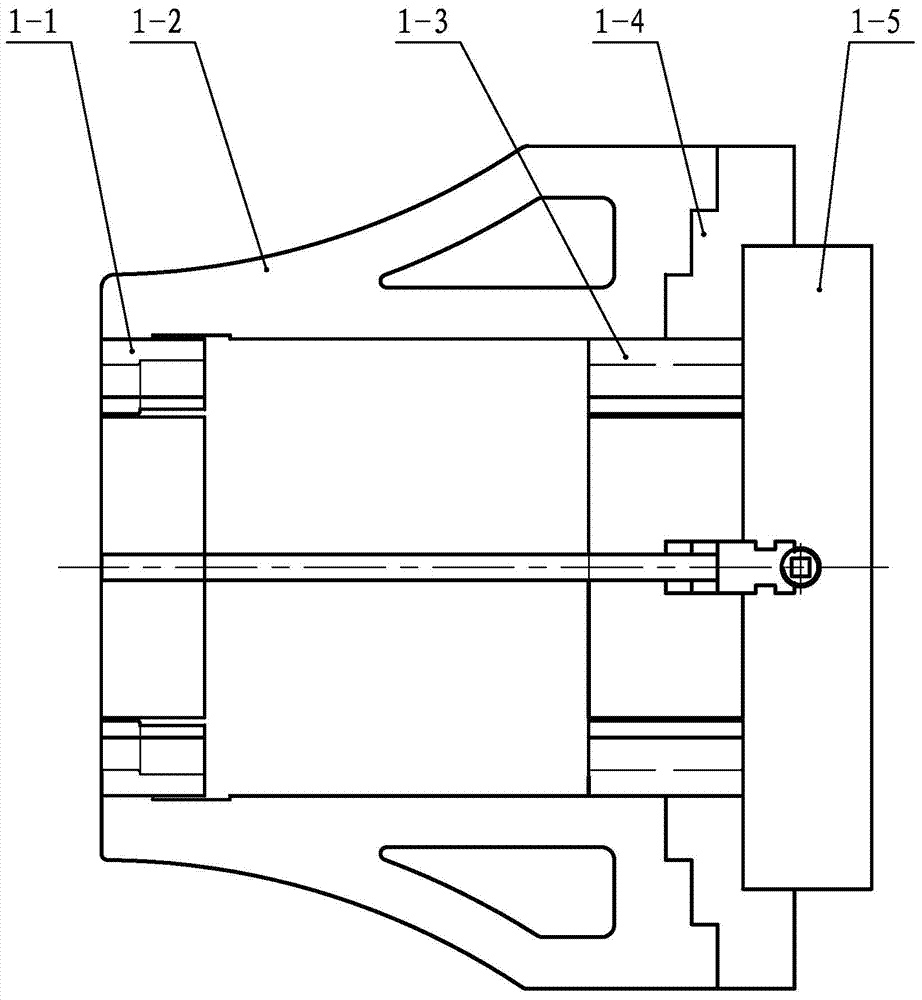

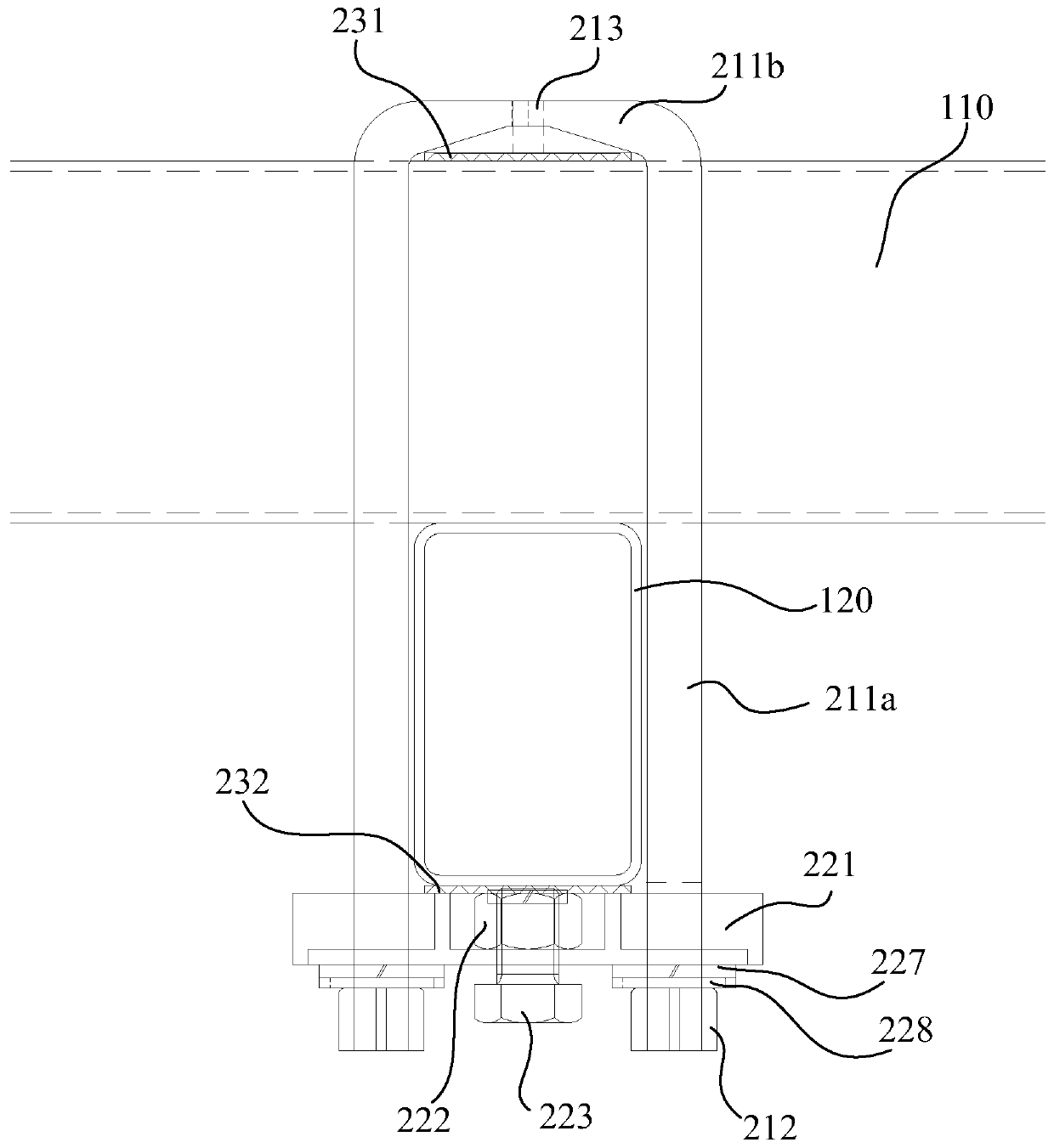

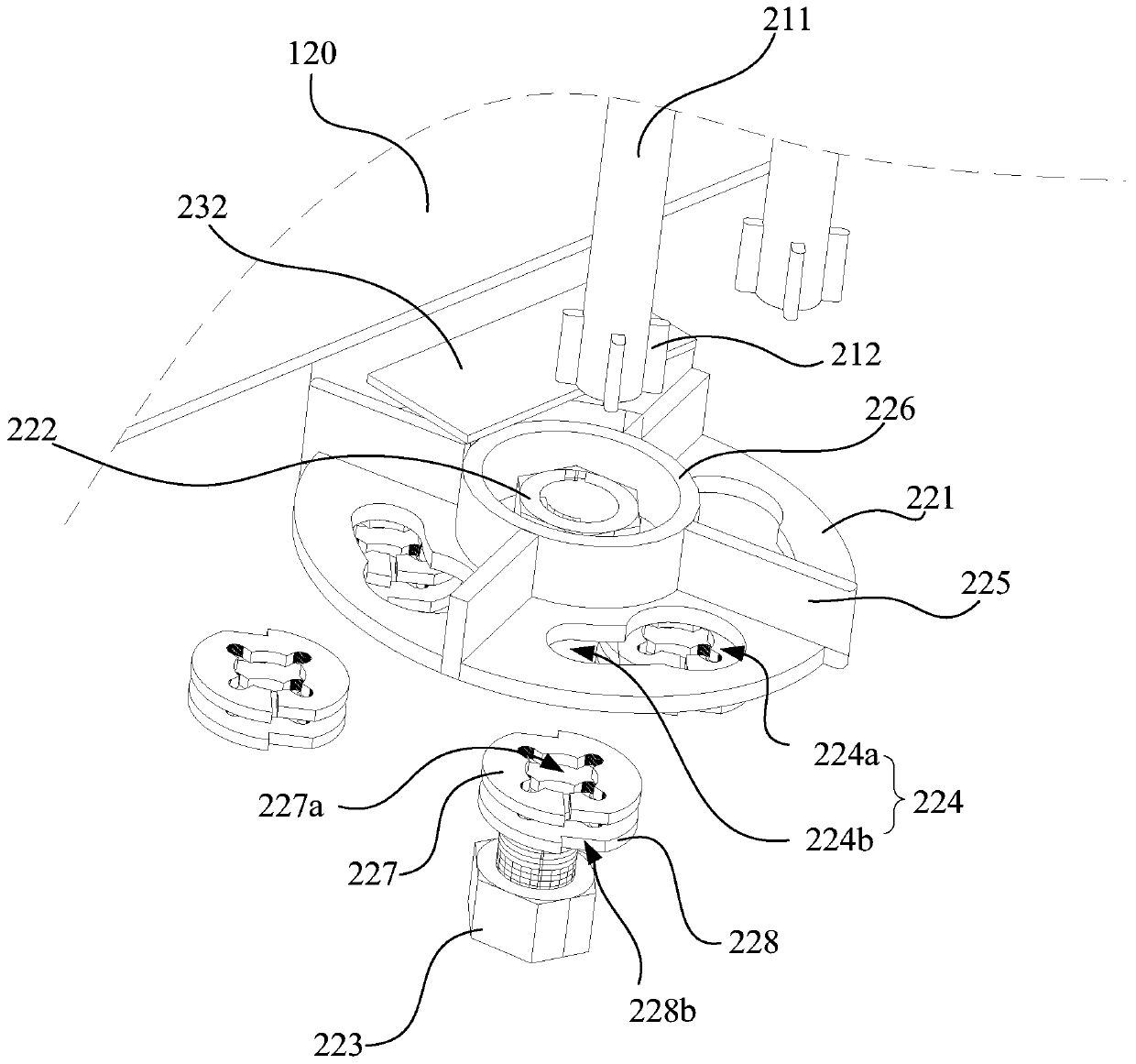

Vacuum container and plasma processing apparatus

ActiveCN101562126AWith compressive strengthSave processing feeElectric discharge tubesSemiconductor/solid-state device manufacturingEngineeringProcessing cost

The present invention provides a vacuum container, capable of keeping a sufficient mechanical strength and implementing a lightweighting, and reducing a material cost and a processing cost to the utmost. A plasma processing container (100a) includes a square tubular lower container (1) and an upper container (10) combining with the lower container (1). The upper container (10) has a frame (21), a spray head (25) connected to the frame through an insulating member (23), and a beam structure (27) arranged above the frame (21) and the spray head (25); a bottom board (31) composing the spray head (25) is exposed in an external space of the atmosphere pressure.

