Binding method for lifting soft-solid synthetic printed circuit board turn-on hole trust degree

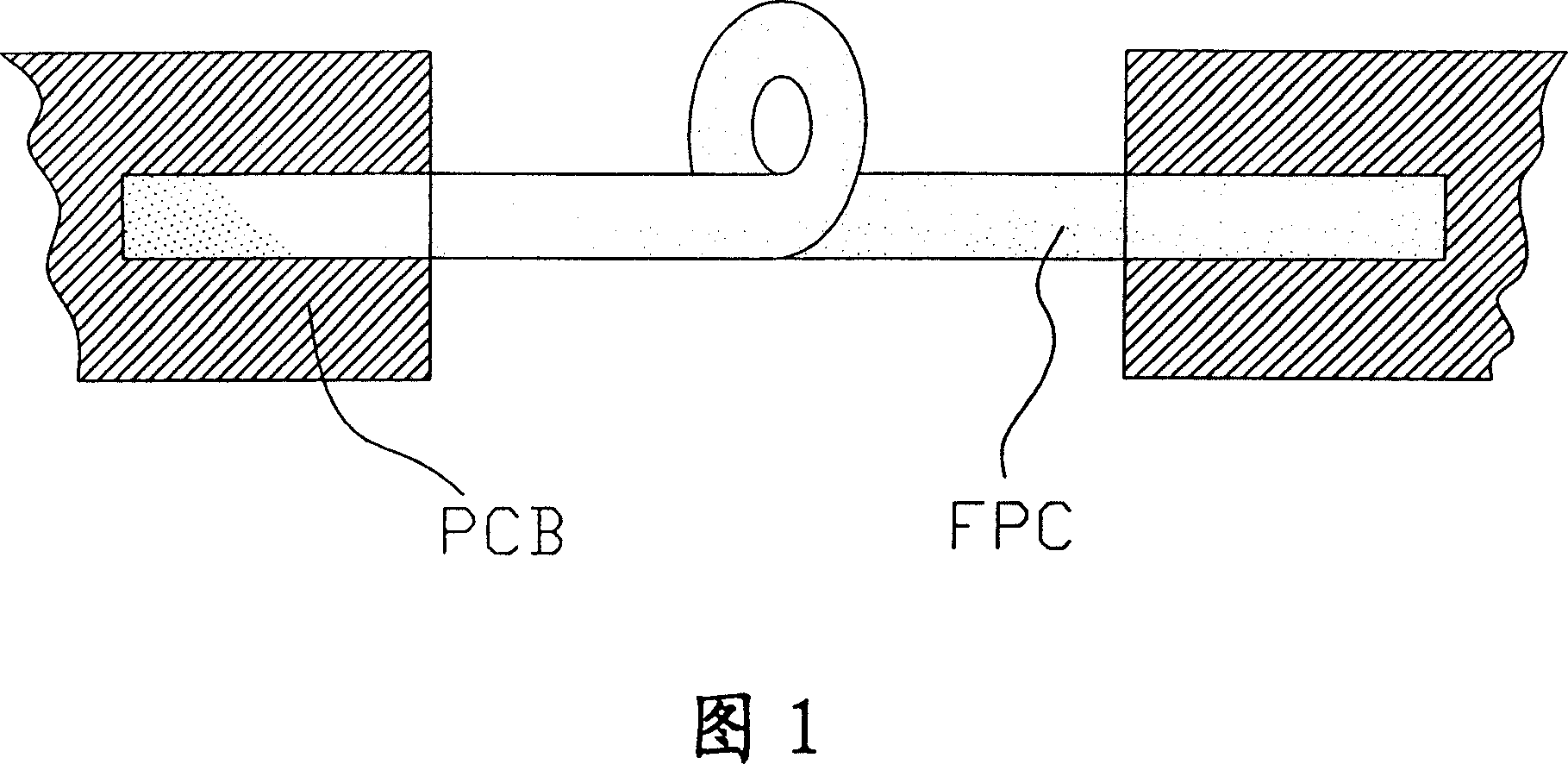

A technology for printed circuit boards and via holes, which is applied in the field of combining the reliability of the via holes of soft and hard composite printed circuit boards, and can solve the problems of poor corrosion resistance, poor copper melting, and inability to conduct electricity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

