Inert and damping integrated gas-filled damper

A shock absorber, an integrated technology, applied in the direction of liquid shock absorber, gas-hydraulic shock absorber, shock absorber, etc., can solve the problems of difficult processing and assembly, complex structure, and many components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

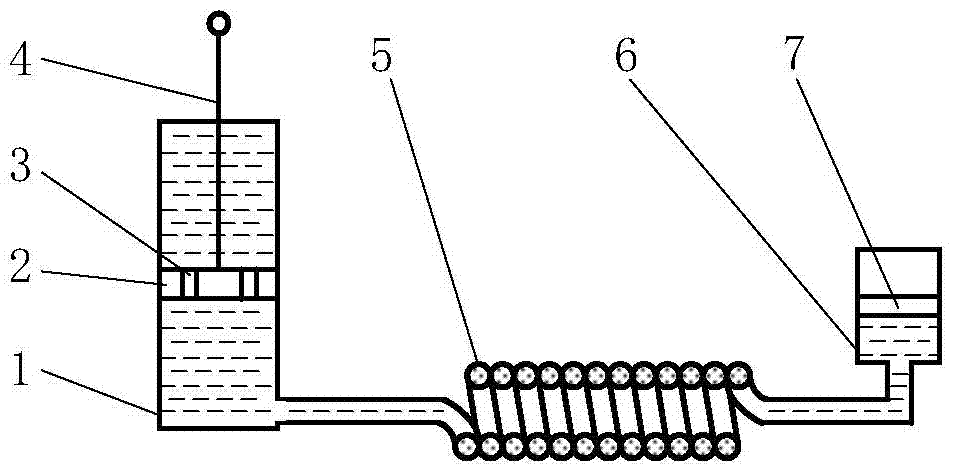

[0019] Such as figure 1 As shown, the inertial and damping integrated gas shock absorber includes a cylinder 1, a piston 2, a damping valve 3, a piston rod 4, a metal spiral tube 5, an external nitrogen tank 6, and a floating piston 7. The piston 2 is connected with the piston rod 4 and placed in the cylinder 1 , the cylinder 1 is divided into a rod chamber and a rodless chamber, and the damping valve 3 is arranged on the piston 2 . The floating piston 7 is placed in the external nitrogen tank 6, and the external nitrogen tank 6 is divided into upper and lower chambers, and the upper chamber of the external nitrogen tank 6 is filled with nitrogen. One end of the metal helical tube 5 communicates with the rodless cavity of the cylinder 1, and the other end communicates with the lower cavity of the external nitrogen tank 6, except for the lower cavity of the external nitrogen tank 6, the metal helical tube 5, and the lower cavity of the cylinder 1. Both the rod cavity and the r...

Embodiment 2

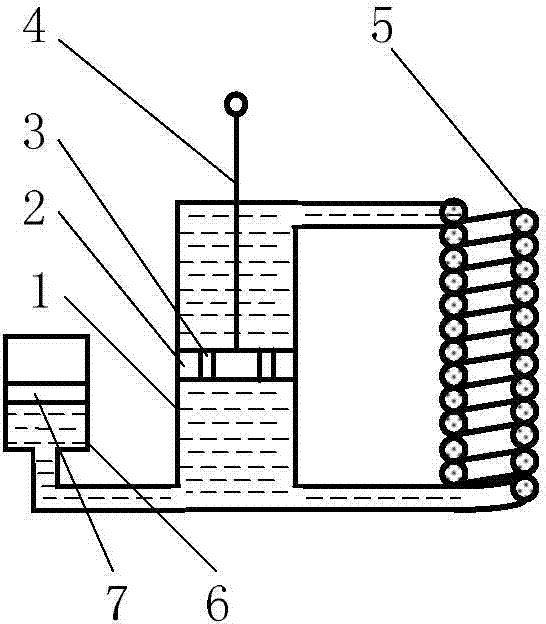

[0029] Such as figure 2 As shown, the difference from Embodiment 1 is that the metal helical tube 5 and the external nitrogen tank 6 are set at different positions. , The rodless chamber is connected; the lower chamber of the external nitrogen tank 6 is directly connected with the rodless chamber of the cylinder 1.

[0030] The specific implementation process of Embodiment 2 of the present invention will be further described below in conjunction with the accompanying drawings.

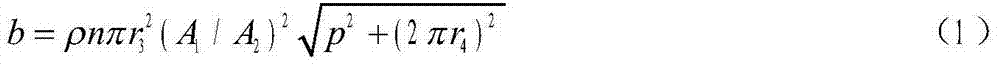

[0031] The cylinder 1, the piston 2, the piston rod 4 and the metal spiral tube 5 together constitute a fluid accumulator. However, the difference between the second embodiment and the first embodiment is that the inertia of the fluid inerter is different in the compression stroke and the stretch stroke, and the calculation method of the inertia of the compression stroke is the same as that of formula (1). Inertia of extension stroke, A in formula (1) 1 is the effective cross-sectional area after s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com