Owner:TOKYO ELECTRON LTD

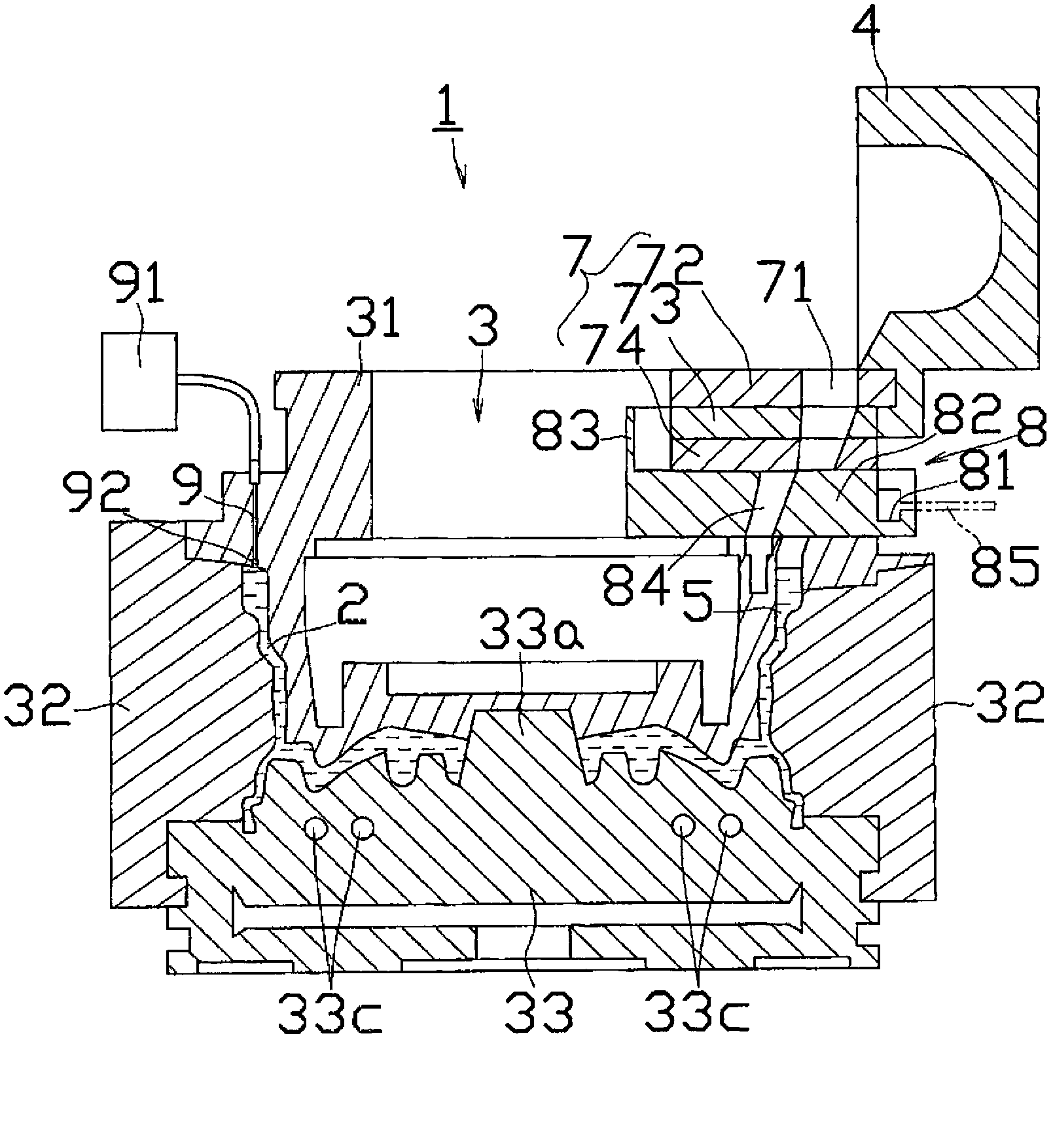

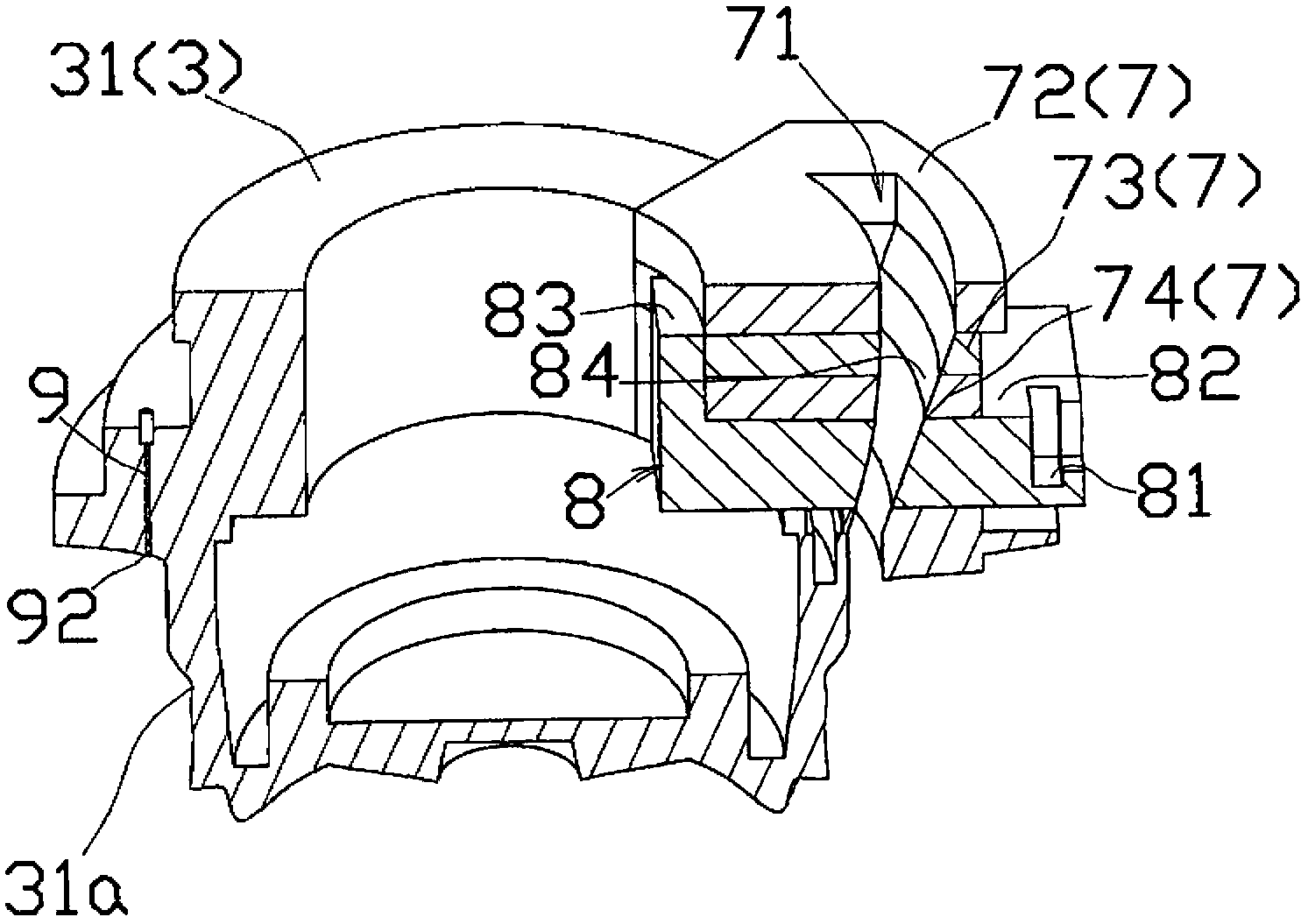

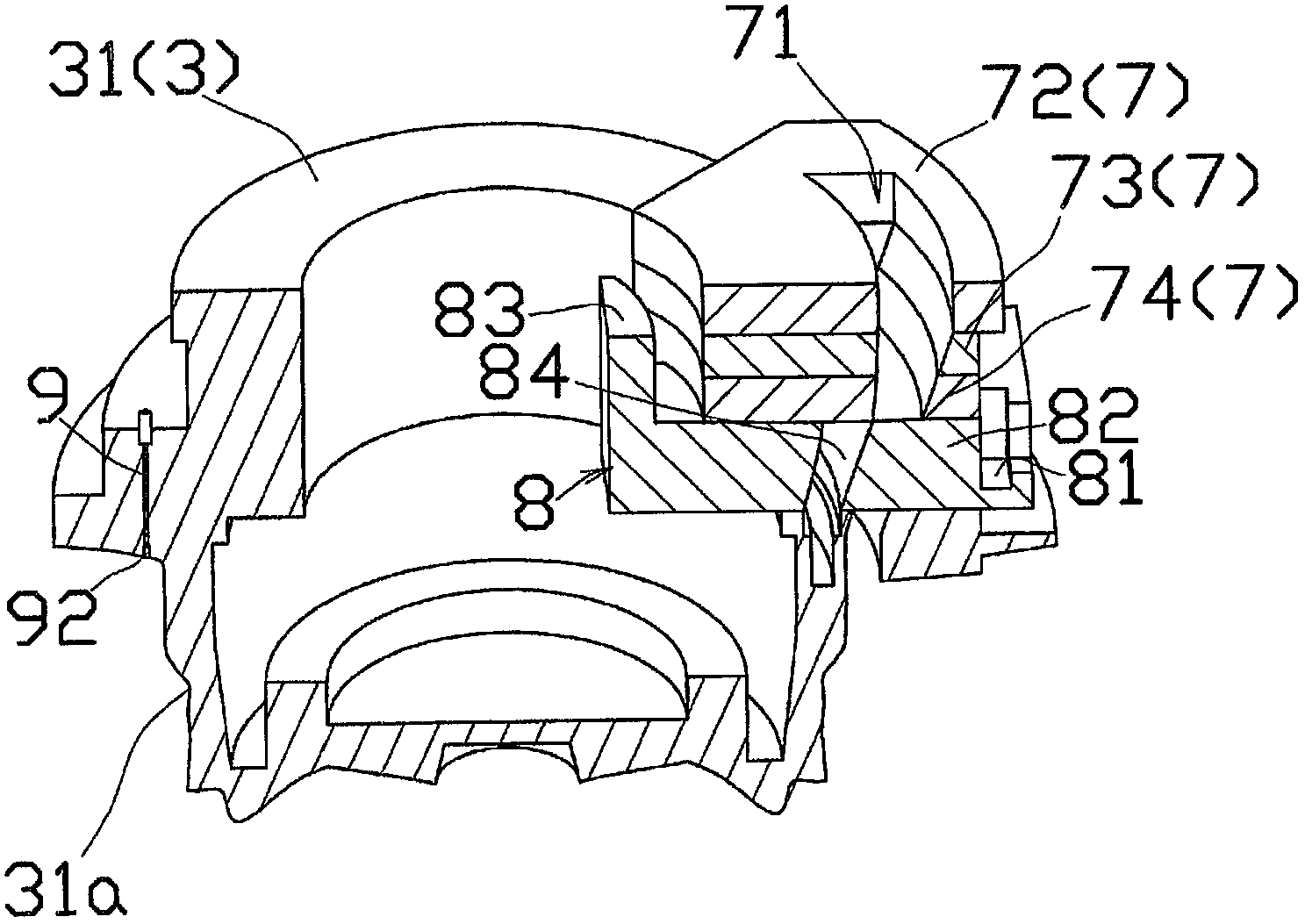

Tilt type gravity molding device

InactiveCN102712041AReduce the amount of timeReduce manufacturing costFoundry mouldsFoundry coresMetallurgyStanding Positions

A tilt type gravity molding device comprises: a mold (3) which can tilt between a fallen position and a standing position raised approximately 90 degrees from the fallen position; a pouring mold (7) in which a pouring gate (71) for guiding molten metal to the cavity (2) for forming a molded article is formed; and a bowl-like member (4) which contains the molten metal and pours the molten metal into the pouring gate (71) as the mold (3) tilts. In order to eliminate the need for a feeder head and for a reduction in the tilt speed and to enable the molten metal within the mold to be appropriately pressurized by gas, the tilt type gravity molding device also comprises: a blocking means (8) which is provided between the pouring gate (71) and the cavity (2) and which can open and close the pouring gate (71); a gas opening (9) which is provided at the upper part of the mold (3) in the standing position, prevents the molten metal from flowing to the outside of the mold (3), and permits only gas to pass therethough; and a gas supply means (91) which can supply a high-pressure gas to the gas opening (9).

Owner:MORIKAWA KANAGATA

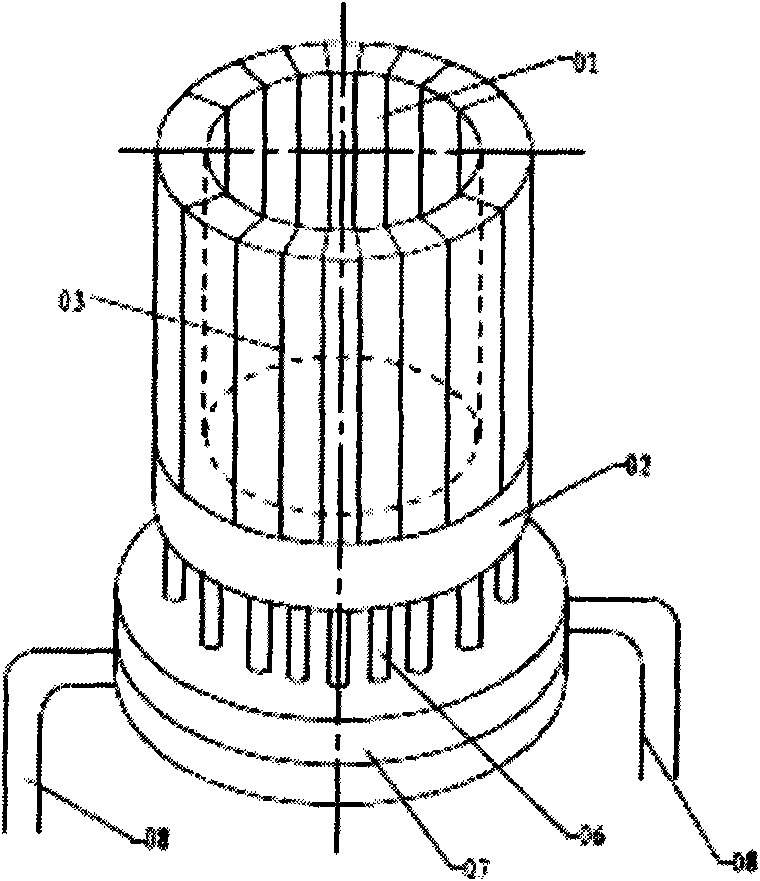

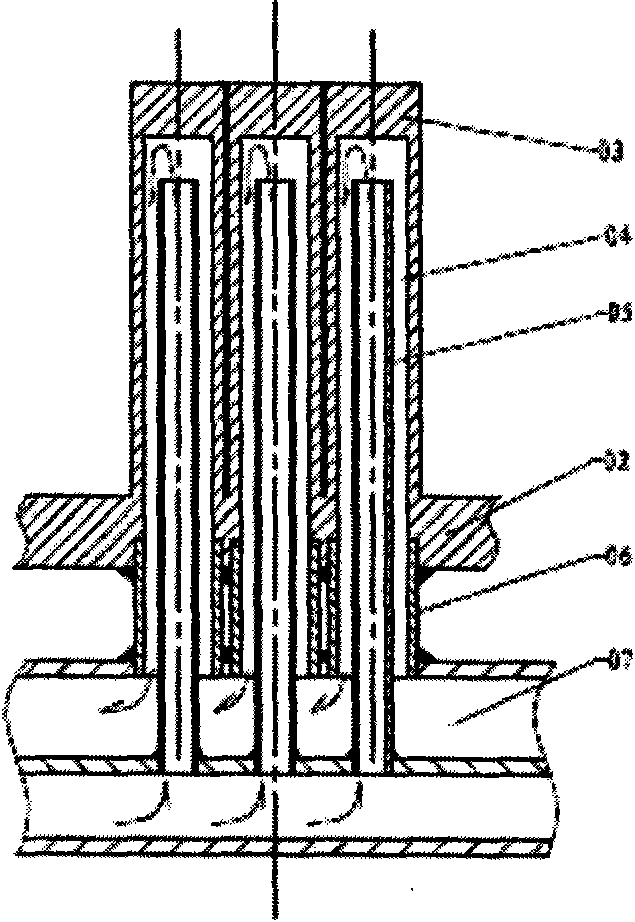

Single-waterway split cold crucible for induction melting and manufacture method thereof

The invention relates to a structural designing and manufacturing method of a cold crucible for vacuum induction melting, in particular to a structural designing and manufacturing method of a cold crucible provided with a single-layer pipe cooling passage and spliced by simple elements. A crucible bottom and a crucible wall are of a split structure, the crucible wall is spliced by same crucible discs with simple structures, a cooling passage adopts a crawl single-layer pipe mode, and the whole cooling passage is seperated into a plurality of crawl units; each crawl unit comprises independent inlet and outlet and a plurality of passage sections, wherein a first passage section enters into a second passage section after passing through a crucible disc and bending 360 degrees and passes through next crucible disc in negative direction, and the rest can be done in the same manner, the trend of each section is along the length direction of the crucible discs; each crawl unit can comprise one, two, three or more passage sections, and the largest number of the passage sections can be equal to the number of the crucible discs. Because the cooling passages pass through every crucible disc, the crucible discs are provided with inner holes vertical to end faces.

