Bell type blast furnace smelting method by using small-size sinters

A technology for small-sized sintered ore and bell-type blast furnace, which is applied in the field of ore smelting, can solve the problems of complicated charging, distribution and air supply operations, and achieves the effects of reducing processing costs, improving economic benefits and ensuring normal production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

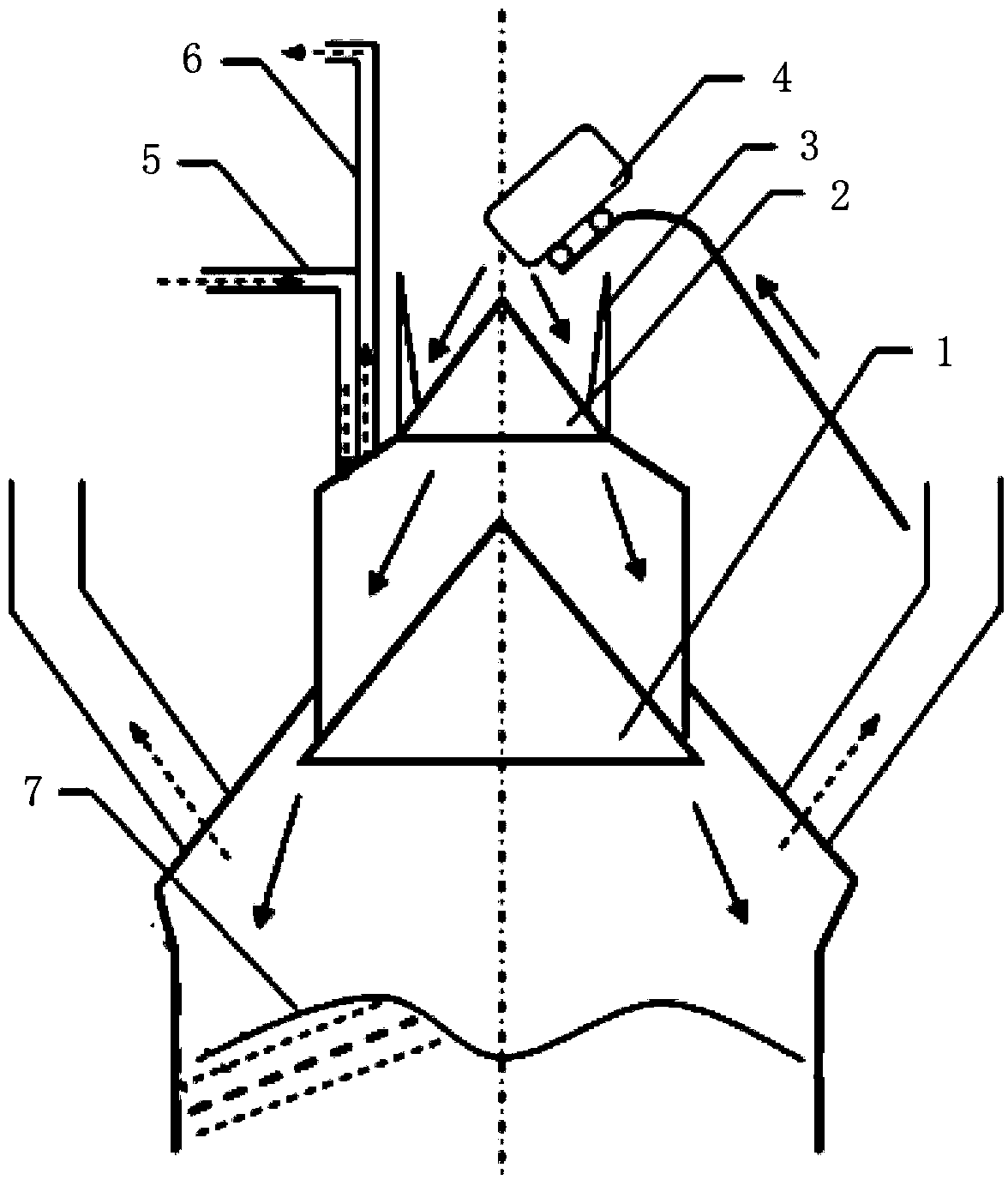

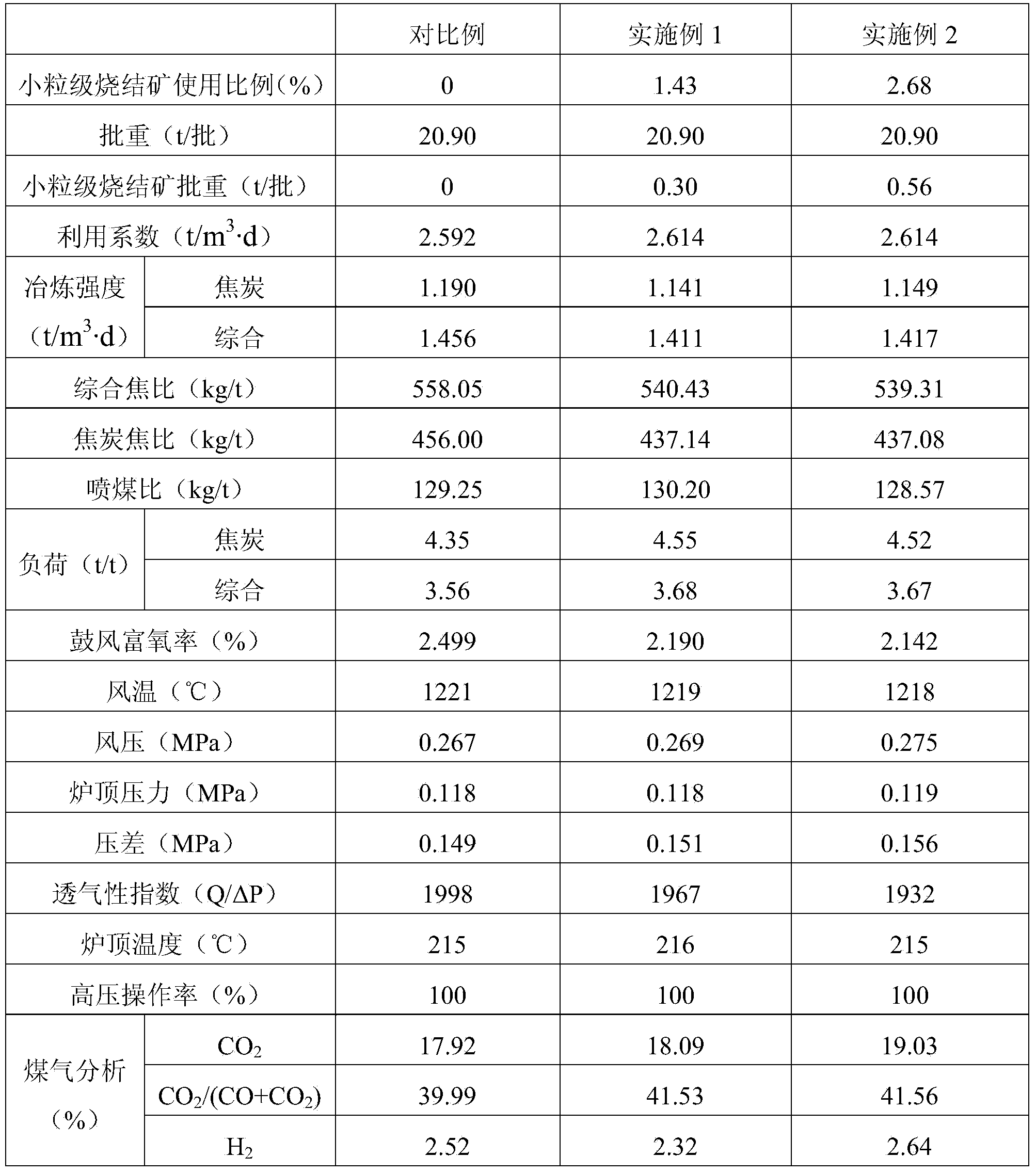

[0054] at 1200m 3 The bell-type blast furnace smelting vanadium-titanium magnetite is taken as an example to illustrate the method of using small-sized sinters for bell-type blast furnace smelting.

