Patents

Literature

111results about How to "Reduce scrap costs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

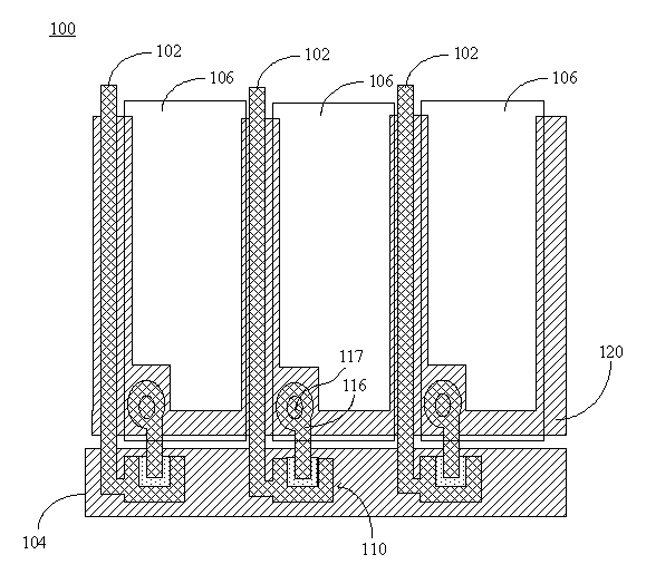

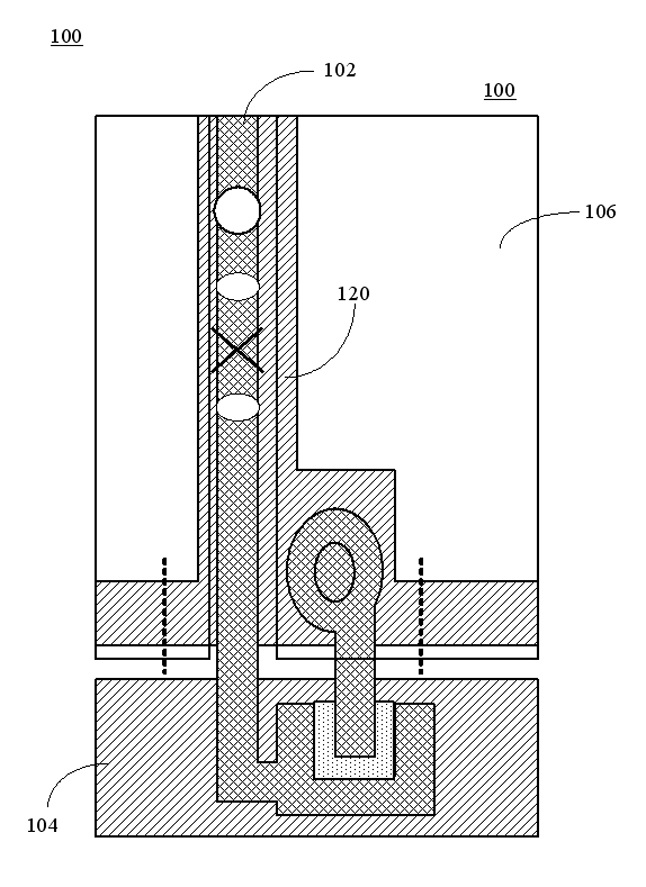

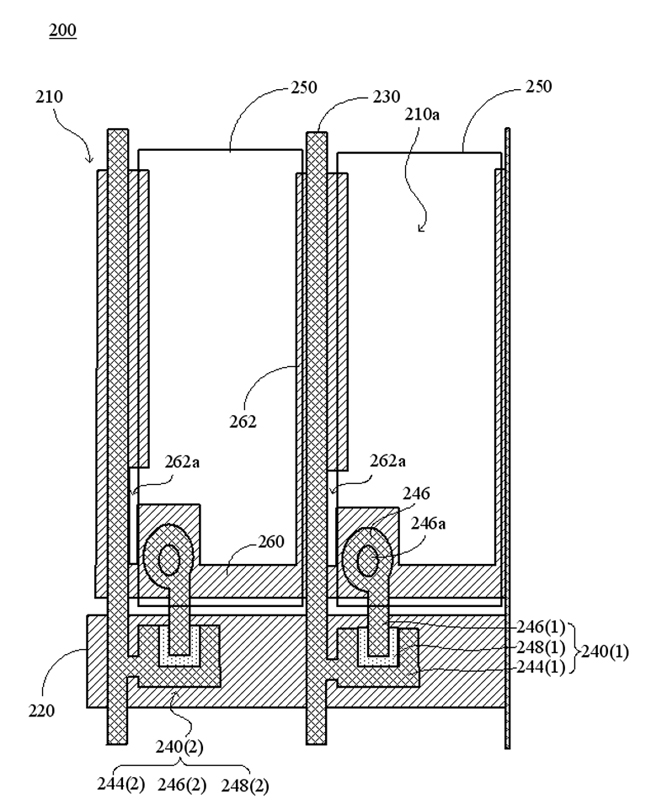

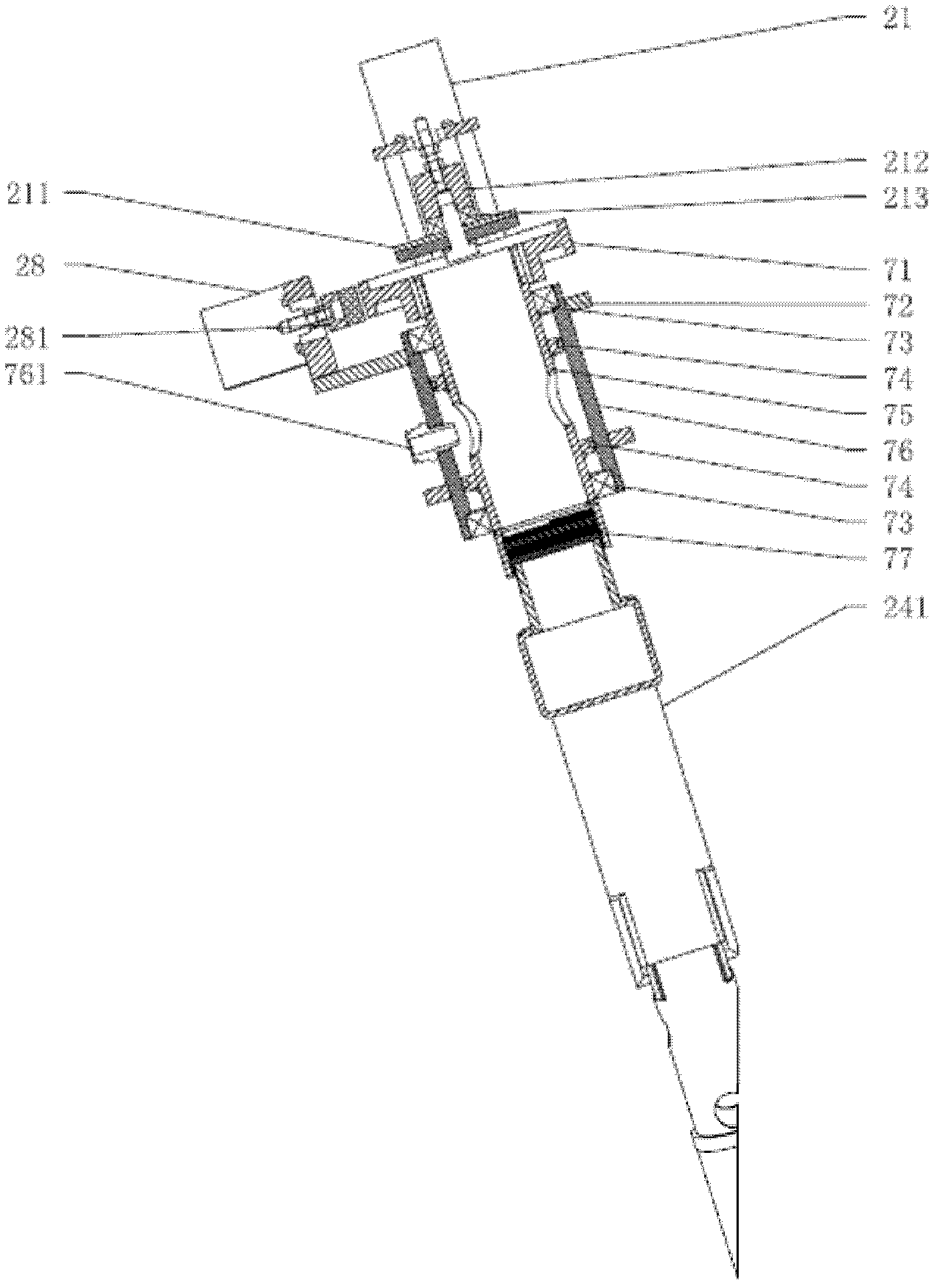

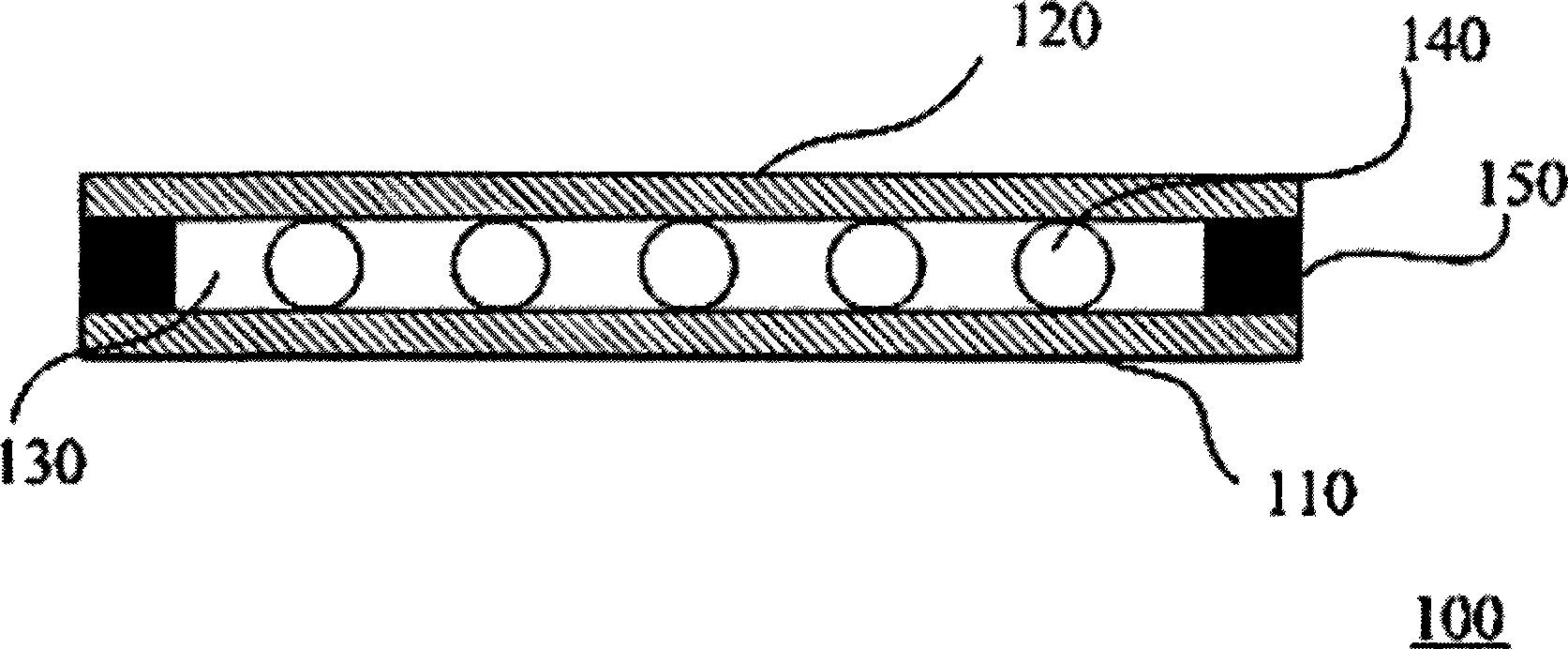

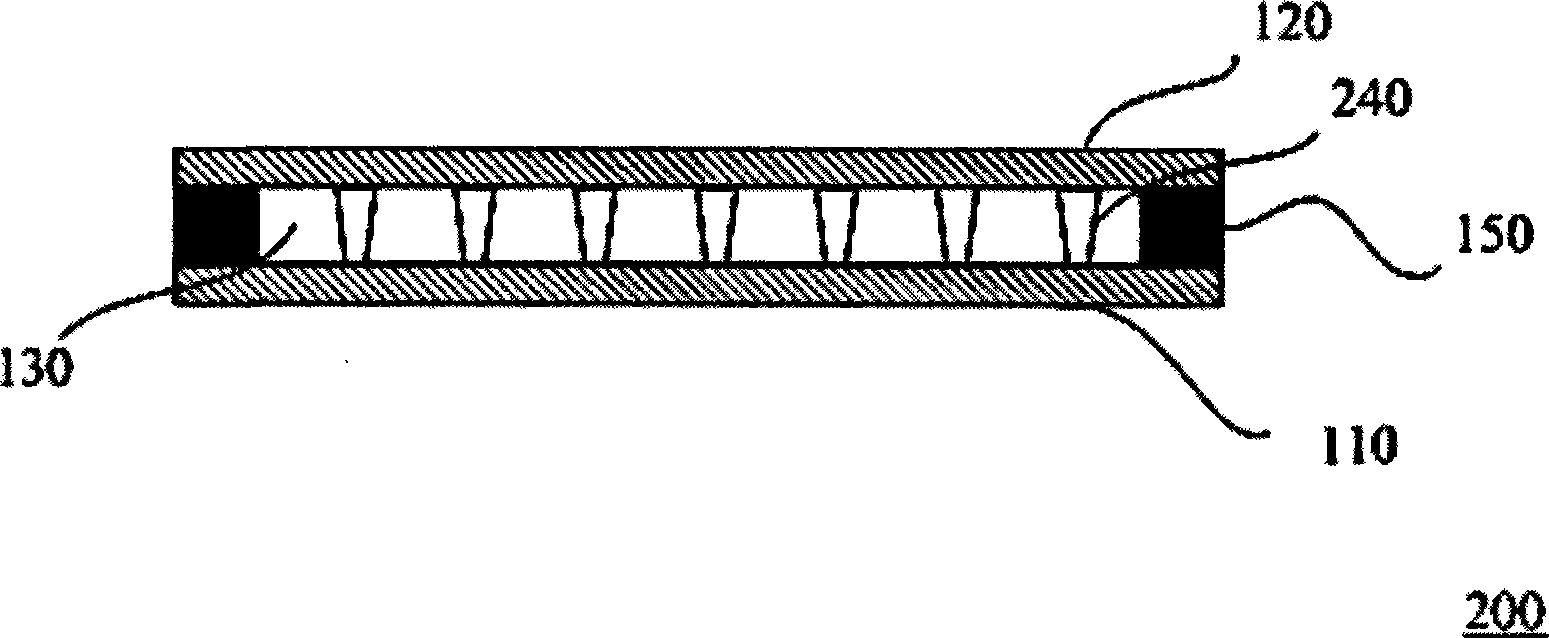

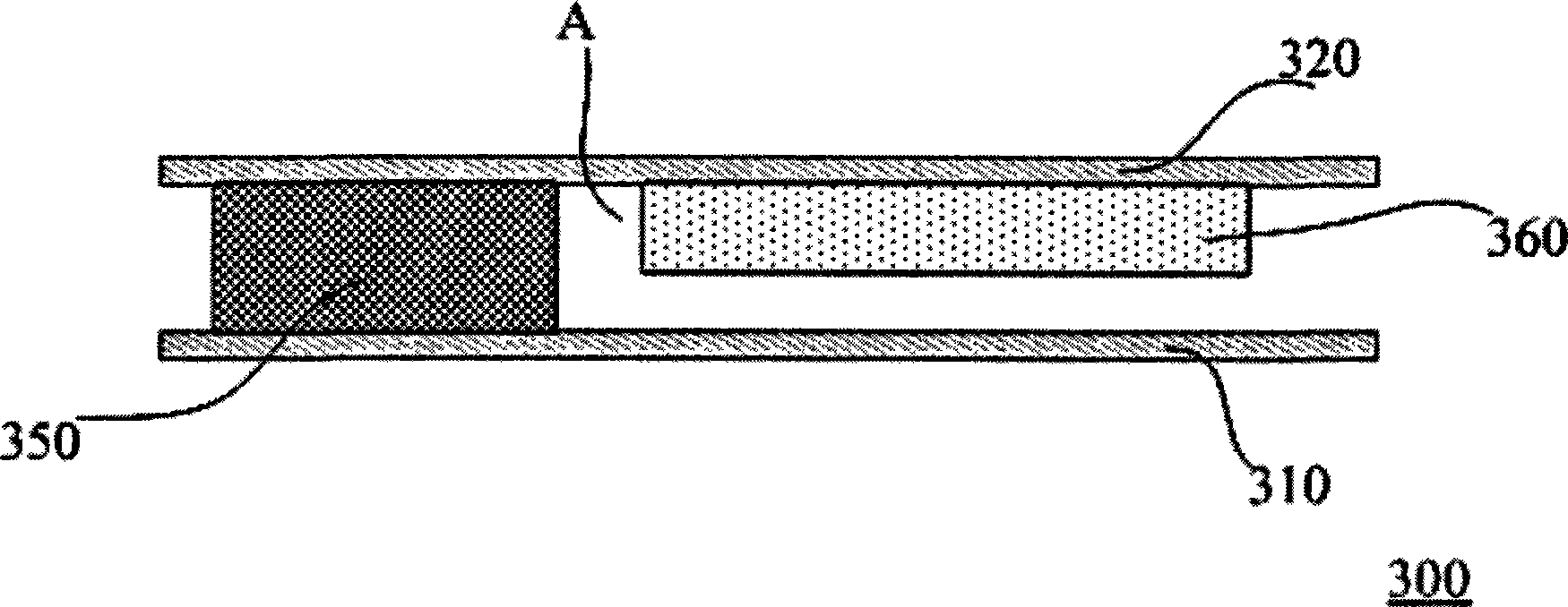

Filter Assembly

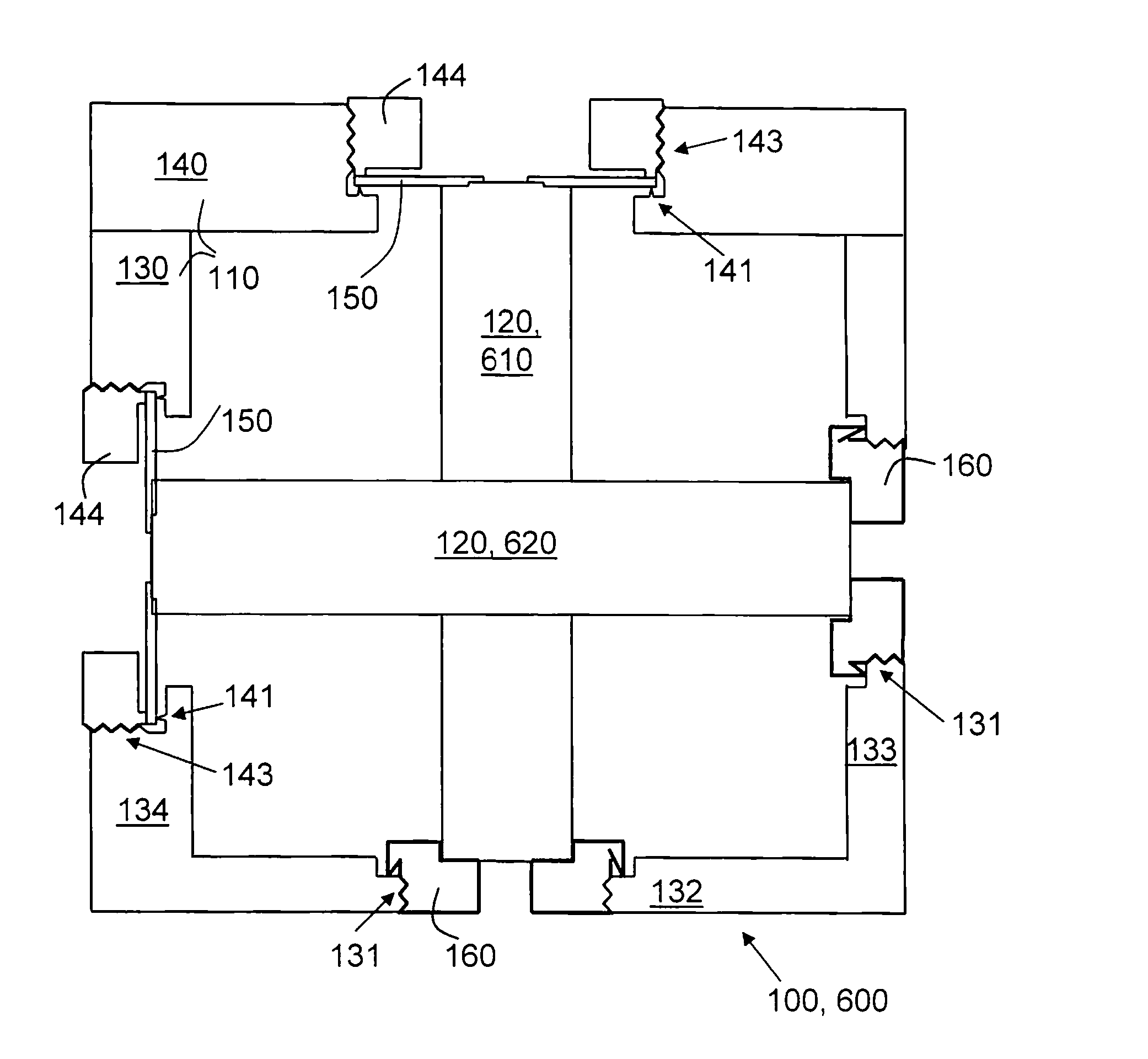

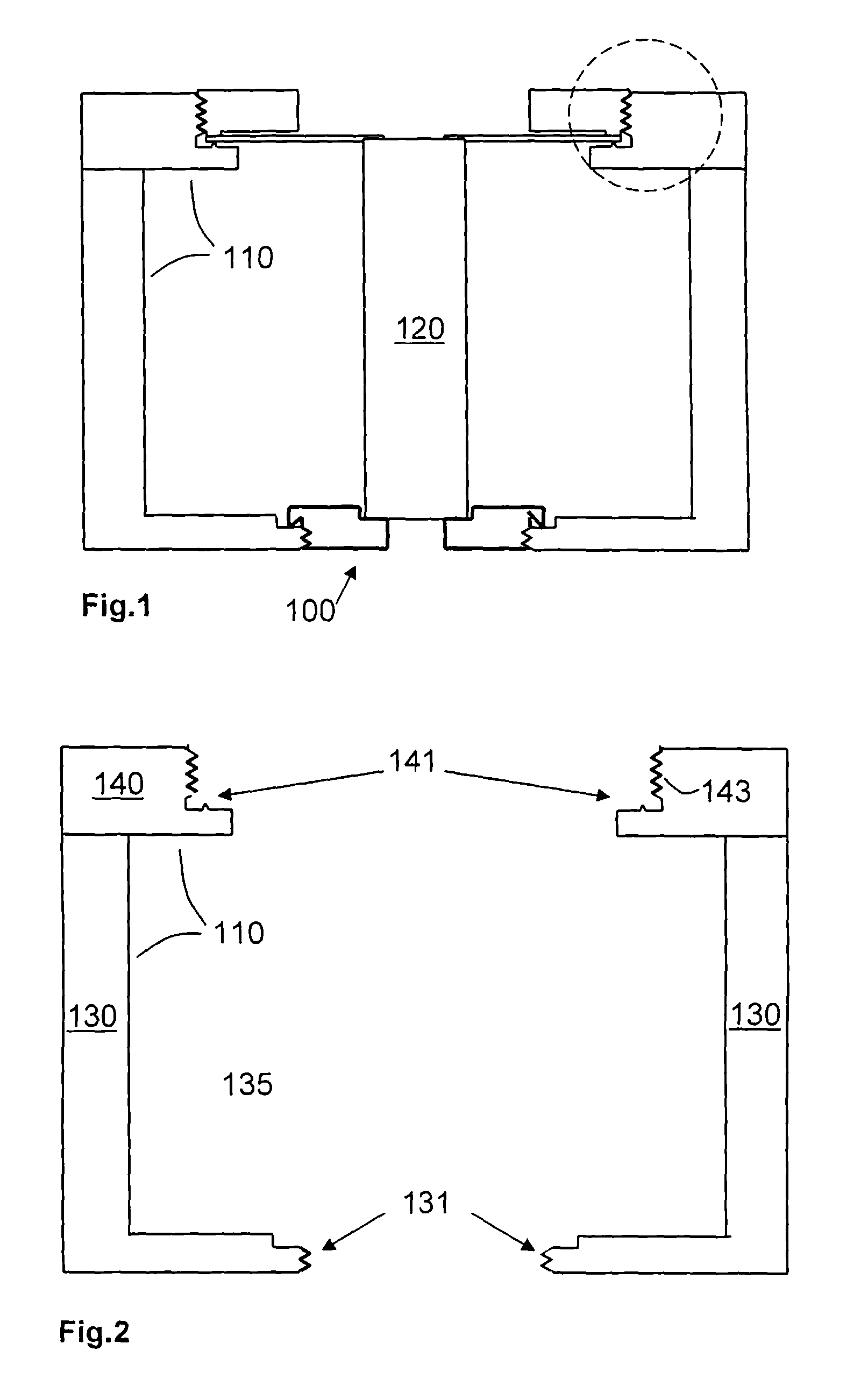

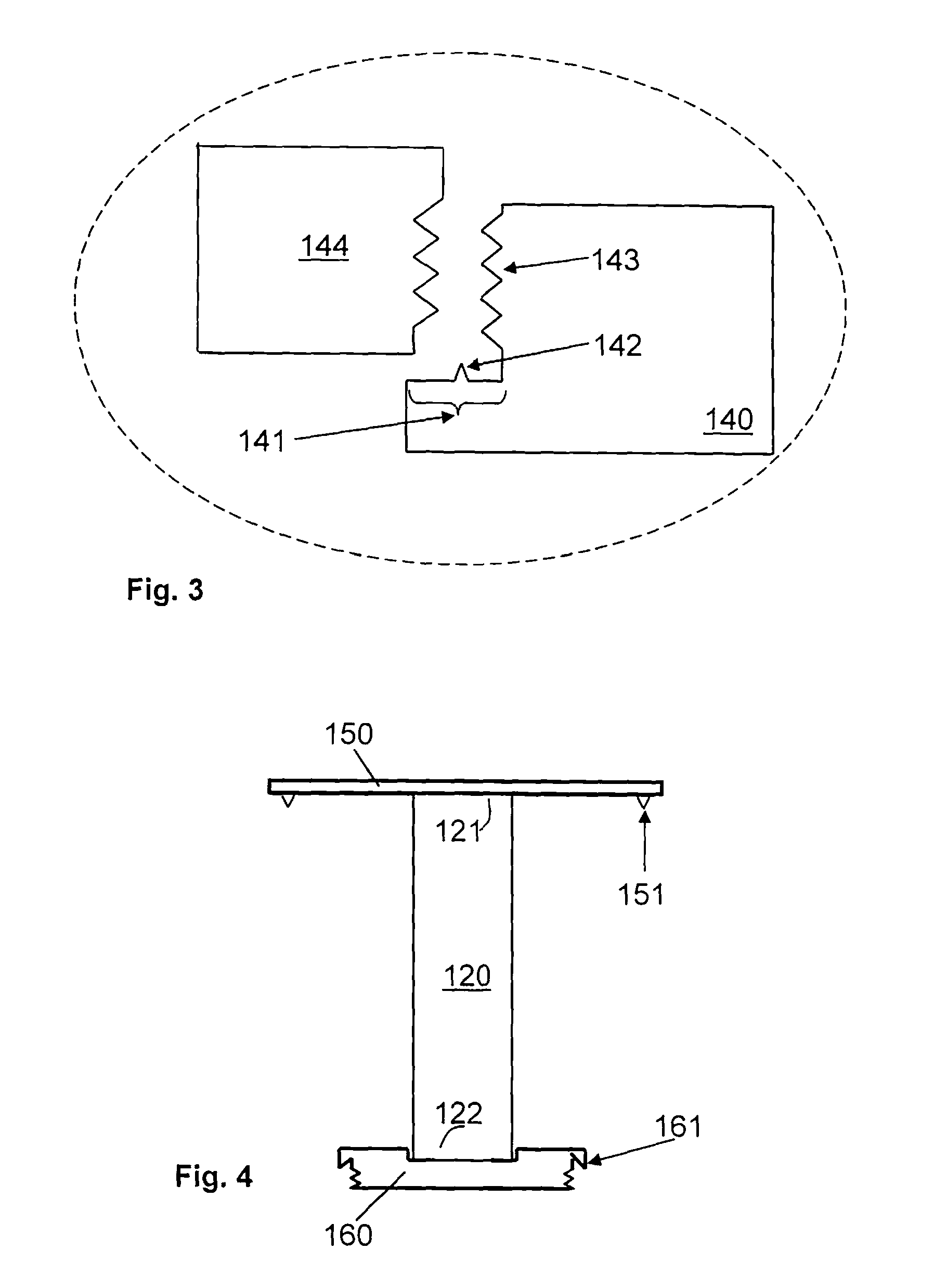

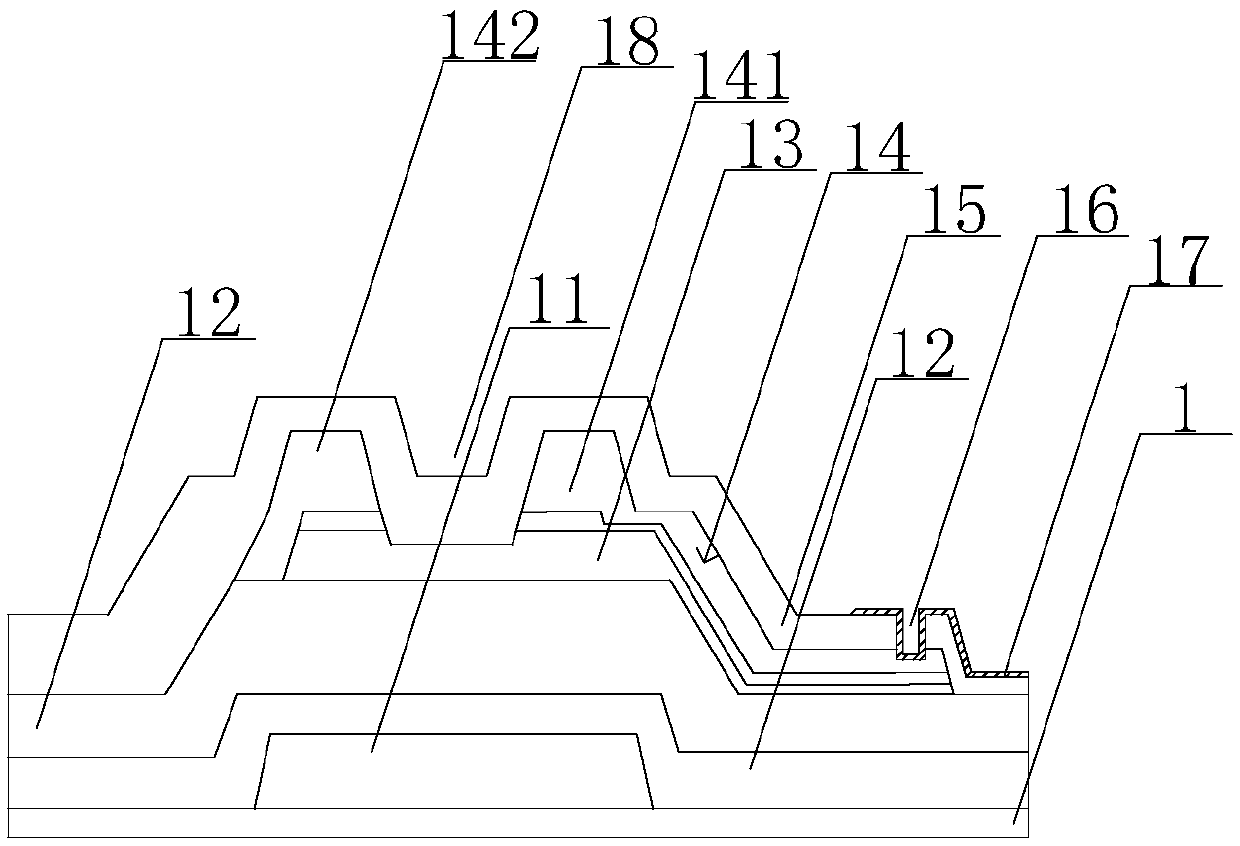

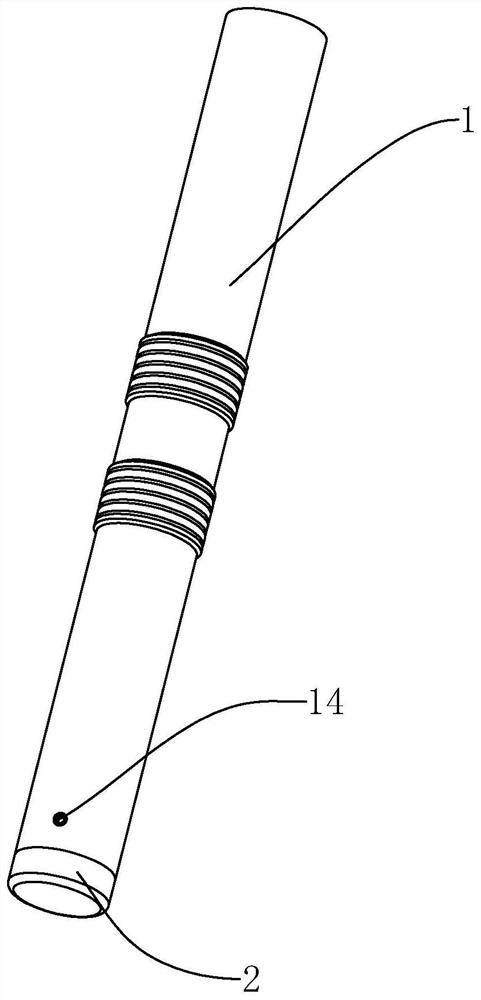

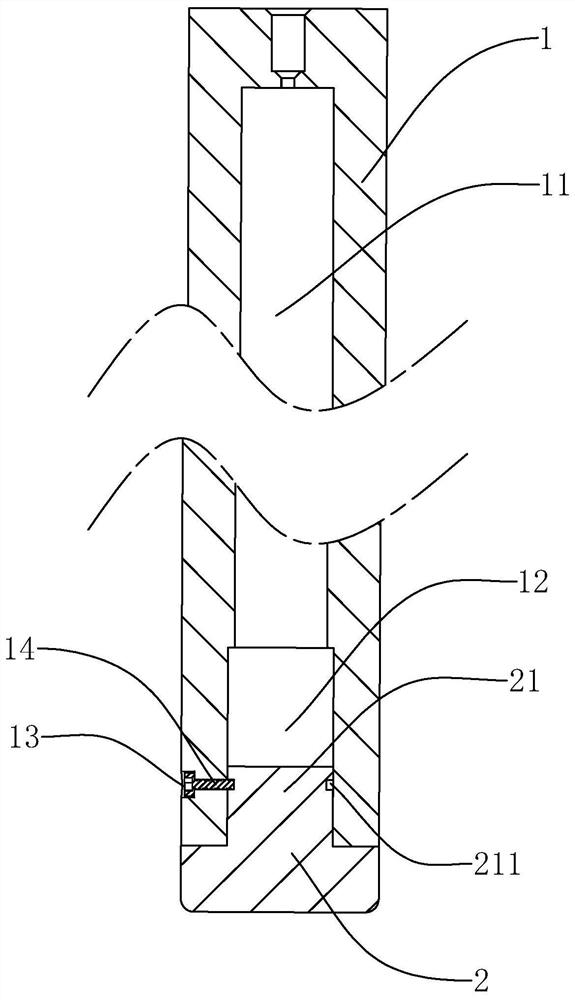

An object of the present invention is to provide an improved and simplified filter assembly. The object is achieved by a dielectric rod (120, 610, 620) for a filter chassis (110). The dielectric rod (120, 610, 620) extends between a first end (121) and a second end (122). The dielectric rod (120, 610, 620) comprises a conductive element (150) placed at the first (end 121). The conductive element (150) is adapted to be in conductive contact with a first contact means (141) of the filter chassis (110). The dielectric rod further comprises a second fastening element (160) placed at the second end (122). The second fastening element (160) is adapted to be attached and detached to a first fastening element (131) comprised in the filter chassis (110), such that the dielectric rod (120, 610, 620) is replaceable in the filter chassis (110).

Owner:TELEFON AB LM ERICSSON (PUBL)

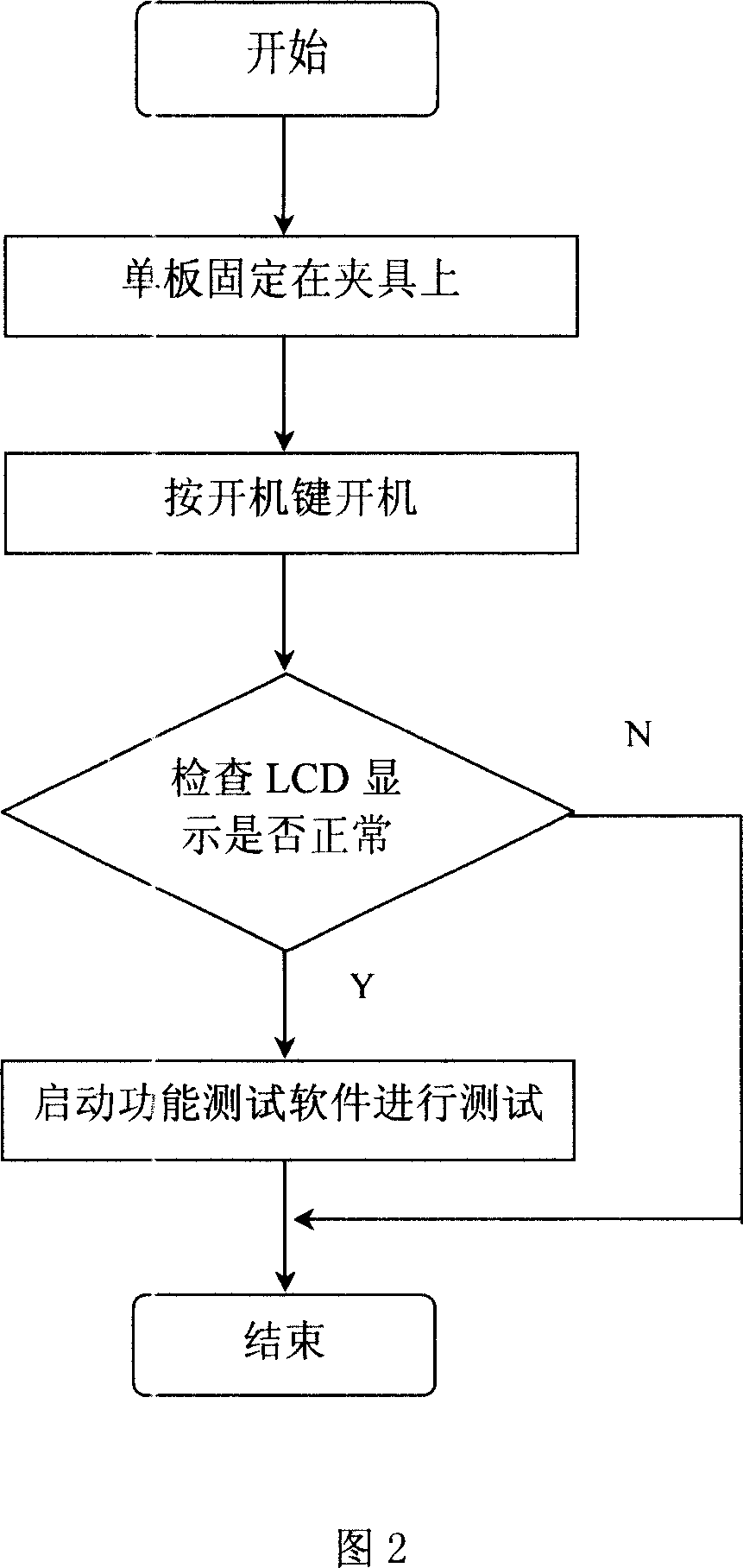