Owner:贵阳泉丰装备制造有限公司

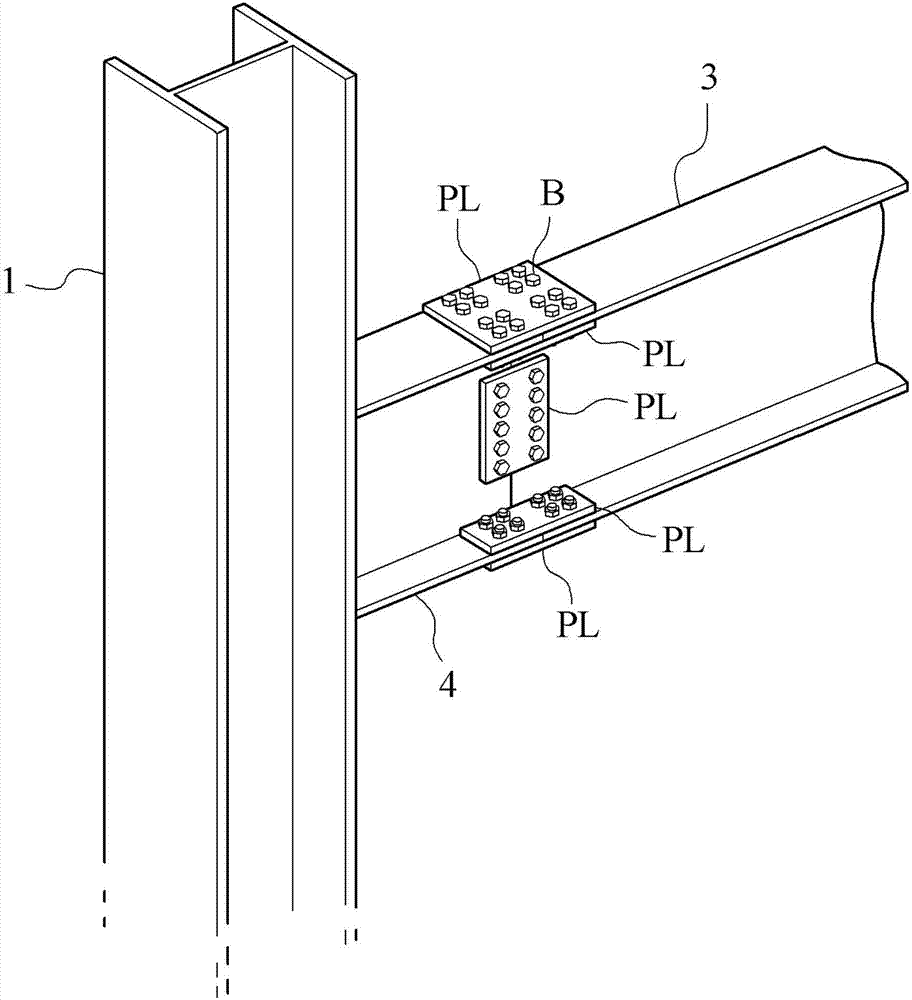

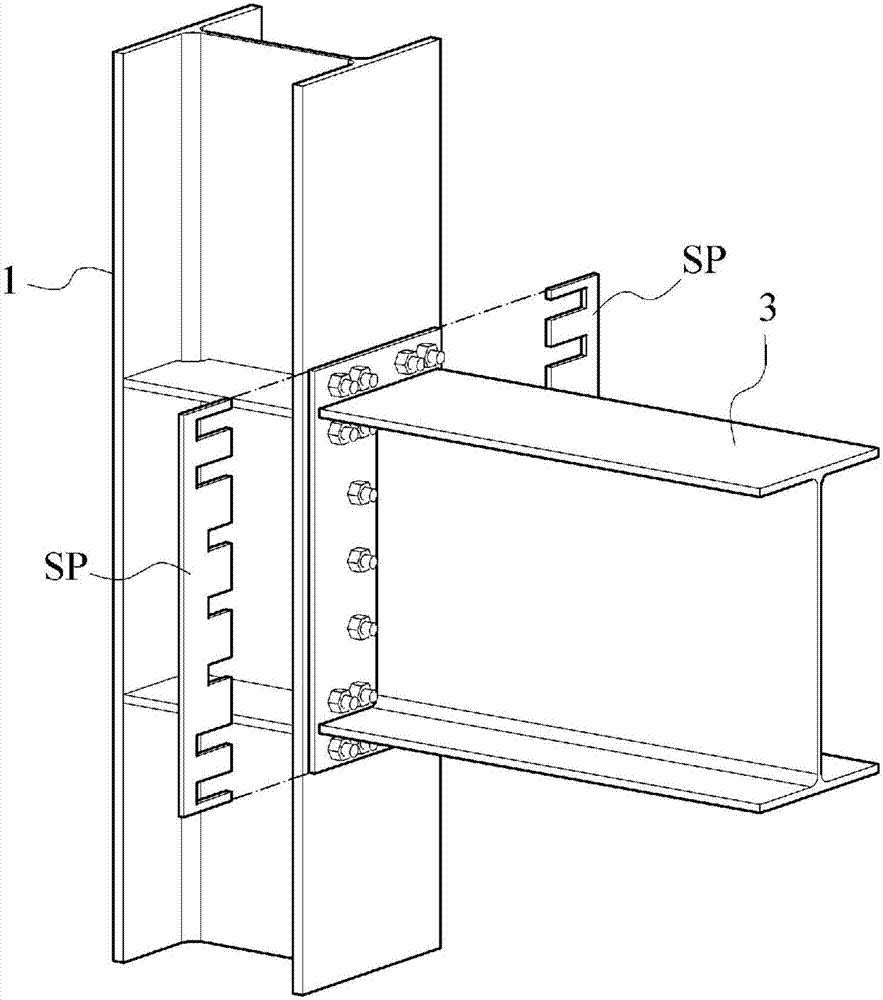

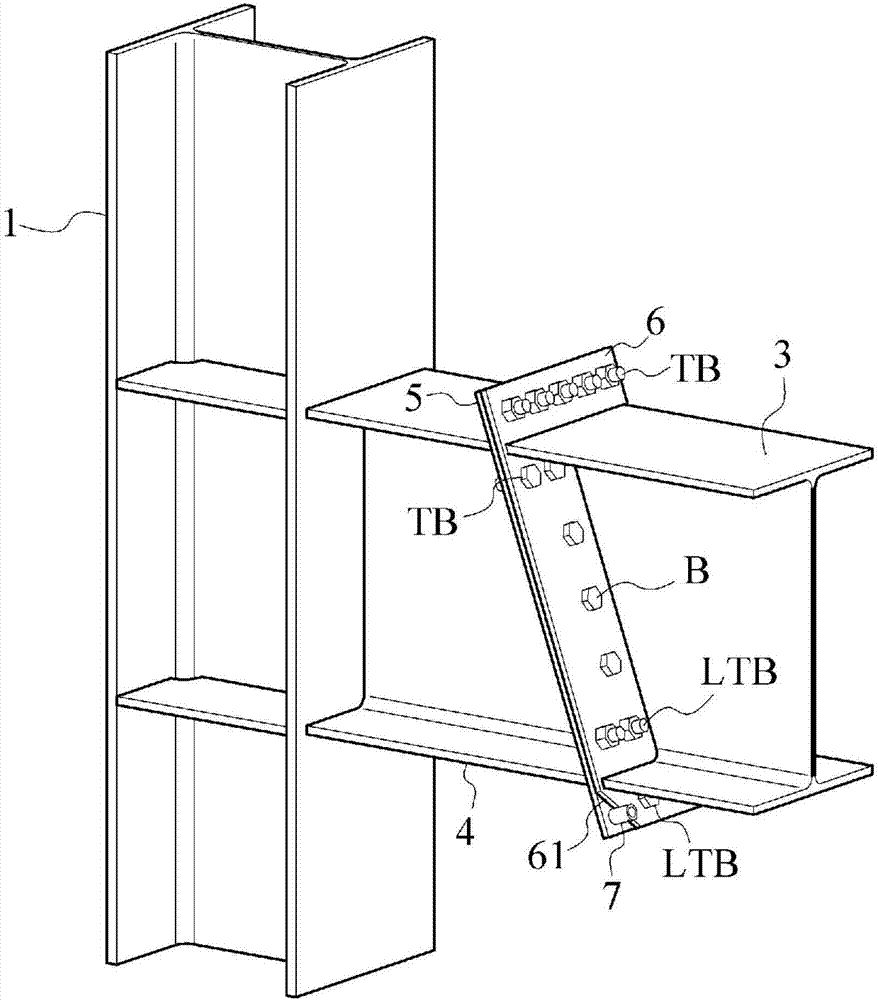

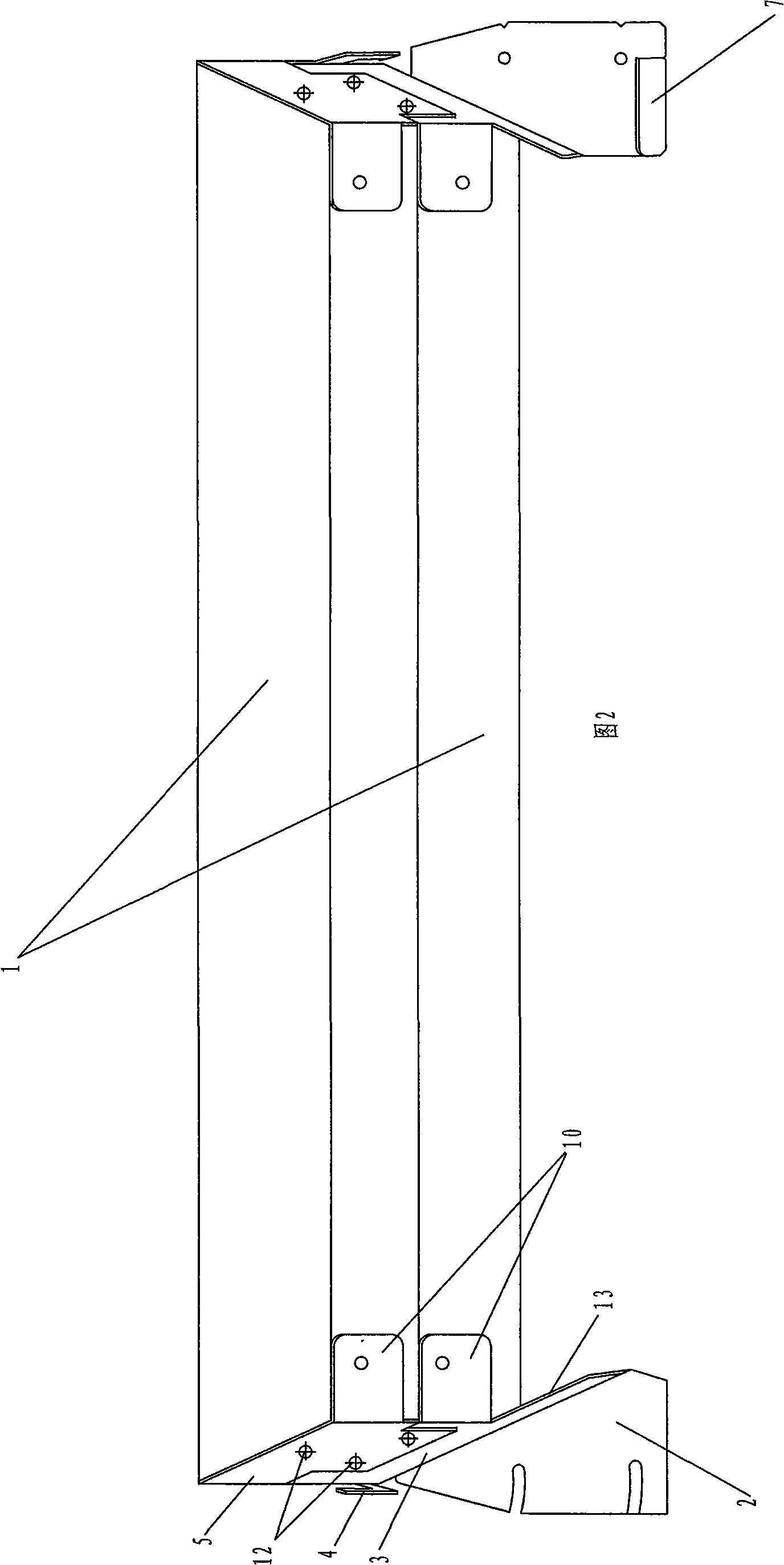

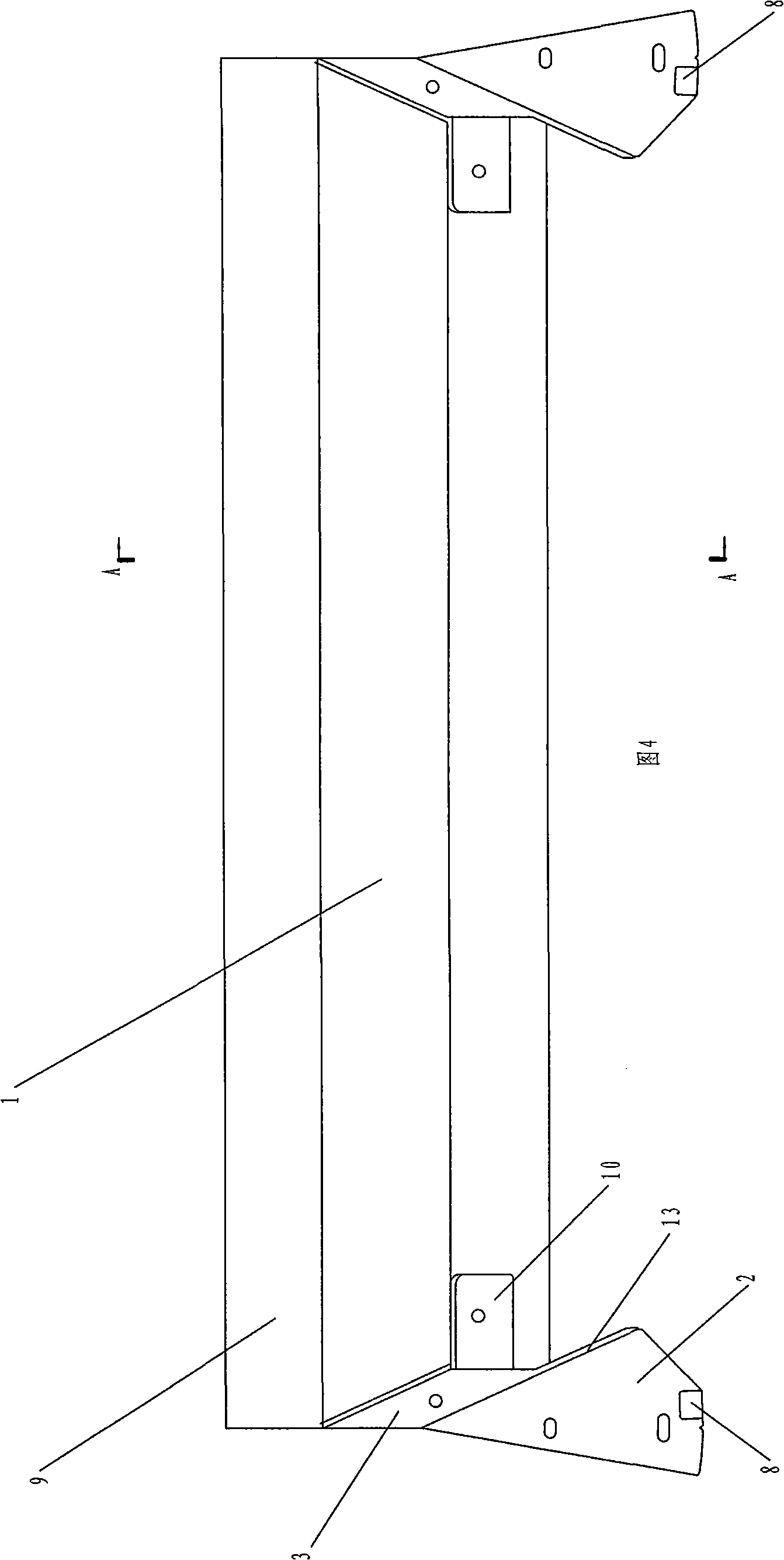

Steel beam attachment structure

ActiveCN107208413AReduce the numberImprove economyConstruction materialSunshadesPull forceAcute angle

The present invention relates to a steel beam attachment structure for coupling a steel beam to the lateral side of a large beam or a pillar and, more specifically, to a steel beam attachment structure enabling a huge decrease in the number of bolts by means of effective transmission of shear force due to a simple structure of the attachment surface of a steel beam and a bracket. In a steel beam attachment structure, according to the present invention, a bracket is coupled and fixed to the lateral side of a large beam or a pillar and a steel beam is coupled to the bracket such that the steel beam is coupled to the lateral side of the large beam or the pillar. One end of the bracket is coupled to the lateral side of the large beam or the pillar, and the other end is inclined such that the lower part thereof forms an acute angle, wherein a first attachment plate is coupled to the inclined end part of the bracket such that a fixed length thereof protrudes from the upper end of the bracket. The lower part of one end of the steel beam is inclined at an obtuse angle so as to correspond to the other inclined end of the bracket, wherein a second attachment plate is coupled to the inclined end part of the steel beam such that a fixed length thereof protrudes from the upper end of the steel beam. The bracket and the steel beam comprise an upper flange and a lower flange, respectively, and a web for connecting the upper and lower flanges, wherein the first attachment plate and second attachment plate are coupled and mutually attached by means of tensioning bolts above and below the upper flange of the steel beam and the bracket.

