Numerical control drilling device

A technology of drilling device and drilling mechanism, which is applied in the direction of boring/drilling, drilling/drilling equipment, boring machine/drilling machine parts, etc., which can solve the problem of complex drilling process, low work efficiency and poor processing accuracy and other problems, to achieve the effect of reducing scrap cost, simple structure and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The substantive features and advantages of the present invention will be further described below in conjunction with examples, but the present invention is not limited to the listed embodiments.

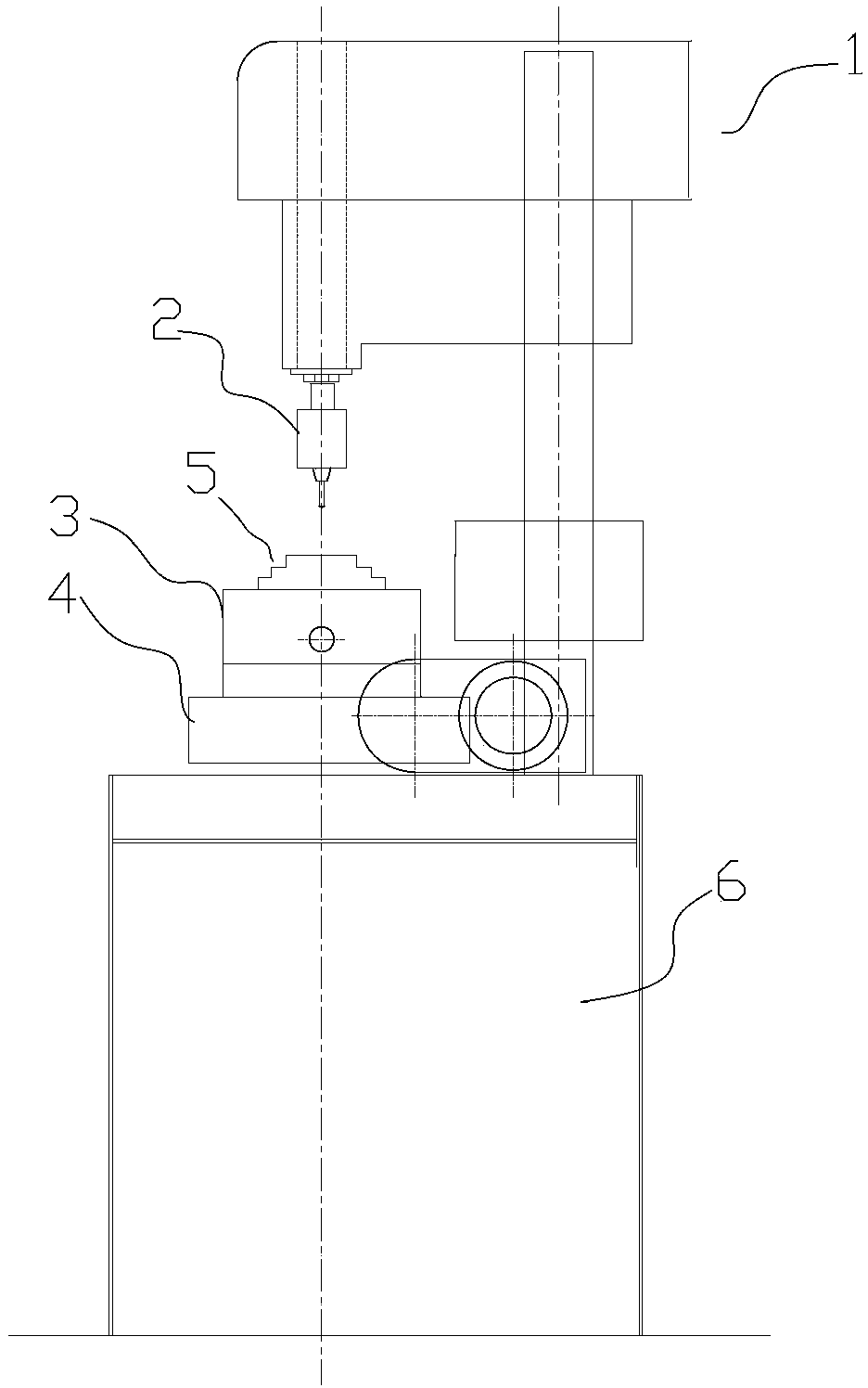

[0013] see figure 1 As shown, the figure shows the structure of a numerical control drilling device provided by the embodiment of the present invention, and for the convenience of description, only the parts related to the embodiment of the present invention are shown.

[0014] Such as figure 1 As shown, a kind of numerical control drilling device, comprises the numerical control drilling mechanism 1 controlled by numerical control system, is provided with the numerical control rotating table 4 controlled by described data system below described numerical control drilling mechanism 1, and described numerical control rotating A workpiece fixture 3 is provided on the workbench 4, a cooling water pipe (not shown) is provided on the CNC drilling mechanism 1, and a water collectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com