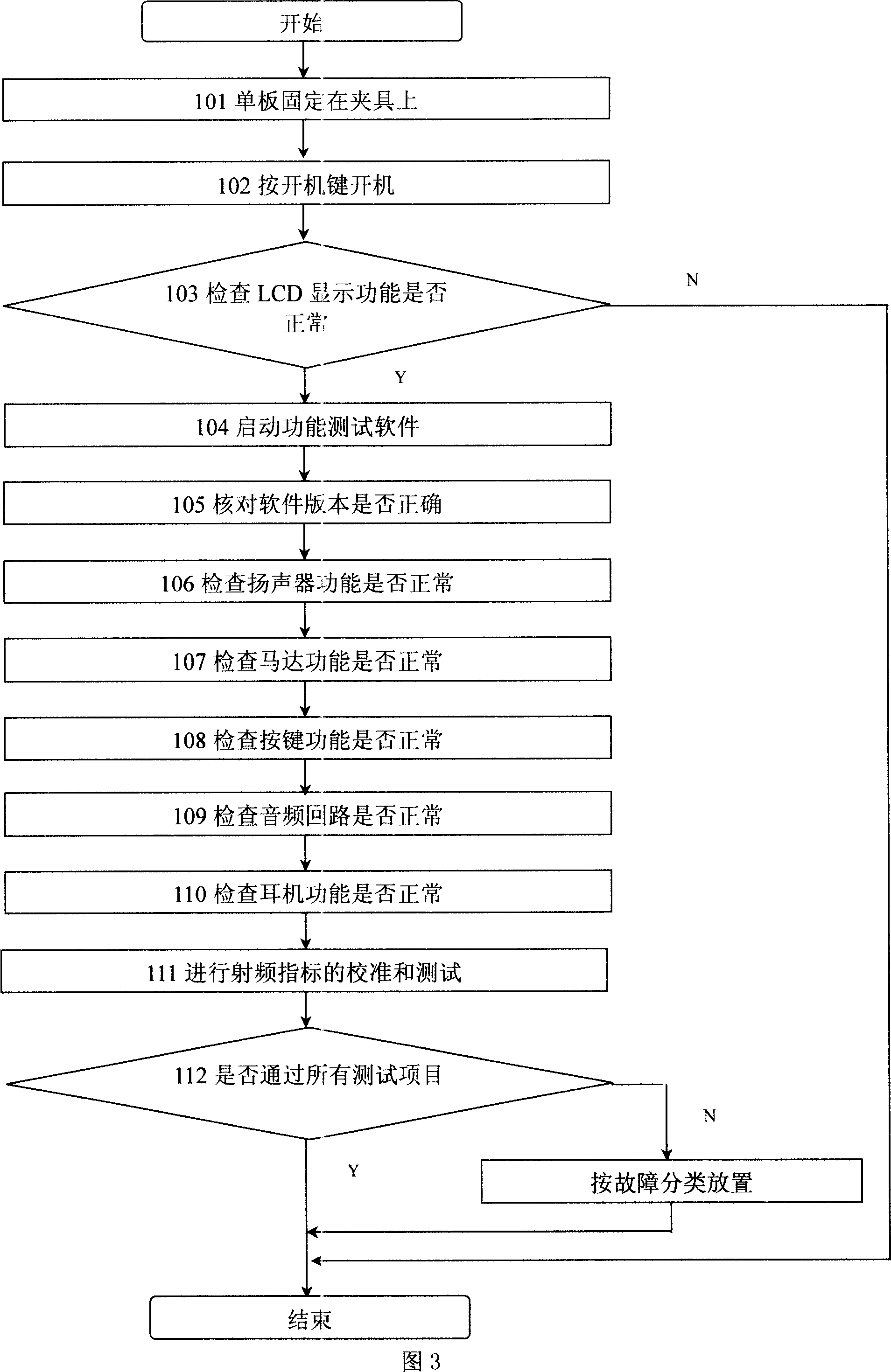

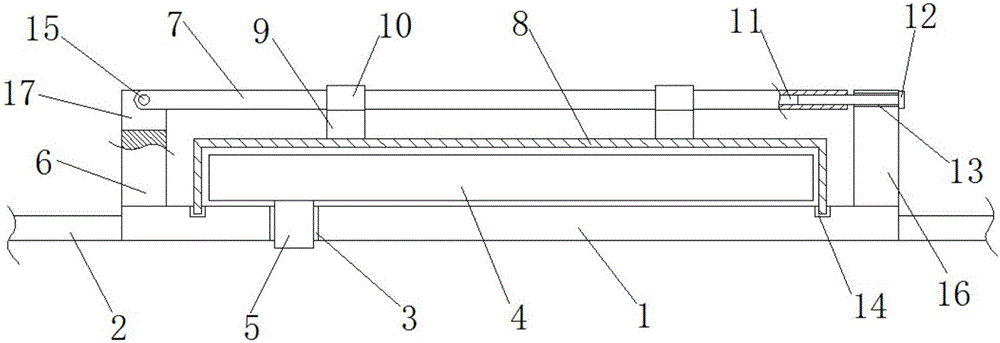

Testing system and method for mobile phone single board

InactiveCN101145859AShort development cycleLow costSubstation equipmentRadio/inductive link selection arrangementsFunctional testingSingle plate

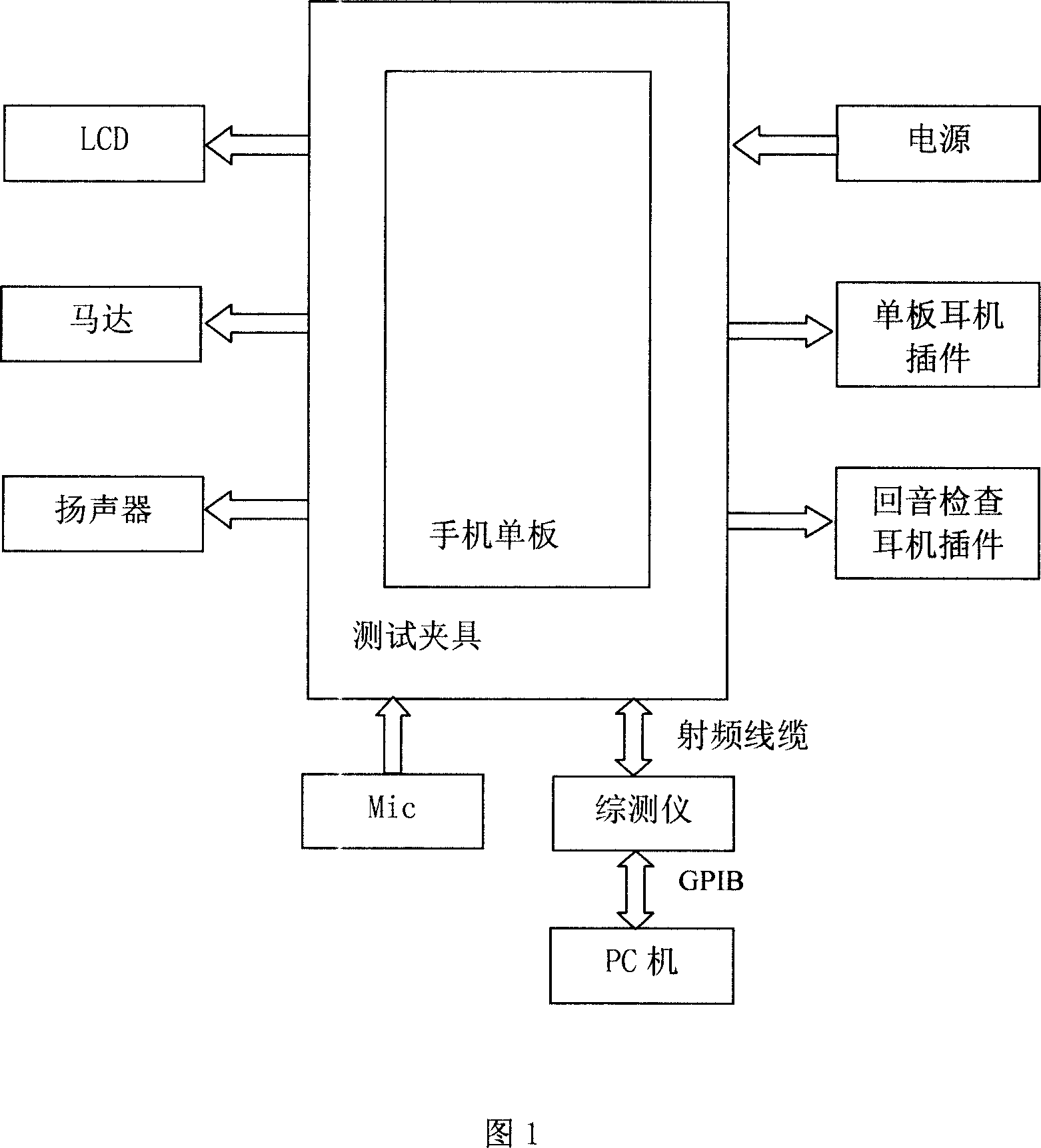

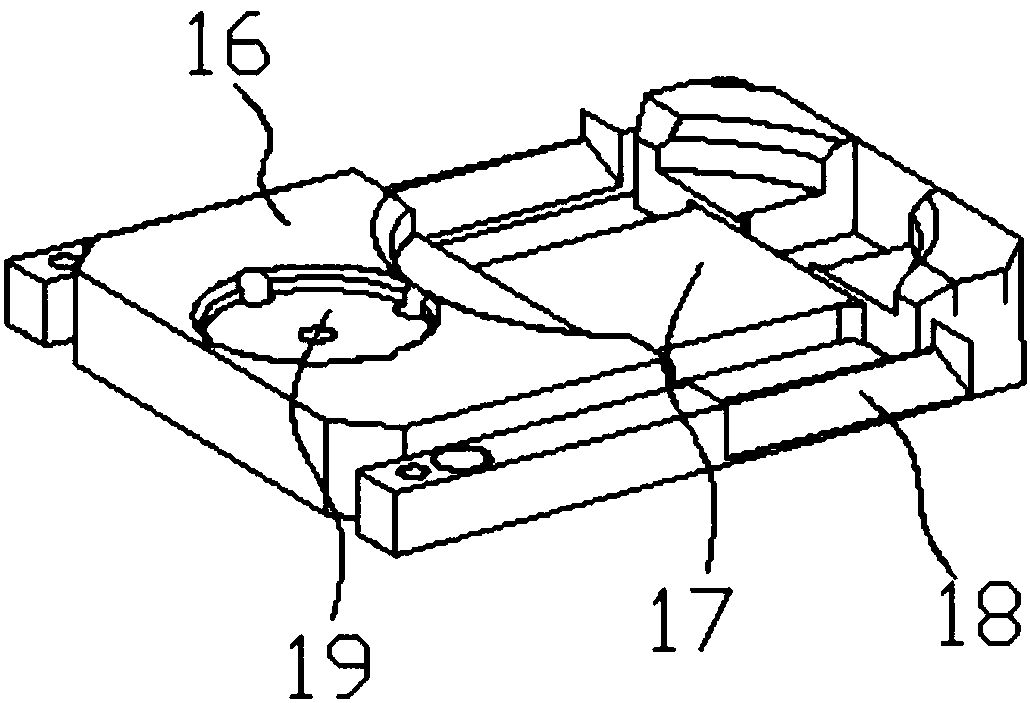

The invention discloses a system and a method for the functional test of a mobile phone single board. Aiming to solve the problems of high cost but low efficiency of functional test technology of the existing mobile phone single board, the mobile phone single board test system of the invention comprises a test fixture, functional components, a power supply, a synthetic tester and a computer. The mobile phone single board is fixed on the test fixture, and the mobile single board test point contacts the test probe of the test fixture. The power supply provides power for the mobile phone single board. The functional components fixed on the test fixture are used for the functional test to the mobile single board. The computer controls the synthetic tester to calibrate and test the radio frequency of the mobile phone single board by the test fixture. The test method comprises the followings steps. Firstly, the mobile phone single board is fixed on the test fixture. Secondly, the mobile phone single board is started. Thirdly, a LCD displays images. If the display is normal, the fourth step can be carryout out; otherwise the test ends. Fourthly, the mobile phone single board is tested. The invention has the advantages of low cost as well as high efficiency.

