Clamp capable of ensuring perpendicularity between end surface of four-section installed and welded thin-wall cylindrical flange plate and axis

A thin-walled cylinder, axis vertical technology, applied in the direction of clamping, chuck, clamping device, etc., can solve the problem of inability to guarantee the tolerance value of the end face of the thin-walled cylinder flange and the axis perpendicularity of the four-stage welding, and improve the The effect of product qualification rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below in conjunction with the accompanying drawings.

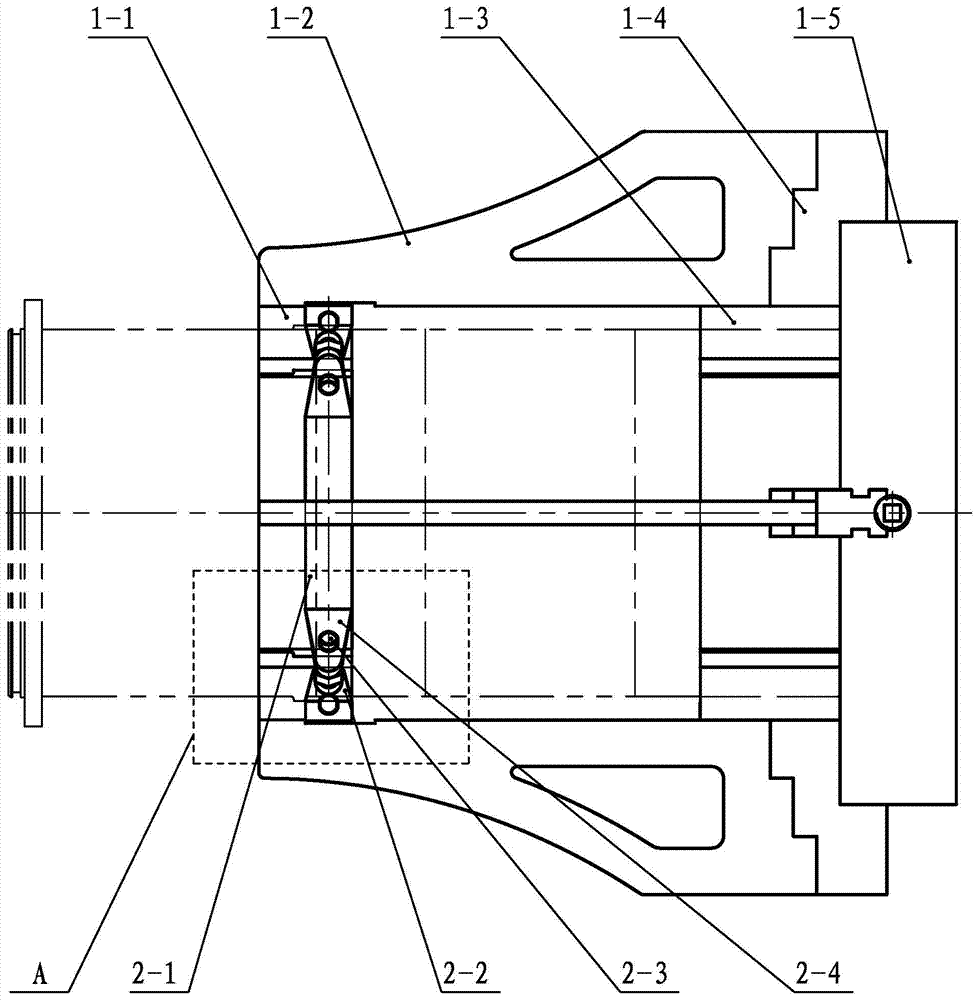

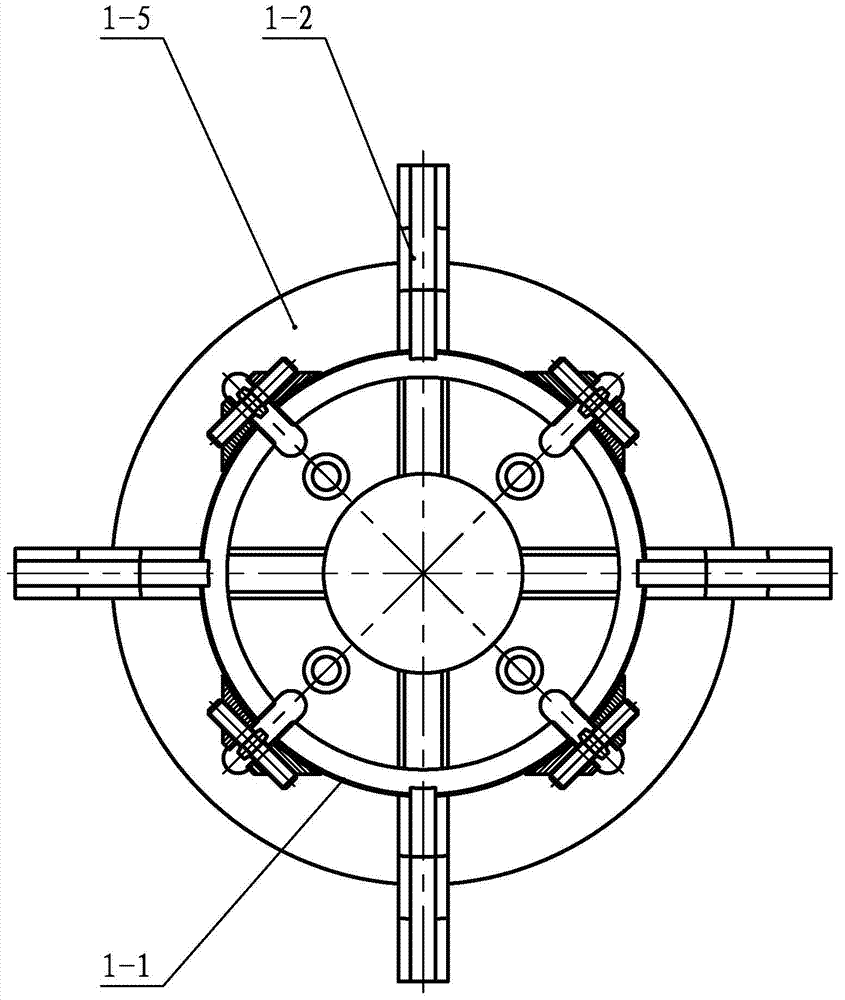

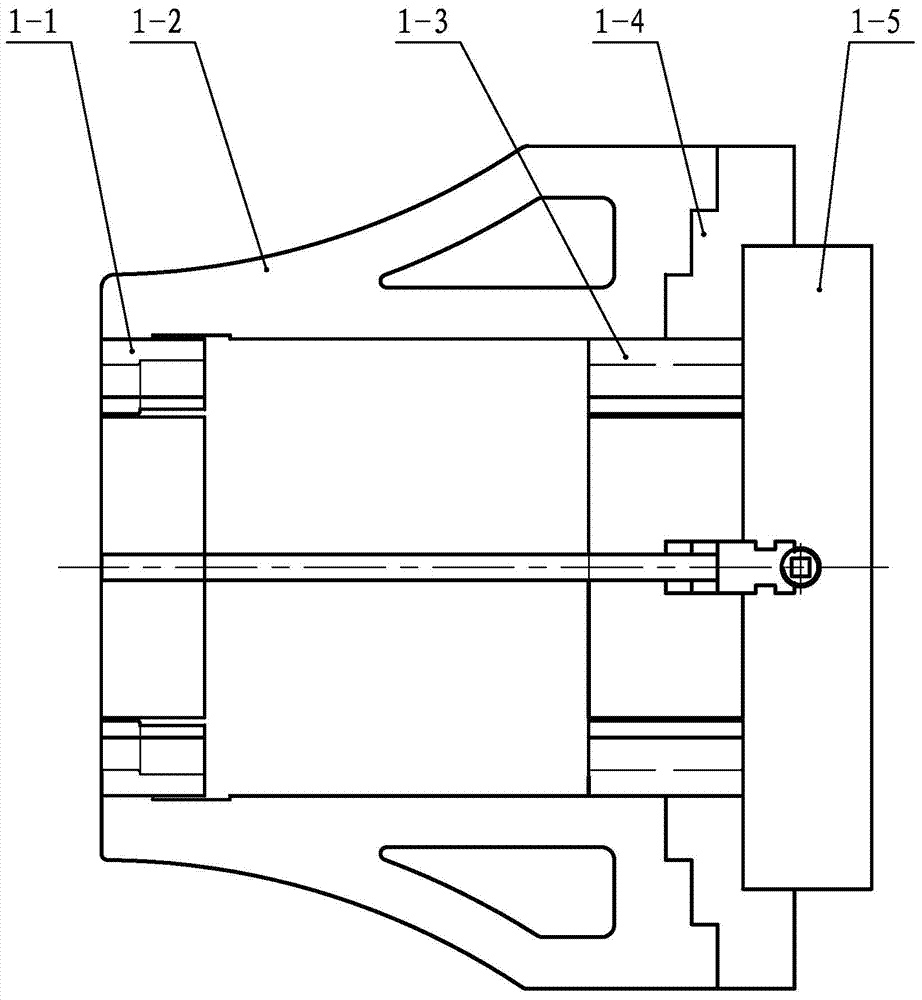

[0021] Such as Figure 1 to Figure 10 As shown, the fixture that can ensure the perpendicularity between the end face of the thin-walled cylindrical flange and the axis of the four-section assembly welding includes an arc-shaped long-arm combined card body assembly and a spring snap ring assembly; the arc-shaped long-arm combined card body assembly includes Four front-end arc-shaped plates 1-1, four extension arms 1-2 and four rear-end arc-shaped plates 1-3; the spring clasp assembly includes four arc-shaped spring steel strips 2-1 , four left-hand thread clamping seats 2-2, four left and right thread locking bolts 2-3 and four right-hand thread clamping seats 2-4; four extension arms 1-2 are symmetrically arranged in a cross shape, and the four front ends The arc-shaped plates 1-1 are symmetrically arranged in a cross shape and are arranged in the space sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com