Rotary rubber turbine

A technology of plastic wave machine and rotary rod, which is applied in the direction of sewing tools and other directions, can solve the problems of the high defective rate of jeans, the prolonged delivery time of jeans, and the impact of timely delivery of orders, so as to shorten the sand cleaning time and shorten the The effect of delivery time and cost saving of production space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

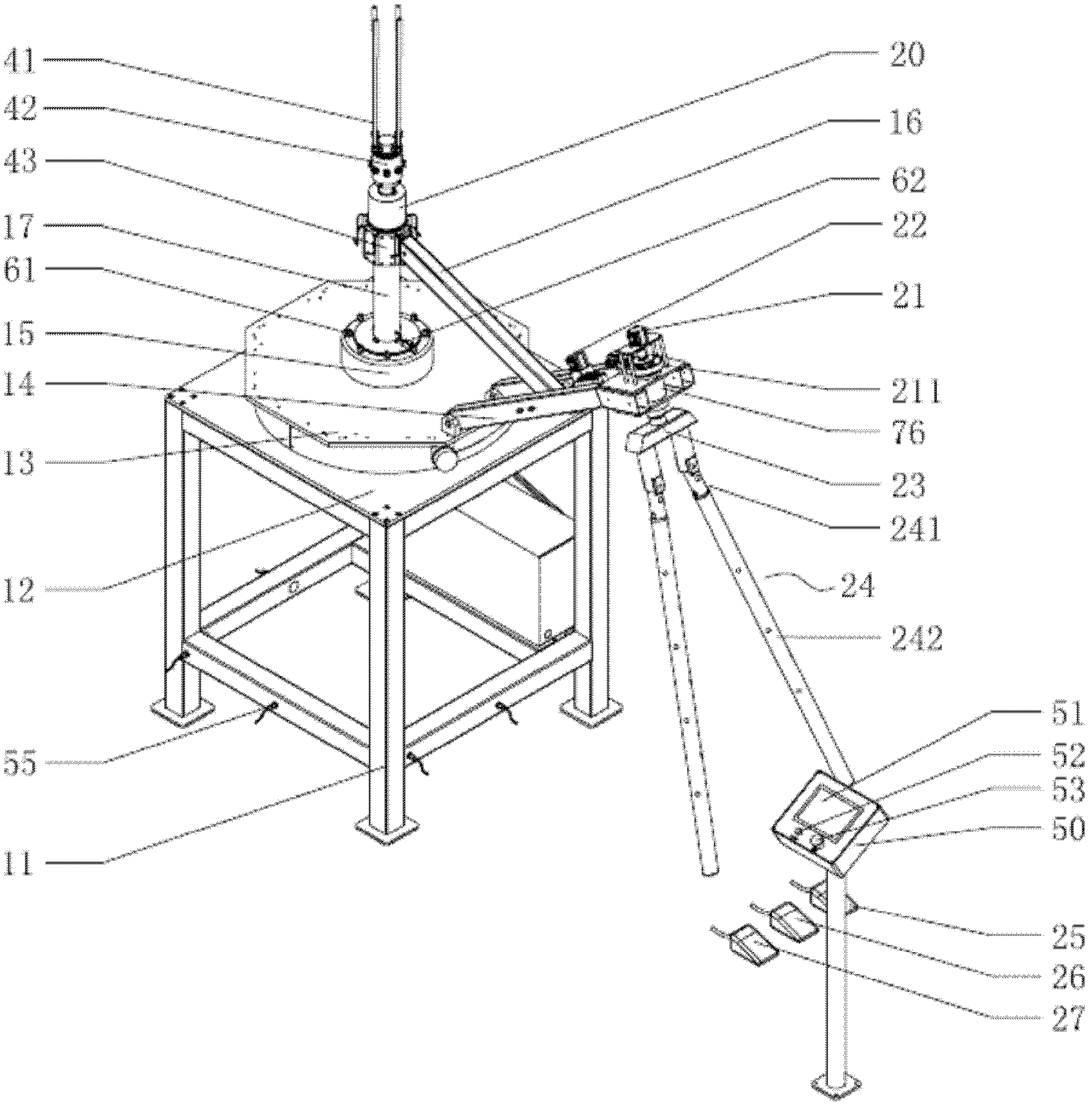

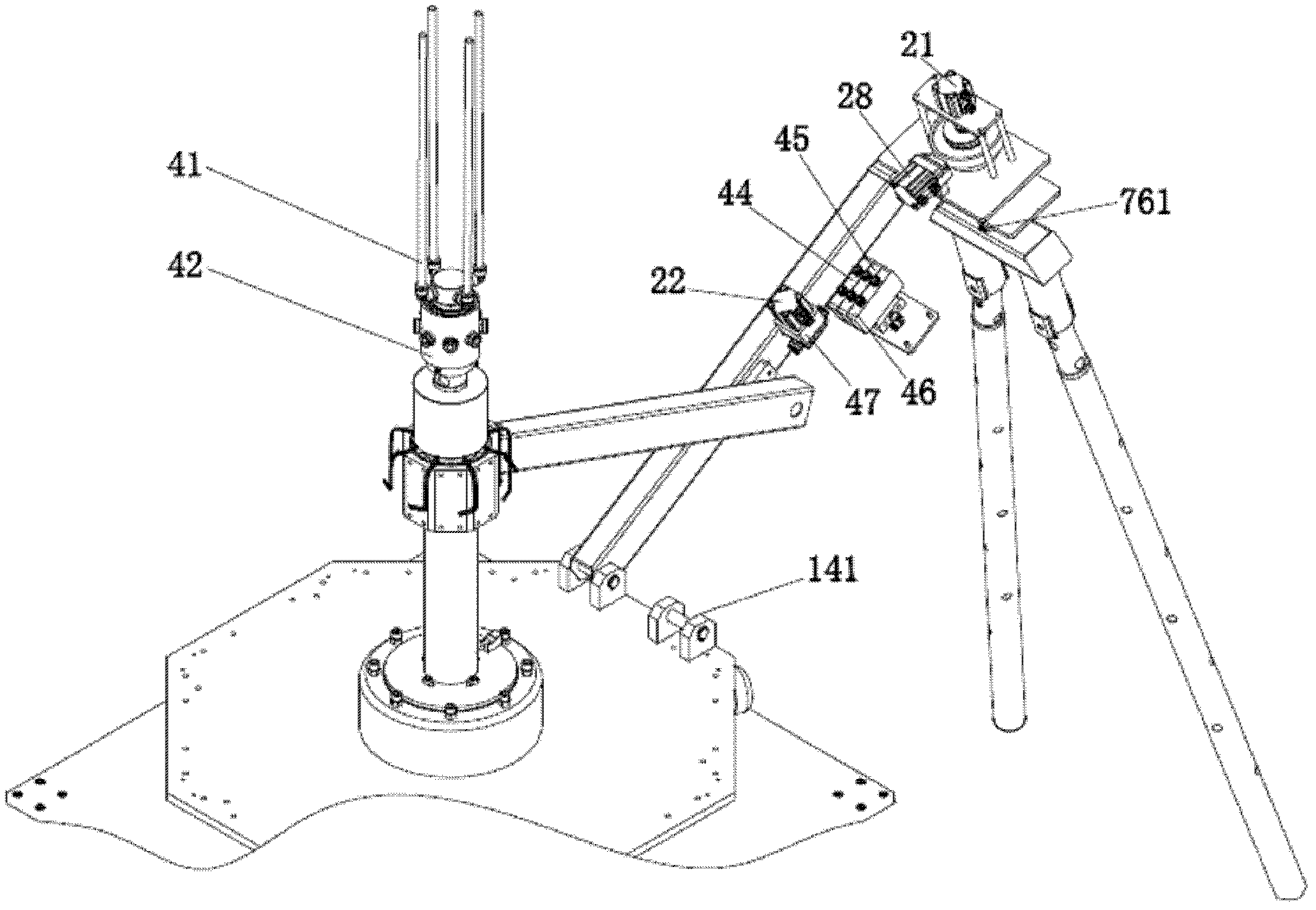