Owner:ZTE CORP

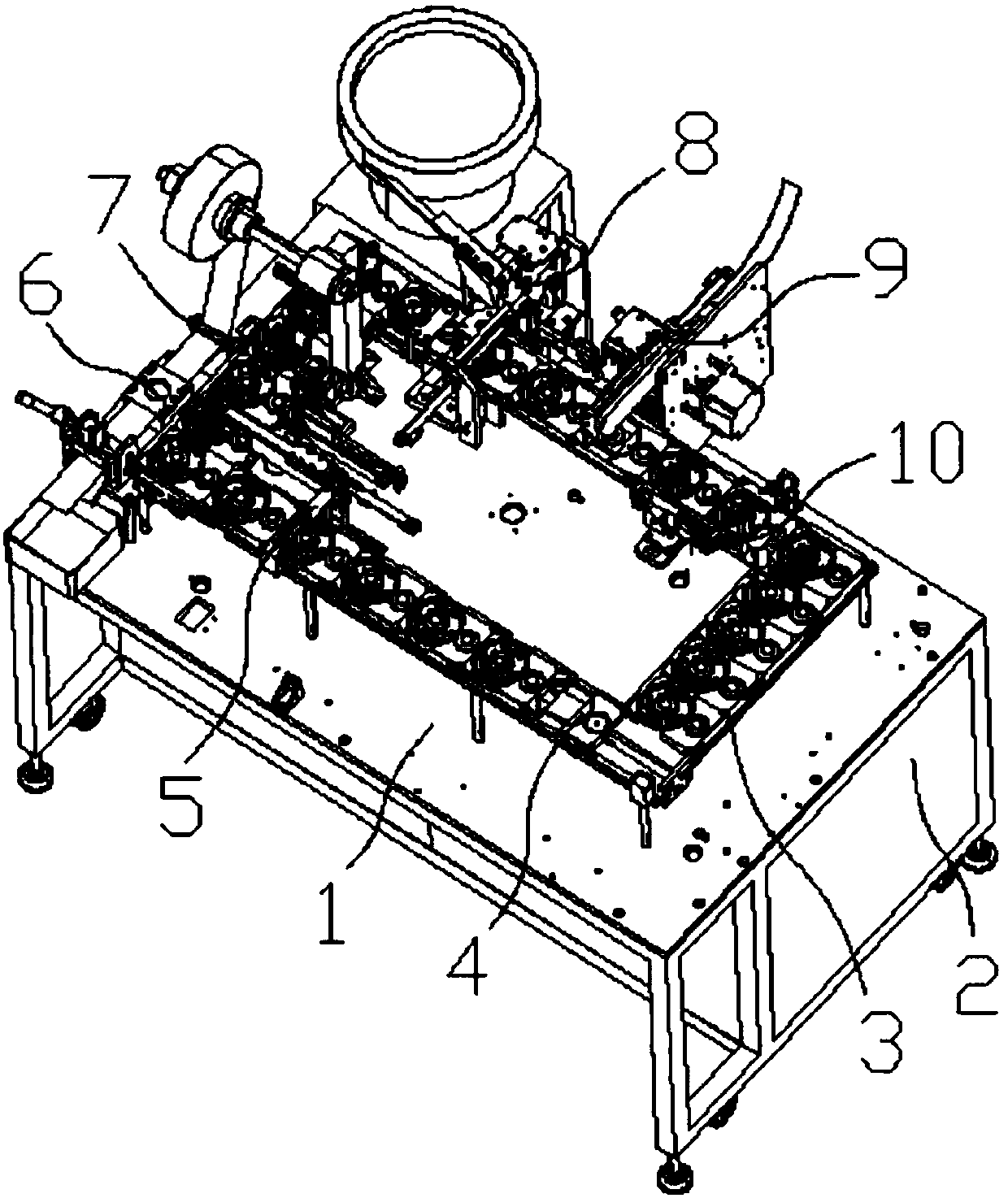

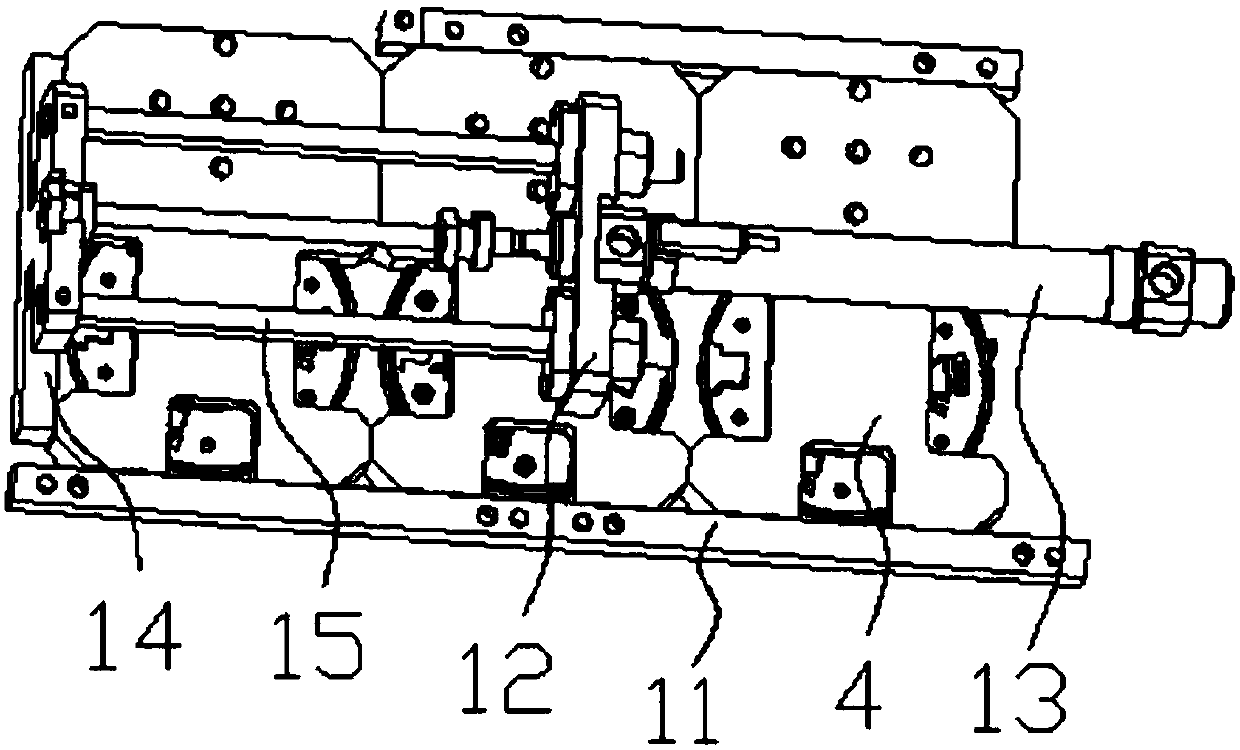

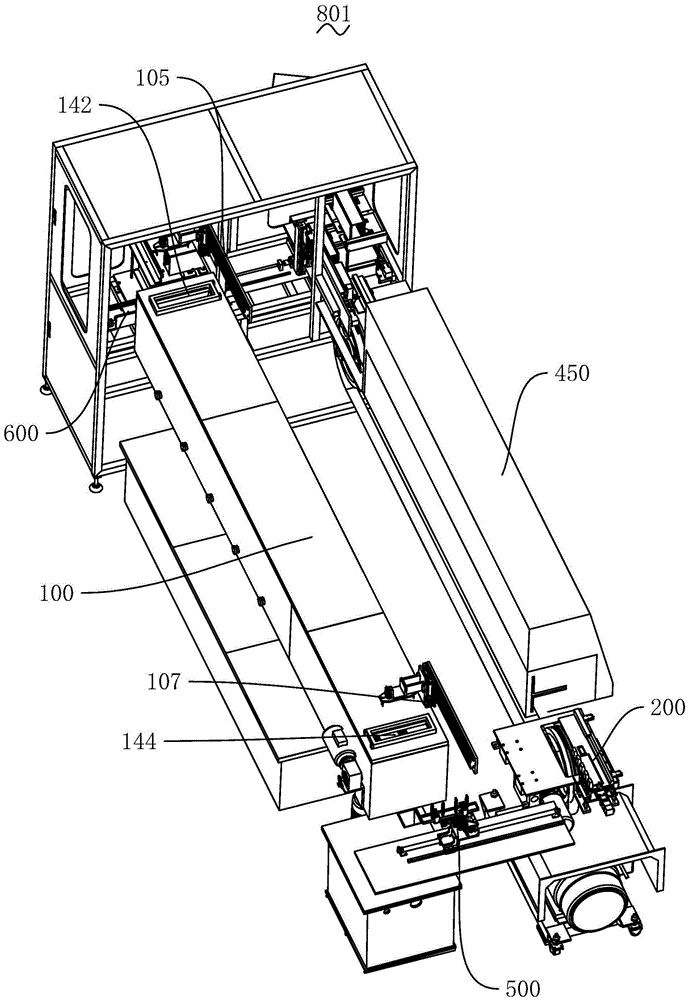

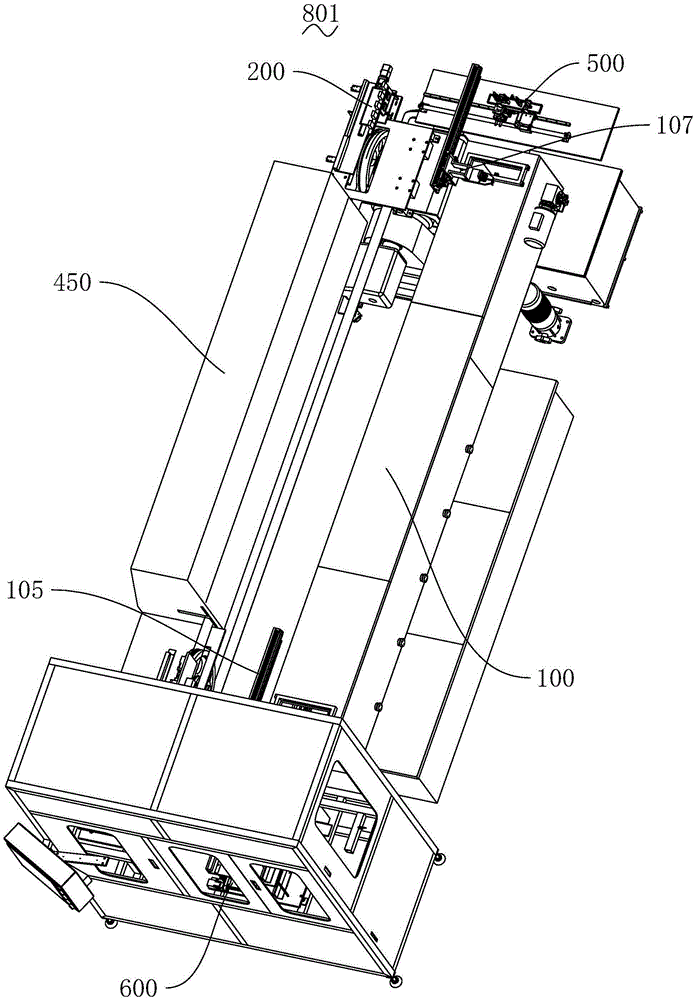

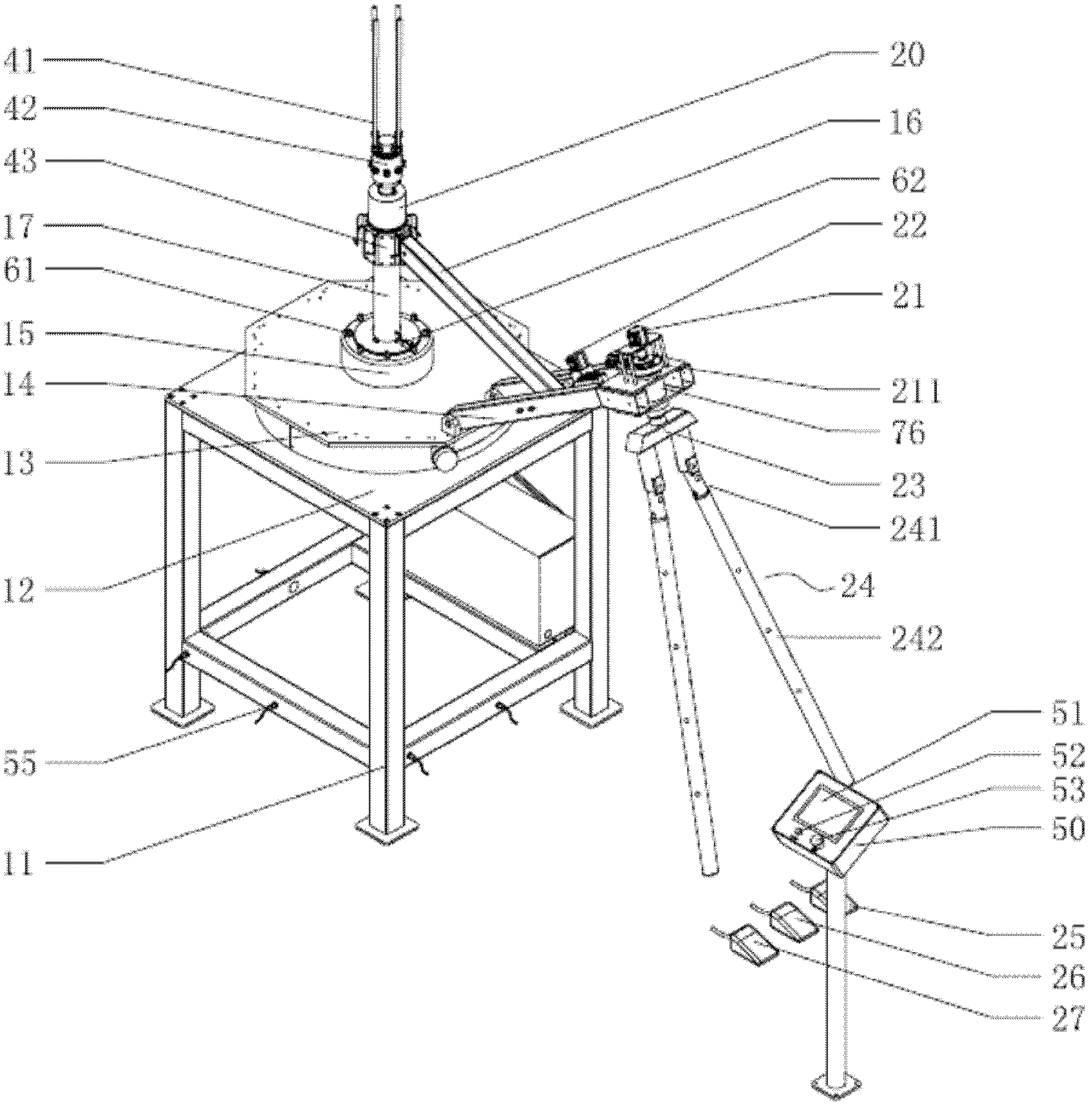

Full-automatic assembly machine for bottom shell component of hanging headphone

ActiveCN107770715AReduce collection and transportation costsIngenious structural designMicrophonesLoudspeakersLight barrierHeadphones

The invention relates to a full-automatic assembly machine for a bottom shell component of a hanging headphone. A rack is provided with a carrier transfer device transferring clockwise, the carrier transfer device comprises a carrier transfer trough, the carrier transfer trough is internally fitted with a carrier, the bottom of the carrier transfer trough is provided with a carrier transfer installation base, the carrier transfer installation base is provided with a carrier feed air cylinder parallel to the carrier transfer trough, a carrier feed trough is arranged in the middle of a feed endof the carrier transfer trough, the carrier feed air cylinder is connected with a carrier feed push block matched with the carrier feed trough, and the rack is provided with a dustproof net feed mechanism, a horn assembling device, a film assembling mechanism, a light barrier assembling mechanism and a horn dispensing device that are matched with the carrier. Through adoption of the full-automaticassembly machine, continuous, automatic assembling is realized, a bottom shell feeding position and an assembled bottom shell discharging position are at the same position, so that a bottom shell material tray can be used for collecting a material of the assembled bottom shell, therefore, the collecting and transporting costs are lowered.

Owner:CHONGQING TECH & BUSINESS UNIV

Manufacturing method for metal semi-hole circuit board

InactiveCN103327753AAvoid WeldingReduce repair costsPrinted element electric connection formationTinningState of art

The invention discloses a manufacturing method for a metal semi-hole circuit board. According to the manufacturing method, after an outer layer graph of the circuit board is manufactured, graph electrolytic tinning treatment is carried out, tinning is carried out on the circuit graph and a drill hole needing to be protected, then a semi-hole is milled in the position of the drill hole, burr flashes are formed in the position of the hole opening after the semi-hole is milled, and then the etching treatment is carried out. As the circuit graph and the drill hole are protected by tinning, the burr flashes in the position of the hole opening are not tinned and can be etched off while the whole circuit graph and the drill hole are not influenced. Compared with the prior art, the manufacturing method is simple in process, avoids the problems of unsecured welding legs and cold solder joints occurring when follow-up welding is carried out on the circuit board, effectively solves the problem of production scrap, and lowers the maintenance cost and the scrap cost caused by the problem of the burr flashes.

Owner:SHENZHEN SUNTAK MULTILAYER PCB

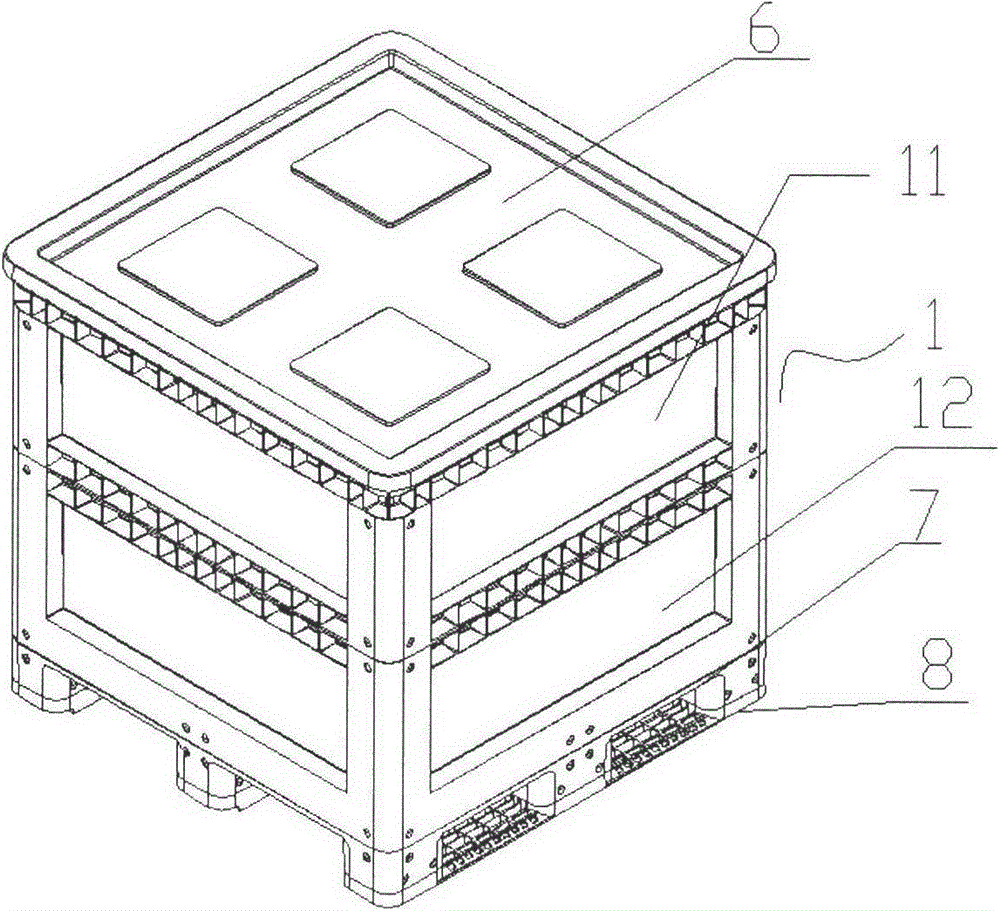

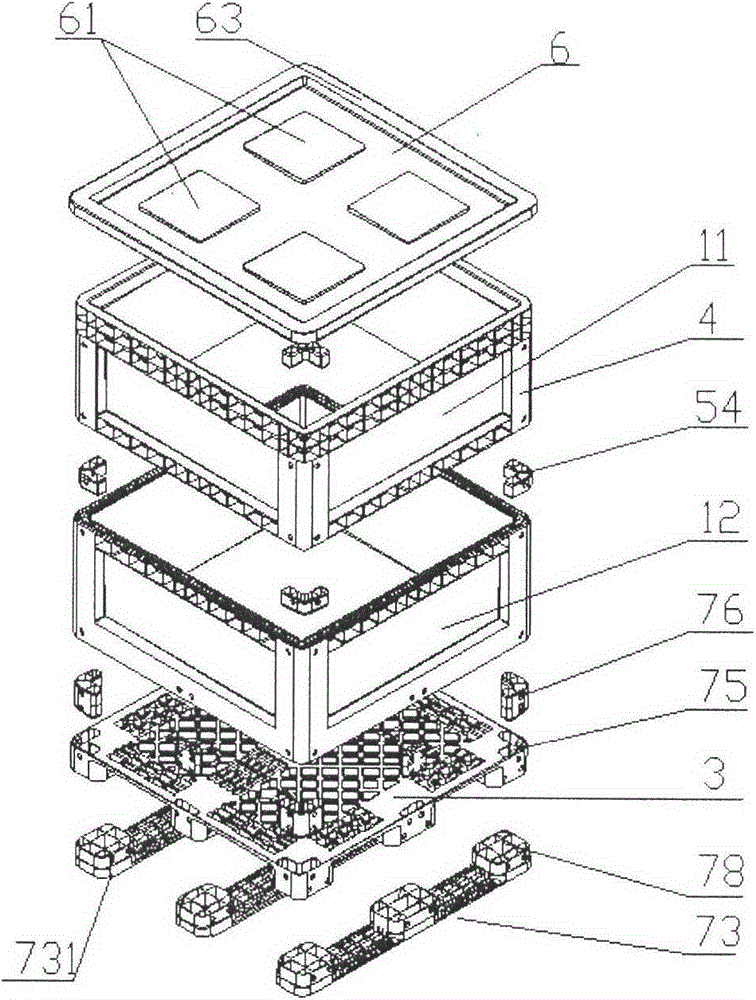

Detachable heat insulation and preservation box

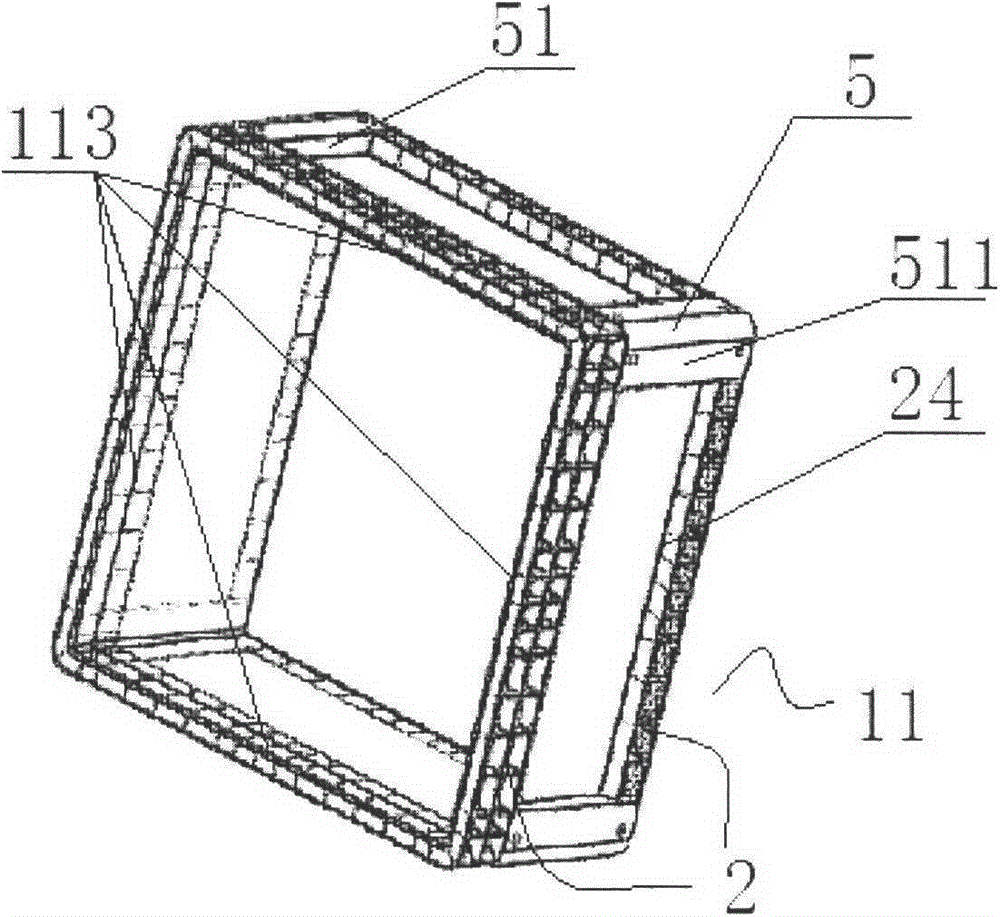

ActiveCN103964076AEasy to produceEasy to assemble and disassembleDomestic cooling apparatusLighting and heating apparatusInsulation layerThermal insulation

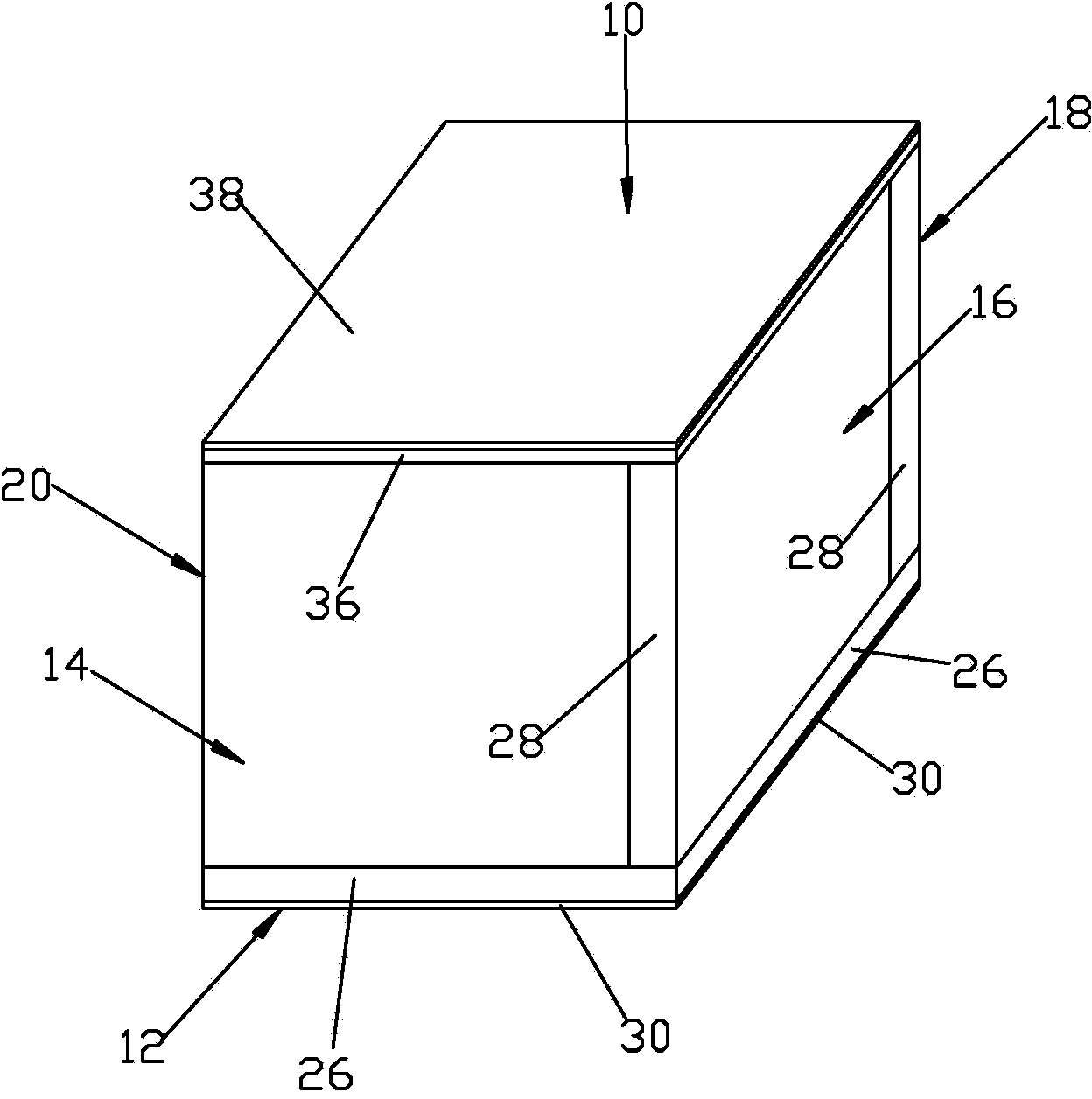

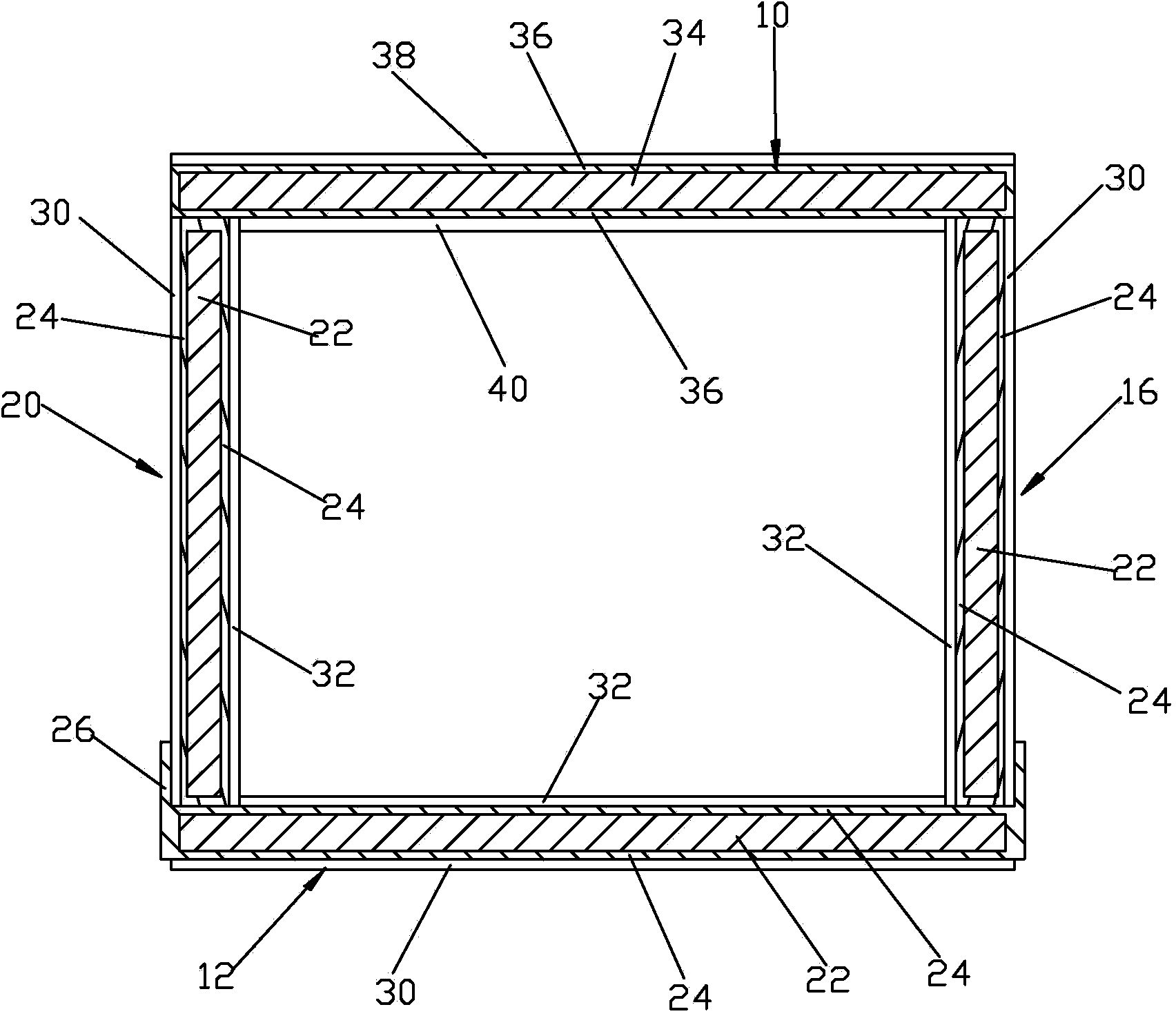

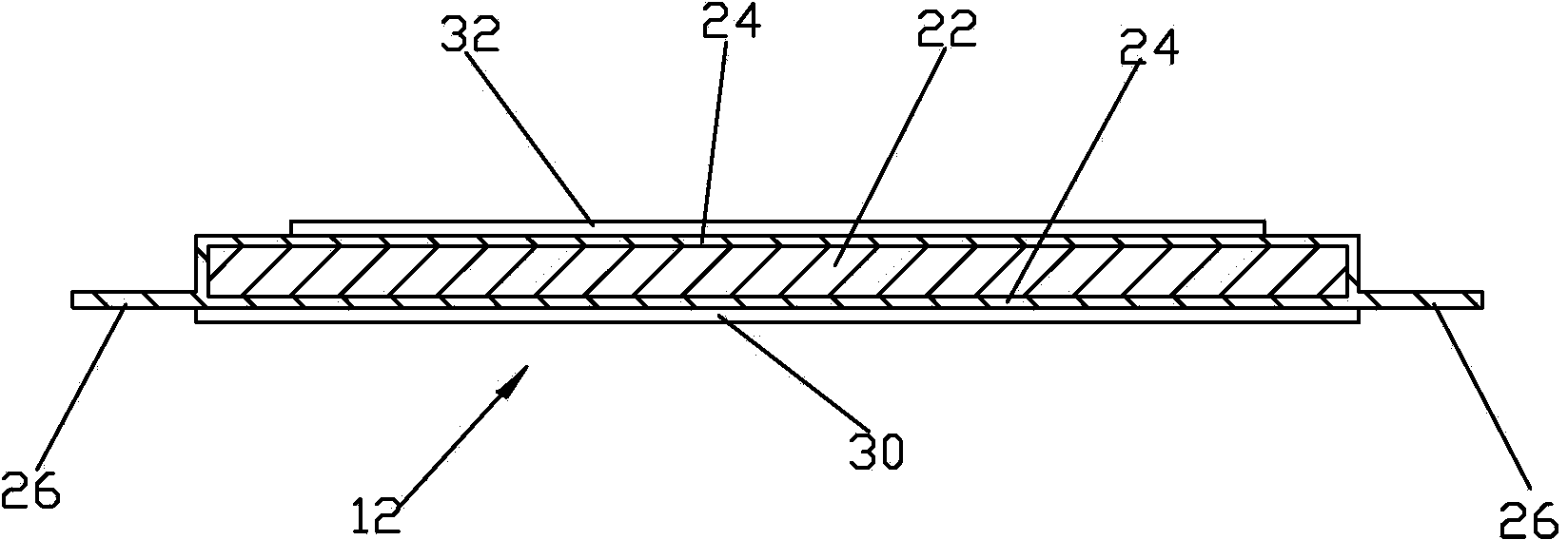

The invention discloses a detachable heat insulation and preservation box. The detachable heat insulation and preservation box comprises a box body. The box body comprises a plurality of heat insulation plate units. The heat insulation plate units can be assembled together to form the box body. Each heat insulation plate unit comprises a heat insulation plate and a coating layer coating the heat insulation plate. Each heat insulation layer is provided with a connecting lug part stretching out of the heat insulation plate. The heat insulation plate units are arrayed into the box body. The connecting lug part of one heat insulation plate unit of every two adjacent heat insulation units is connected to the other heat insulation plate unit. The heat insulation plate units can be mounted, demounted and connected to form the box body and can be repeatedly assembled after being demounted, so that industrial assembly line production is facilitated, and the detachable heat insulation and preservation box is convenient to mount and demount and can save cost. The heat insulation and preservation box can be demounted, transport and storage space is saved, and turnover cost and use cost are reduced; only a part of the box needs to be replaced if the part is damaged, whole replacement is not needed, and therefore scrap cost is reduced.

Owner:厦门绿链集成服务有限公司

Treatment production line of lead frame

ActiveCN105428284AEasy to moveAvoid damageSemiconductor/solid-state device manufacturingProduction lineChemical treatment

The invention discloses a treatment production line of a lead frame. The treatment production line of the lead frame comprises a material taking mechanism, a lead frame treatment groove, a lead frame jig, lead frame pushing equipment and a water jet cutter, wherein a material pushing device of the material taking mechanism is driven by a first driving device and can realize automatic working; an immobilizing mechanism of the lead frame treatment groove is used for maintaining a semiconductor lead frame at a vertical position, so that the semiconductor lead frame is small in occupied space and long in soaking time, and a better soaking effect is obtained; a liquid receiving groove formed in the lead frame jig can be used for completely receiving a chemical treatment solution dripping from the lead frame, so that the phenomenon that since the chemical treatment solution drips on structures such as an air cylinder and guide rails, the corrosion is caused is avoided.