Owner:SAMSUNG C&T CORP +1

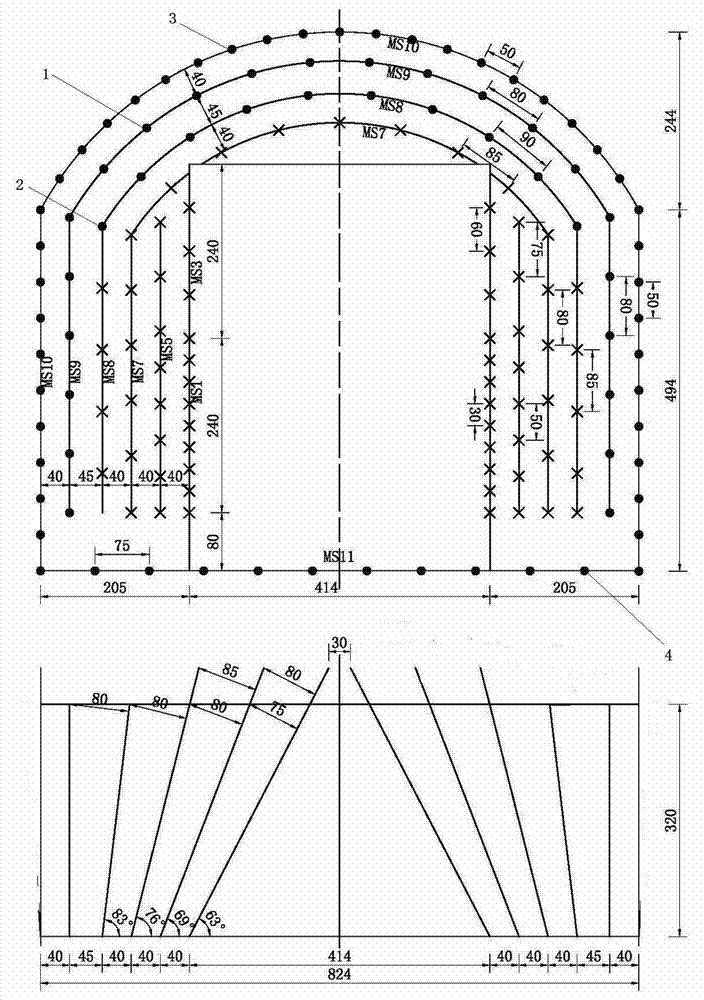

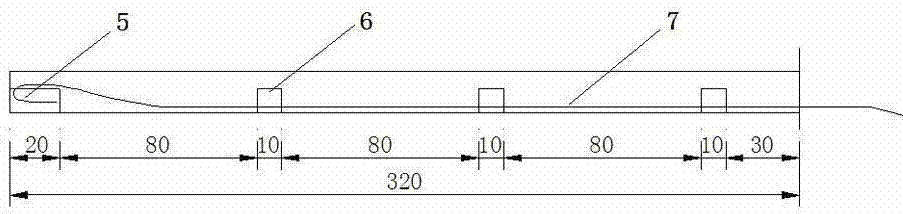

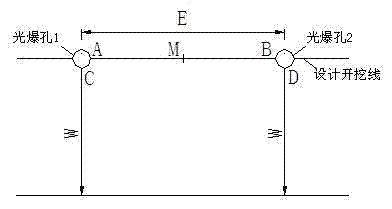

Smooth blasting method based on phi 32 mm cartridges

The invention provides a smooth blasting method based on phi 32 mm cartridges. The method includes the steps that punching, powder charging and the initiation process are conducted on a working face, and a smooth blasting layer is composed of a peripheral smooth blasting hole array located on the outer side and more close to the boundary of the top, and an outer ring spallation hole array located in the peripheral smooth blasting hole array. The density coefficient m of peripheral smooth blasting holes ranges from 1.25 to 1.43. Charged powder in the peripheral smooth blasting holes in the peripheral smooth blasting hole array comprises bottom charged powder located at the bottoms and multiple bags of middle charged powder located at different depths in the holes. The powder charging amount of the middle charged powder is smaller than that of the bottom charged powder. The intervals between the bottom charged powder and the middle charged powder and between the bags of the middle charged powder are the same, and the initiation time of the peripheral smooth blasting hole array is later than that of the outer ring spallation hole array. Smooth blasting powder string processing procedures and processing materials are reduced; smooth blasting powder string processing cost, and cost of materials such as bamboo chips and adhesive tape are saved, and over-excavation is effectively controlled, so that a large amount of concrete backfill caused by over-excavation is reduced, and construction cost is reduced.

Owner:SINOHYDRO BUREAU 5

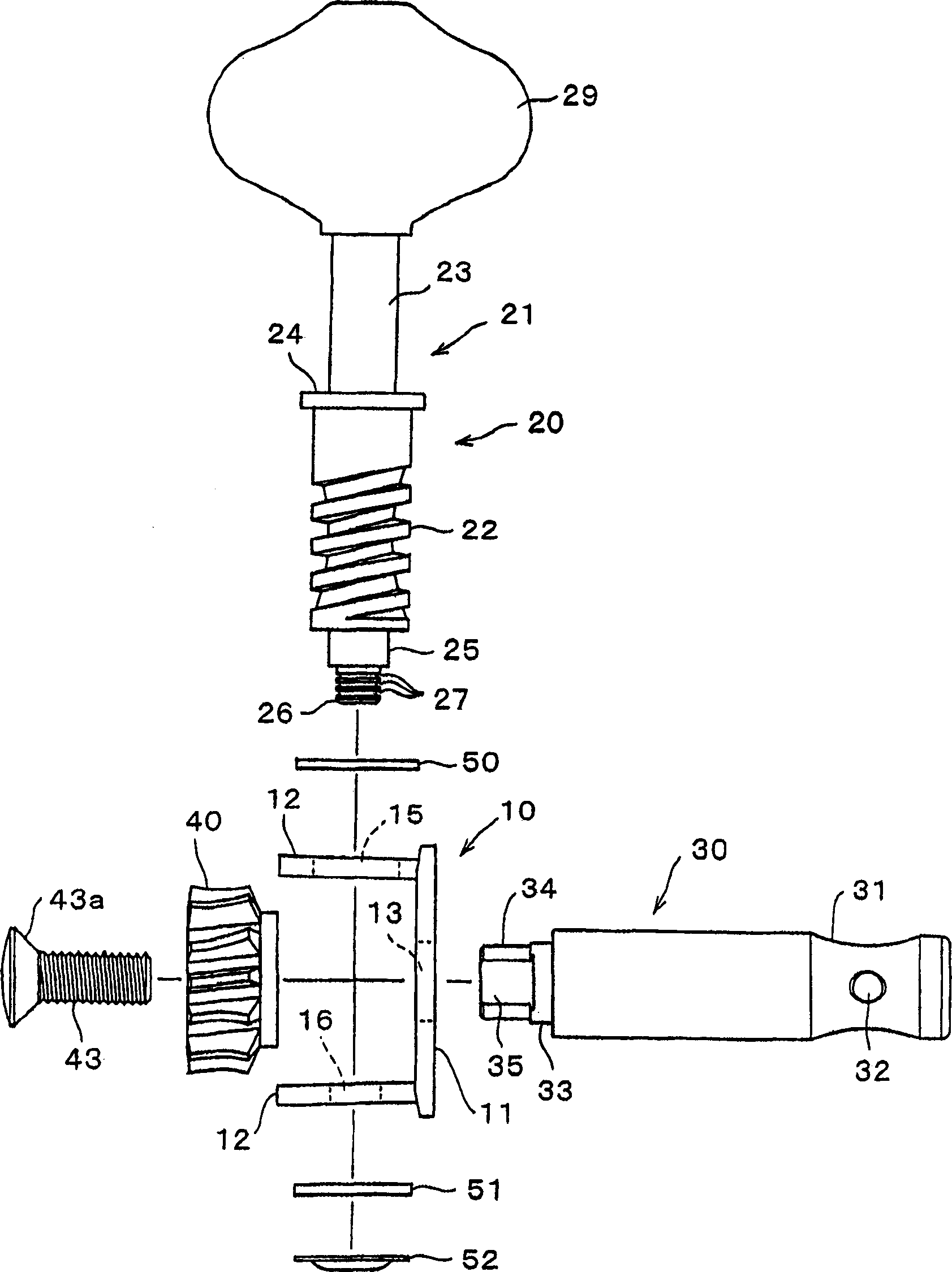

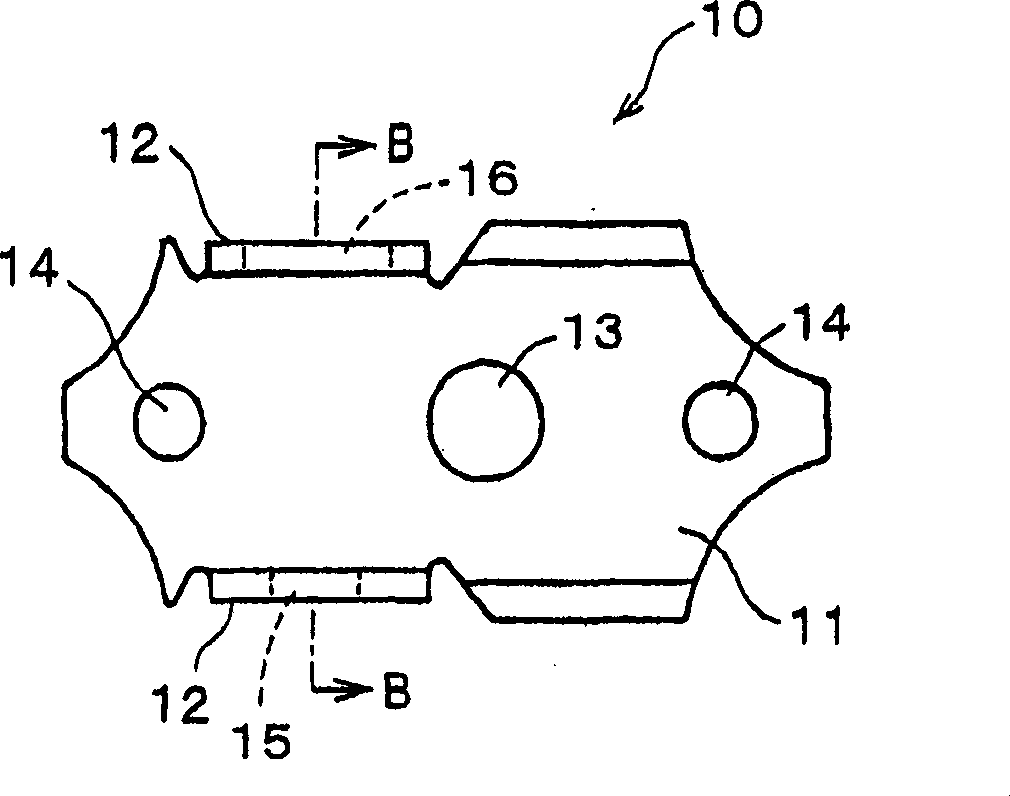

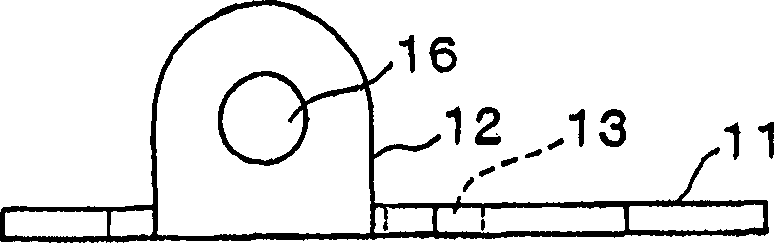

Chord axis apparatus for stringed instrument and its manufacture method

A stringed instrument string winder, comprising a main body (10), bearings (12) rising from both sides of the main body (10) and opposed to each other, a worm gear (21) supported rotatably on a largediameter hole (15) and a small diameter hole (16) of the bearings(12) and having a peg (29) at one end part thereof, and a windup shaft (30) connected to the worm gear (21) through a worm wheel (40),wherein the bearings (12) are made of a spring material, whereby an elastic limit of the bearings is increased to prevent a deformation from occurring.

