Non-groove rolling technology of horizontal mill

A horizontal, rolling mill technology, applied in metal rolling, manufacturing tools, metal rolling, etc., can solve problems such as unreported, and achieve the effect of reducing reserve funds, reducing intermediate rolling waste, and improving utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

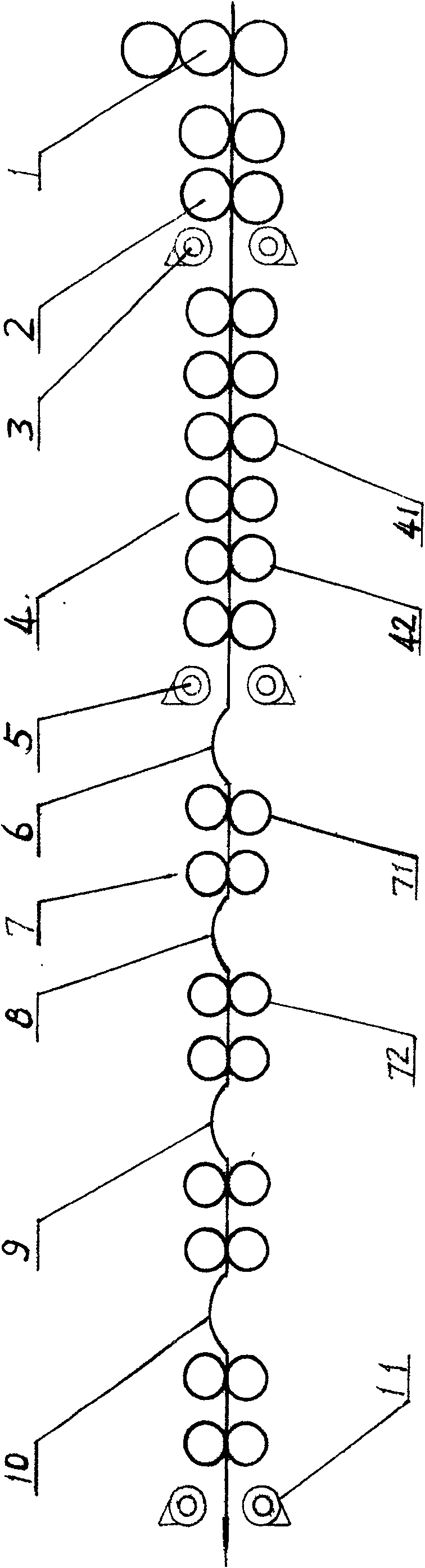

[0017] Embodiment 1: as attached image 3 The multi-strand rolling production process shown.

[0018] The multi-line rolling production process of the grooveless rolling process of the full horizontal rolling mill comprises a blooming mill 1, a junior rolling mill 2, a first flying shear 3, a second flying shear 5 and a third flying shear 11, an intermediate rolling unit 4, The first looper 6, the second looper 8, the third looper 9, the fourth looper 10, and the fine hole unit 7. Among them, the preliminary rolling mill 1 is a three-roll mill with a single stand, the junior rolling mill 2 is a two-roll mill, the middle rolling mill 4 is a six two-roll mill, and the finishing mill 7 is an eight two-roll mill (some rolling mills according to different specifications) optional), it is a fully horizontal rolling mill, arranged in tandem, and constitutes a continuous rolling mill. The first flying shears 3 are flying shears for head cutting, the second flying shears 5 are flying...