Owner:SHANGHAI SINYANG SEMICON MATERIALS

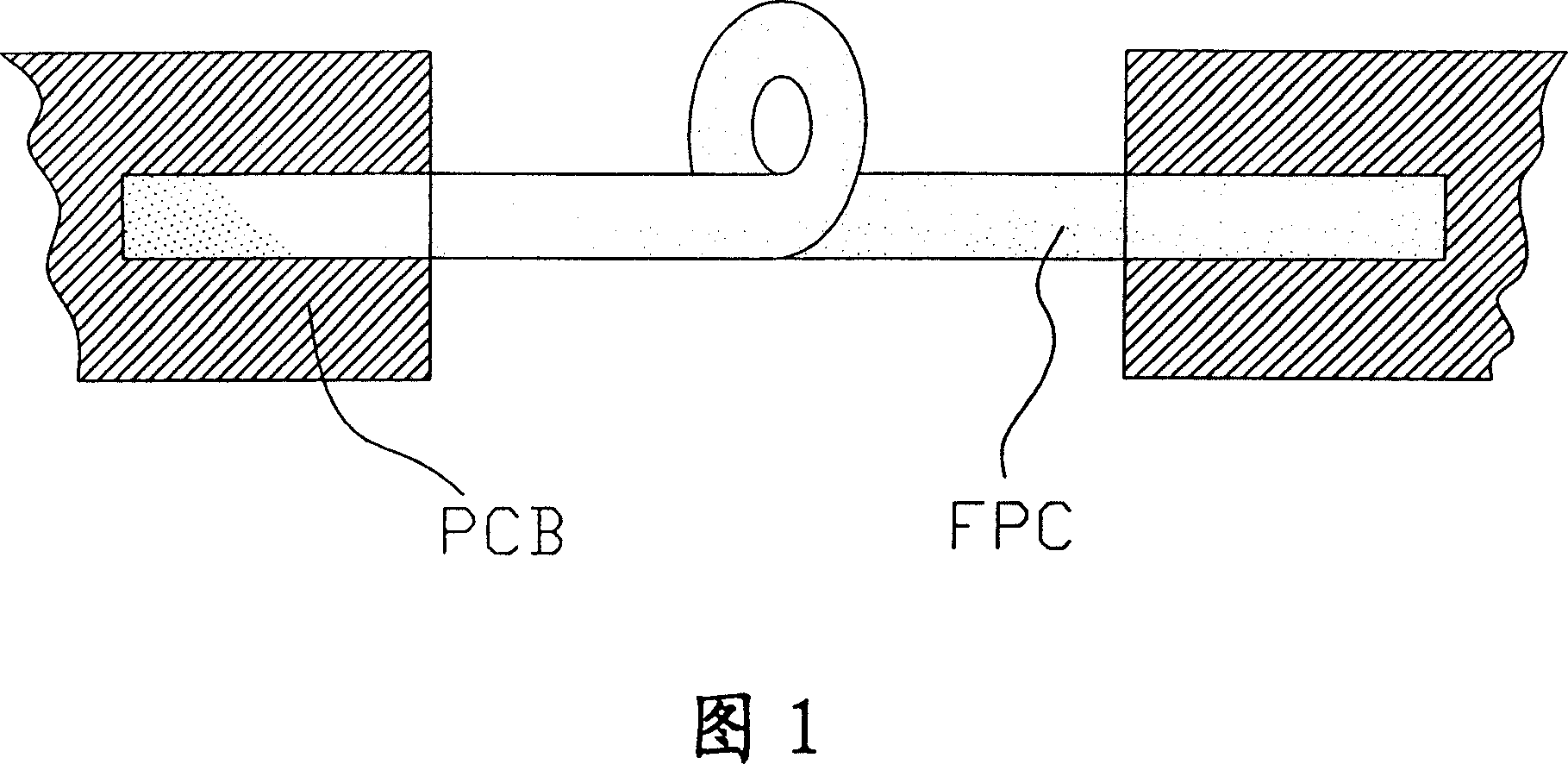

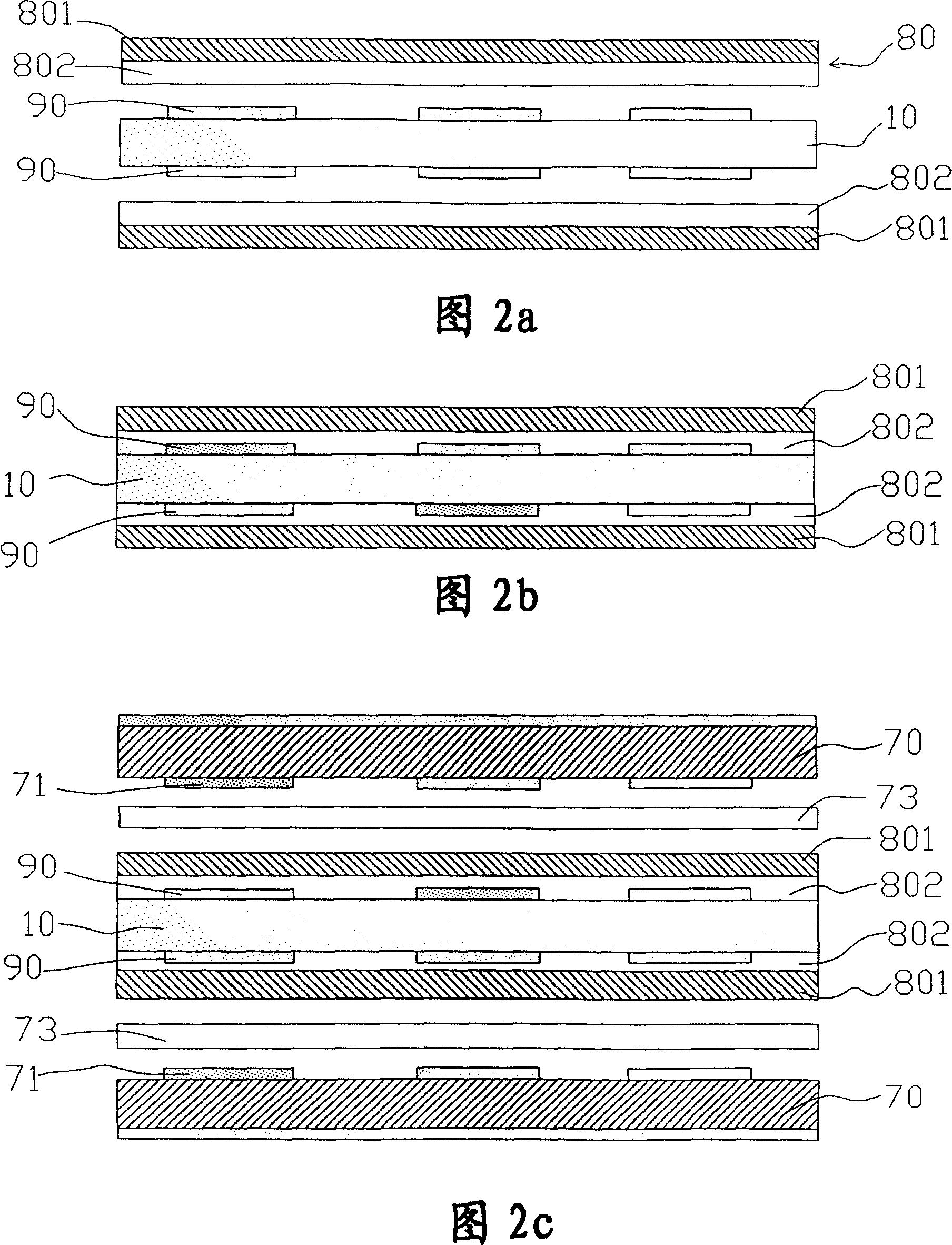

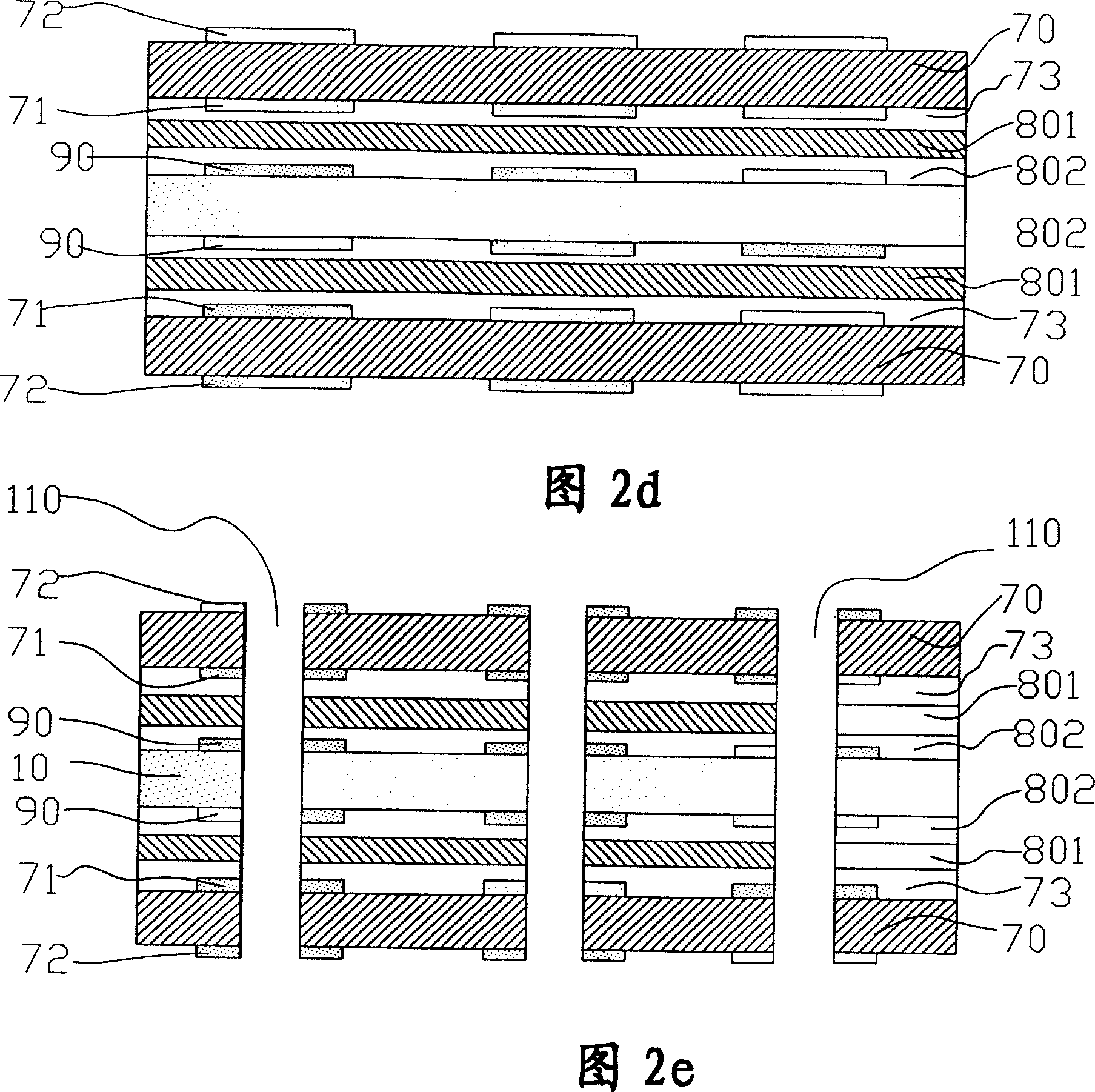

Binding method for lifting soft-solid synthetic printed circuit board turn-on hole trust degree

InactiveCN1988761AImprove yieldShorten production timePrinted circuit assemblingCopper coatingCopper foil

This invention relates to a method to improve the via reliability of soft-hard synthetic PCB, which is mainly to produce the copper coating on the surface of soft PCB substrate to be the electrical wiring through the photolithography and etching method, and then affix the membrane which has been drilled at the predetermined position and has larger diameter compared with via onto the soft PCB in the way of hot-pressing, affix rigid PCB that pre-forms electrical wire onto the membrane in the way of hot-pressing, drill via at the set position by tools, and process procedures of chemical deposition of copper and electroplating on via. Thus, because the diameter of pre-hole is more than that of via, the agent layer contained by the membrane does not be corroded seriously by chemical to enable the chemical corroding copper deposit on the inner wall of via equally avoiding copper tumor or breaking hole formed on the surface of via and improving the performance of circuit boards.

Owner:UNITECH PRINTED CIRCUIT BOARD CORP

Tobacco box

The invention provides a tobacco box. The tobacco box comprises an upper box body and a lower box body, the upper box body is provided with a first opening end and a second opening end which are oppositely arranged, the lower box body is provided with a third opening end, and the second opening end and the third opening end are hermetically and fixedly connected to form the tobacco box. The upper box body and the lower box body are molding parts, the tobacco box is 700 cm by 700 cm by 700 to 1300 cm by 1300 cm by 1300 cm and is applicable to the fields of automatic production lines and storage and transport and the like; the tobacco box is manufactured by molding, industrial batch production is easy to realize, production cost can be reduced, and the tobacco box has high functional expansibility.

Owner:青岛冠宇工业设备有限公司 +1

Manufacturing method for printed circuit board

ActiveCN105517350AReduce scrap costsNormal nickel platingInsulating layers/substrates workingEngineeringPrinted circuit board

The invention provides a manufacturing method for a printed circuit board. The method comprises: S1, alignment holes are formed in non-working areas of all design units on a jointed printed circuit board; S2, quality detection is carried out on the design unit; if defective product existence is detected, one alignment hole corresponding to the defective product is covered and shielded to prevent light transmission; if good product existence is detected, one alignment hole corresponding to the good product is not covered and shielded; S3, alignment exposure is carried out on the jointed printed circuit board; when light transmission of the alignment hole corresponding to one certain design unit is detected, the design unit is exposed normally; and when no light transmission of alignment hole is detected, the design unit is processed by no-shield exposure; and S4, the manufactured jointed printed circuit board is segmented to obtain a printed circuit board. The design unit processed by normal exposure can be plated with nickel and gold; and the design unit processed by no-shield exposure can not be plated with nickel and gold. Therefore, manufacturing of the good product design unit can be guaranteed and the scrap cost of the defective product design unit can be reduced.

Owner:NEW FOUNDER HLDG DEV LLC +1

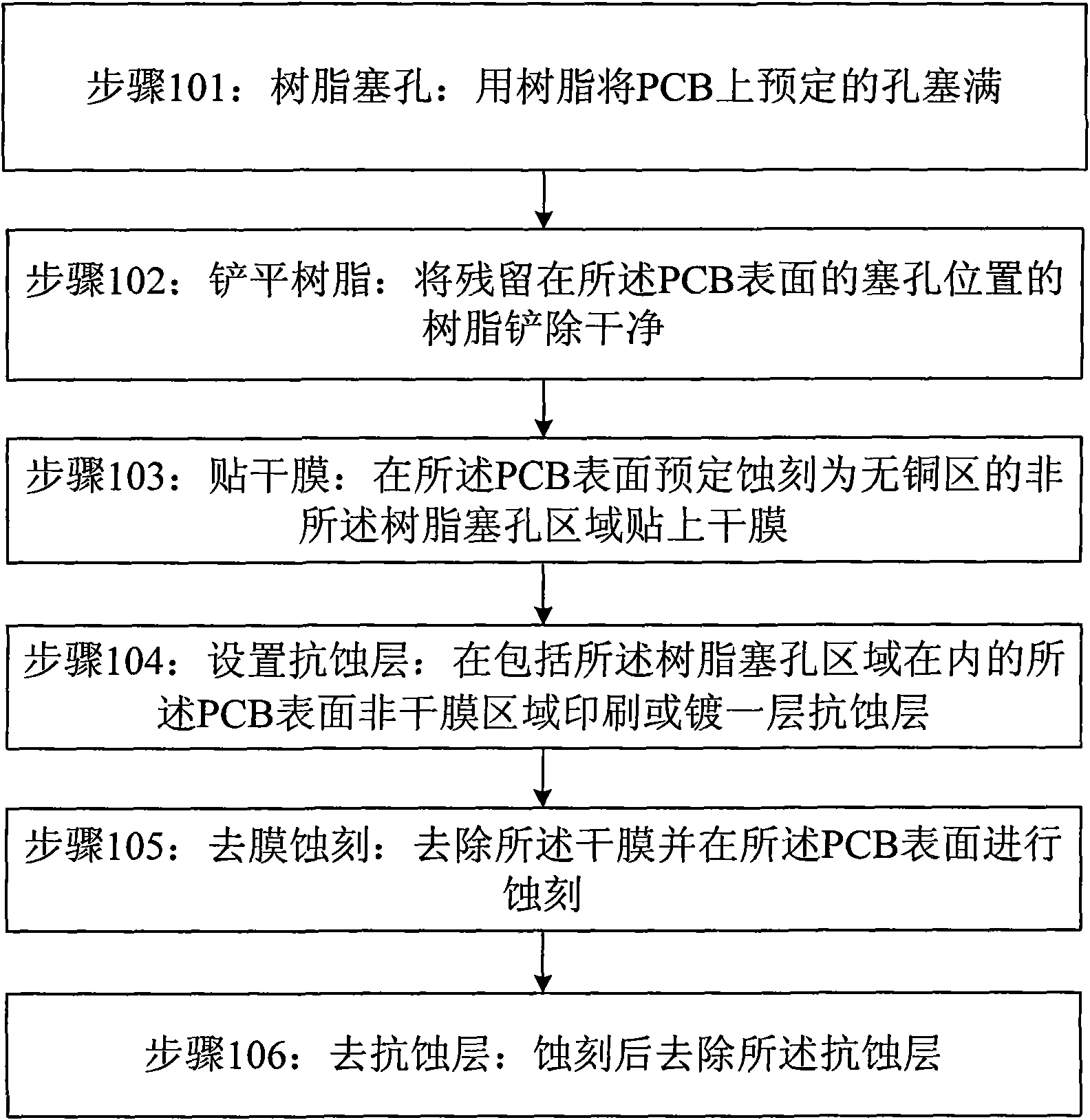

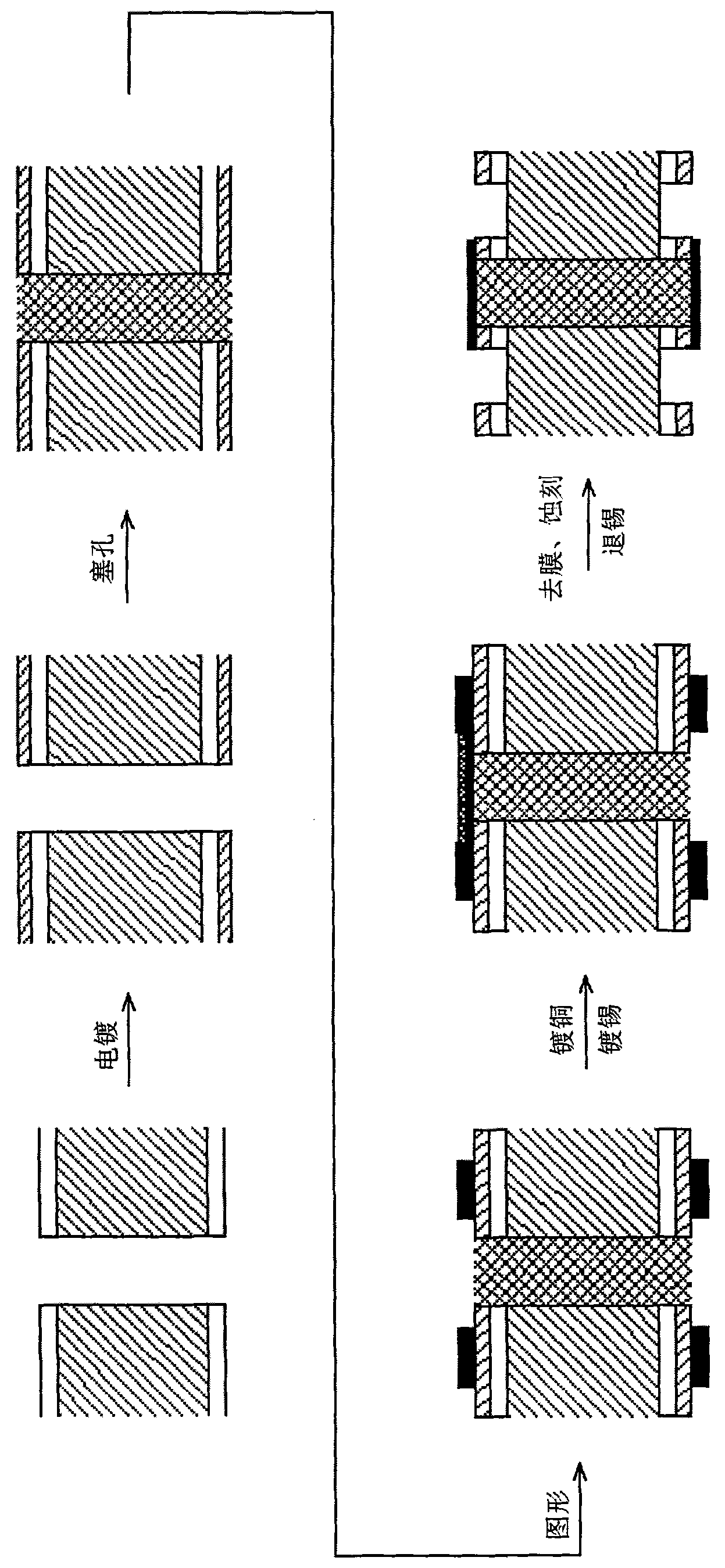

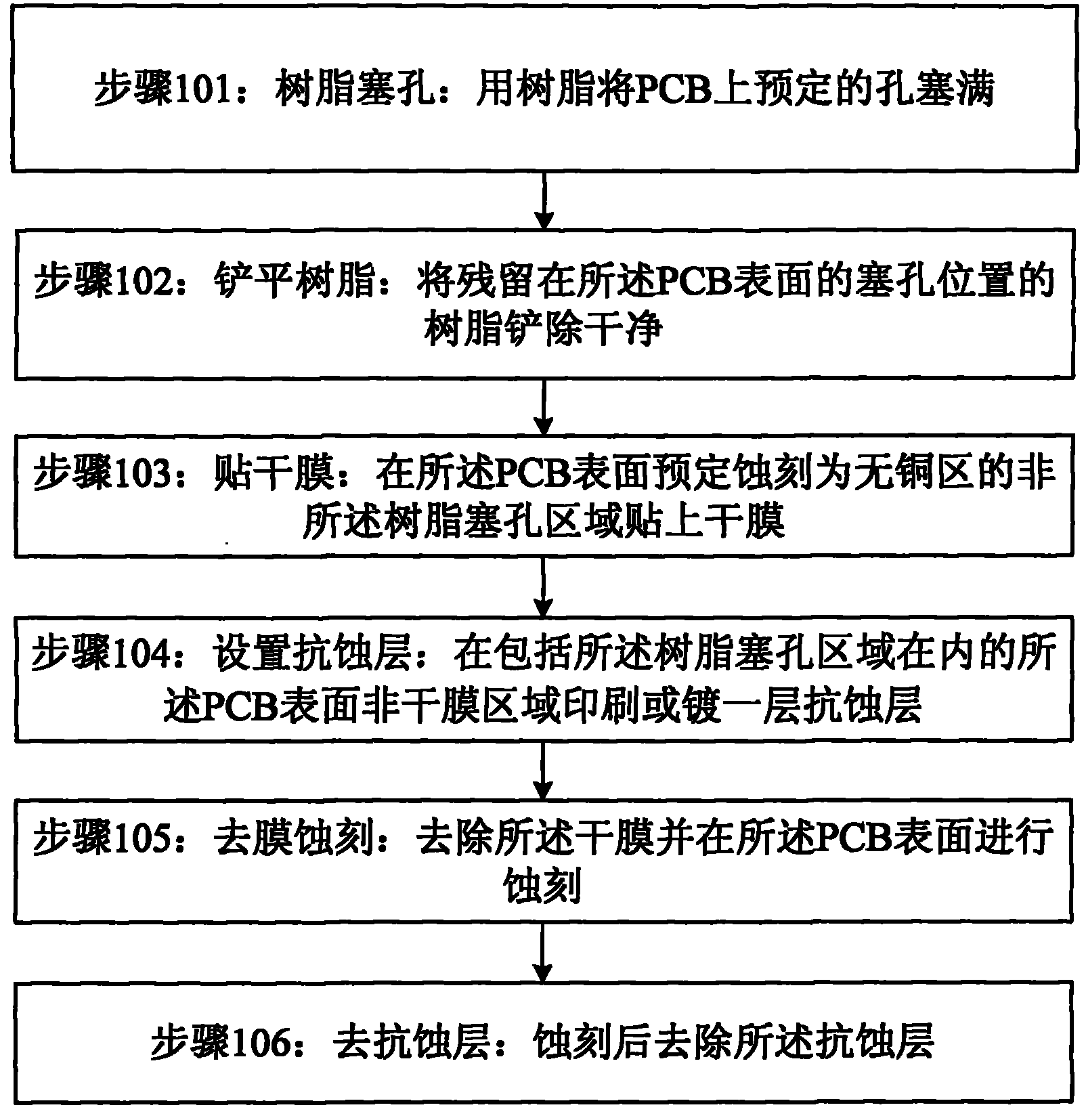

PCB (Printed Circuit Board) processing method

ActiveCN101772269AStrong process adaptabilityImprove craftsmanshipPrinted element electric connection formationEngineeringCopper

The invention discloses a PCB (Printed Circuit Board) processing method which comprises the following steps of: resin hole cramming: cramming preset holes on a PCB by using resin; resin leveling: shoveling resin left at the positions of the crammed holes on the surface of the PCB completely; drying film pasting: pasting a dry film on a non-resin hole cramming area preset to be etched into a copper-free area on the surface of the PCB; anti-corrosion layer arrangement: printing or plating an anti-corrosion layer on a non dry film area on the surface of the PCB, which comprises the resin hole cramming areas; film removing and etching: removing the dry film and etching on the surface of the PCB; and anti-corrosion layer removing: removing the anti-corrosion layer after etching. The invention has good adaptability to the resin hole cramming process and can greatly reduce the scrap cost.