Owner:GOTOH GUT

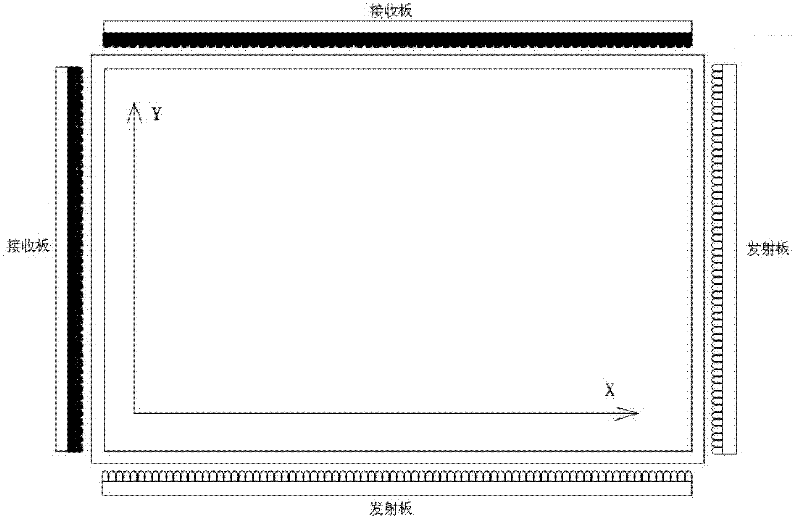

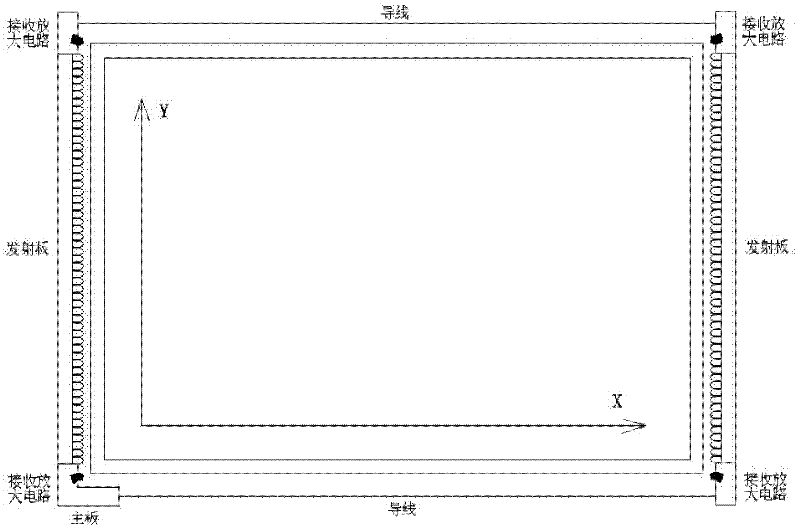

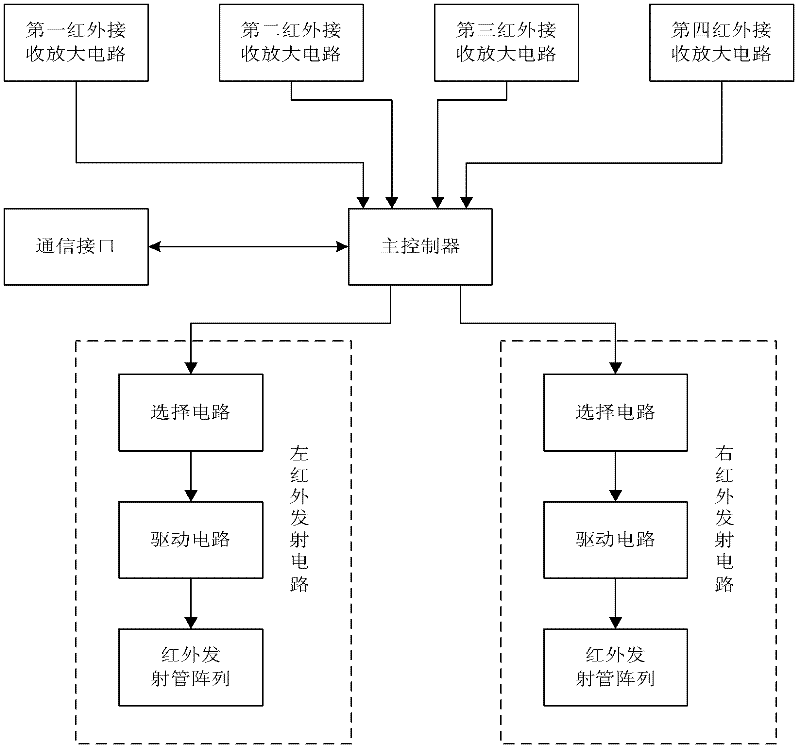

Infrared electronic whiteboard and control method

ActiveCN102339173ASave processing feeLow failure rateInput/output processes for data processingWhiteboardInfrared

The invention discloses an infrared electronic whiteboard and a control method. The infrared electronic whiteboard comprises a rectangular screen and a whiteboard circuit, wherein the whiteboard circuit comprises a control circuit, an infrared receiving circuit, a first infrared transmitting circuit and a second infrared transmitting circuit; each infrared transmitting circuit comprises a plurality of infrared transmitting tubes; the circuit board of the first infrared transmitting circuit and the circuit board of the second infrared transmitting circuit are oppositely arranged at the two rim parts of the rectangular screen; the infrared receiving circuit comprises four infrared receiving tubes; and the four infrared receiving tubes are respectively arranged at four corners of the rectangular screen. The infrared electronic whiteboard has the advantages of simple circuits, a few components, low fault rate and low cost; and the response speed and the whole anti-interference capacity of the infrared electronic whiteboard are improved.

Owner:HITEVISION CO LTD

Thormobend shaping method of rubber sealing strip for automobile door window and its mould

ActiveCN100999132ASave processing feeSolving Quality Control IssuesDomestic articlesVulcanizationMechanical engineering

The present invention discloses a thermobending setting method of glass guide channel rubber weather strip for automobile door and window and its mould. Said method includes the following steps: (a), marking out on the position of rubber weather strip extruded and vulcanized by rubber extruding machine and said position can be thermally bent; (b), positioning the rubber weather strip on the setting mould, heating and vulcanizing; and (c), taking out said rubber weather strip, naturally cooling so as to implement thermobending setting operation. Said mould includes bending-setting mould, movable mould and lower template.

Owner:萨固密渝锦(重庆)橡塑制品有限公司

Black sesame syrup and its making method

InactiveCN1473514AConducive to correcting deficienciesHigh medicinal valueFood preparationLeakage testImpurity

The present invention relates to the production process of black sesame syrup with unique taste, rich nutritive components and special medicinal value. The material includes black sesame in 65-80 wt% and black bean in 20-35 wt%, and the production process includes eliminating impurities, water washing, soaking, milling to produce milk, steam heating, cooling, adding supplementary material, homogenizing, packing, sterilizing, cooling, turning up, and leakage test to obtain finished product. The black sesame syrup is fine in oral feeling, scented, delicious and appetizing.

Owner:郭兴田

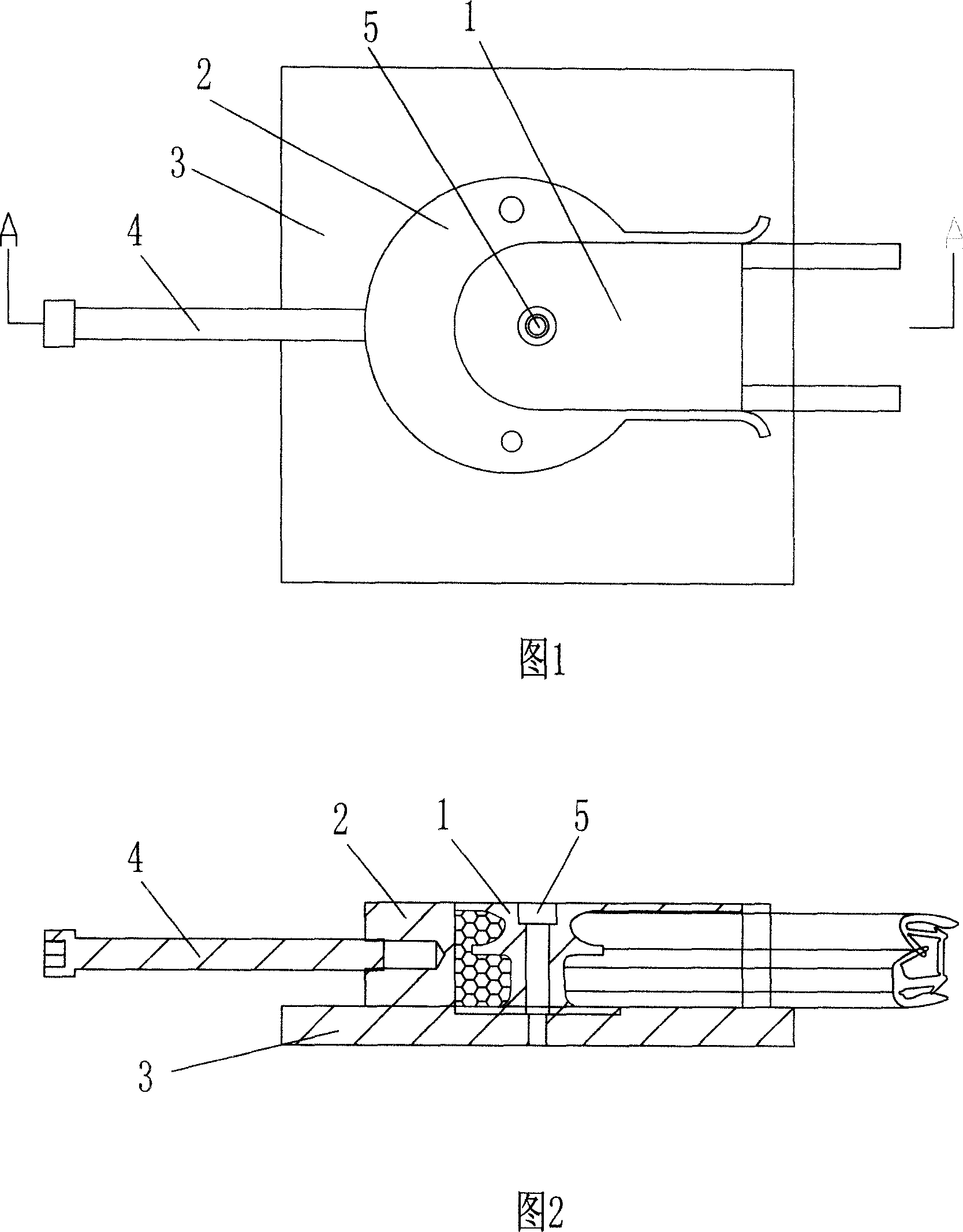

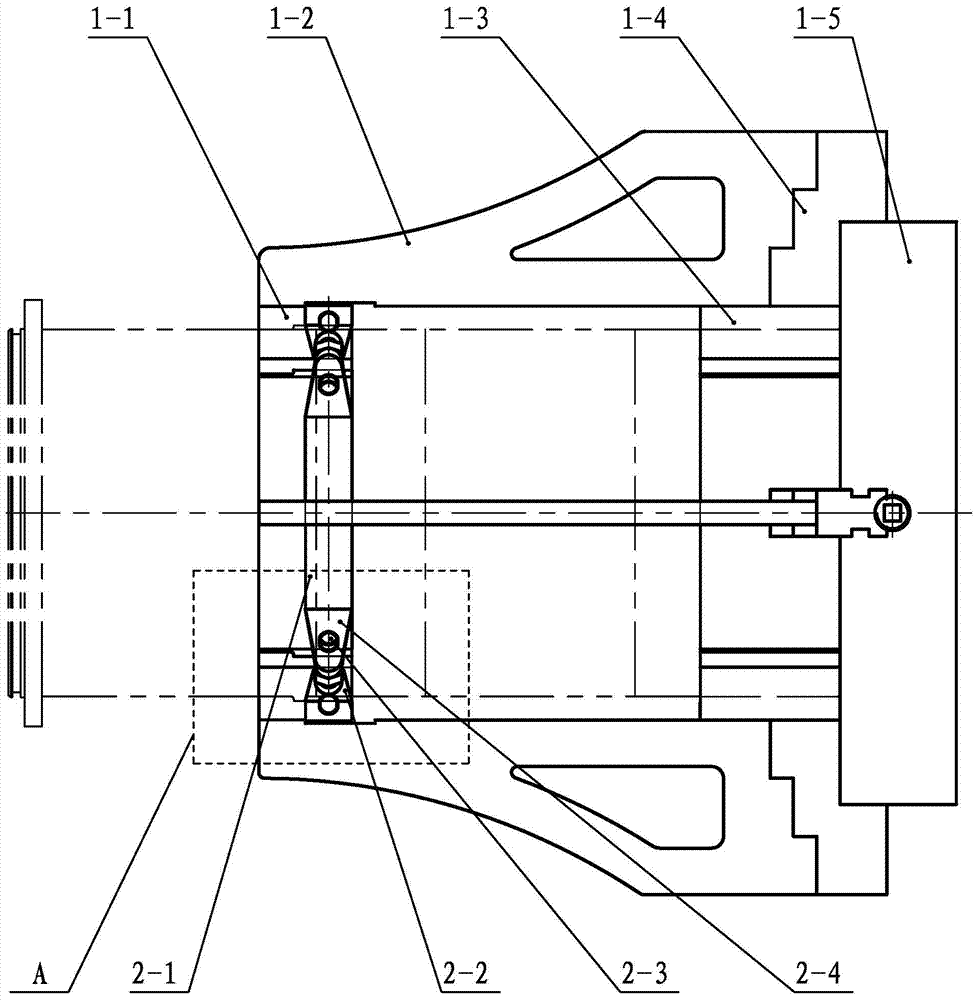

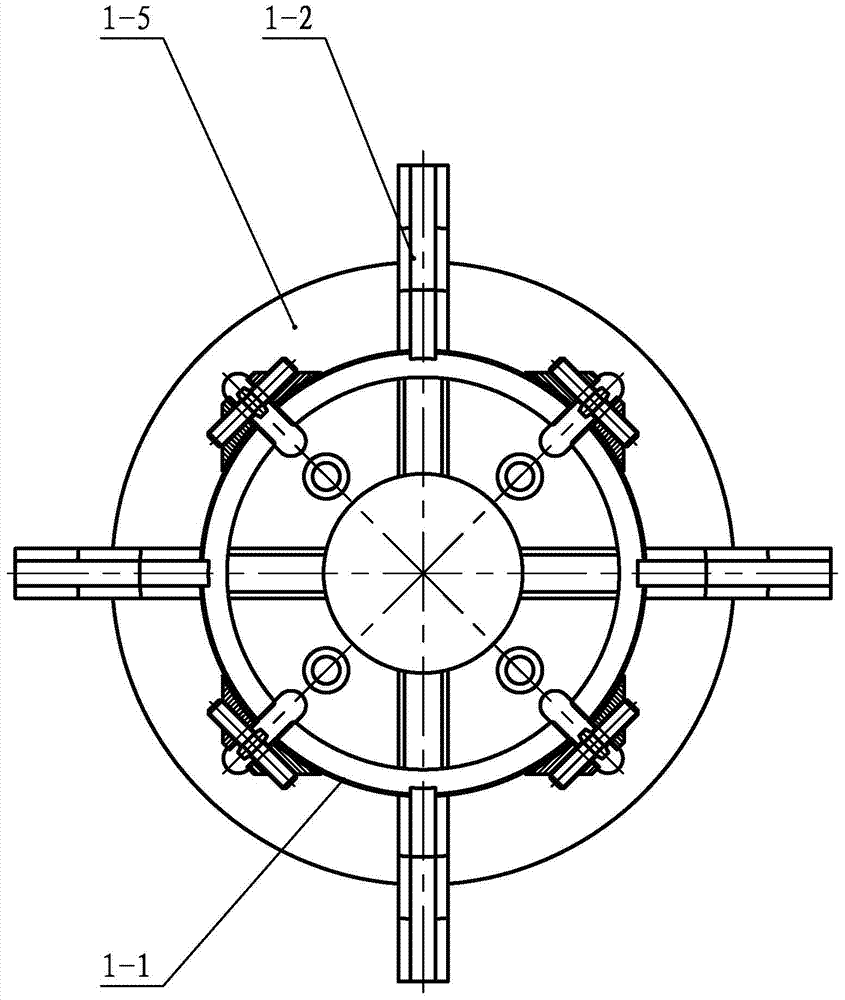

Clamp capable of ensuring perpendicularity between end surface of four-section installed and welded thin-wall cylindrical flange plate and axis

ActiveCN104759903ASave processing feeImprove pass rateWork clamping meansChucksCruciformSpring steel

The invention discloses a clamp capable of ensuring perpendicularity between an end surface of a four-section installed and welded thin-wall cylindrical flange plate and an axis and relates to a clamp capable of ensuring perpendicularity between the end surface of the welded thin-wall cylindrical flange plate and the axis. The clamp is used for solving the problem that the tolerance value of the perpendicularity between the end surface of the four-section installed and welded thin-wall cylindrical flange plate and the axis is within FORMULA. Four lengthened arms are symmetrically arranged in a crossed manner, four front end circular-arc plates and four rear-end circular-arc plates are arranged in a space enclosed by the four lengthened arms; front and rear end circular-arc plates are welded at front end rear ends of long straight side surfaces of the lengthened arms respectively; the step end surfaces at the rear ends of the lengthened arms are matched and welded with the step end surface of a lathe chuck claw; the lathe chuck claw is connected with a threaded rod of the lathe chuck; left and right threaded clamping bases are welded at the two ends of a circular-arc-shaped spring steel belt, and the left and right threaded clamping bases are connected with left and right threaded locking bolts; spring chuck ring assemblies are arranged on four front-end circular-arc plates in a sleeving mode. The clamp can be used for ensuring the perpendicularity between the end surface of the four-section installed and welded thin-wall cylindrical flange plate and the axis.