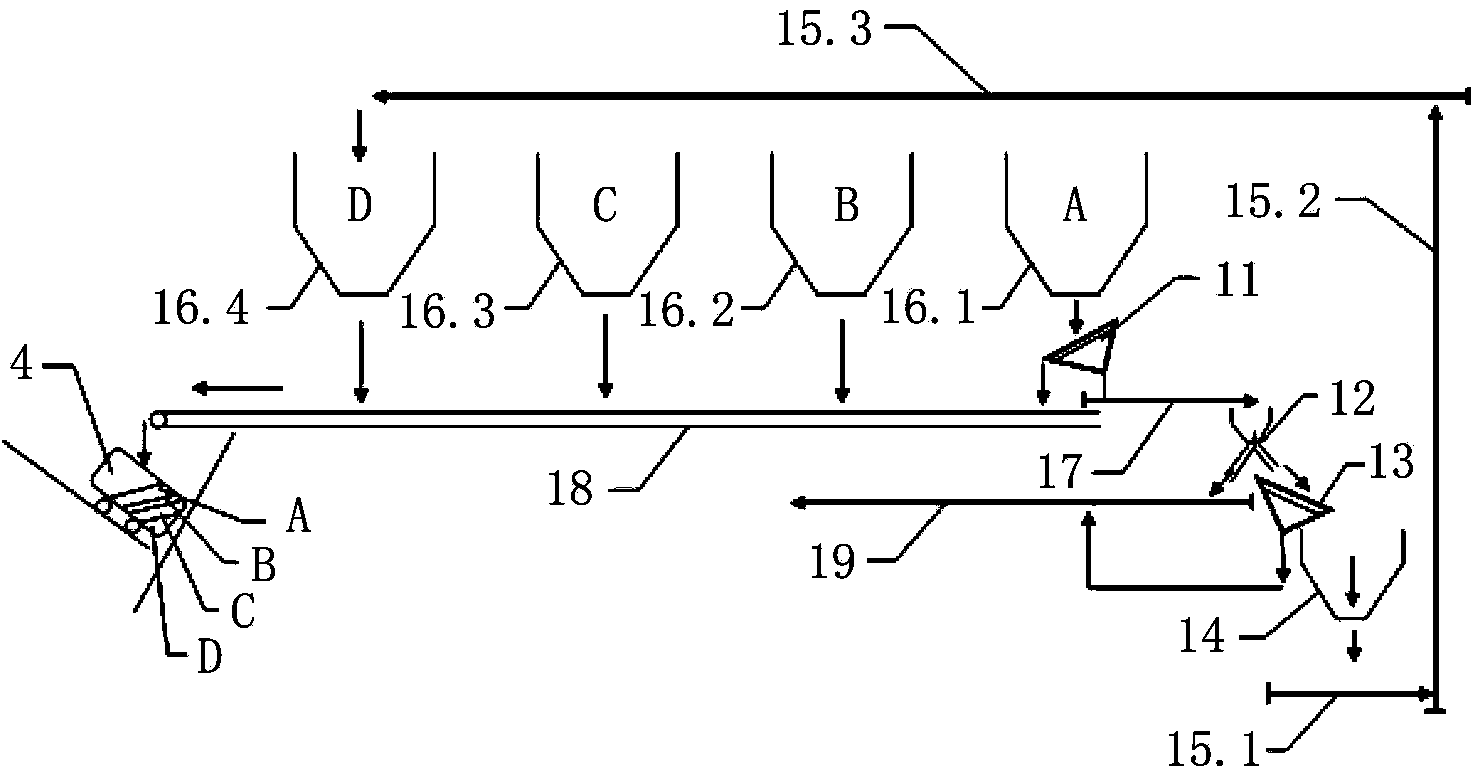

[0055] Preparation of small-sized sintered ore: the sintered ore stored in the ore storage tank 16.1 under the trestle bridge is screened by the sintering vibrating screen 11 under the ditch, and the sintered ore with a particle size of >5mm falls on the main feeding belt 18 under the ditch and enters the feeding In the trolley 4; the sintered ore (returned ore) with a particle size of 3mm is screened out from the returned ore, and stored in the ore tank 14, and then new belt conveyors 15.1, 15.2, 15.3, etc. are built or the small grained sintered ore >3mm is transferred to an independent mine under the ditch by using the blast furnace trestle belt Tank 16.4 is stored for use in the blast furnace; the returned ore of the undersize <3mm passes through a small belt or a drain (not s...

Embodiment 2

[0064] The process flow is the same as in Example 1, and the process parameters and smelting effects are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com