Owner:SHENNAN CIRCUITS

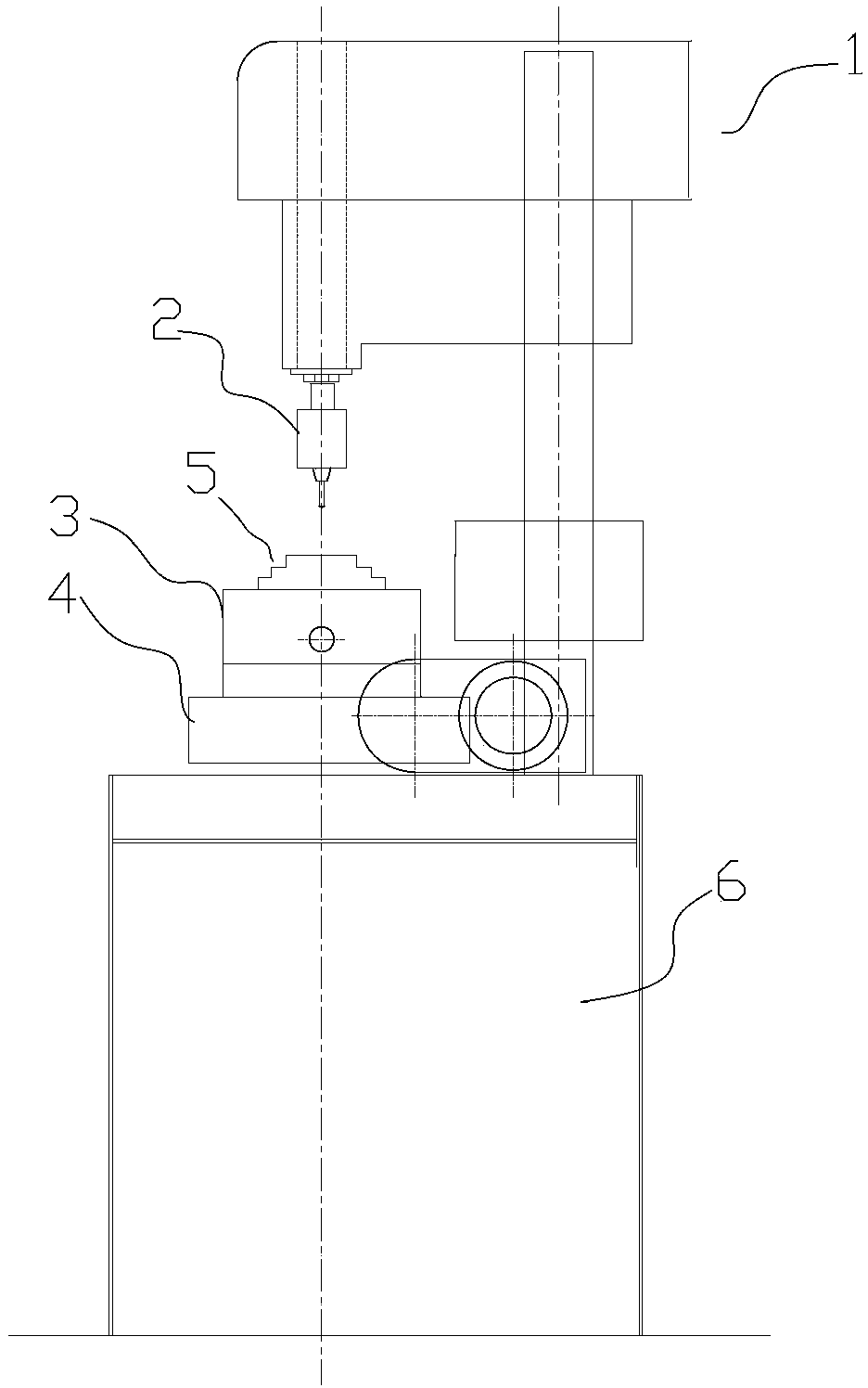

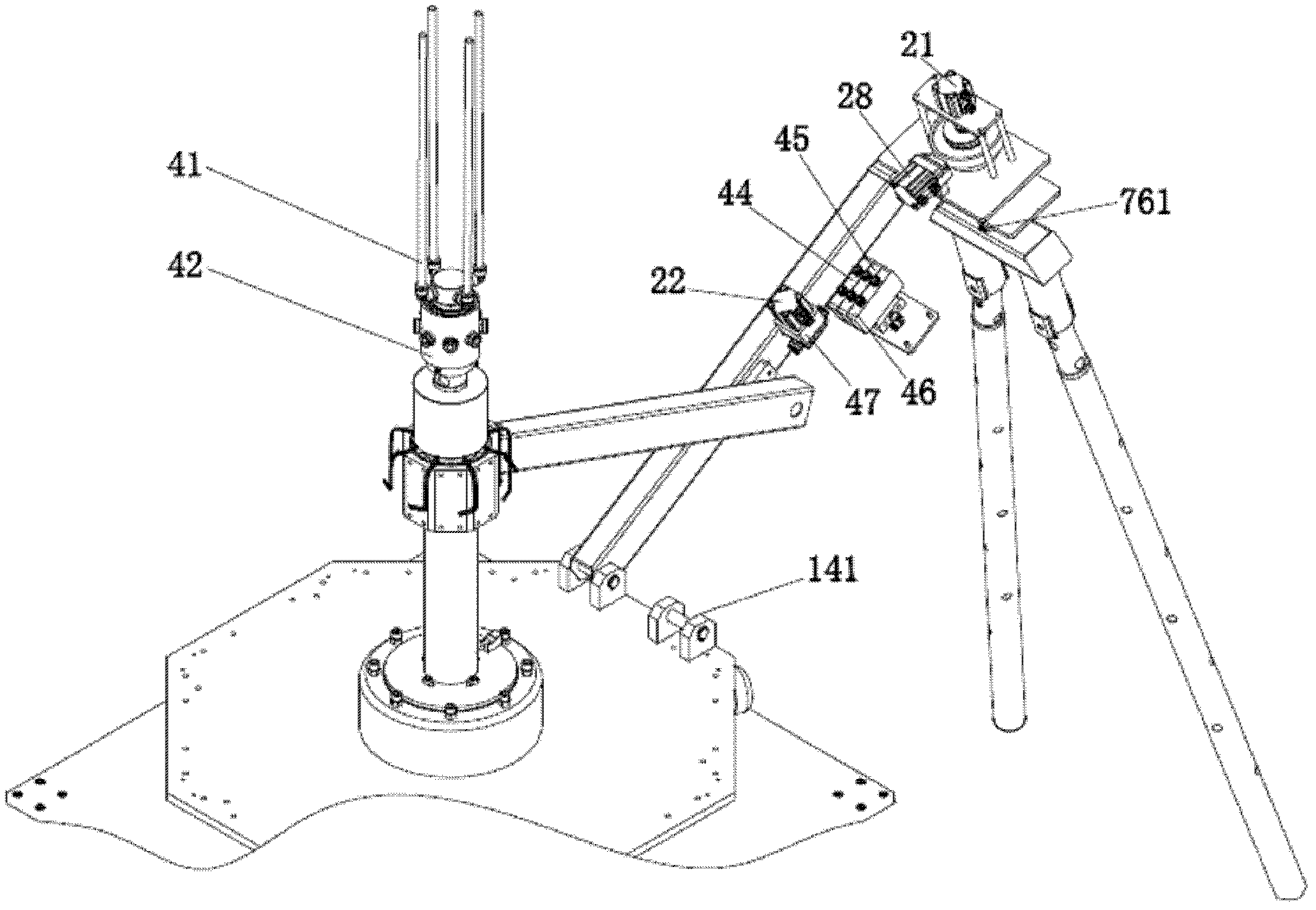

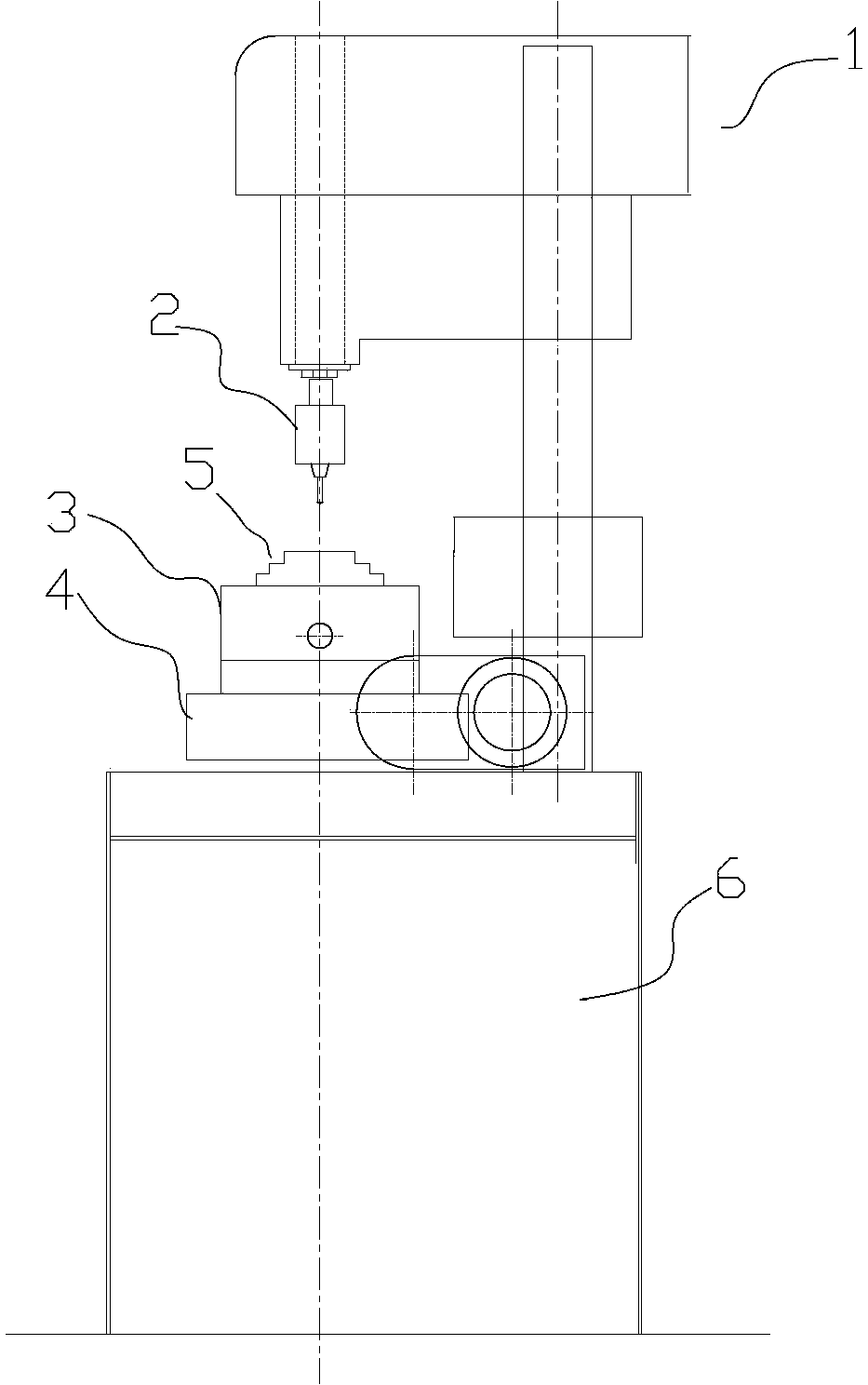

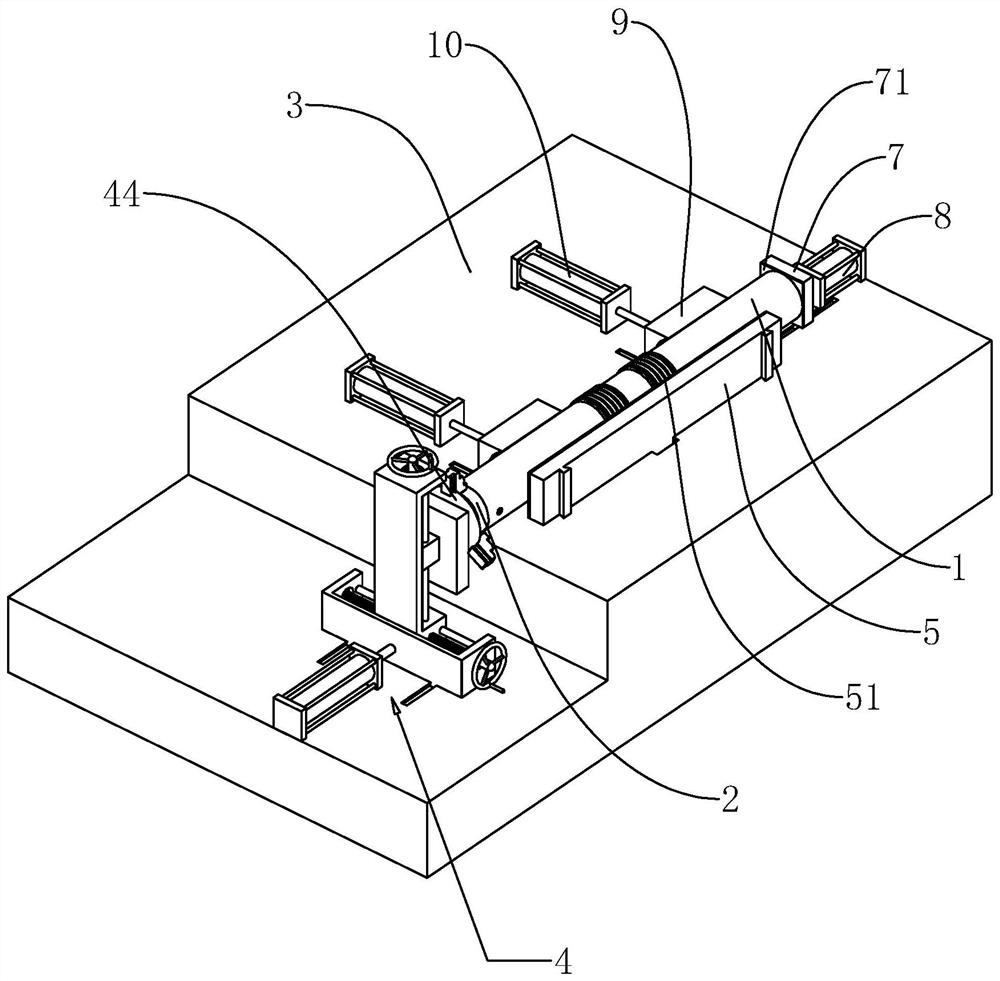

Numerical control drilling device

InactiveCN104117713AReduce scrap costsImprove processing efficiencyBoring/drilling componentsMaintainance and safety accessoriesNumerical controlEngineering

The invention belongs to the technical field of numerical control drilling devices, and particularly discloses a numerical control drilling device. The numerical control drilling device comprises a numerical control drilling mechanism. A numerical control rotating workbench is arranged below the numerical control drilling mechanism. A workpiece clamp is arranged on the numerical control rotating workbench. A cooling water pipe is arranged on the numerical control drilling mechanism. A water collection tank is arranged below the numerical control rotating workbench. By the adoption of the technical scheme, the numerical control drilling device greatly improves machining efficiency, and is convenient to operate, simple in structure, easy to maintain and low in cost; in addition, due to the fact that the numerical control technology is adopted for control, machining precision is high, the reject ratio is low, the scrap cost in production and machining of an enterprise is greatly reduced, and the surface of a machined piece is clean, so that no secondary cleaning is needed.

Owner:TIANJIN KESAISI IND & TRADE

Repairing structure and repairing method for liquid-crystal display (LCD) panel

The invention discloses a repairing structure and a repairing method for a liquid-crystal display (LCD) panel. The LCD panel is provided with a plurality of shared wirings and a plurality of scanning lines, wherein the shared wirings are parallel to the scanning lines, and the shared wirings and the scanning lines are alternately arranged on a base plate; each shared wiring is provided with a plurality of branches and a plurality of notches; the plurality of branches are parallel to a plurality of signal lines, and are overlapped but separated from the signal lines; and each branch, the corresponding signal line and a pixel electrode are configured to enable the corresponding notch to be exposed, so that an external tool can be provided to cut off the shared wiring from the notch, thereby disconnecting the shared wiring and the branch.

Owner:HUAYING OPTOELECTRONICS +1

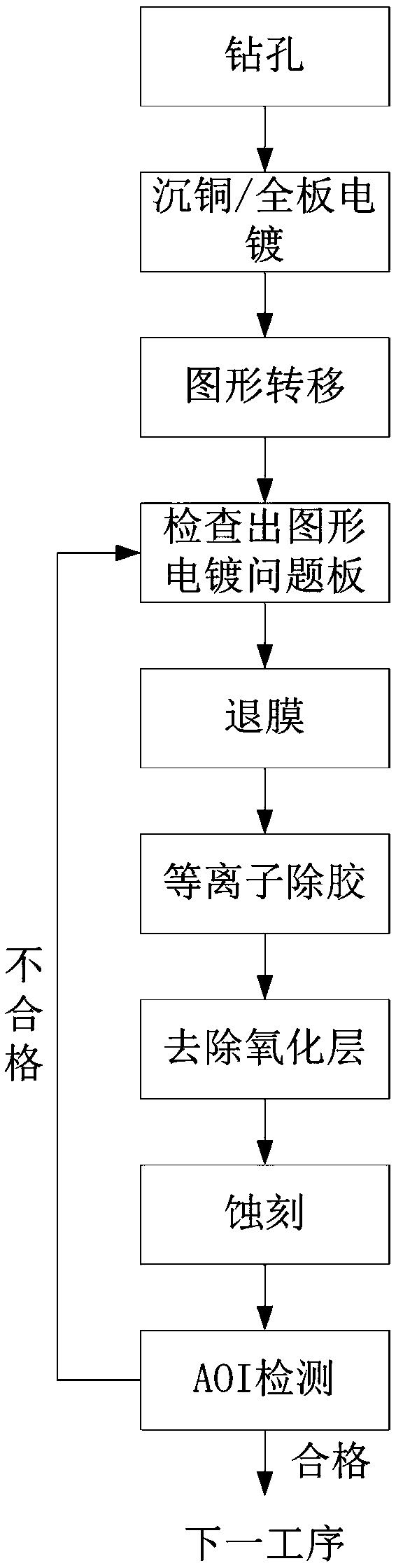

Reworking method for electroplated clamping membrane defective products

InactiveCN108650802AIncrease productivityNot corrodedPrinted circuits repair/correctingTinningSurface oxidation

The invention discloses a reworking method for electroplated clamping membrane defective products. The method comprises the steps that when pattern transferring is carried out after electroless plating copper of circuit boards or electroplating of the whole boards, unqualified boards on which pattern electroplating problems occur are checked out; film stripping treatment is carried out on the unqualified plates; the plasma degumming mode is adopted to remove glue remaining on the unqualified plates; oxidation layers on the surfaces of the unqualified plates are removed; etching is carried outto obtain line patterns in accordance with requirements; AOI inspection is carried out. The adopted plasma degumming mode can remove film residues clamped among lines, the etching quality is ensured,the scrap cost is reduced, the production efficiency of circuit board printing is improved, and after degumming is completed, the circuit boards are soaked in ammonium hydroxide or washed with the ammonium hydroxide to remove the surface oxidation layers, therefore it is ensured that tin coating layers cannot be corroded. The method thoroughly solves the problem that electroplated clamping membranes cause scrapping due to abnormal quality, the reworking quality is improved, abnormal scrapping is reduced, the working procedure plan achieving rate is improved, the scrap cost caused by abnormityis reduced, the working procedure supplementing rate is reduced, and the comprehensive competitive power of enterprises is improved.

Owner:珠海杰赛科技有限公司 +1

Rotary rubber turbine

ActiveCN102551254AShorten the production cycleReduce bending timesClothes making applicancesStaff trainingYarn

The invention relates to a rotary rubber turbine, which comprises a base and a rotating plate rotatably connected with the base in a vertical direction. A rotary air distribution block is arranged at a position, close to the center, of the rotating plate, at least one yarn abrading unit is arranged on the edge of the rotating plate, each yarn abrading unit comprises a rotating barrel and a rotating rod rotatably connected with the rotating barrel, each rotating rod is provided with a rubber turbine leg, each yarn abrading unit is further provided with a brake cylinder, an inflating cylinder and a deflating cylinder, wherein each brake cylinder is used for limiting rotation of the corresponding rotating rod, and each inflating cylinder and the corresponding deflating cylinder are respectively used for inflating and deflating the corresponding rubber turbine leg. A plurality of yarn abrading stations are integrated on the same rotating plate, complexity of each station is reduced, on the one hand, cost of staff training of a company is reduced, on the other hand, skill of staffs is improved advantageously, and product percent of pass is improved. Simultaneously, yarn abrading time of single products is shortened due to assembly line production, close-fitting pants can be transferred to a next work procedure in time, integral production period of production of the pants is shortened, and delivery time is shortened.

Owner:江门市宝发纺织服饰制造有限公司

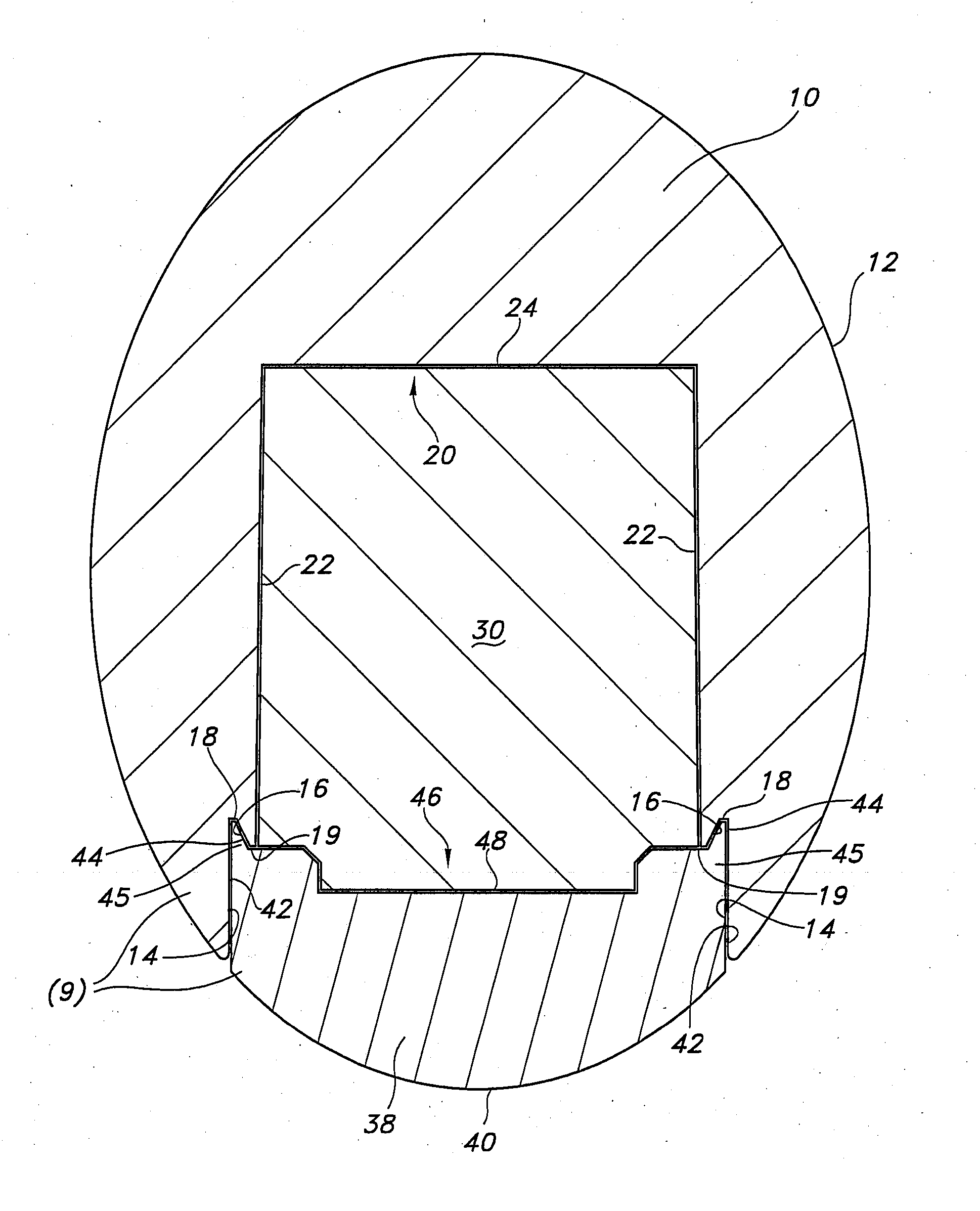

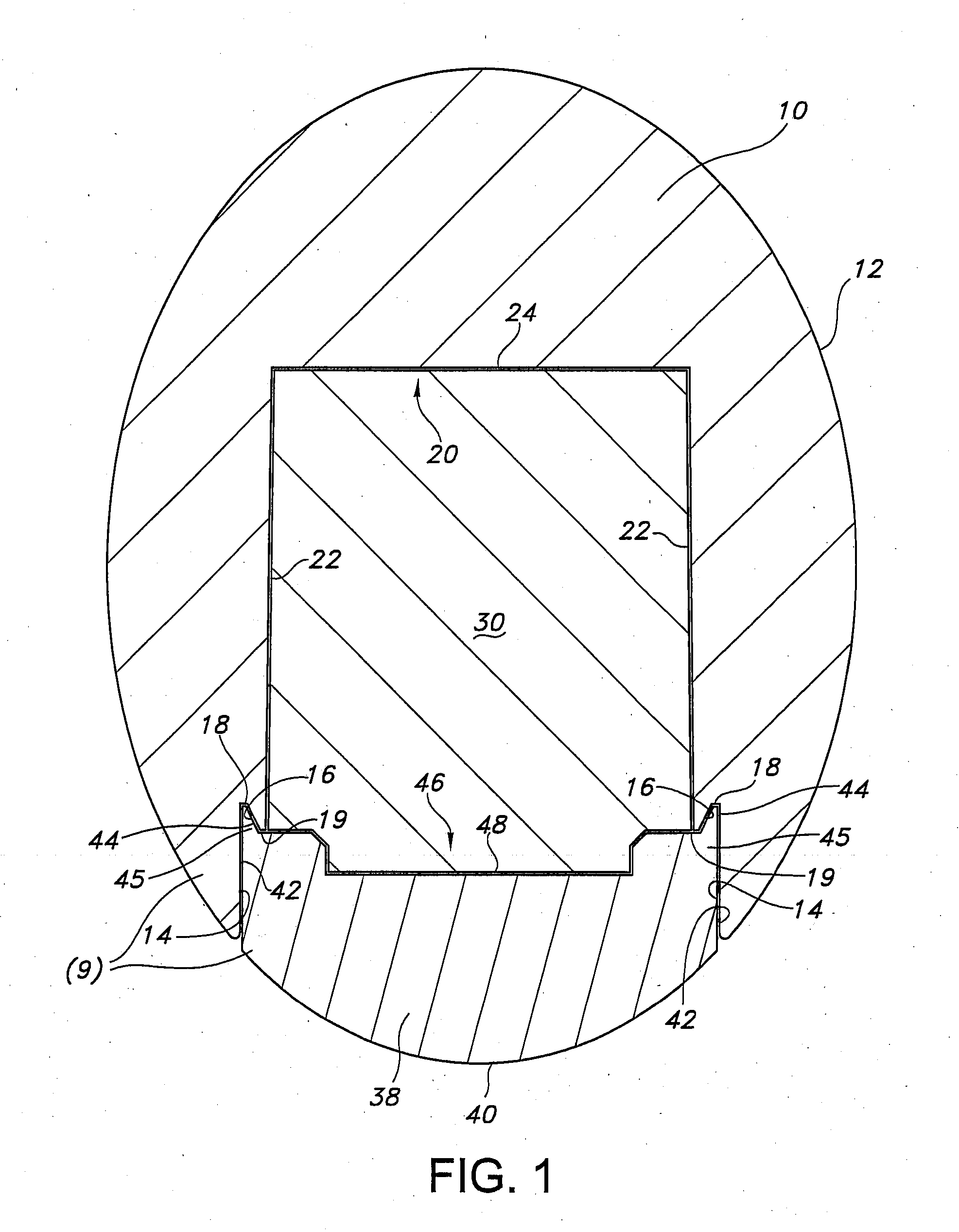

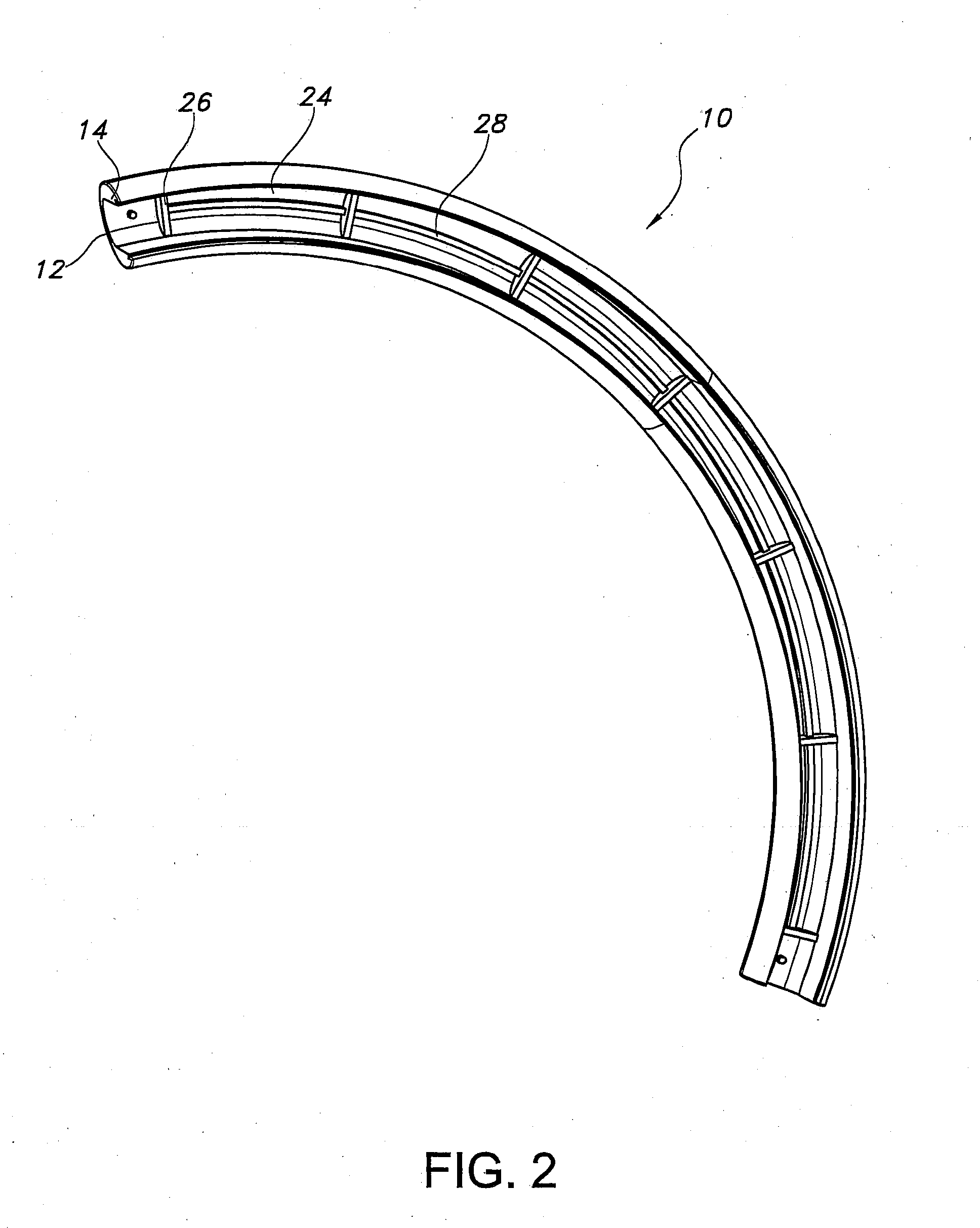

Decorative shells for steering wheels

InactiveUS20080060470A1Improve aestheticsLow costControlling membersMechanical apparatusSteering wheelEngineering

An improved decorative shell covering for steering wheels is provided that enables the seams between the shells to be out of the driver's line of sight and in a position less noticeable to the touch of a driver's fingers, ensures proper placement of the shells on the wheel, and prevents movement of the shells after placement. The use of the improved covering further reduces the cost of decoration and wheel processing scrap, manufacturing costs, and transportation costs. The improved covering includes a first shell for covering a first portion of an outer surface of the wheel. The first shell may have an outer surface comprising an arc that subtends generally more than about 180° and an inner surface configured to correspond with the first portion of the outer surface of the wheel. The covering may further include a second shell for covering a second portion of the outer surface of the wheel. The second shell may be configured to be disposed adjacent to the first shell and may further have an outer surface comprising an arc that subtends generally less than about 180° and an inner surface configured to correspond with the second portion of the outer surface of the wheel. A method of covering steering wheels is also provided.