Owner:HARBIN JIANCHENG GRP

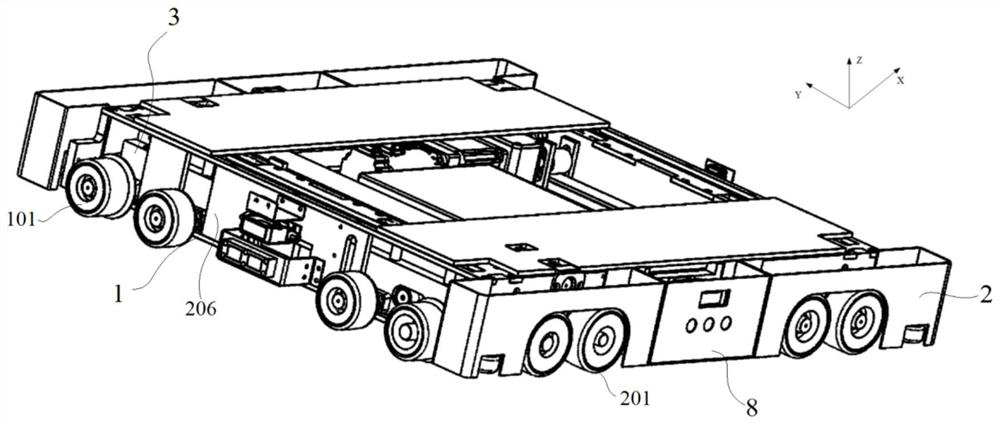

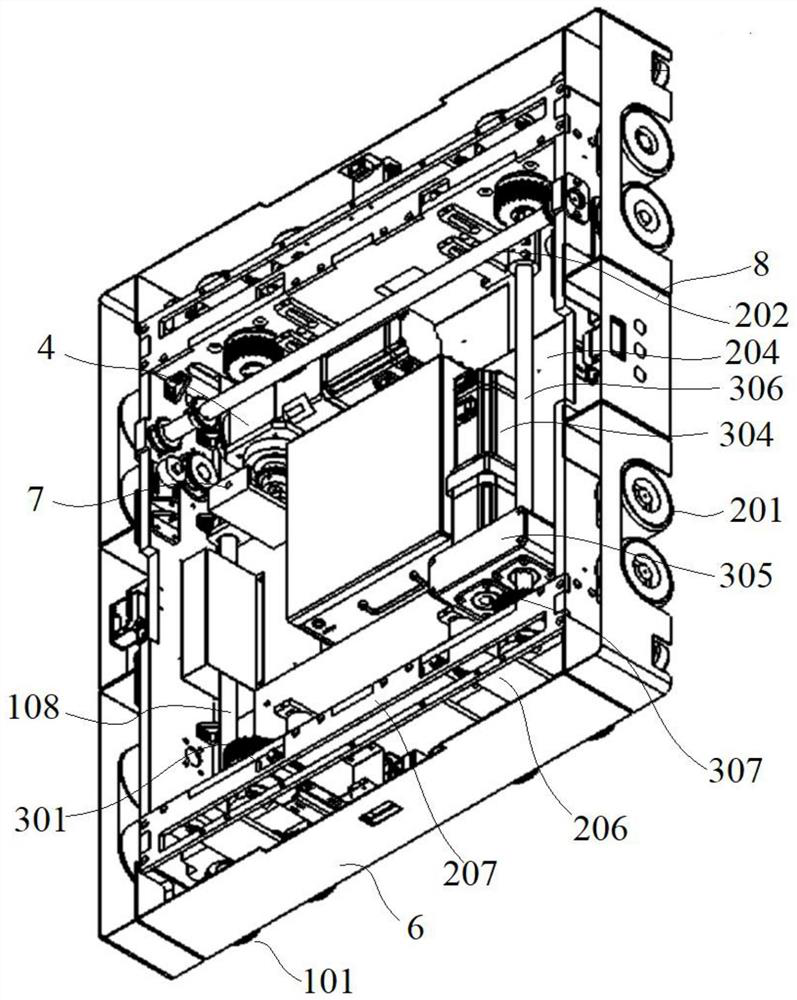

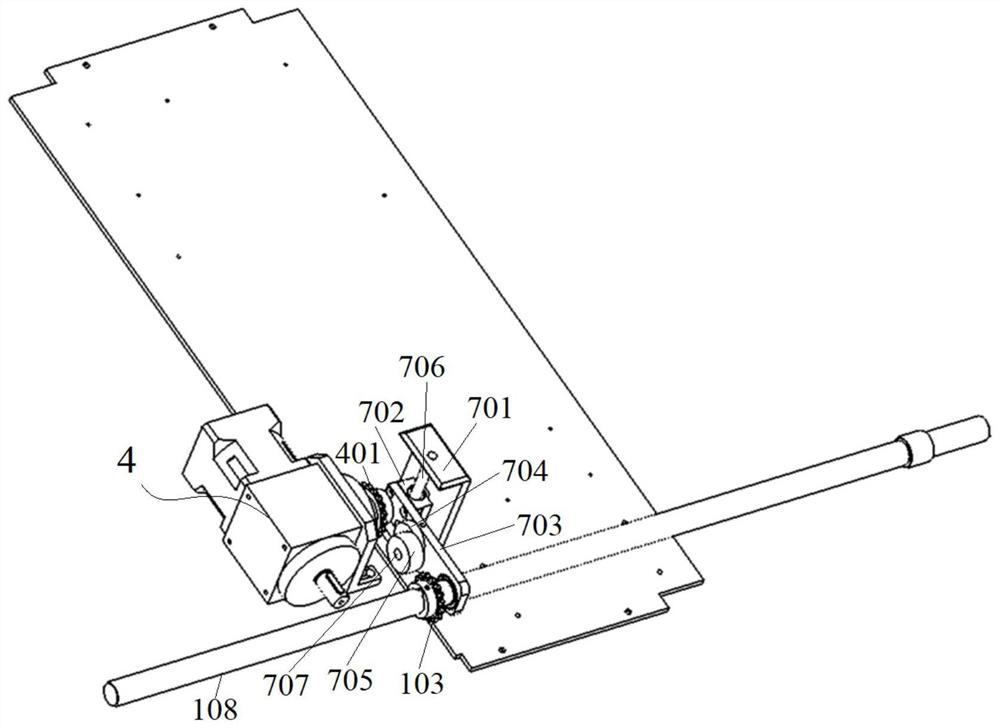

Lifting type reversing position intelligent adjusting rail guided vehicle

PendingCN113184438ASolve technical problems with unstable operationSmooth transmissionStorage devicesElectric machineryControl theory

Owner:乔禹峰

Burner combined by a plurality of polygon prism cavity fire distributors

InactiveCN102588965AAvoid liftingPrevent uneven spatial distributionGaseous fuel burnerCombustorEngineering

The invention discloses a burner combined by a plurality of polygon prism cavity fire distributors, which comprises a central pipe and outer ring pipes, wherein the central pipe is positioned at a centre position and the outer ring pipes are annularly arranged at the periphery. The lower ends of the central pipe and the outer ring pipes correspond to a nozzle position of fuel; a sensing needle and an ignition needle are arranged at a position adjacent to the central pipe; the central pipe and the outer ring pipes are polygon prisms; and a through hole on a limiting disc or an air port disc, through which the central pipe and the outer ring pipes pass, are polygons correspondingly, and the polygonal through hole is used for limiting the central pipe and the outer ring pipes. In the invention, as the burner fire distributors are in polygon prism shapes, the burner fire distributors can be conveniently limited by polygon holes at the downside to prevent from rotating along the axial line per se, so as not to result in the situation that the space distribution of the fuel injected by respective fire distributors is uneven.

Owner:林庆森

Side forms for paving asphalt concrete pavement

InactiveCN101275382ASave raw material costSave processing feeRoads maintainenceRoad surfaceProtection layer

An asphalt concrete pavement laying used side mould, pertains to the road building molded board facilities technique field, which is used to omit side section incising operation in the construction. The side mould is configured with a stretched body long stick in the middle part and fixing catch plates on the both ends, both ends of the stretched body long stick is in wedge shape, whose inner surfaces are perpendicular to the bottom face, risers of the fixing catch plates are connected with the wedge shape terminal, holes are nailed on the motherboard, and a matched locator card is provided between the two fixing catch plates. The locator card can clamp wires small riser, the inner surface of the stretched body long stick can be additively sticked with a rubber plate, and the external surface can be covered with a protection layer. The order suitable side section can be directly formed in the process of using the invention to lay the asphalt concrete pavement, thereby omitting the side section incising operation, thus the asphalt concrete raw material cost, processing charges and carriage charges can be saved; the construction operation amount can be reduced, the construction period can be cut short, and can be used as a side section molding molded board facilities in the asphalt concrete laying construction.

Owner:张军 +1

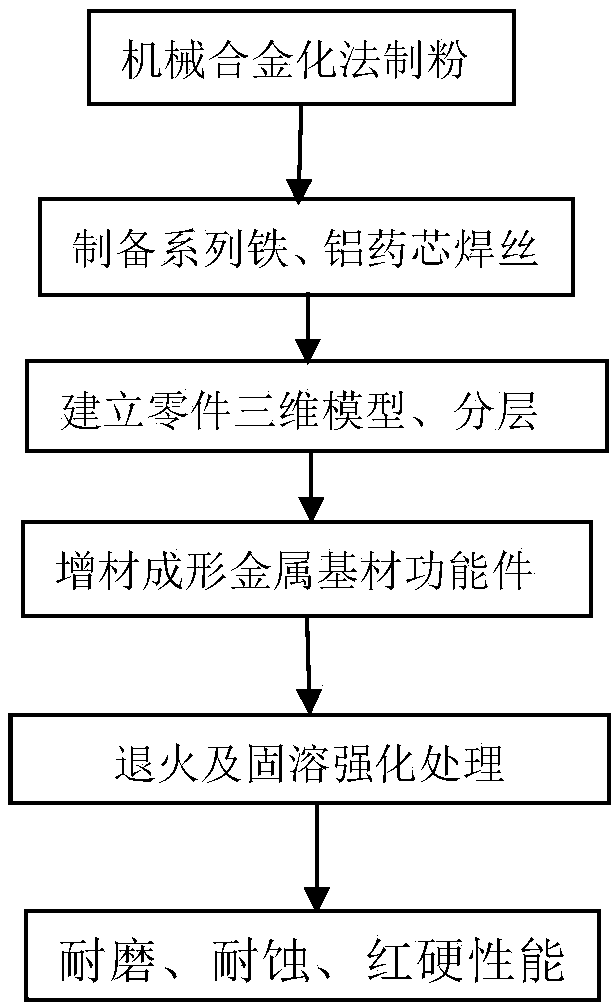

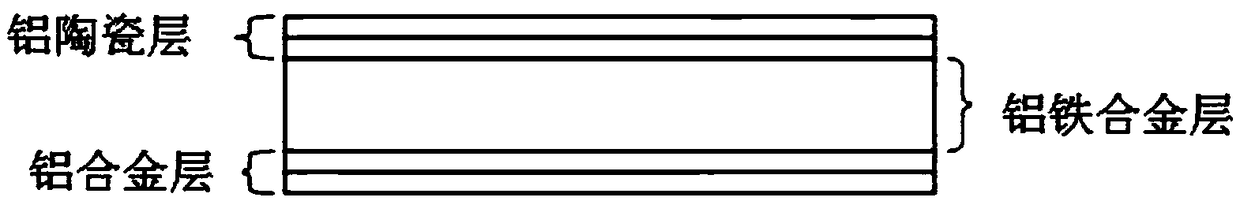

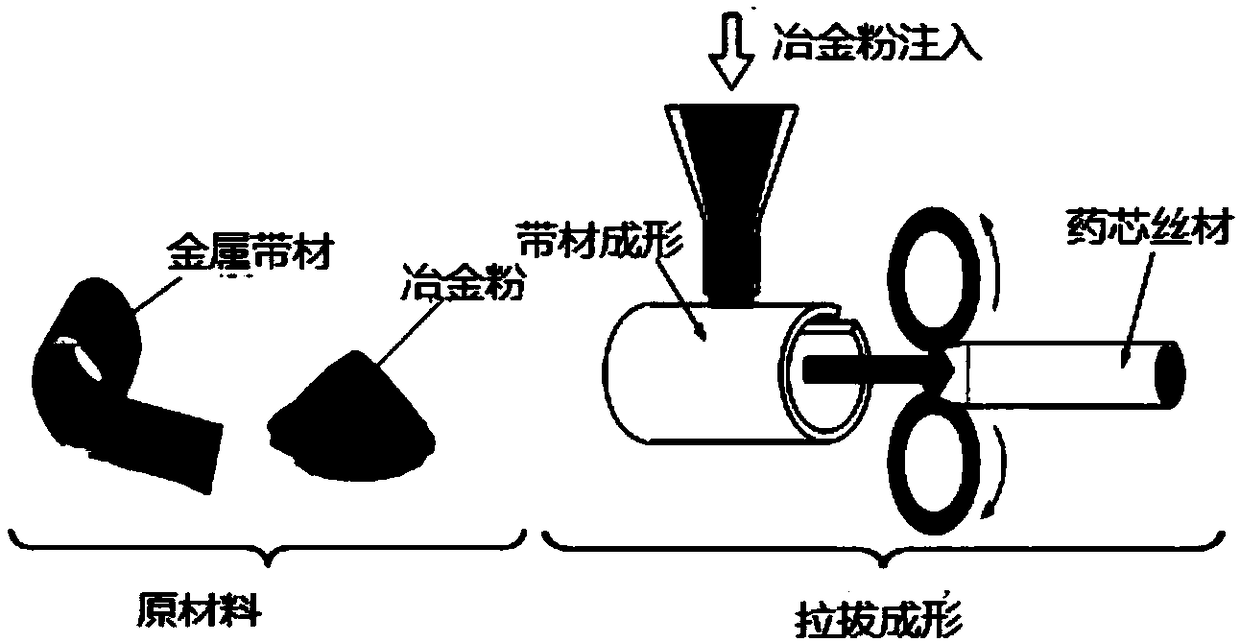

Metal substrate functional part and additional material processing preparation method thereof

ActiveCN108296602AImprove performanceCorrosion resistanceArc welding apparatusHeat resistanceOxidation resistant

The invention discloses a metal substrate functional part and an additional material processing preparation method thereof. An aluminum alloy layer, an aluminum-iron alloy layer and an aluminum ceramic layer are arranged, the aluminum-iron alloy layer comprises a plurality of aluminum-iron alloy sublayers, and the content of iron of each aluminum-iron alloy sublayer is increased layer by layer inthe direction from the aluminum alloy layer to the aluminum ceramic layer, so that the aluminum alloy end is continuously in transition to the aluminum-iron alloy layer and to the aluminum ceramic layer finally, the finally formed metal substrate functional part not only has the good properties of the aluminum alloy, for example, corrosion resistance, abrasion resistance, good thermal conductivityand low weight, but also has the good heat resistance, high temperature resistance, high mechanical strength, high-temperature oxidation resistance and other properties, and at the same time, as an intermediate layer is composed of the cheap aluminum-iron alloy layer with high toughness, the whole cost is reduced effectively.