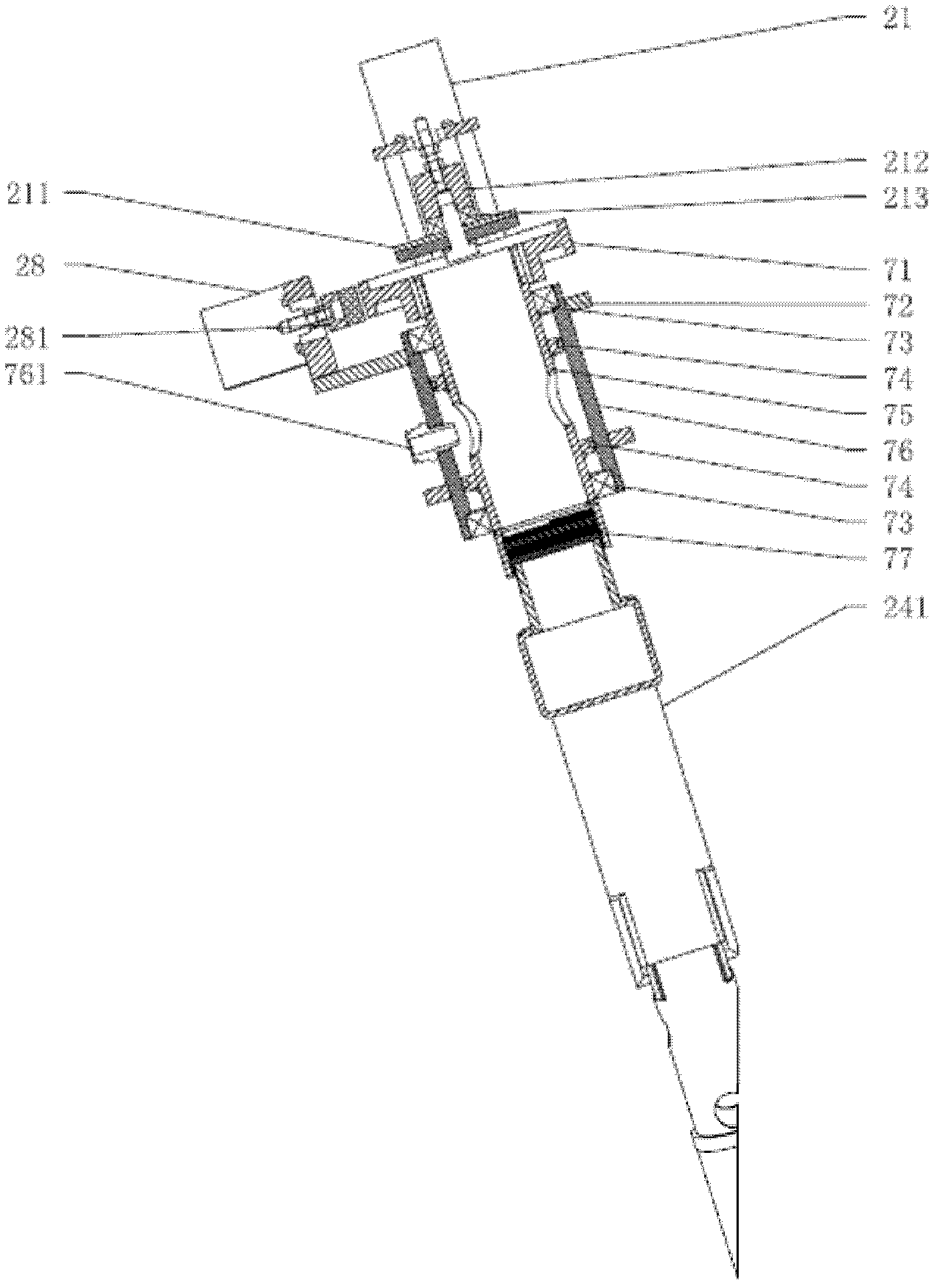

[0026] Below in conjunction with accompanying drawing, the present invention will be further described:

[0027] see Figure 1-Figure 4, the rotary rubber wave machine of the present invention includes a base and a turntable 13 that is rotatably connected to the base in the vertical direction. The turntable 13 is provided with a rotating air distribution block 42 near the center and a There is at least one yarn wiping unit, and the yarn wiping unit includes a rotating drum 76 and a rotating rod 75 that is rotatably connected to the rotating drum 76. The rotating rod 75 is provided with rubber wave legs 24 through the frame tube 23, and the yarn wiping unit A brake cylinder 28 for restricting the rotation of the rotating rod 75 and an inflation cylinder 22 and a deflation cylinder 21 for inflating and deflating the plastic wave leg 24 are also provided on the top, and the rotating rod 75 is a cylindrical structure with openings at both ends. Its outer surface is rotatably conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com