Owner:CENTOCO WHEEL CORP

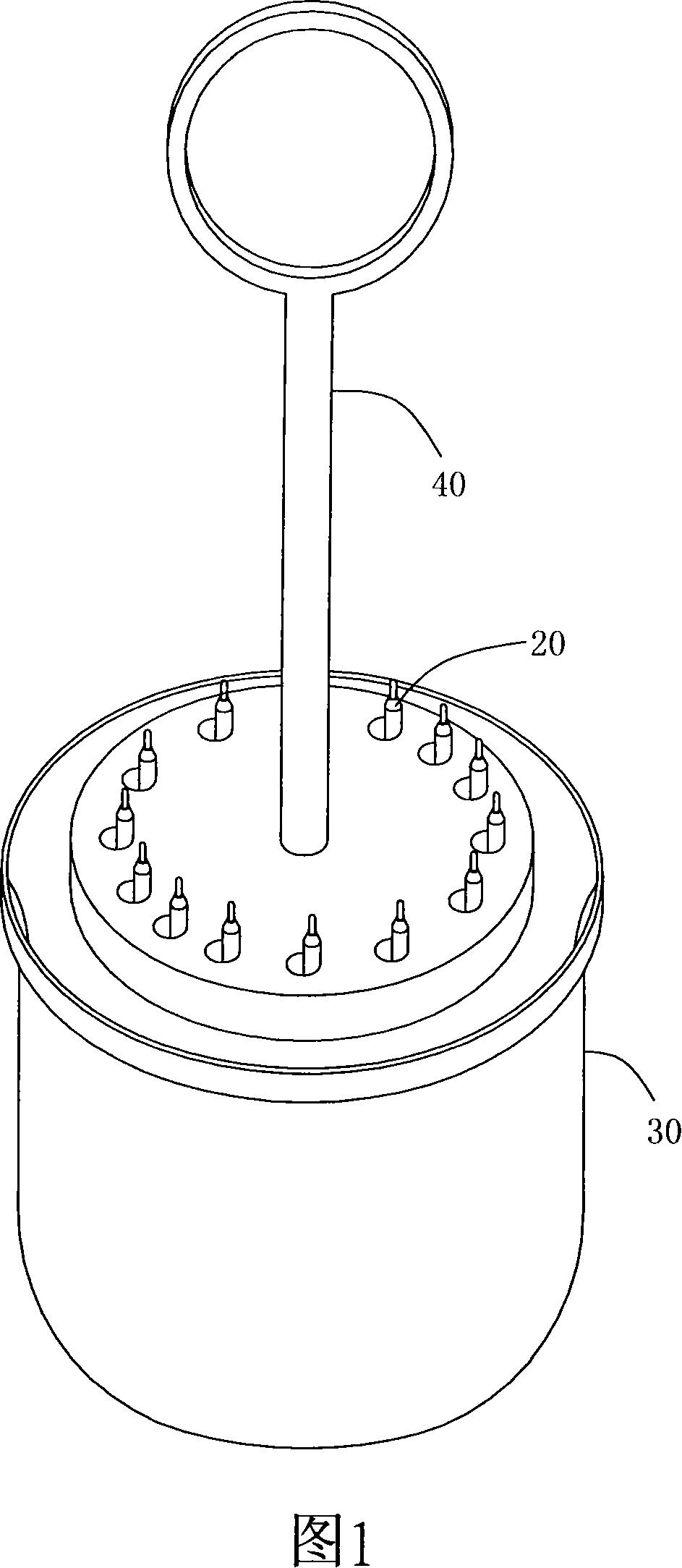

Cleaning device and method for cleaning the equipment joining with the same

InactiveCN101121171AThere will be no blowingEasy to cleanSpraying apparatusCleaning using gasesControl systemCleaning methods

The present invention discloses a cleaning device and equipment cleaning method combined with the cleaning device; the cleaning device comprises a cleaning carrier and pressure control system; the cleaning carrier comprises a base and a shell which are combined together to form a cleaning chamber; the shell top is equipped with a guide hole and the base inside comprises a liquid channel communicated with the cleaned articles; the pressure control system is equipped with a pressure supply part communicated with the guide hole by pressure which makes the pressure control system communicated with the cleaning carrier by pressure; with the conversion between the positive and negative pressures, the pressure control system produces liquid force in the cleaning chamber and liquid channel to remove the residual material.

Owner:AU OPTRONICS CORP

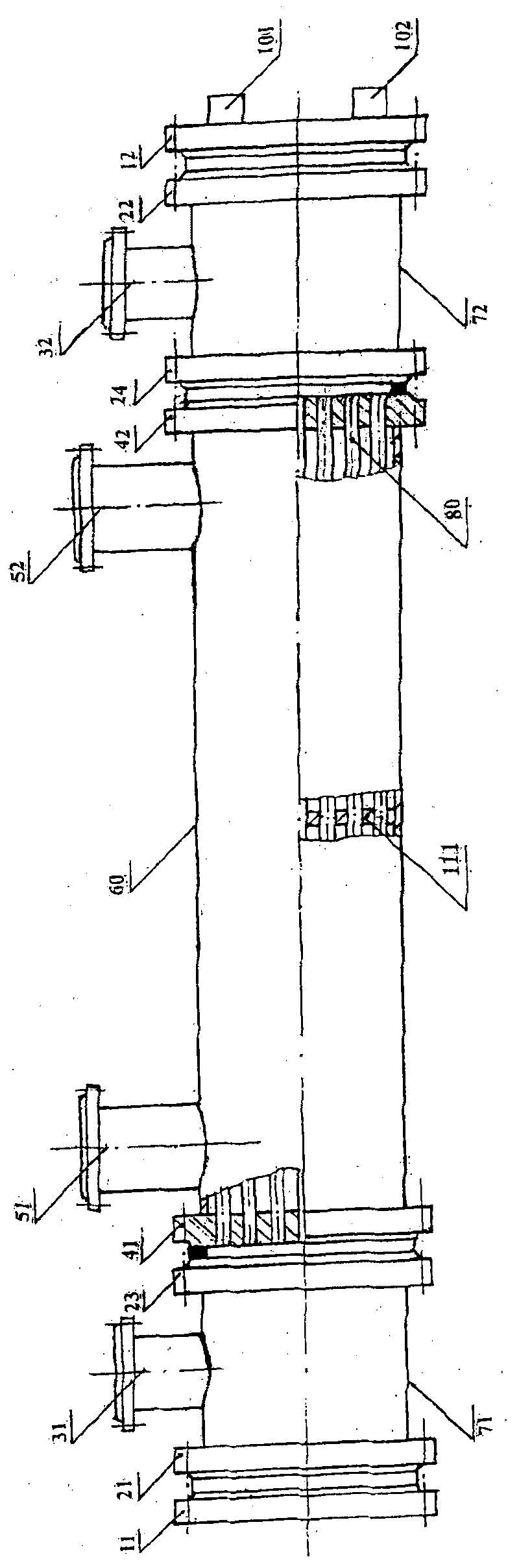

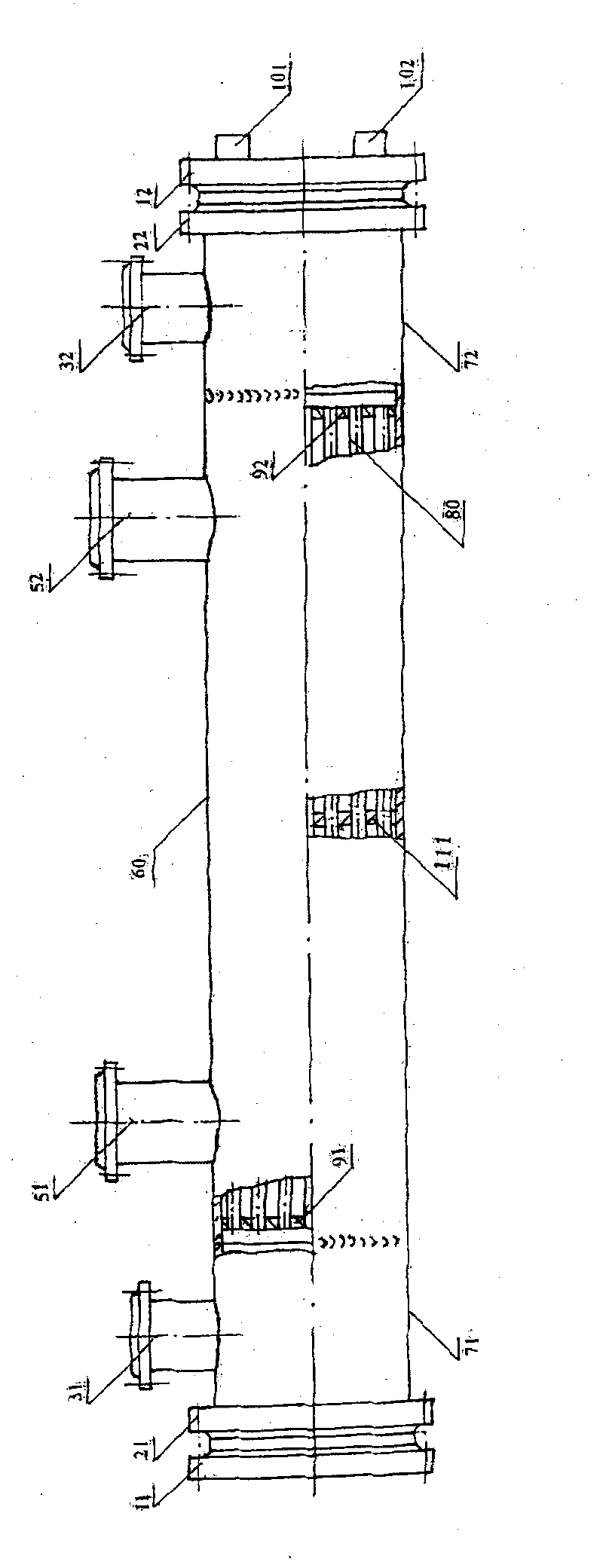

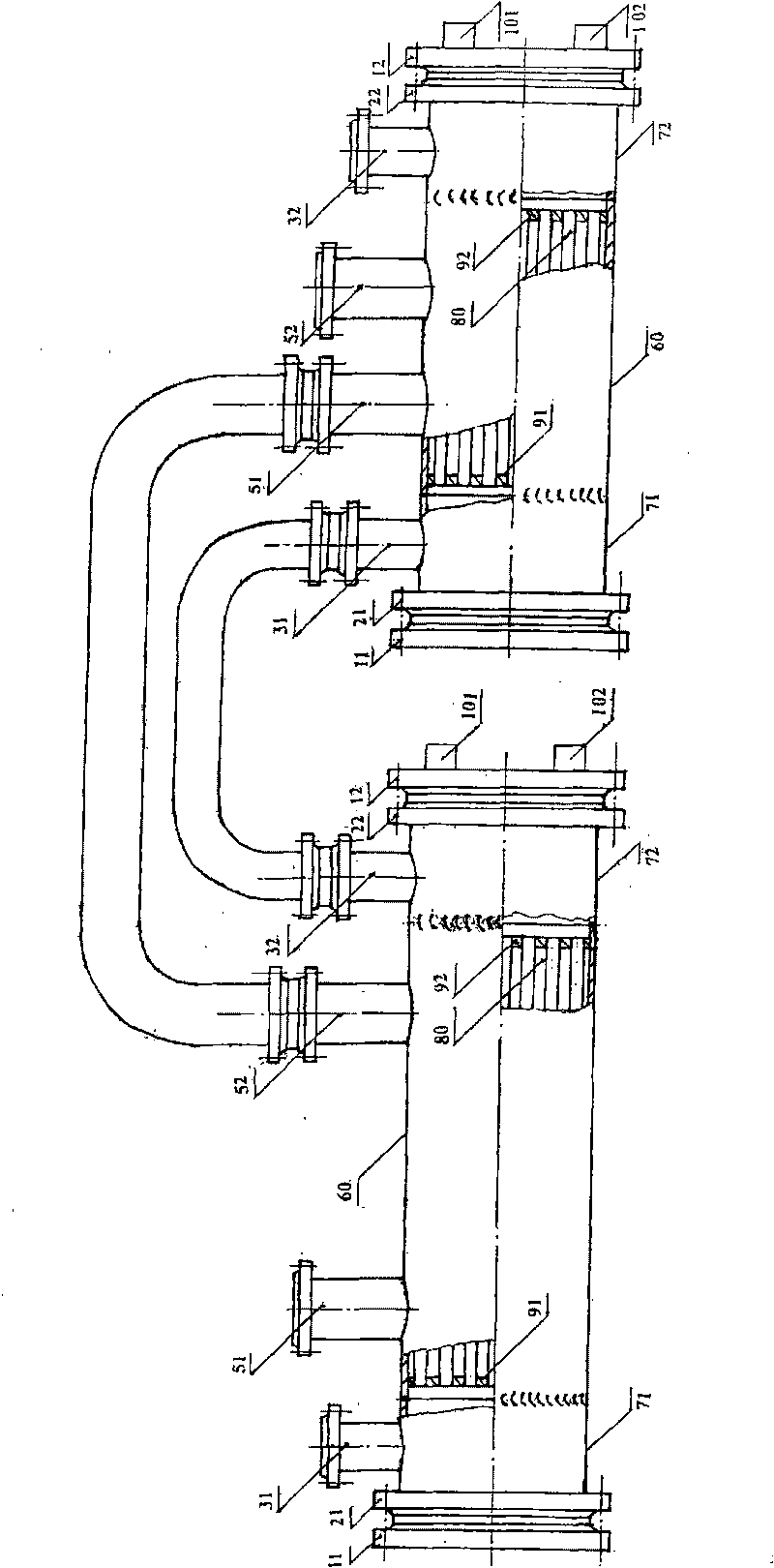

Stainless steel tube-shell type concentrated sulfuric acid cooler with thin tube sheet stage cooling and anode protection

InactiveCN101706219ASave processing feeReduce scrap costsHeat exchanger casingsStationary tubular conduit assembliesChillerSteel tube

The invention discloses a stainless steel tube-shell type concentrated sulfuric acid cooler with thin tube sheet stage cooling and anode protection. A shell pass, a tube pass and an anode protection assembly form an independent run unit, and two ends of a cylinder of the shell pass are connected with a water tank cylinder belonging to the part of the tube pass. The stainless steel tube-shell type concentrated sulfuric acid cooler with thin tube sheet stage cooling and anode protection is characterized in that tube sheets are fixed on the inner walls of two ends of the cylinder of the shell pass through welding to form a fixed heat exchange tube bundle and sealing devices at two ends of the shell pass; the tube sheets are positioned at the inner sides of the outer edges of the inner walls at two ends of the cylinder of the shell pass, and the cylinder of the shell pass and the cylinder of the water tank are connected in a sealing mode by welding; two or a plurality of the independent run units are connected in series and divided into single or a plurality of high-temperature section run systems and low-temperature section run systems with equal mount or unequal amount according to temperature. The invention can solve the technical problems of a traditional concentrated sulfuric acid cooler, such as high equipment investment expense, great abandonment loss and other technical problems, which are caused by using a great deal of stainless steel.

Owner:龙学义

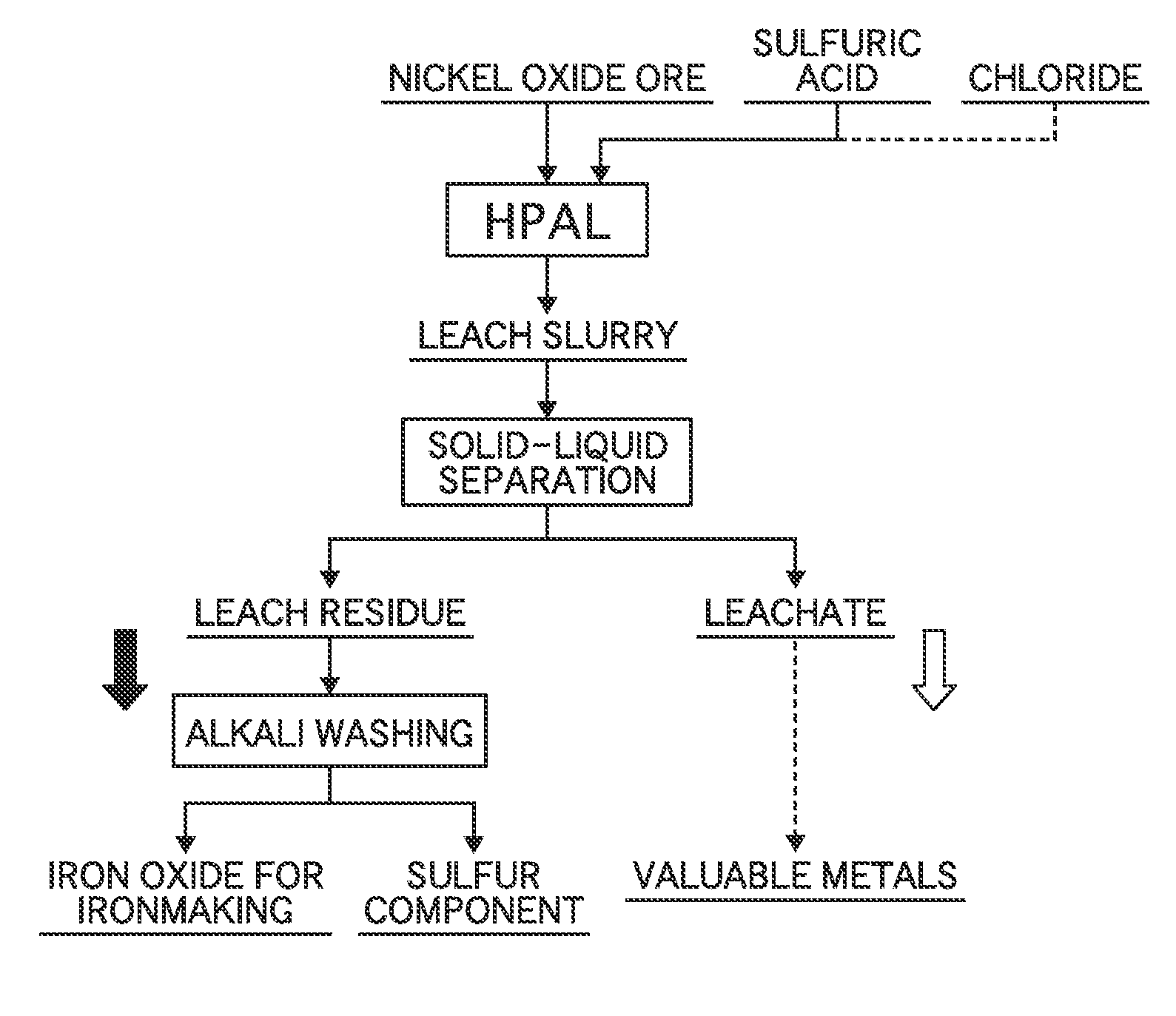

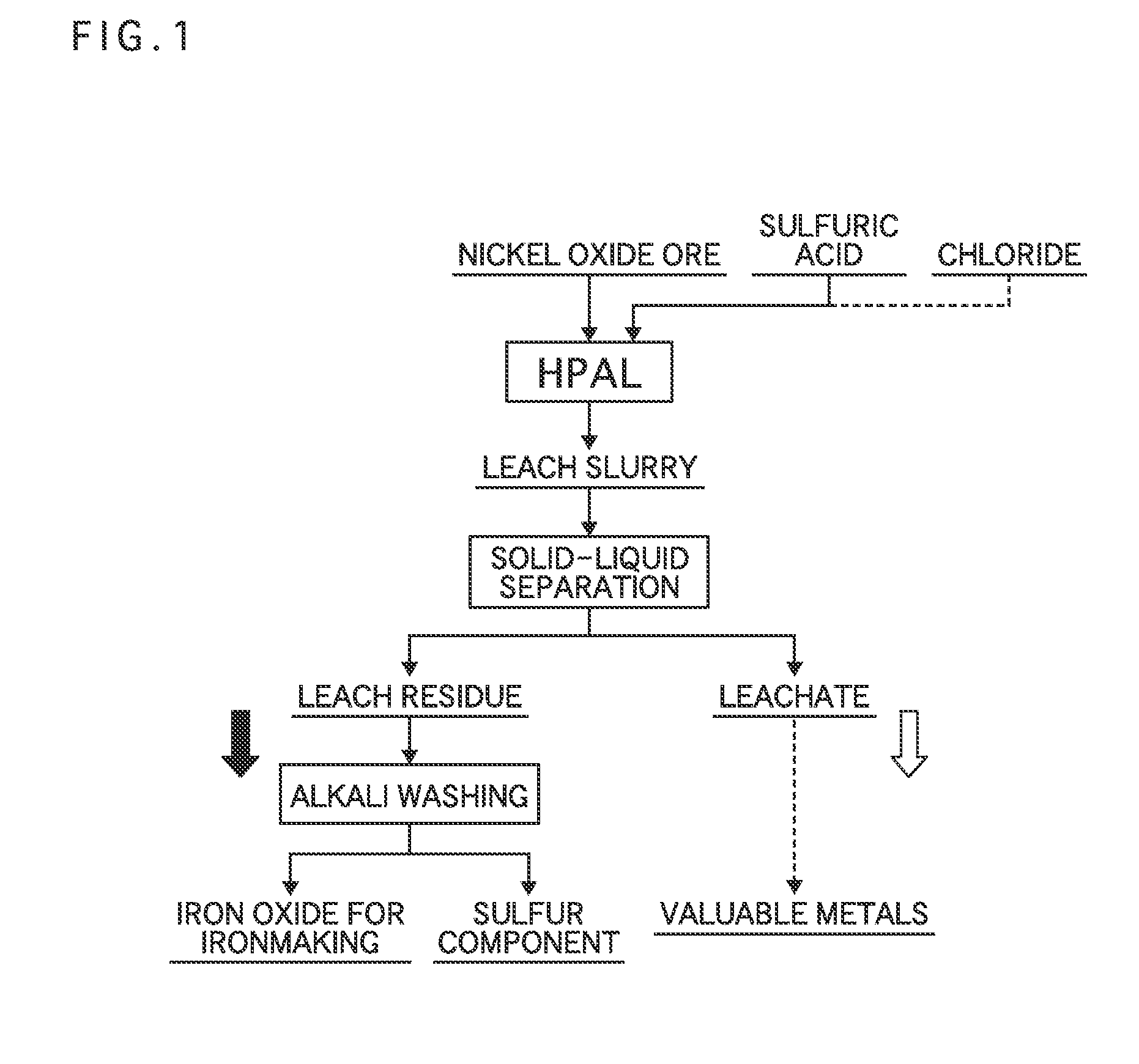

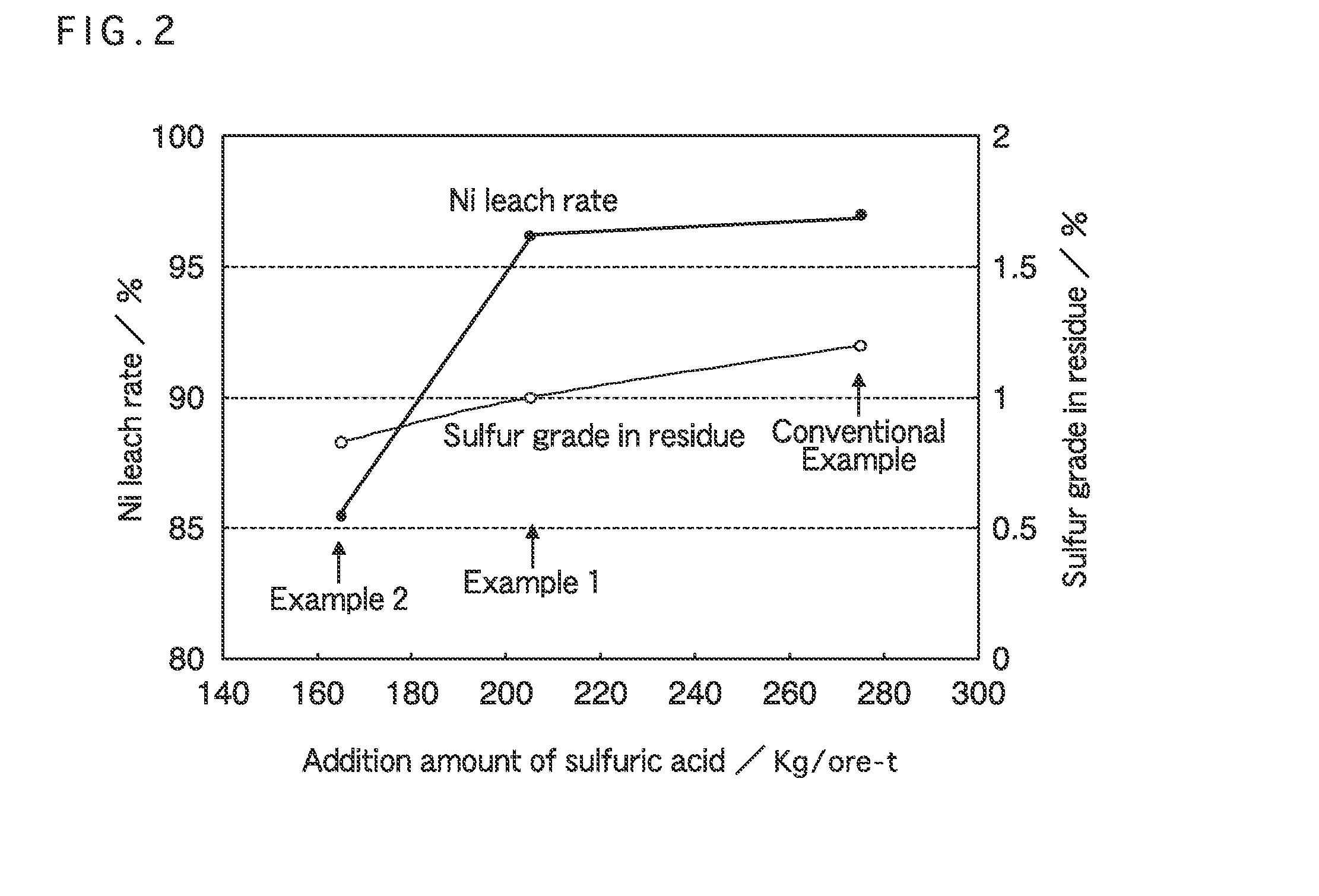

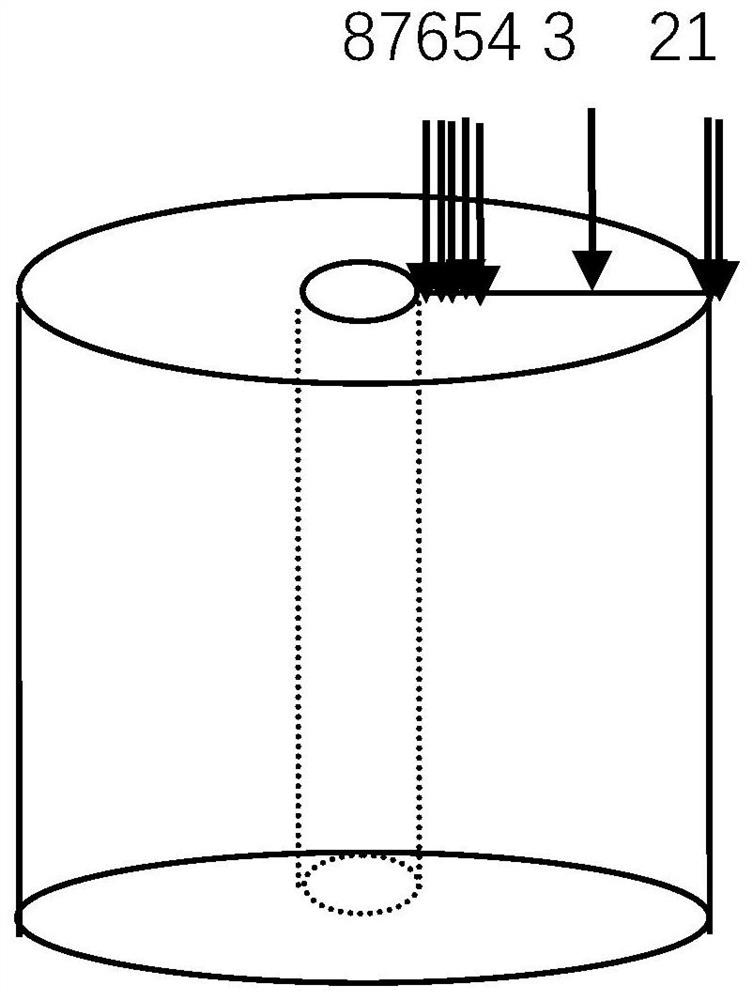

Method for producing hematite for ironmaking

InactiveUS20150050201A1Easy to getCheaply and stably procuredSolvent extractionTransportation and packagingIron oxideHigh pressure

Provided is a production method for refining iron oxide (hematite), which has such a low sulfur content as to be used as an iron-making raw material, from a leach residue containing iron oxide produced by a high pressure acid leach (HPAL) process. In the method for refining iron oxide for ironmaking by a process of adding sulfuric acid to nickel oxide ore and then leaching nickel from the nickel oxide ore using a pressure vessel, an amount of the sulfuric acid added is 150 kg or more and 220 kg or less per ton of nickel oxide ore.