Owner:湖北启宏热工设备有限公司

Sliding formwork construction method

InactiveCN107675876ASave processing feeSave on inactivity feesForms/shuttering/falseworksFalseworkChinese characters

The invention discloses a sliding formwork construction method. The specific sliding formwork construction method comprises the following steps of a, provisional platform building; b, mounting of frames shaped like a Chinese character 'kai'; c, enclosure mounting; d, formwork assembly; e, formwork and enclosure adjustment; f, inner and outer platform building; g, jack and supporting rod mounting;h, acceptance inspection of a whole system and construction of a first-section sliding formwork; i, inner and outer hanging frame perfection; and j, normal sliding up of the sliding formwork system. Inner and outer platforms, inner and outer hanging frames, the frames shaped like the Chinese character 'kai' and formwork enclosures of the sliding formwork system adopt scaffold steel pipes and steelbuckles, and the formwork enclosures and the frames shaped like the Chinese character 'kai', the frames shaped like the Chinese character 'kai' and the inner and outer platforms as well as the innerand outer platforms and the inner and outer hanging frames adopt steel pipe-buckle connecting modes correspondingly; and the cost is low, the constriction progress is rapid, the engineering construction period is shortened, meanwhile, on-site machining and welding are reduced, and environment pollution is reduced accordingly.

Owner:刘重新

Thin-tube-plate segment anodic protection stainless steel shell-and-tube concentrated sulfuric acid cooling tower

InactiveCN101526318ASave stainless steel materialSave processing feeSulfur compoundsHeat exchanger casingsSulfuric acidAnode

The invention discloses a thin-tube-plate segment anodic protection stainless steel shell-and-tube concentrated sulfuric acid cooling tower. The cooling tower is an independent operating unit consisting of a shell side, a tube side and an anodic protection component; and two ends of a cylinder body of the shell side are connected with a cylinder body of a water tank which belongs to the tube side. The cooling tower is characterized in that: a sealing device fixing heat exchange tube bundles and the two ends of the shell side is formed on the inner wall at the two ends of the cylinder body of the shell side by welding a fixed tube plate; and the tube plate is positioned at the inner side on the periphery of the inner wall at the two ends of the cylinder body of the shell side, and the cylinder body of the shell side is welded with the cylinder body of the water tank for sealing connection; and two or more independent operating units are serially connected and divided into one or more high-temperature segment operating systems and one or more low-temperature segment operating systems with same or different number according to temperature. The cooling tower can solve the technical problems of high equipment investment cost, huge abandonment loss and the like of concentrated sulfuric acid coolers due to excessive use of stainless steel in the traditional concentrated sulfuric acid coolers.

Owner:龙学义

Stainless steel tube-shell type concentrated sulfuric acid cooler with thin tube sheet stage cooling and anode protection

InactiveCN101706219ASave processing feeReduce scrap costsHeat exchanger casingsStationary tubular conduit assembliesChillerSteel tube

The invention discloses a stainless steel tube-shell type concentrated sulfuric acid cooler with thin tube sheet stage cooling and anode protection. A shell pass, a tube pass and an anode protection assembly form an independent run unit, and two ends of a cylinder of the shell pass are connected with a water tank cylinder belonging to the part of the tube pass. The stainless steel tube-shell type concentrated sulfuric acid cooler with thin tube sheet stage cooling and anode protection is characterized in that tube sheets are fixed on the inner walls of two ends of the cylinder of the shell pass through welding to form a fixed heat exchange tube bundle and sealing devices at two ends of the shell pass; the tube sheets are positioned at the inner sides of the outer edges of the inner walls at two ends of the cylinder of the shell pass, and the cylinder of the shell pass and the cylinder of the water tank are connected in a sealing mode by welding; two or a plurality of the independent run units are connected in series and divided into single or a plurality of high-temperature section run systems and low-temperature section run systems with equal mount or unequal amount according to temperature. The invention can solve the technical problems of a traditional concentrated sulfuric acid cooler, such as high equipment investment expense, great abandonment loss and other technical problems, which are caused by using a great deal of stainless steel.

Owner:龙学义

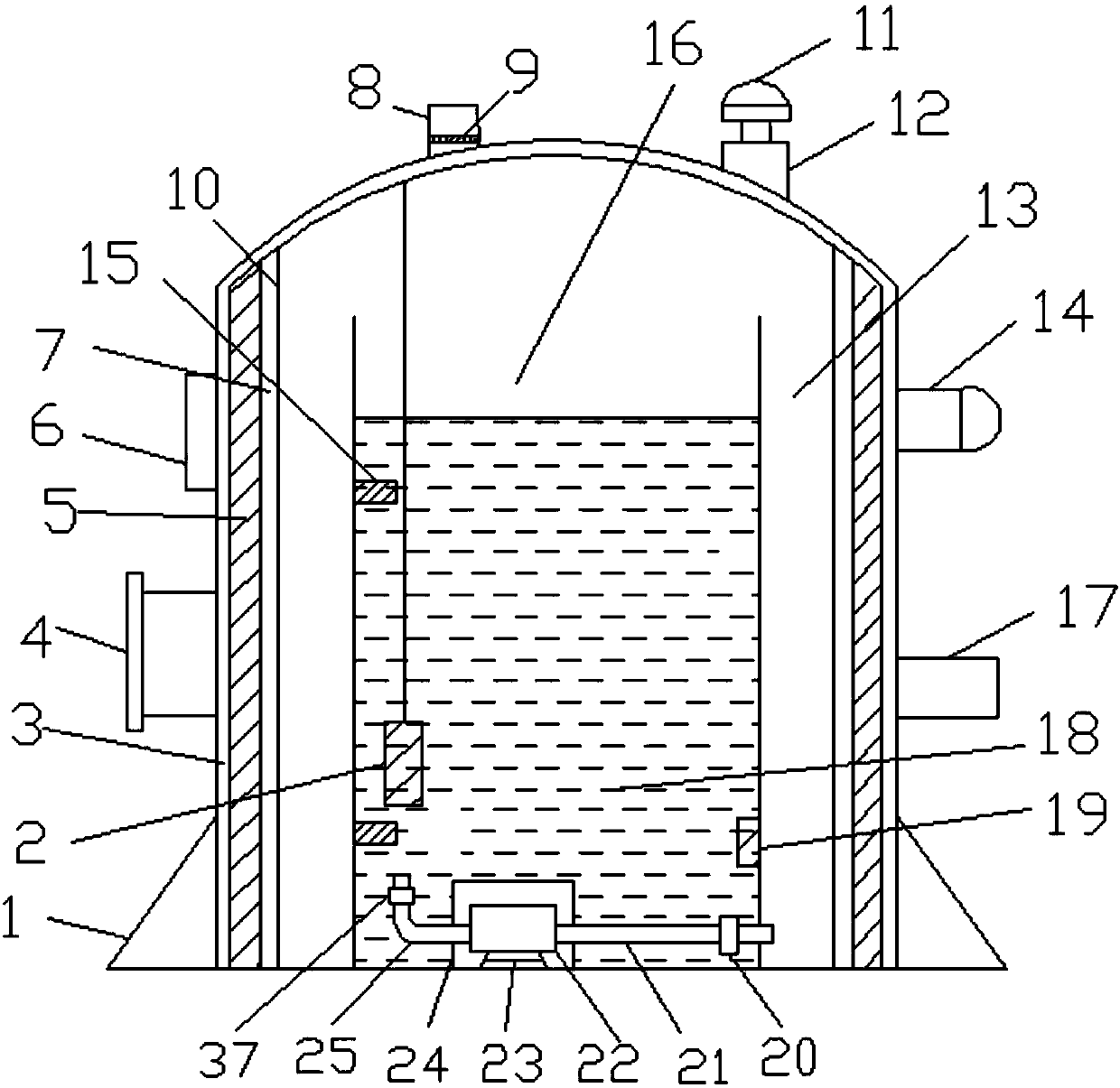

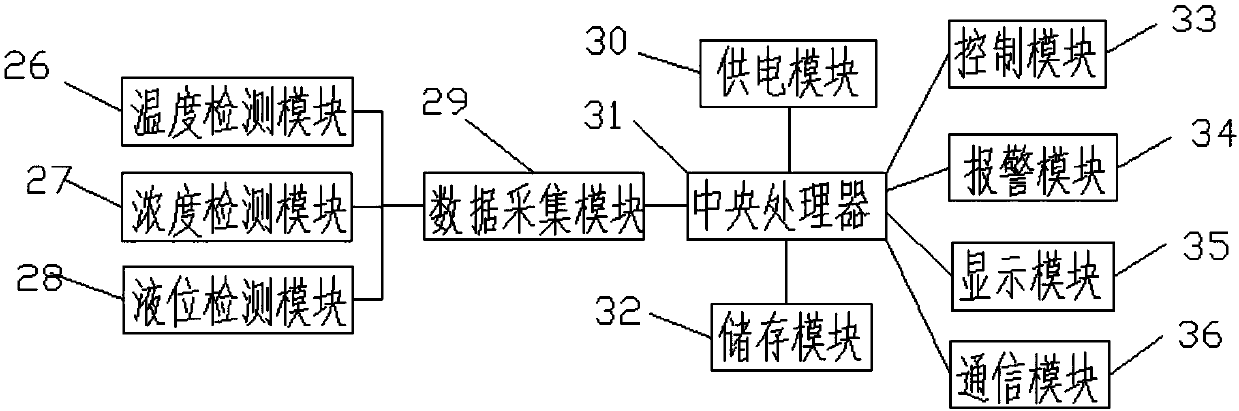

Oil storage tank with double-layer structure

ActiveCN108033158AIncrease temperatureFull circulationMeasurement devicesLarge containersComputer moduleDisplay device

The invention discloses an oil storage tank with a double-layer structure. The oil storage tank comprises an oil storage tank body and a control module, the oil storage tank body comprises an outer wall, a manhole is formed in one side of the bottom of the outer wall, a displayer is arranged above the manhole, an oil outlet pipe is arranged on the other side of the bottom of the outer wall, a warning light is arranged on the upper portion of the oil outlet pipe, an oil inlet pipe is arranged on one side of the top of the outer wall, a filter screen is arranged at the bottom of the oil inlet pipe, a fire barrier is arranged on the other side of the top of the outer wall, a breather valve is arranged on the top of the fire barrier in a penetrating mode, an electromagnetic heating layer is arranged on the inner side of the outer wall, an insulating layer is arranged on the inner side of the electromagnetic heating layer, and the inner wall is arranged on the inner side of the insulating layer. The oil storage tank has the advantages that design is reasonable, the structure is simple, oil product stratification problem in the oil storage tank is effectively solved, and then the sales volume is effectively guaranteed; meanwhile, the processing charges of oil products are effectively lowered, and then the cost is effectively reduced.

Owner:定州市东方石油设备有限公司

Non-groove rolling technology of horizontal mill

ActiveCN101007315BOvercome the current overcurrent alarm phenomenonReduce loadRollsMetal rolling arrangementsStrip millEngineering

The invention discloses a slotless rolling art for all-horizontal rolling mill which rolls round bar and screw-thread steel on semi-continuous rolling process online. It arranges junior mill 2, crop flying shear 3, junior mills group 4, crop and crop end flying shear 5, loop 6 or 8 or 9 or 10, finishing mills group 7 and times ruler flying shear 11 after blooming mill 1 consecutively; installs plain-barreled roll 41 or 42 and 71 or 72 on the third or fifth rolling mill frames of junior mills group 4 and the first and third rolling mill frames of finishing mills group 7, the plain-barreled rolls need not be processed hole-type groove, the rolling pressure is decreased significantly. The plain-barreled rolling mills does not have wrong rollers in whole rolling process, does not generate ears, decreases central waste rollers, saves changing roller time, increases rolling mill efficiency. The plain-barreled roll slotless rolling art not only can be used in flat alternative continuous rolling process line, but has a bright prospect in development and application of all-horizontal rolling mill process line.