Embodiment 2

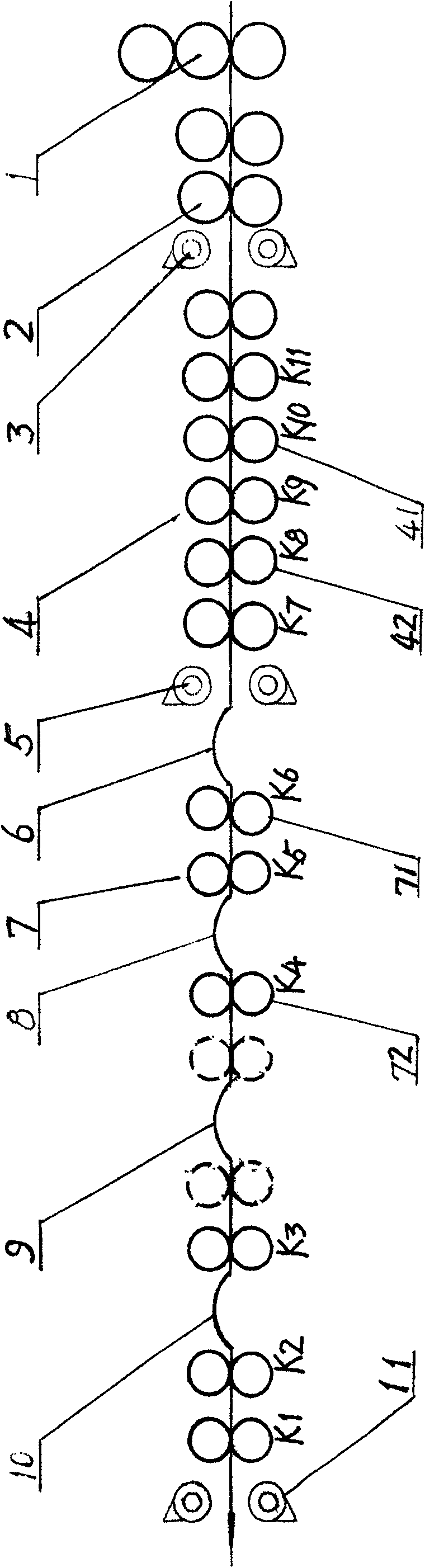

[0021] as attached Figure 4 The single-strand rolling process shown

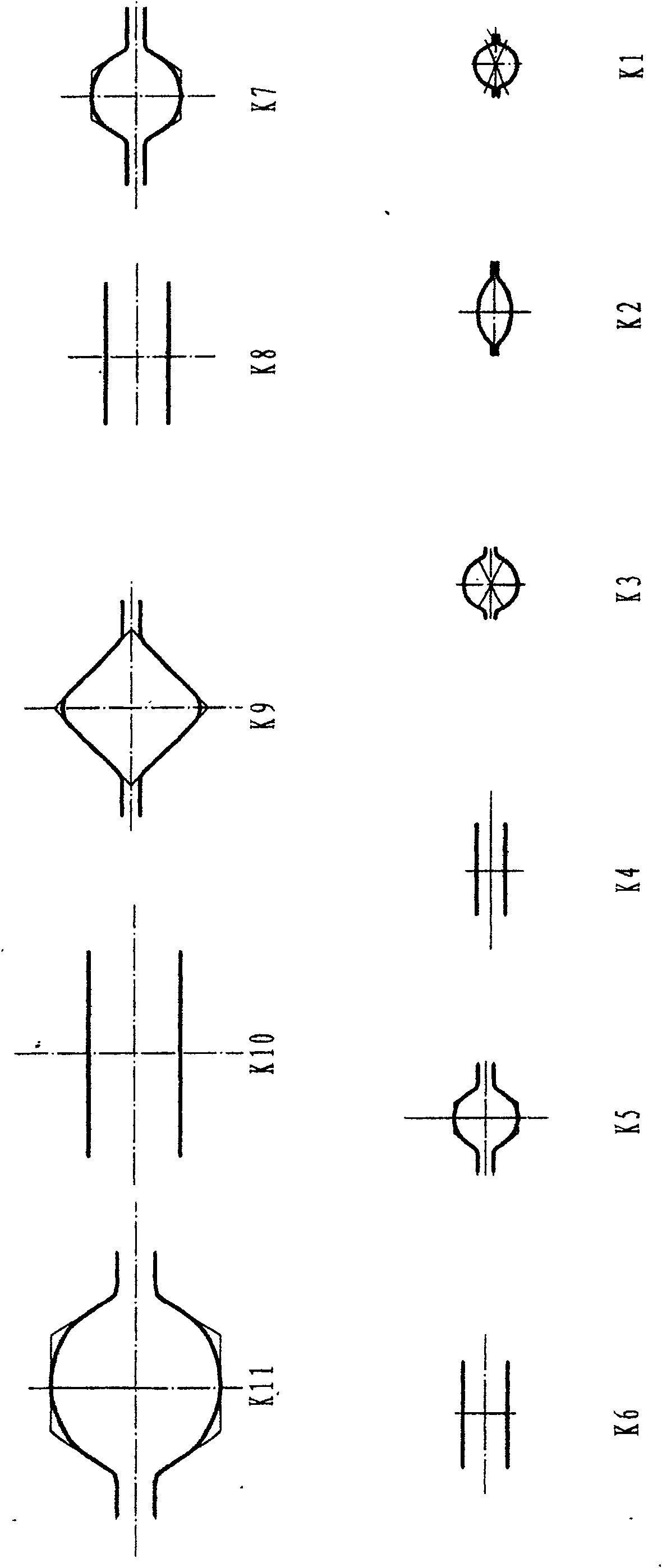

[0022] From the third rolling stand of the finishing rolling unit 7 (pass type is K 4 ) before the distribution of rolling mills and the distribution of rolling mills in the multi-strand rolling process (attached image 3 ) are the same, the passes of the fourth, fifth and sixth stands of the finishing rolling group 7 are as follows figure 2 K shown 3 、K 2 、K 1 .

[0023] During single-line rolling, the third rolling stand of the finishing rolling unit 7 (pass type is K 4 ) is a flat roll mill, and the flat roll material rolled by it enters the fourth stand of the finishing rolling unit 7 after being twisted by the torsion guide for 90° (pass type K 3 ) is rolled into a round hole-shaped material or a universal hole-shaped material, and enters the fifth rolling mill of the finishing rolling unit 7 through the third looper 9 (the pass type is K 2 ) rolled into a flat ellipse-shaped material, and aft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com