Owner:SUMITOMO METAL MINING CO LTD

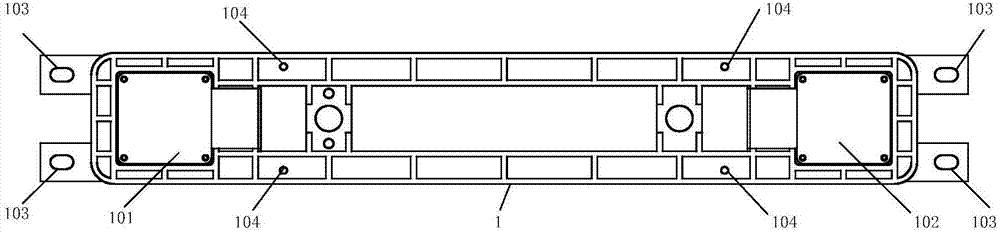

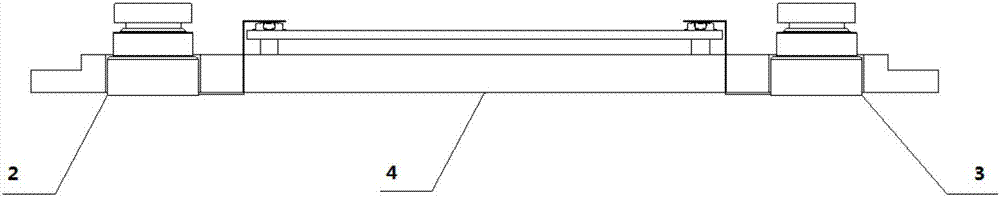

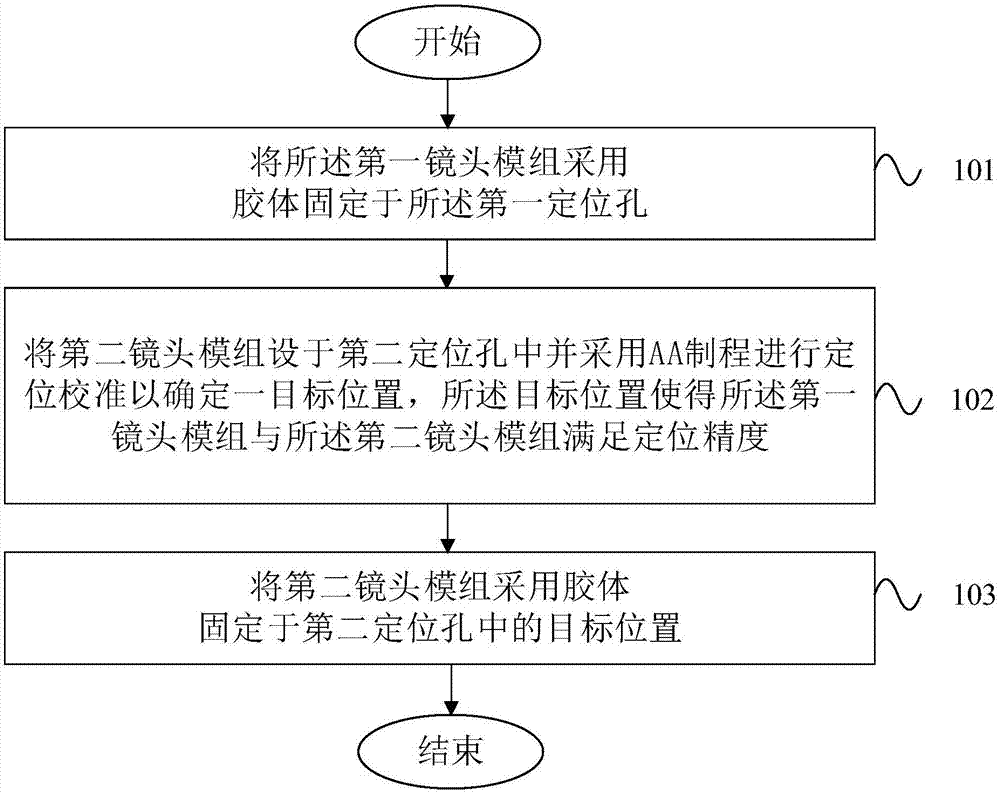

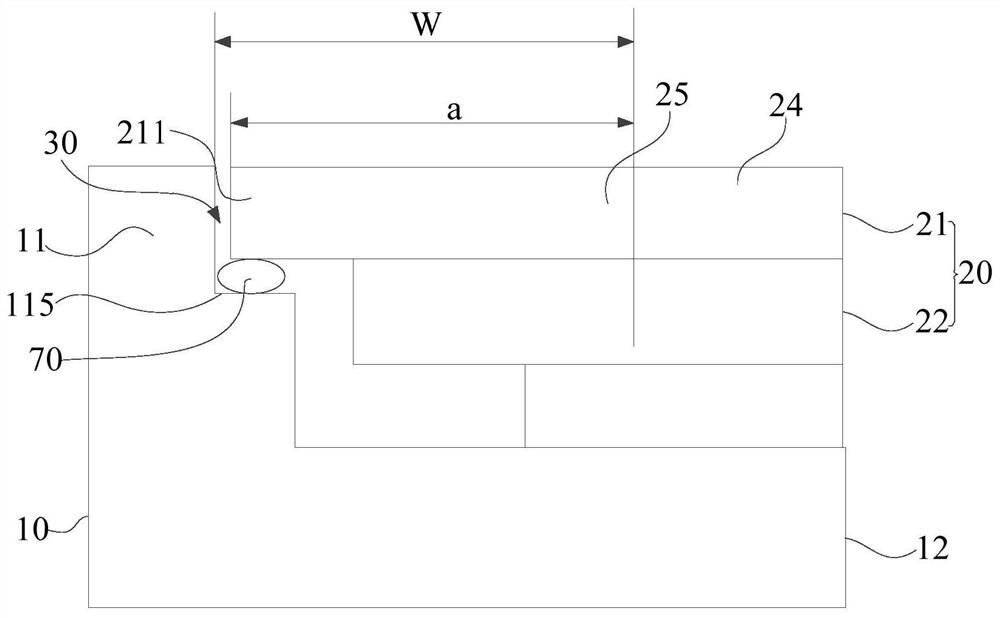

Support for double-camera assembly, split support type double-camera assembly and assembling method

PendingCN107990108AEasy to adjust relative accuracyReduce maintenance costsStands/trestlesCamera body detailsRelative precisionOptical axis

The invention discloses a support for a double-camera assembly, the split support type double-camera assembly and an assembling method. The support comprises a support body, and the support body is provided with a first positioning hole, a second positioning hole, a plurality of shell positioning locking points and a plurality of PCB positioning locking points. The first positioning hole is used for being fixedly connected with a first camera module, and a first gap for calibration is reserved between the first positioning hole and the first camera module. The second positioning hole is used for being fixedly connected with a second camera module, and a second gap for calibration is reserved between the second positioning hole and the second camera module. The shell positioning locking points are used for fixedly connecting the support body to a shell. The PCB positioning locking points are used for fixedly connecting a PCB to the support body. The gaps for calibration are reserved between the camera modules and the positioning holes, the relative precision of optical axes of two cameras can be adjusted conveniently, and the separate design of the PCB, the camera modules and the support is beneficial for reduction of the repair or scrap cost.

Owner:SHANGHAI MORUAN COMM TECH

Flexible board cover plate for processing flexible circuit board and technological process of flexible board cover plate

PendingCN108395748AReduce skewReduce scrap costsPrinted circuit manufacturePowdery paintsEngineeringFlexible circuits

The invention discloses a flexible board cover plate for processing a flexible circuit board. The flexible board cover plate comprises a substrate body and a resin plate body. Since the resin plate body is formed after fine particles are solidified; and the substrate body comprises a cold stamped plate or kraft paper or aluminum. When the flexible board cover plate is used and the resin plate bodyis drilled, a small drill pin is stabilized in an instant that the small drill pin is in contact with the surface of the resin plate body, so that the deflection is reduced; and cutting powder is generated after the resin plate body is cut by the small drill pin and is converted into dust to be absorbed, so that in the drilling process, an optimal hole position precision is provided for drillingin the drilling process, and on the premise of meeting the hole position precision in drilling, the problem that a tiny drill pin of 0.075-0.10 mm is broken is improved. In addition, the flexible board cover plate has an effect of simply and conveniently processing.

Owner:SHENZHEN HONGYUHUI TECH CO LTD

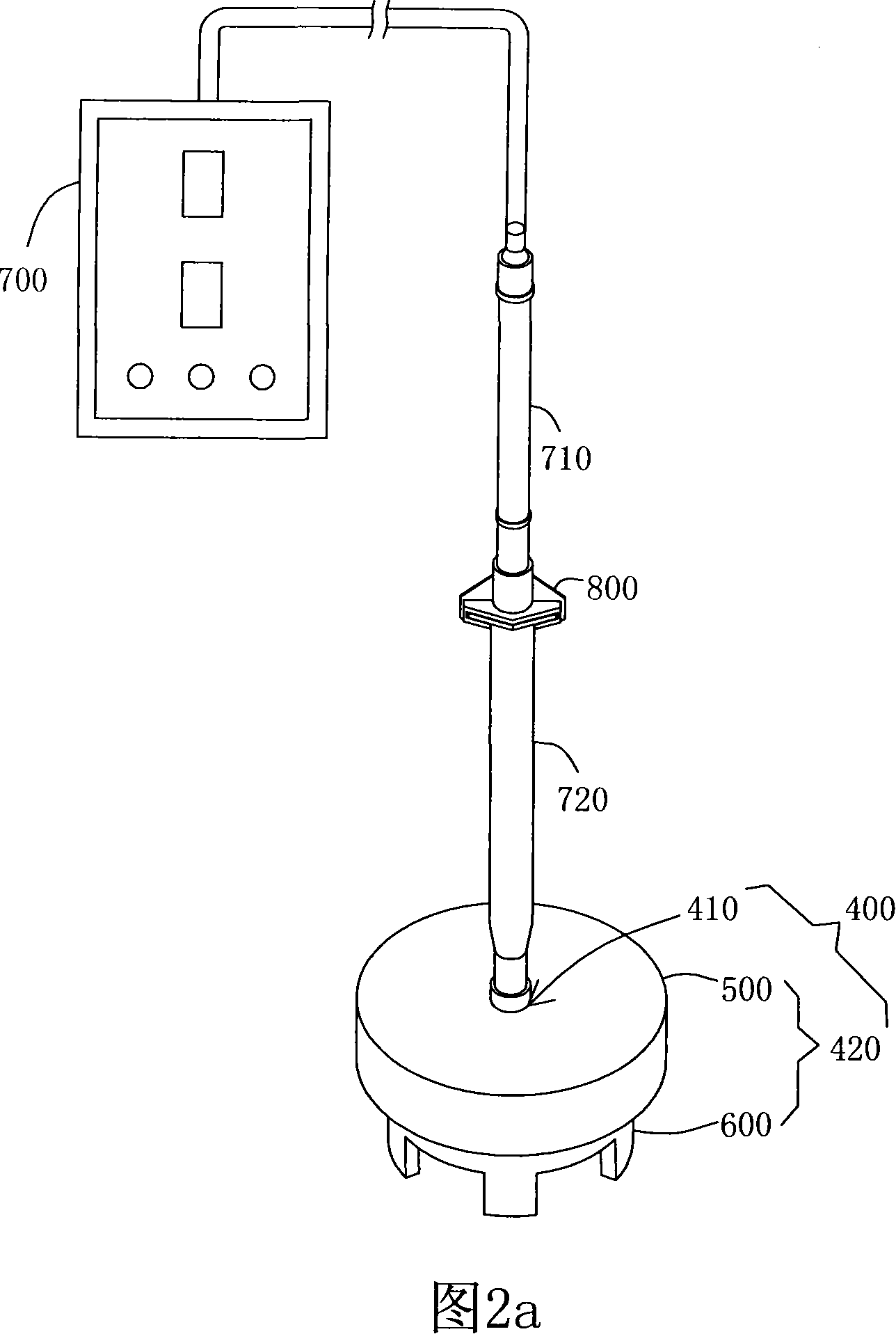

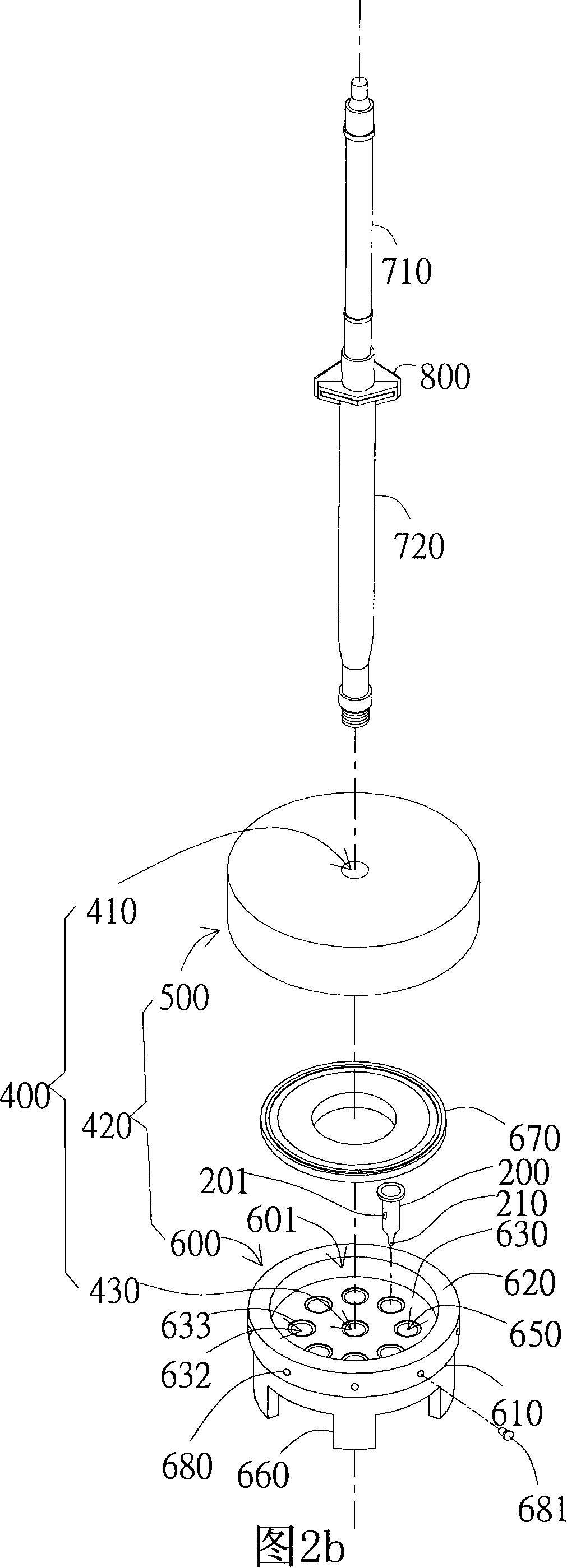

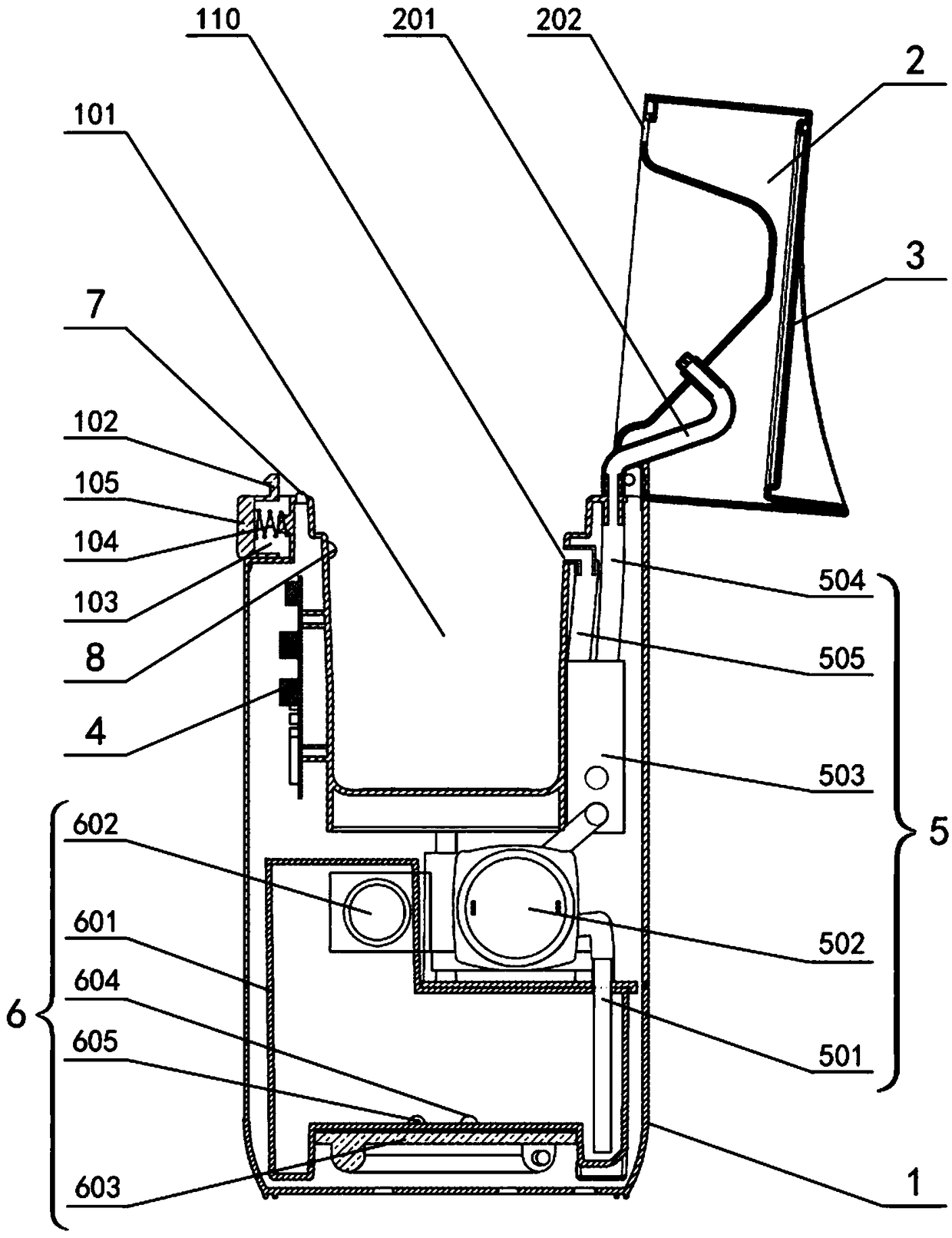

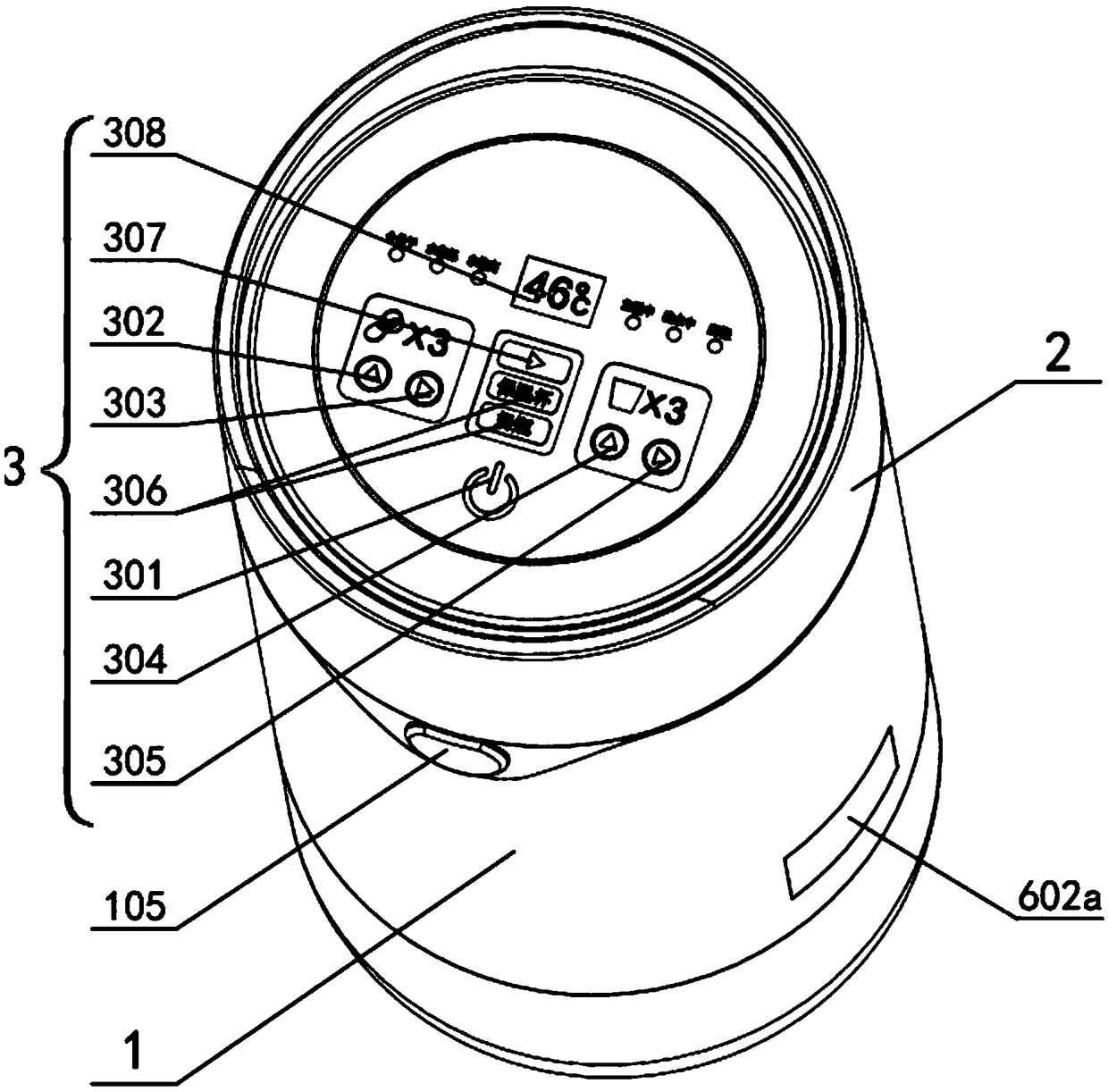

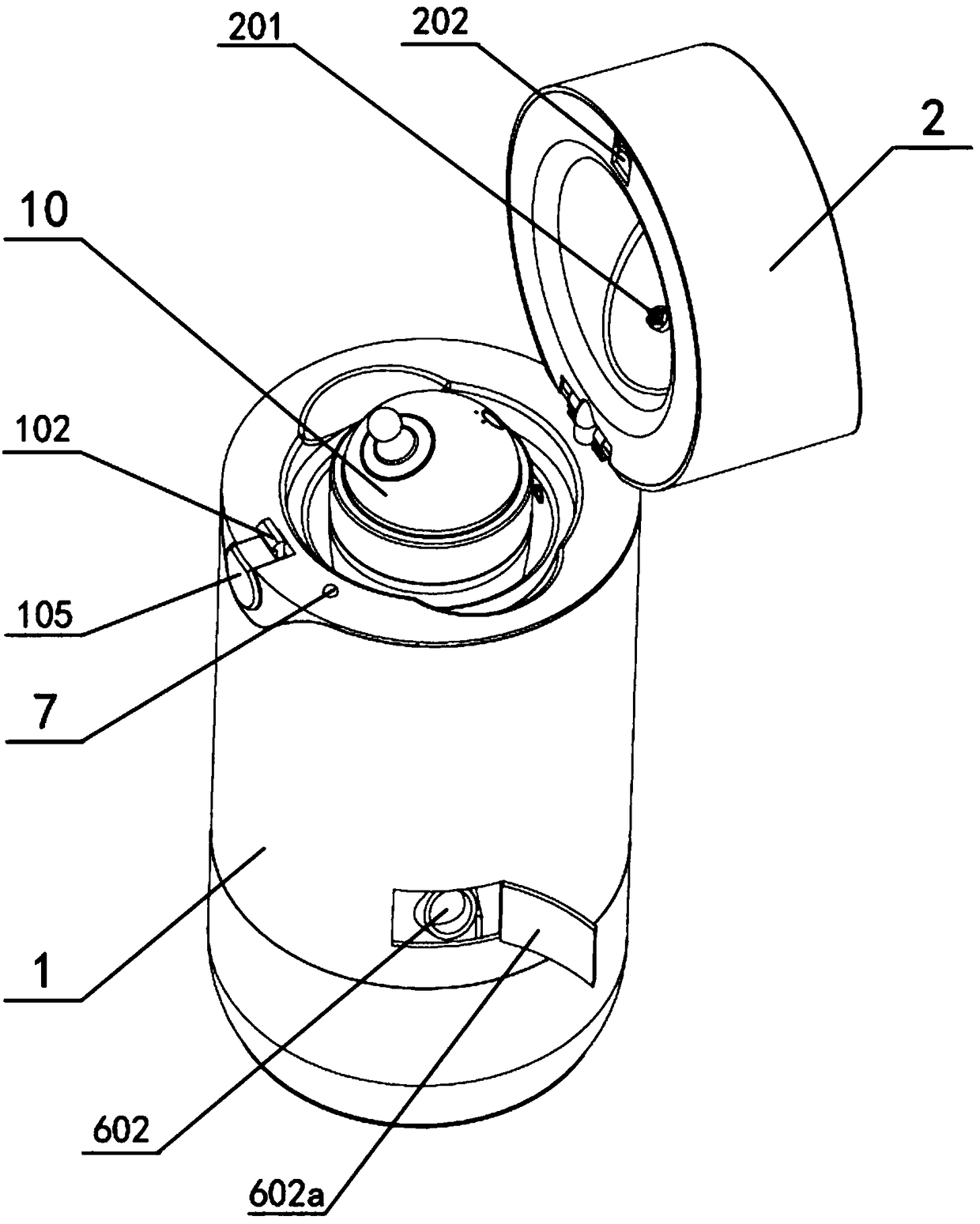

Milk powder dissolving device with heat insulation and disinfection functions and milk powder dissolving equipment

PendingCN109431272AImprove convenienceSave production materials and production resourcesFeeding-bottlesBeverage vesselsThermal insulationChemistry

The invention relates to the field of living supplies, and discloses a milk powder dissolving device with heat insulation and disinfection functions and milk powder dissolving equipment, and providesa novel milk powder dissolving device integrating milk powder dissolving, heat insulation and disinfection functions and novel milk powder dissolving equipment. According to the novel milk powder dissolving device, a closed U-shaped cavity, a water supply mechanism and a stored water heating box are arranged in the milk powder dissolving device, closed milk powder dissolving, heat insulation, disinfection and the like can be achieved, so that convenience degree is greatly improved, parents more focus on baby care, a lot of production materials and production resources can be saved, and the purchasing cost of a user and the scraping cost of a product are reduced. The milk powder dissolving device and the milk powder dissolving equipment have the advantages that pollution is eliminated, splashing of liquid milk is prevented, milk powder dissolving time is saved, water and electricity cost is saved, the device is convenient to operate, high in automation degree, good in sealing effect, easy to open, simple to manufacture and the like. Practical popularization and application are facilitated.

Owner:李述章 +1

Digital control drilling machine

InactiveCN104043854AReduce scrap costsImprove processing efficiencyFeeding apparatusDriving apparatusEngineeringDrive motor

The invention belongs to the technical field of digital control machining equipment and particularly discloses a digital control drilling machine. The digital control drilling machine comprises a digital control drilling mechanism; a digital control revolving table is arranged below the digital control drilling mechanism; the digital control revolving table is provided with a workpiece holder; the digital control drilling mechanism comprises a drill and a drill driving motor for driving the drill to rotate and rise or fall for drilling; the digital control revolving table is connected with a table driving motor through a transmission mechanism; the transmission mechanism is a worm and gear transmission mechanism; a stepping motor is adopted as the table driving motor. According to the digital control drilling machine disclosed by the invention, by adopting the technical scheme, the machining efficiency is greatly improved; moreover, the operation is convenient, the structure is simple, maintenance is easy, and the cost is low; moreover, the digital control drilling machine disclosed by the invention is controlled by the digit control technique, the machining precision is high, the reject ratio is low, and the scrap cost during production and processing of enterprises is greatly reduced.

Owner:TIANJIN KESAISI IND & TRADE

Method for judging whether internal and external color difference exists in cone yarn

The invention relates to a method for judging whether internal and external color difference exists in cone yarn. The method comprises the steps that the cone yarn is subjected to layering treatment, and inner-layer yarn, middle-layer yarn and outer-layer yarn are obtained in the direction from inside to outside or from outside to inside along the cone yarn during layering; then each layer of yarns and the spacer yarns are spliced and weaved to obtain the fabric; interval yarn is arranged between every two adjacent layers of yarn in the splicing weaving process, and the color of the interval yarn and the color of the cone yarn are contrast colors; and after splicing and weaving, yarn on the two sides of each spaced yarn on the weaved fabric is subjected to color difference analysis, the color difference condition of the cone yarn is judged according to a color difference analysis result, the color difference condition of the cone yarn can be effectively distinguished through the method, and whether internal and external color difference exists in the cone yarn is judged.

Owner:GUANGDONG ESQUEL TEXTILES CO LTD

A structure of liquid crystal display panel

InactiveCN101533168APrevent uneven colorIncrease marginStatic indicating devicesNon-linear opticsColor gelLight filter

The invention relates to a structure of liquid crystal display panel. The structure comprises a colour light filter base plate, an electric crystal array base plate and a liquid crystal layer. The colour light filter base plate includes a substrate and a light shielding layer. The surface of the light shielding layer around the substrate is provided with at least one sunken holding chamber. The liquid crystal layer is packed between the electric crystal array base plate and the colour light filter base plate by means of a frame. The structure of liquid crystal display panel can not only solve the problem of non-uniform chromaticity caused by insufficient liquid crystal filling amount, also enhance margin of the liquid crystal filling amount, so as to effectively reduce scrap cost.

