Smooth blasting method based on phi 32 mm cartridges

A technology of smooth blasting and light blasting, which is applied in blasting and other directions, can solve problems such as unavailable, shortage of bamboo chips and fine charges, and inability to meet the effect of light blasting, so as to save processing costs, save concrete backfill, reduce The effect of construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The specific embodiment of the present invention will be further described in detail below in conjunction with the accompanying drawings.

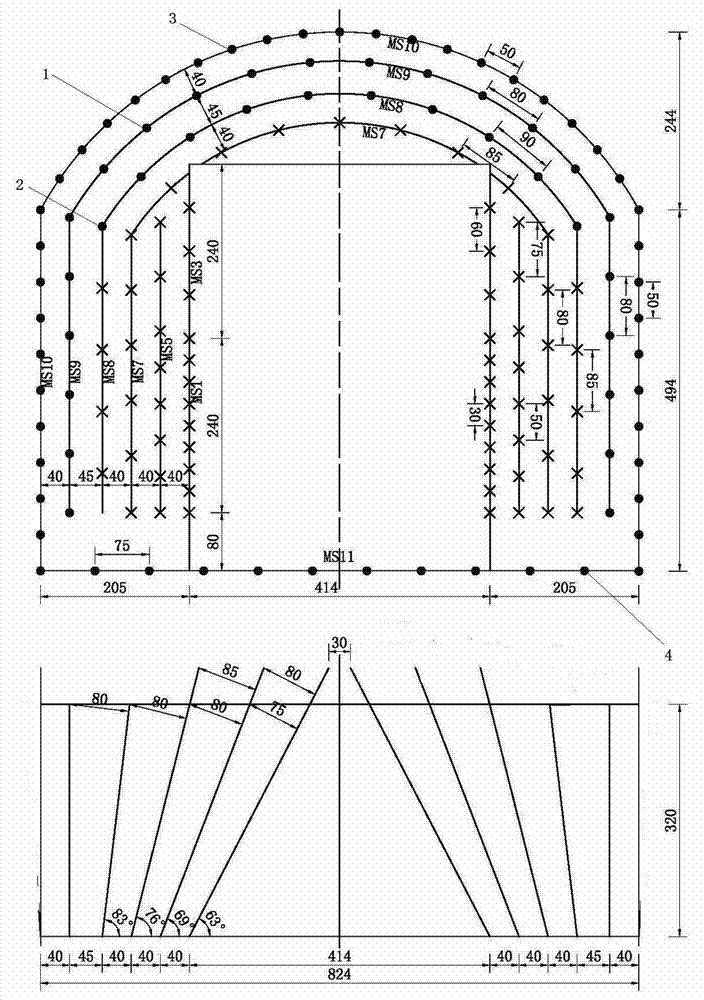

[0029] figure 1 In the specific embodiment shown, the working surface is a door-shaped structure with an arc-shaped top for tunnel excavation, figure 1 The upper part is a schematic diagram of drilling, and the dotted line in the middle is the symmetry axis of the working surface. figure 1 The MS in the middle indicates that the non-electric millisecond detonators of different sections are used to obtain different detonation delays at the corresponding holes.

[0030] The light explosion layer is at the boundary of the two side walls and the arc boundary at the top, and the thickness of the light explosion layer can be 35-45 cm, for example figure 1 Taking 40 cm as the center, the thickness of the photo-explosion layer is reduced compared with the 45-55 cm of the prior art. After the thickness of the photo-explosion layer is reduc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com