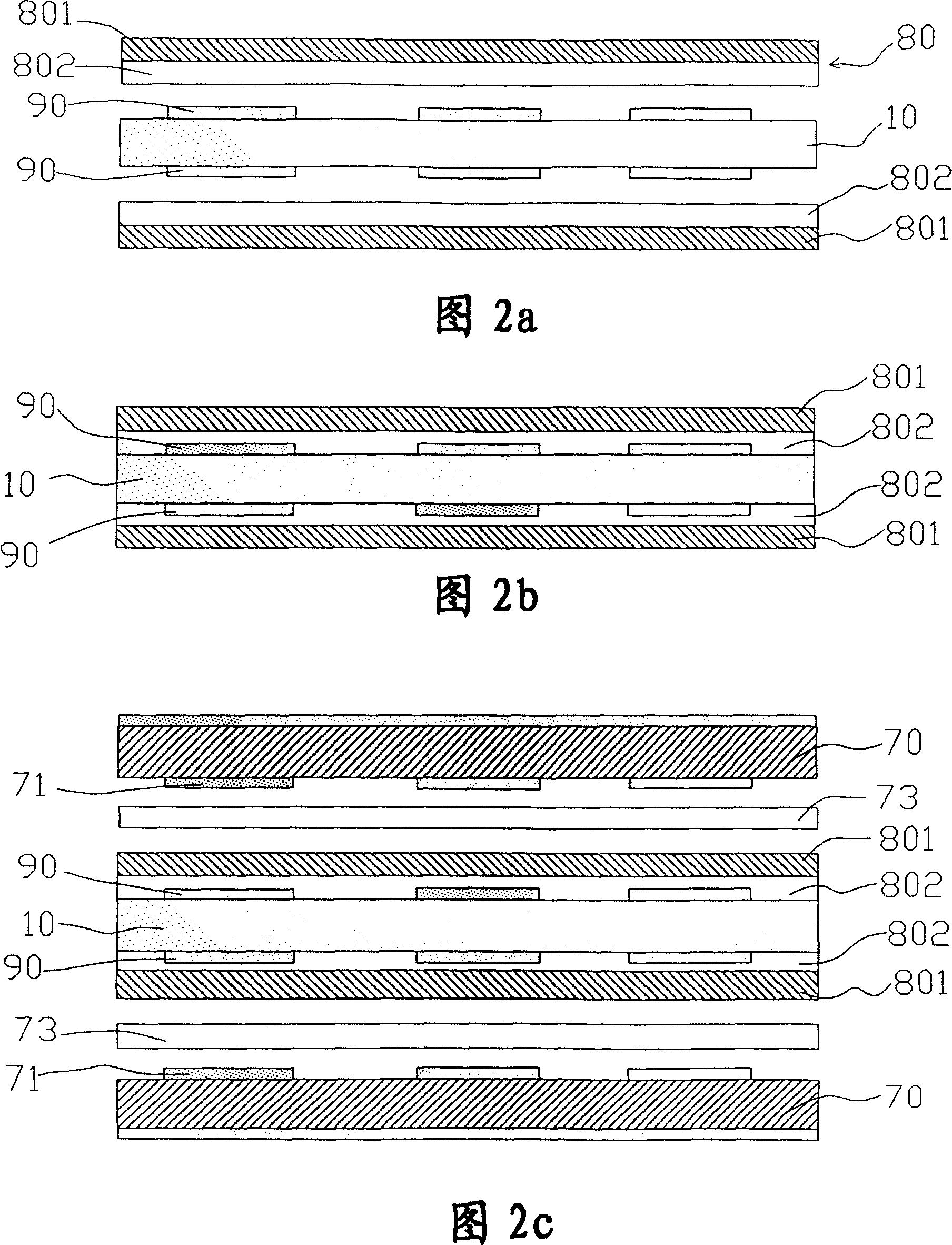

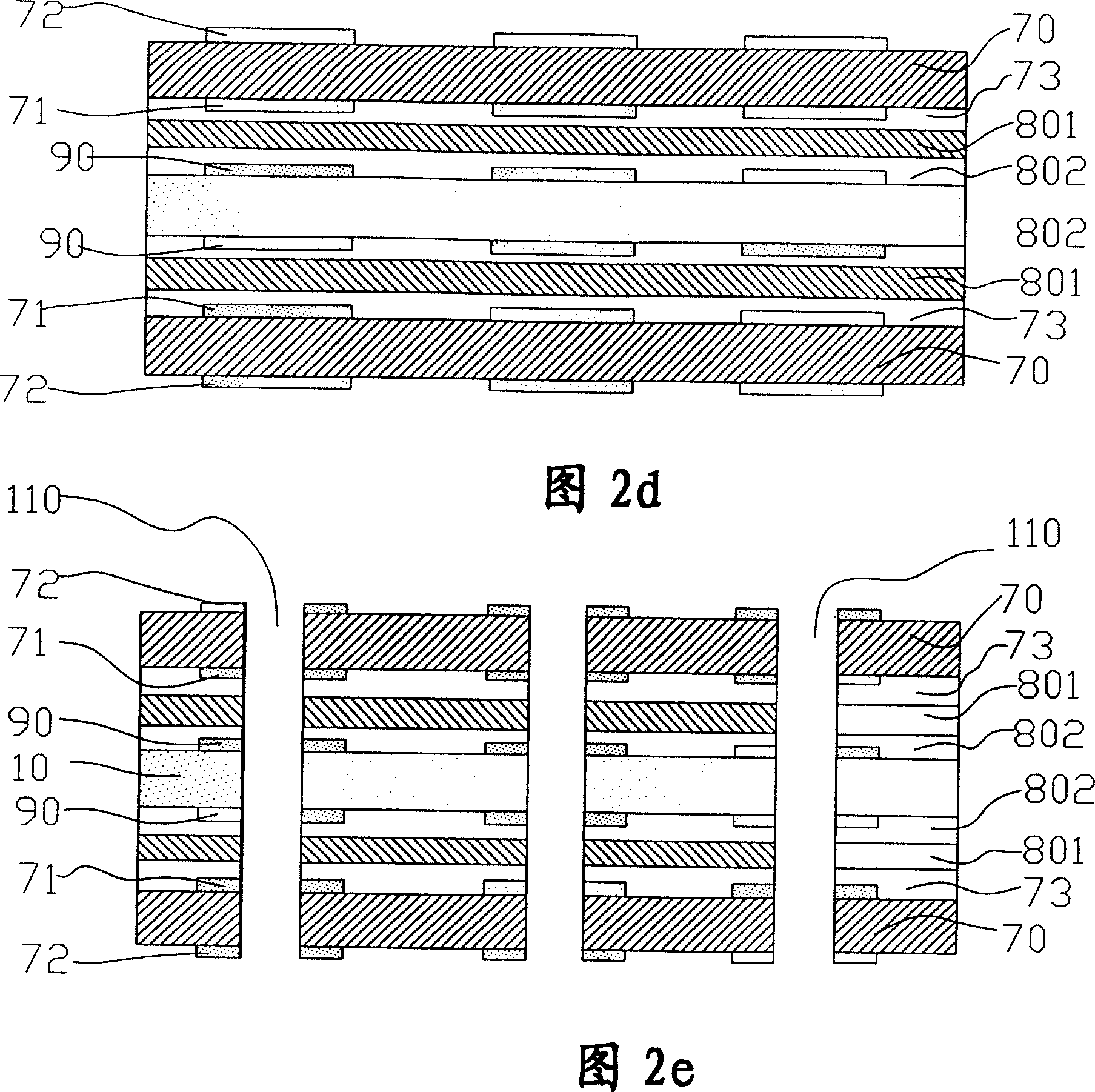

[0021] The invention relates to a method for combining flexible and rigid printed circuit boards. The method is as follows:

[0022] Please refer to Fig. 3 a, shown in 3b, the making of flexible printed circuit board is to be by the substrate (FCCL) 10 of flexible printed circuit board made of polyimide (Polyimide, be called for short PI) material, and in it The surface of the substrate 10 of the flexible printed circuit board is coated with copper foil 20 (Copper Foil), and the electrical circuit is made by photolithography and etching (Etching). The cover film 30 is pasted on the substrate 10 of the flexible printed circuit board having completed the electric circuit in a combined manner to protect the surface of the electric circuit to complete the flexible printed circuit board; and the cover film 30 is made of polyimide ( polyimide (referred to as PI) layer 32 and adhesive (EPOXY glue or acrylic glue) layer 33 (as shown in Figure 3a), and are bonded to the flexible printe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com