Owner:CPTF VISUAL DISPLAY (FUZHOU) LTD +1

Method for rolling and/or heat treating a metal strip

ActiveCN108779508AEasy to controlEasy to adjustProgramme controlHot-dipping/immersion processesEngineeringProcess engineering

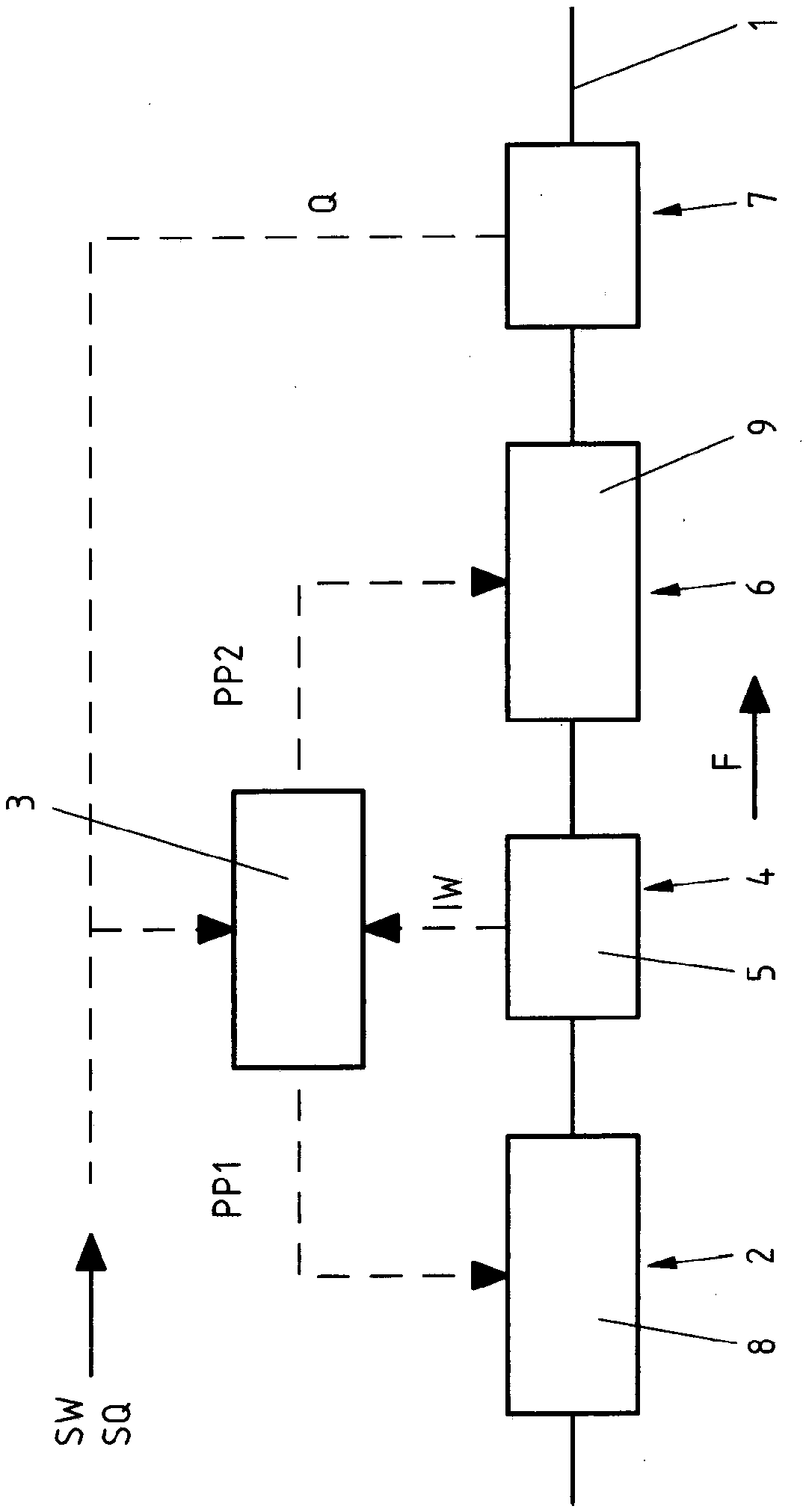

The invention relates to a method for rolling a metal product (1), wherein the metal product is subjected to a rolling operation at a first station (2), which rolling operation is controlled by a control device (3), wherein the product (1) is subjected to a measurement at a second station (4), wherein the product (1) is subjected to a further processing operation at a third station (6), and wherein the product (1) is in a specified quality at a fourth station (7). In order to increase the quality of the produced strip, the invention provides that the method has the following steps: a) measuring the value of a material property (IW) at the second station (4); b) feeding the value measured at the second station (4) to the control device (3), comparing the measured value with a value (SW) stored in the control device (3), and adjusting a parameter (PP1) if the measured value deviates from the stored value (SW), c) measuring a value of a quality material property (Q) at the fourth station(7); d) comparing the measured value with a stored value, and initiating a measure to influence the quality material property (Q) if the measured value deviates from the stored value beyond a permissible tolerance.

Owner:SMS GRP GMBH

MPO optical fiber connector

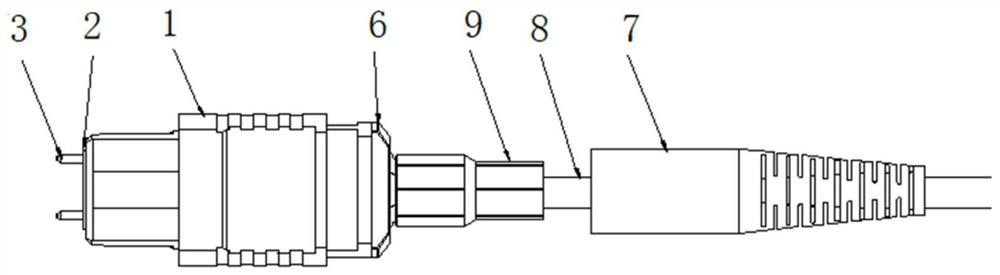

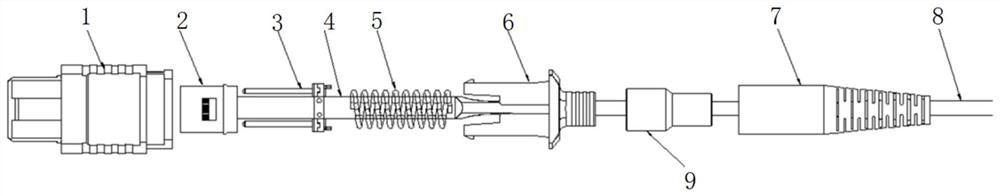

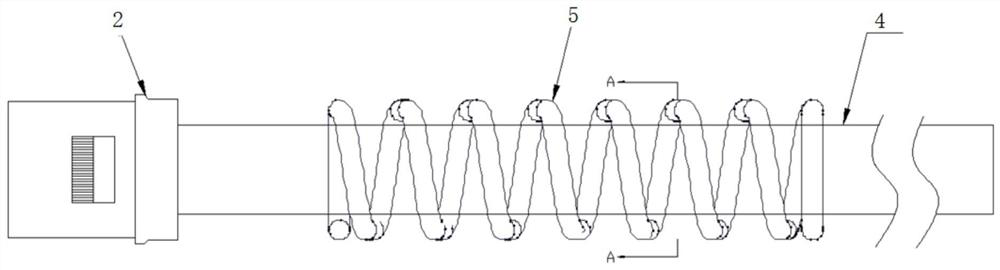

PendingCN112987191AAvoid the problem of scratching the fiberPromote repairCoupling light guidesFiberOptical fiber connector

The invention discloses an MPO optical fiber connector which comprises a locking sleeve, an insertion core, a ribbon fiber, an optical cable, a spring, a spring base and a sheath, the insertion core is installed in the locking sleeve, the insertion core is connected with one end of the ribbon fiber, the other end of the ribbon fiber is connected with the optical cable, the optical cable penetrates out of the sheath, the spring is installed on the spring base, and the locking sleeve and the spring base are locked and assembled together and tightly press the spring. The spring applies pressing elastic force to the insertion core, the spring base is of a split structure, the spring base comprises a first base assembly and a second base assembly which are detachable, the spring comprises a first spring element and a second spring element, the first spring element is detachably assembled on the first base assembly, the second spring element is detachably assembled on the second base assembly, and the first base assembly and the second base assembly are combined together and detachably assembled with the locking sleeve. The MPO optical fiber connector can prevent the spring from scratching the optical fiber, is convenient to repair, and reduces the cost of product scrap.

Owner:T&S COMM

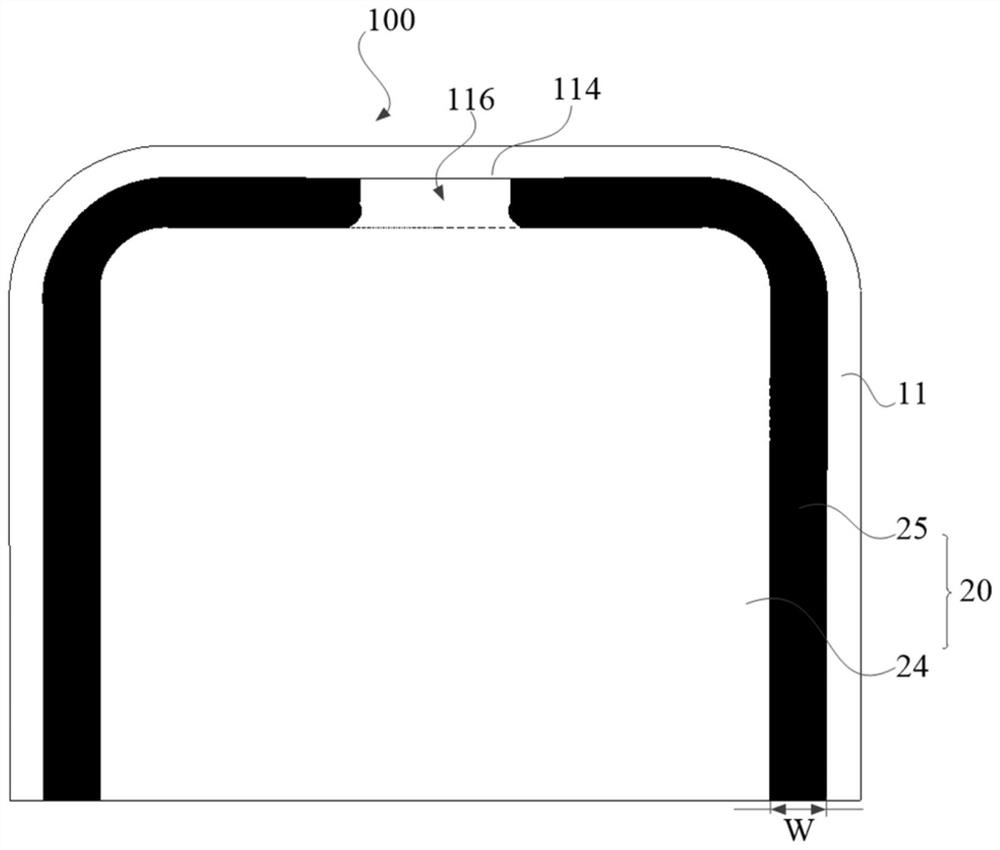

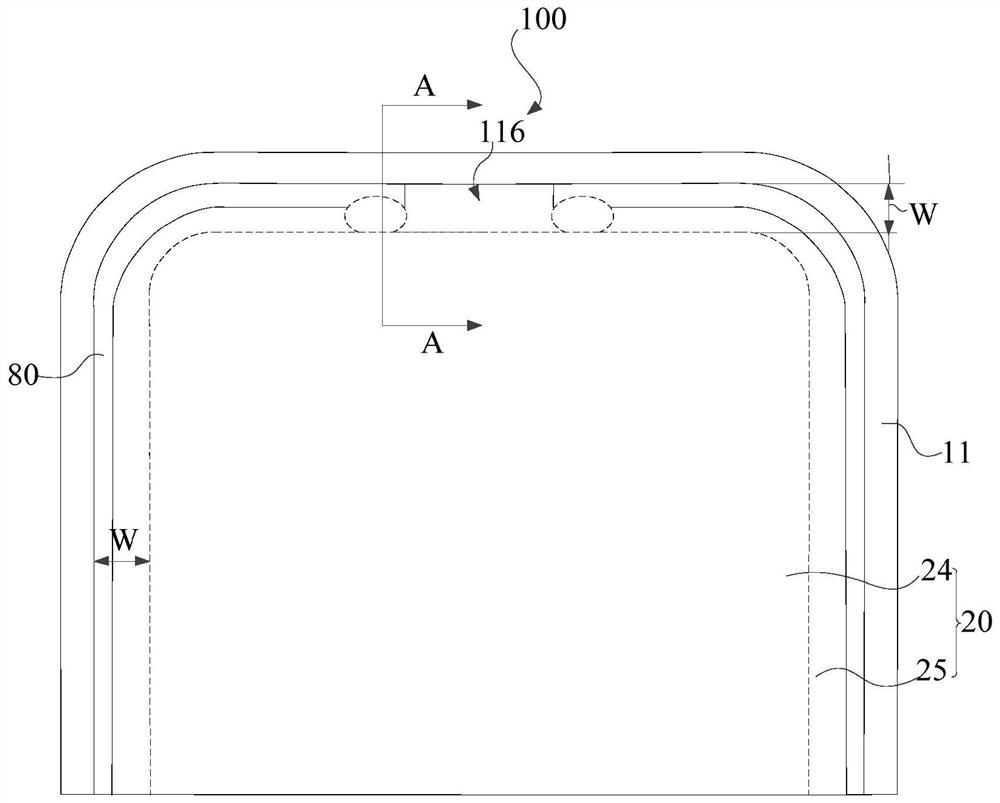

Electronic equipment

ActiveCN113596206AReduce black border widthImproved protection against liquid ingressHermetically-sealed casingsTelephone set constructionsEngineeringMechanical engineering

The invention provides electronic equipment, and the electronic equipment comprises a shell and a display screen; the display screen comprises a display module and a screen cover plate; an installation space is defined between the shell and the screen cover plate, the display module is fixed in the installation space, and a containing cavity is defined by the display module and the inner side wall of a frame. A gap communicated with the containing cavity is formed between the screen cover plate and the inner side wall of the frame, the gap is filled with a first bonding piece, and the screen cover plate is bonded to the inner side wall of the frame through the first bonding piece. A plurality of partition pieces distributed at intervals are further arranged in the containing cavity, and the partition pieces are bonded between the shell and the display screen and divide the containing cavity into a plurality of isolation cavities. The display screen of the electronic equipment has good liquid inlet protection capability.

Owner:HONOR DEVICE CO LTD

Sensor detachable structure of heart rate monitor

InactiveCN107518886AEasy to disinfectEasy to operateSensorsMeasuring/recording heart/pulse rateMaintainabilityEngineering

The invention relates to the technical field of heart rate belt sensors, in particular to a detachable sensor structure for a heart rate belt, which includes a support plate, both ends of which are connected to the heart rate belt body, and a first side plate and a On the second side plate, one end of the support plate is provided with a first through hole, the top surface of the support plate is provided with a return-shaped groove, and a housing is provided above the support plate and between the first side plate and the second side plate, and the four sides of the housing are provided. The bottom ends of the two side walls are all arranged in the return-shaped groove, the inner cavity of the housing is provided with a heart rate sensor, the heart rate sensor is connected to the heart rate detector, and one end of the bottom surface of the heart rate sensor is provided with an electrode, and the electrode passes through the first through hole and extends to the bottom surface of the support plate On one side, two fixed blocks are provided on the outer bottom surface of the housing, and a semi-fixed ring is installed on the top surface of each fixed block. A U-shaped opening is opened at the central position of the end of the first side plate away from the support plate. In the present invention, the operation is simple and can be The disassembly structure facilitates the disinfection of the heart rate belt, improves maintainability, and reduces scrap costs.

Owner:黄石翰林信息科技有限公司

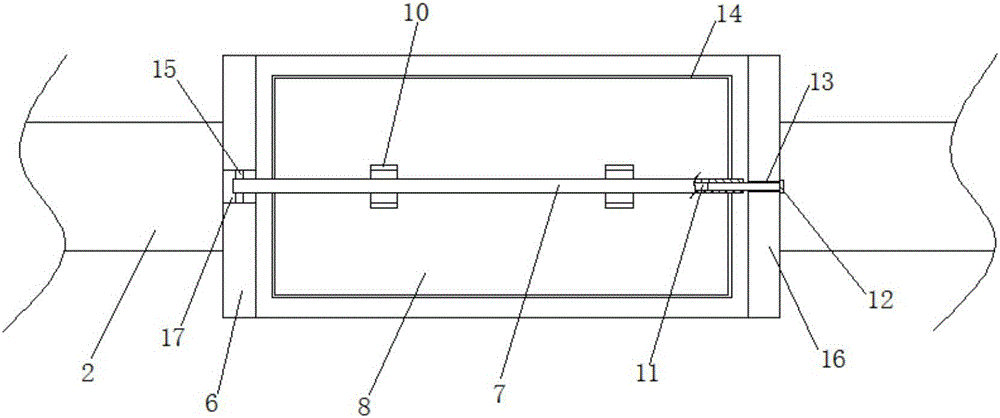

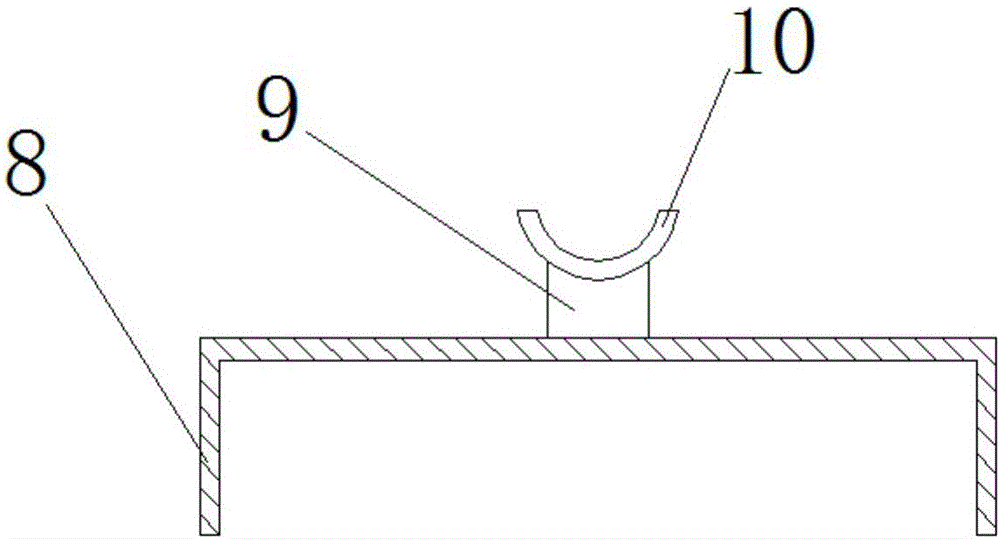

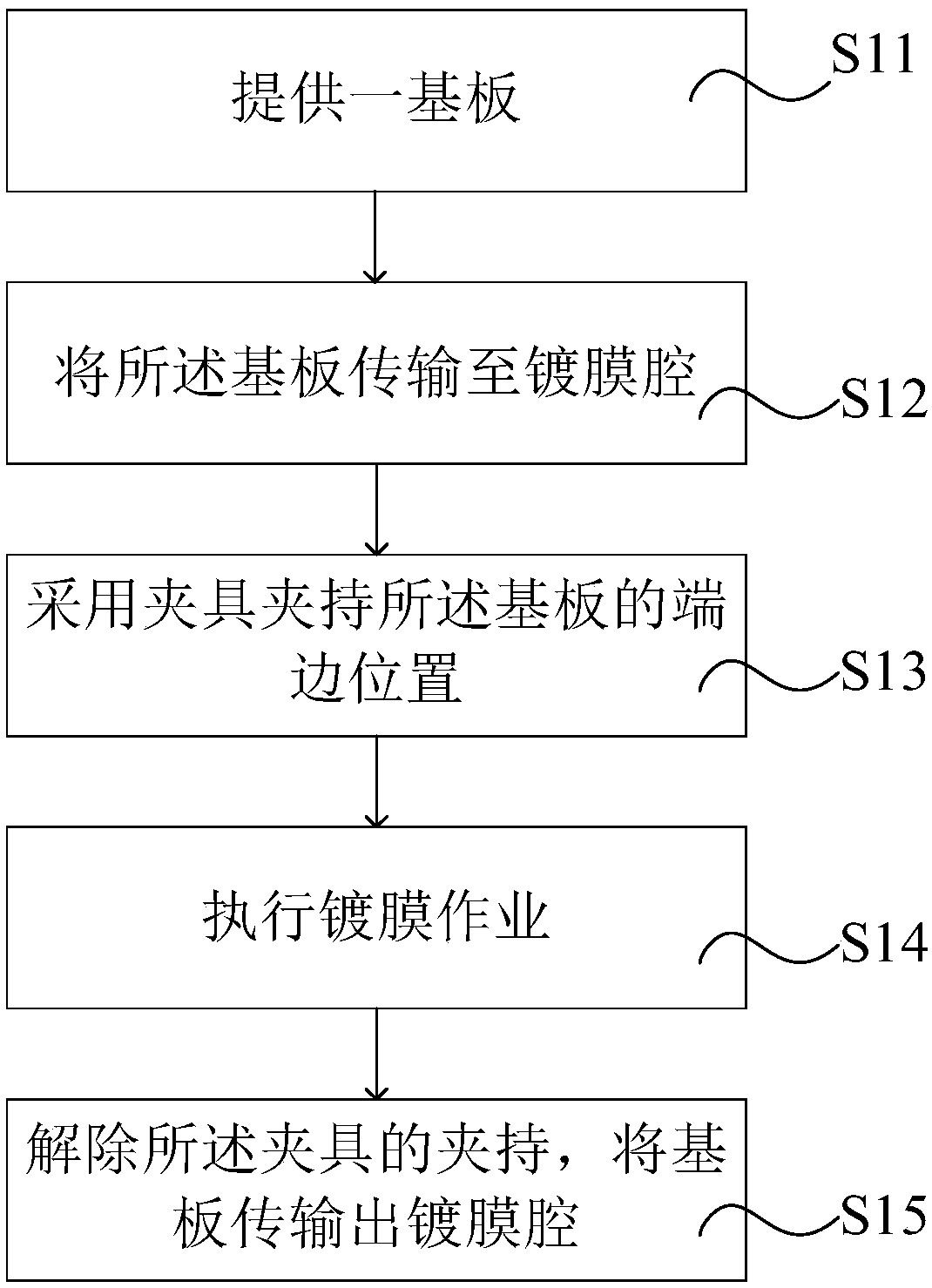

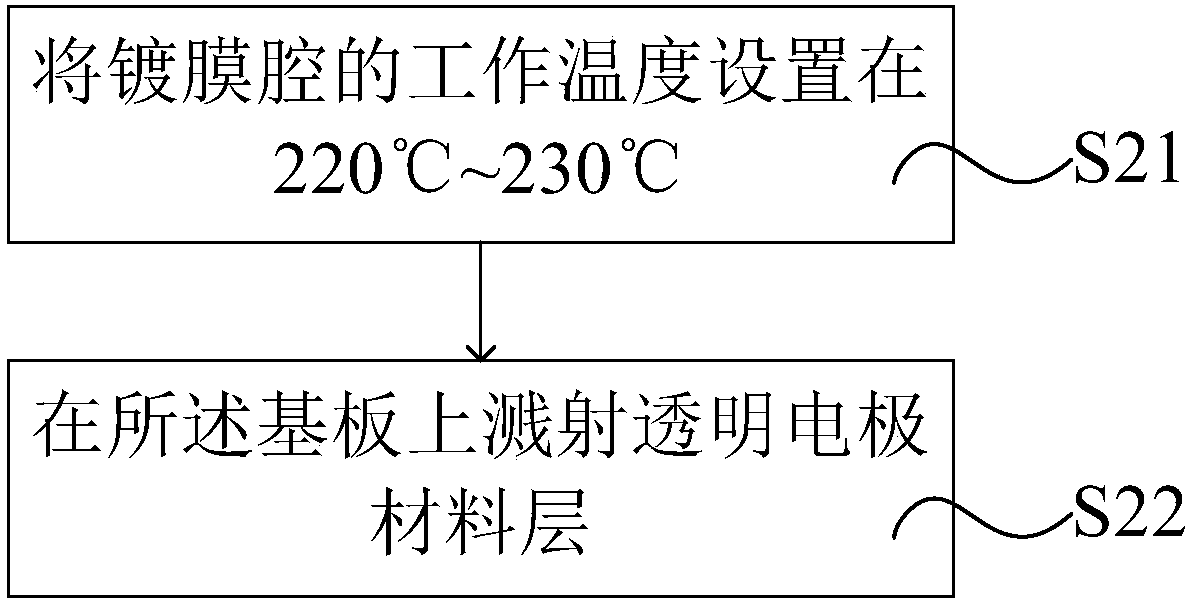

Display panel preparing method and preparing device

ActiveCN107564847AAvoid scratch damage pointsReduce Fragmentation RateVacuum evaporation coatingSputtering coatingEngineering

Owner:HKC CORP LTD +1

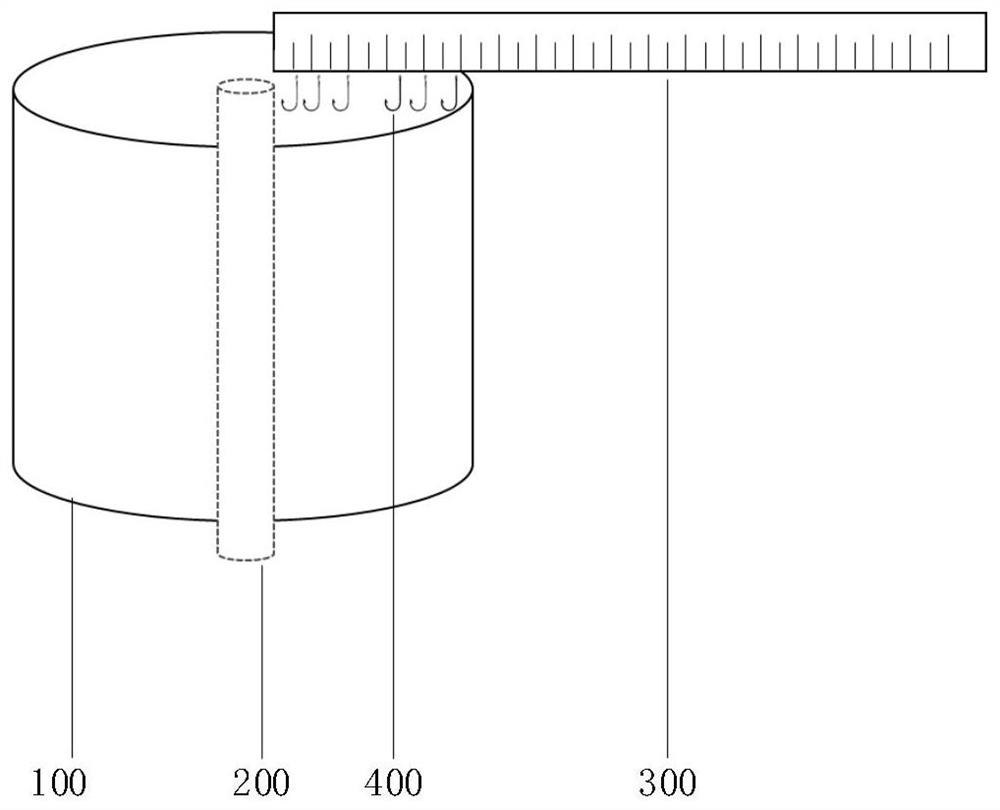

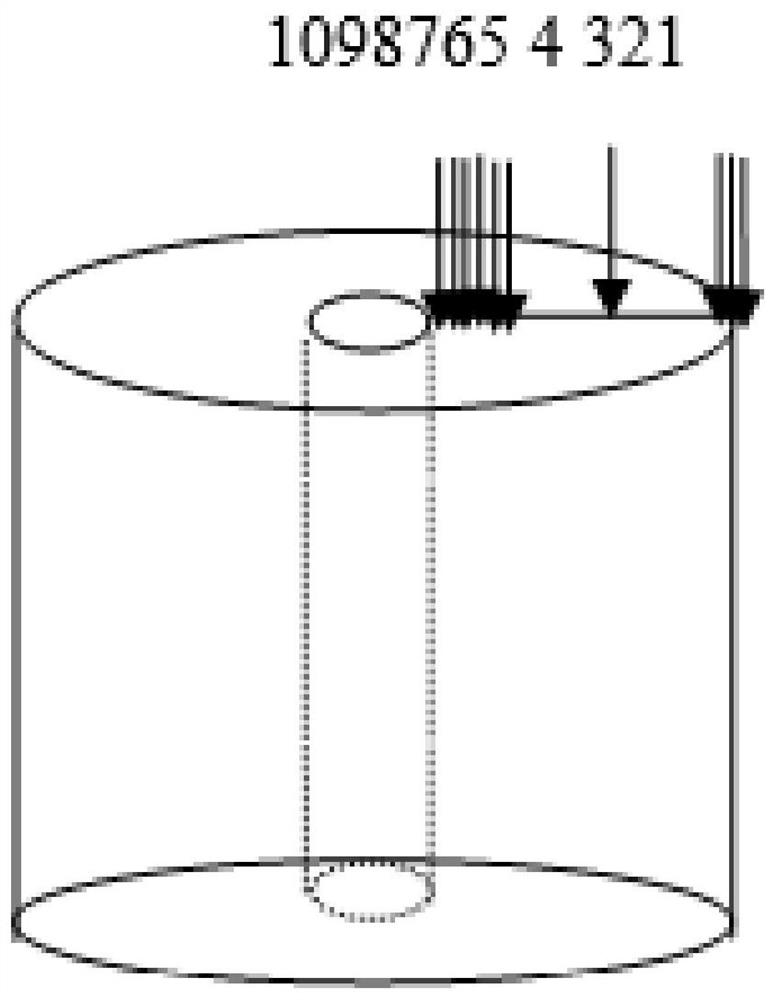

Split type piston for breaking hammer and equipment for installing split type piston

InactiveCN112855658AReduce scrap costsEasy to installWork holdersSoil-shifting machines/dredgersEngineeringPiston

The invention relates to a split type piston for a breaking hammer and equipment for installing the split type piston. The split type piston comprises a piston body, a mounting cavity penetrating through one end of the piston body is formed in the piston body, the interior of the piston body communicates with the outside through the mounting cavity, and a striking head is arranged on the side, close to the mounting cavity, of the piston body; a mounting block is fixedly arranged at one end, close to the piston body, of the striking head, is arranged in the mounting cavity, and is detachably connected with the piston body; and the piston body and the striking head are detachably connected together through the mounting cavity and the mounting block, in the normal working and using process of the breaking hammer, the striking head continuously crushes and strikes an object, after normal working for a period of time, the striking head can deform and be damaged, the striking head is scrapped, at the moment, an operator only needs to detach the striking head from the piston body, a new striking head is adopted, only the detached striking head is scrapped, and the piston body is reserved, so that the effect of reducing the scrap cost is achieved.

Owner:山东锐凯工程机械有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com