Owner:湖南华菱涟源钢铁有限公司

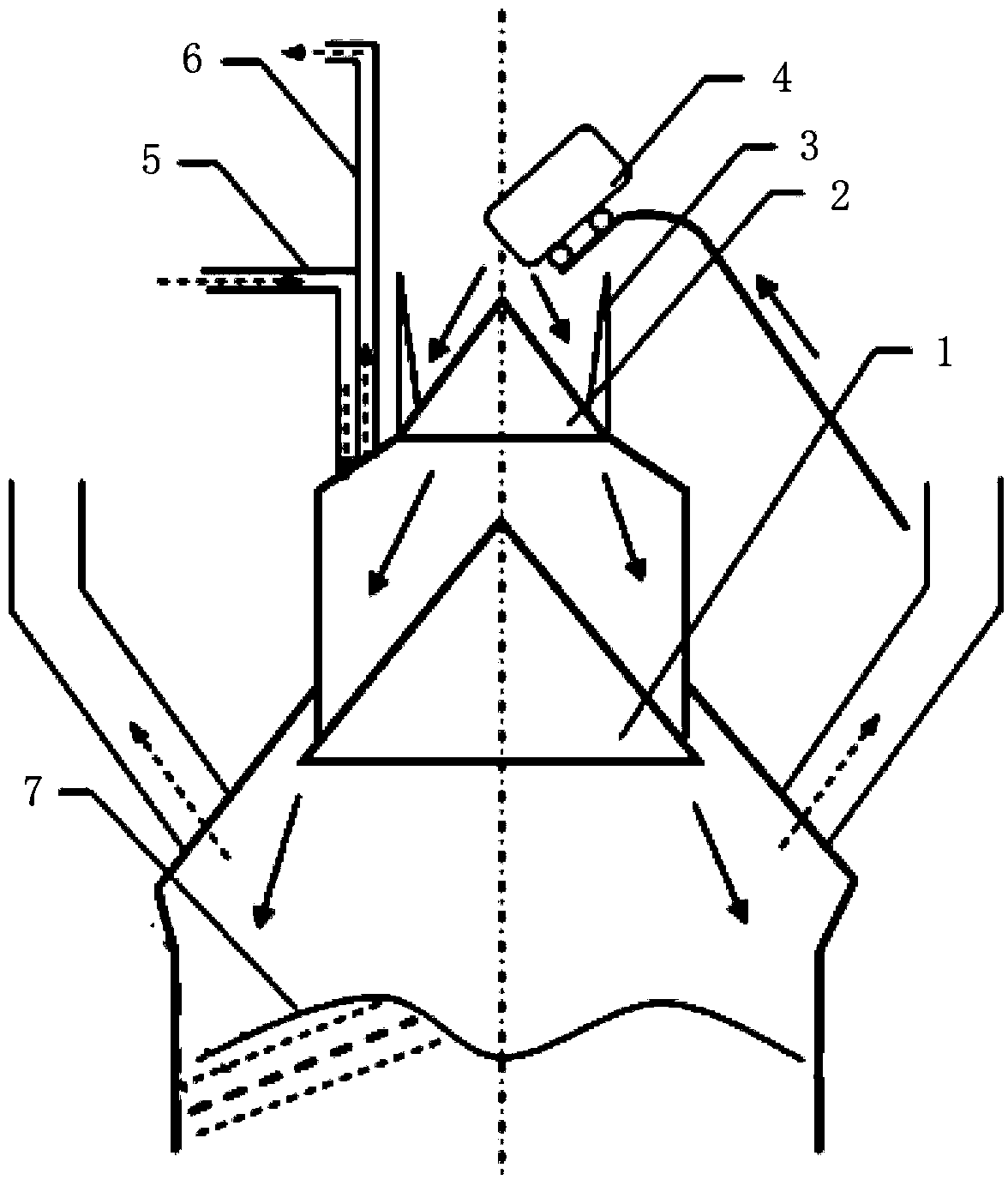

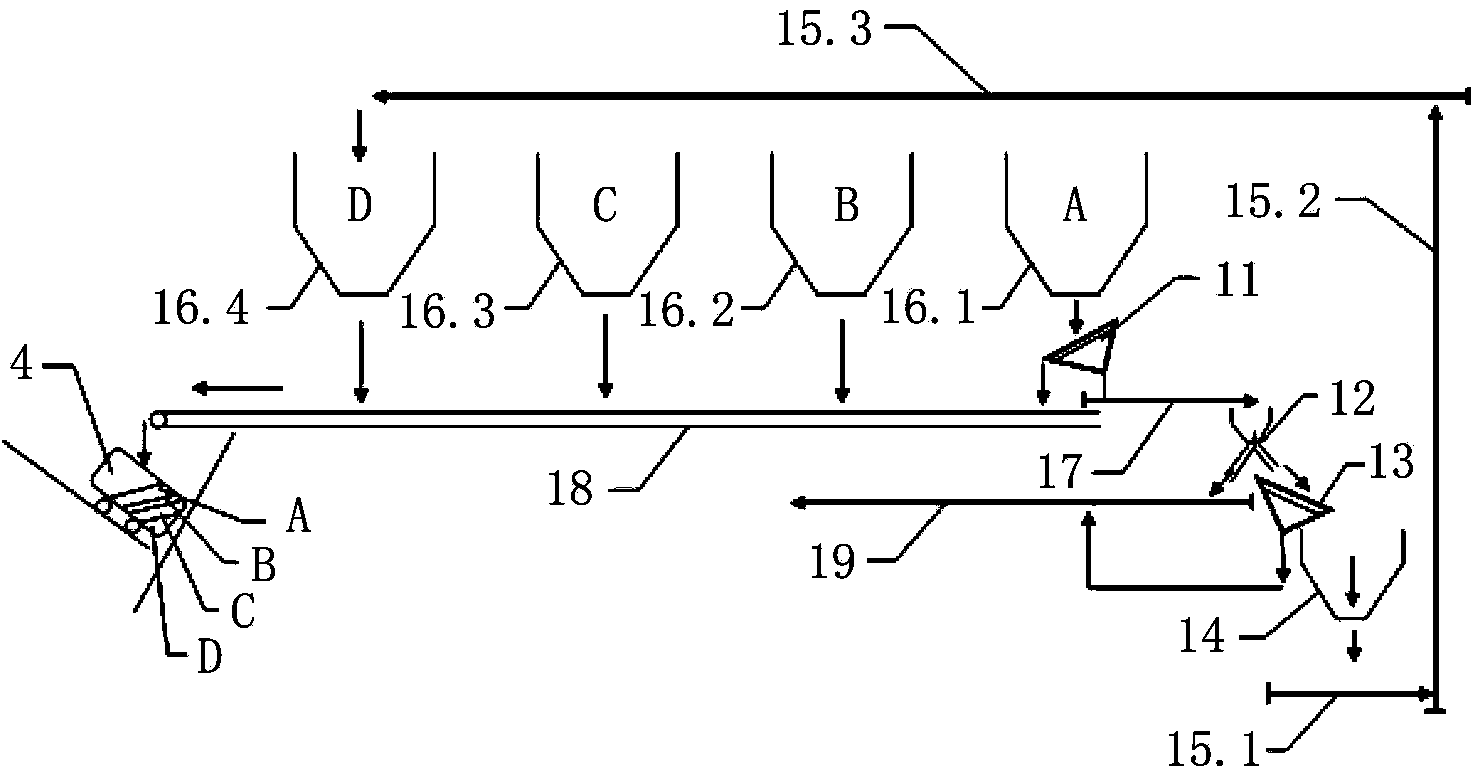

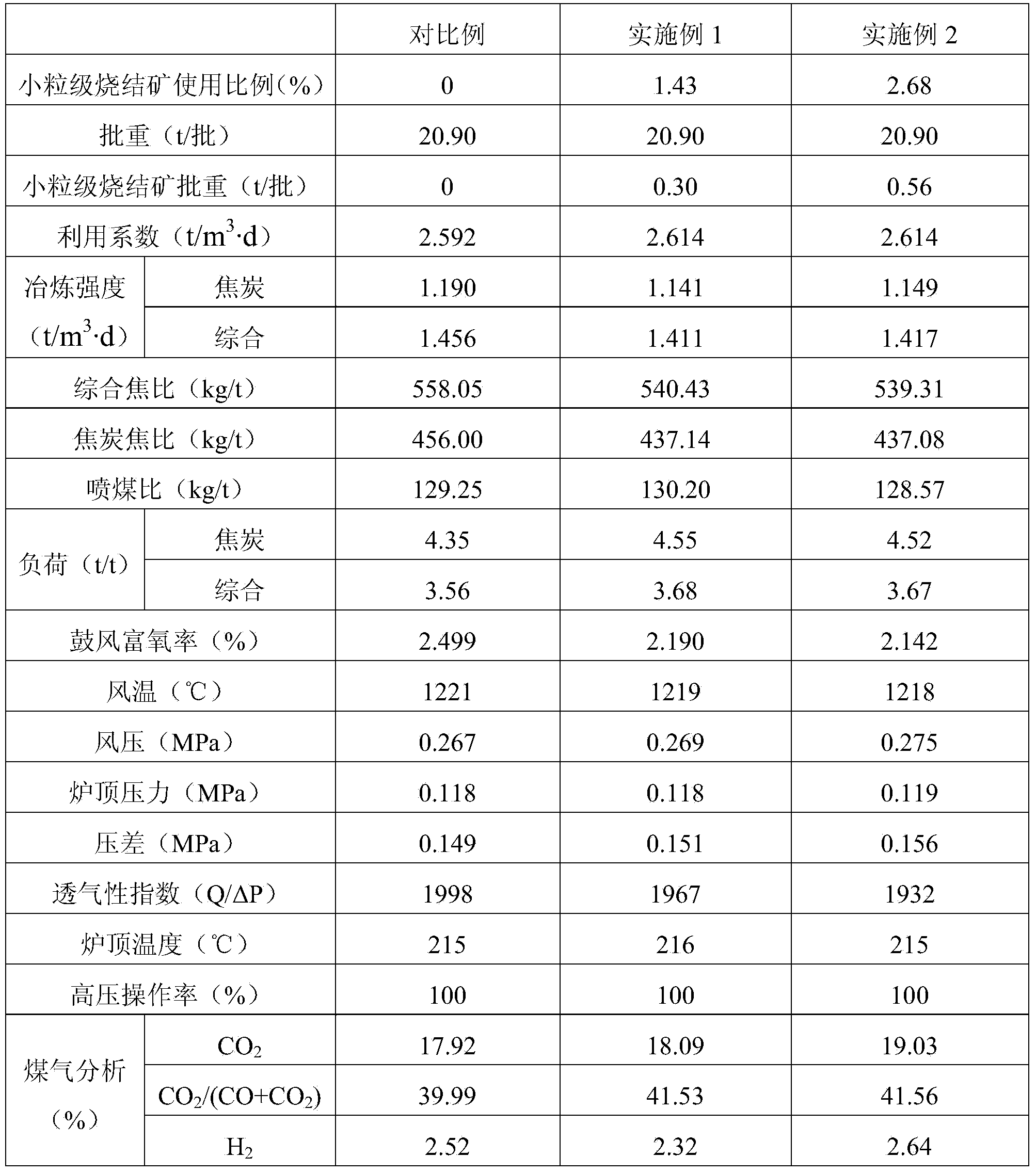

Bell type blast furnace smelting method by using small-size sinters

ActiveCN103820591ASave processing feeSolve the shortage situationBlast furnace detailsEconomic benefitsBlast furnace smelting

The invention discloses a bell type blast furnace smelting method by using small-size sinters. The method comprises the steps as follows: loading, that is, ore and coke both containing the small-size sinters are added into a bell type blast furnace; blowing, specifically, air blast kinetic energy is controlled to be 150-230kJ / s, the air blast temperature is not lower than 1,180 DEG C, and the air blast oxygen enrichment percentage is not lower than 1 percent; wherein, the small-size sinter comprises the following components by weight percentage: 45-55 percent of sinter which is 3-5 mm in particle size, 35-45 percent of sinter with particle size greater than 5 mm and 0-20 percent of sinter with particle size smaller than 3 mm. According to the bell type blast furnace smelting method by using small-sized sinter, disclosed by the invention, the defect that the small-size sinter cannot be used by a bell type blast furnace for smelting is overcome, and by regulating process parameters, the normal production is ensured and the economic benefit is improved. Moreover, the processing cost of sorting the grades of the singers is reduced by recovering the small-sized sinters in returned ore into the blast furnace for smelting. Furthermore, by adopting the small-size sinters, the state of the material shortage of blast furnace is eliminated, and the cost of raw materials is lowered.

Owner:PANGANG GRP PANZHIHUA STEEL & VANADIUM

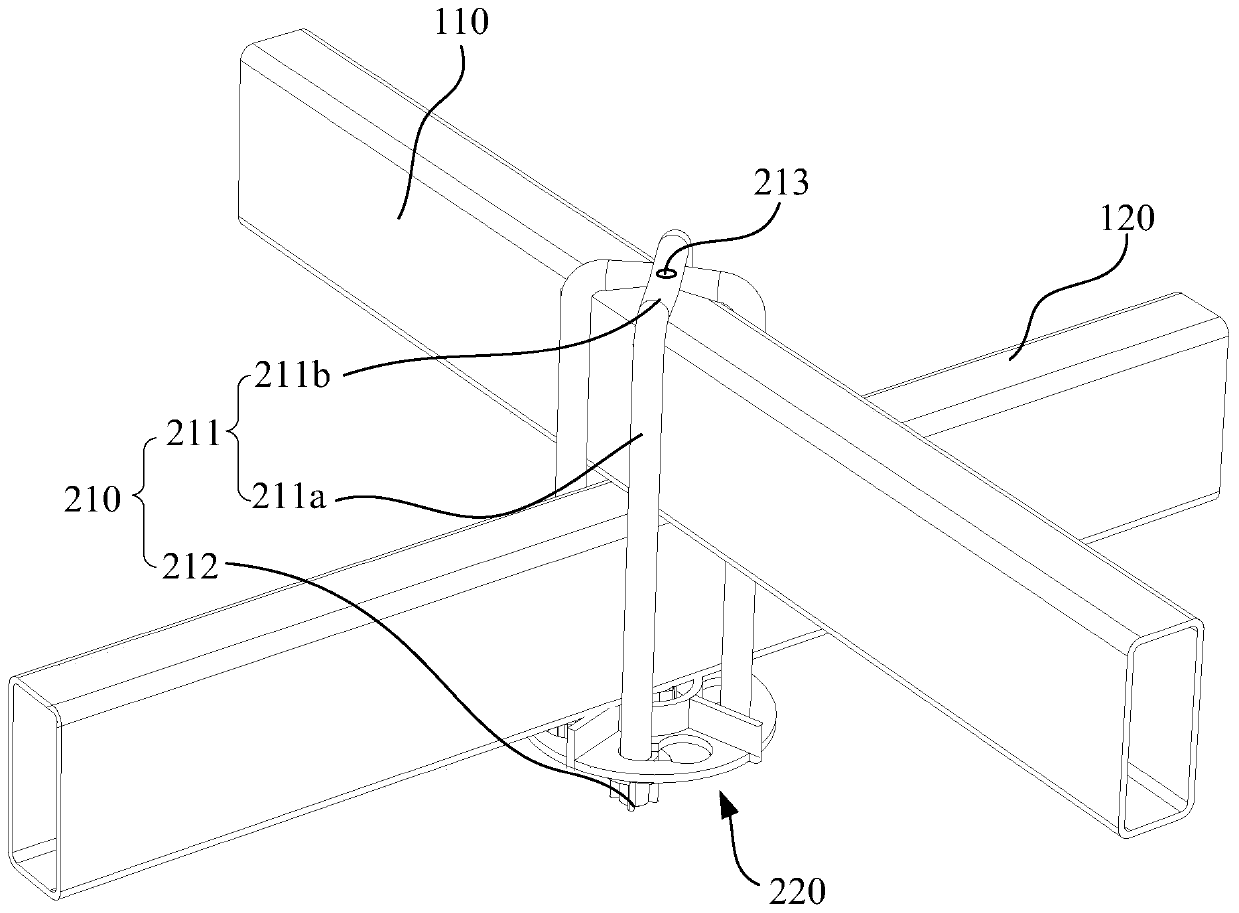

Connecting structure of cross rod pieces

ActiveCN111271353ARealize non-porous connectionPrevent rotationPhotovoltaic supportsRod connectionsEngineeringScrew joint

The invention provides a connecting structure of cross rod pieces. The connecting structure is used at the joint of the first rod piece and the second rod piece which are crosswise lapped, and comprises a spider claw and a bolt assembly. The spider claw comprises a plurality of claw arms; the first connecting end of each claw arm is located on the end face of the side, away from the second rod piece, of the first rod piece, and the multiple first connecting ends are movably connected to one position; and the second connecting ends of the claw arms stretch out of the second rod piece, and a plurality of limiting parts are arranged close to the second connecting ends in a protruding manner. The bolt assembly comprises a nut plate, a nut arranged on the nut plate and an adjusting bolt in matched screw joint with the nut, the periphery of the nut is provided with a plurality of through holes for the claw arms to pass through, the limiting parts abut upon the bottom surface, away from the second rod piece, of the nut plate, and the first rod piece and the second rod piece are clamped between the first connecting ends of the claw arms and the adjusting bolt in a limited manner. By meansof the technical scheme, fixed connection of the cross rod pieces can be conveniently and rapidly realized without forming holes.

Owner:ZHUHAI SINGYES RENEWABLE ENERGY TECH +3

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com