PCB (Printed Circuit Board) processing method

A processing method and a technology for a resist layer, which are applied in the formation of electrical connection of printed components, electrical components, and printed circuit manufacturing, etc., can solve the problems of limited dry film sealing ability, poor dry film adhesion, and easy shovel of resin. , to achieve the effect of reducing the risk of scrapping, improving the process capacity and reducing the cost of scrapping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

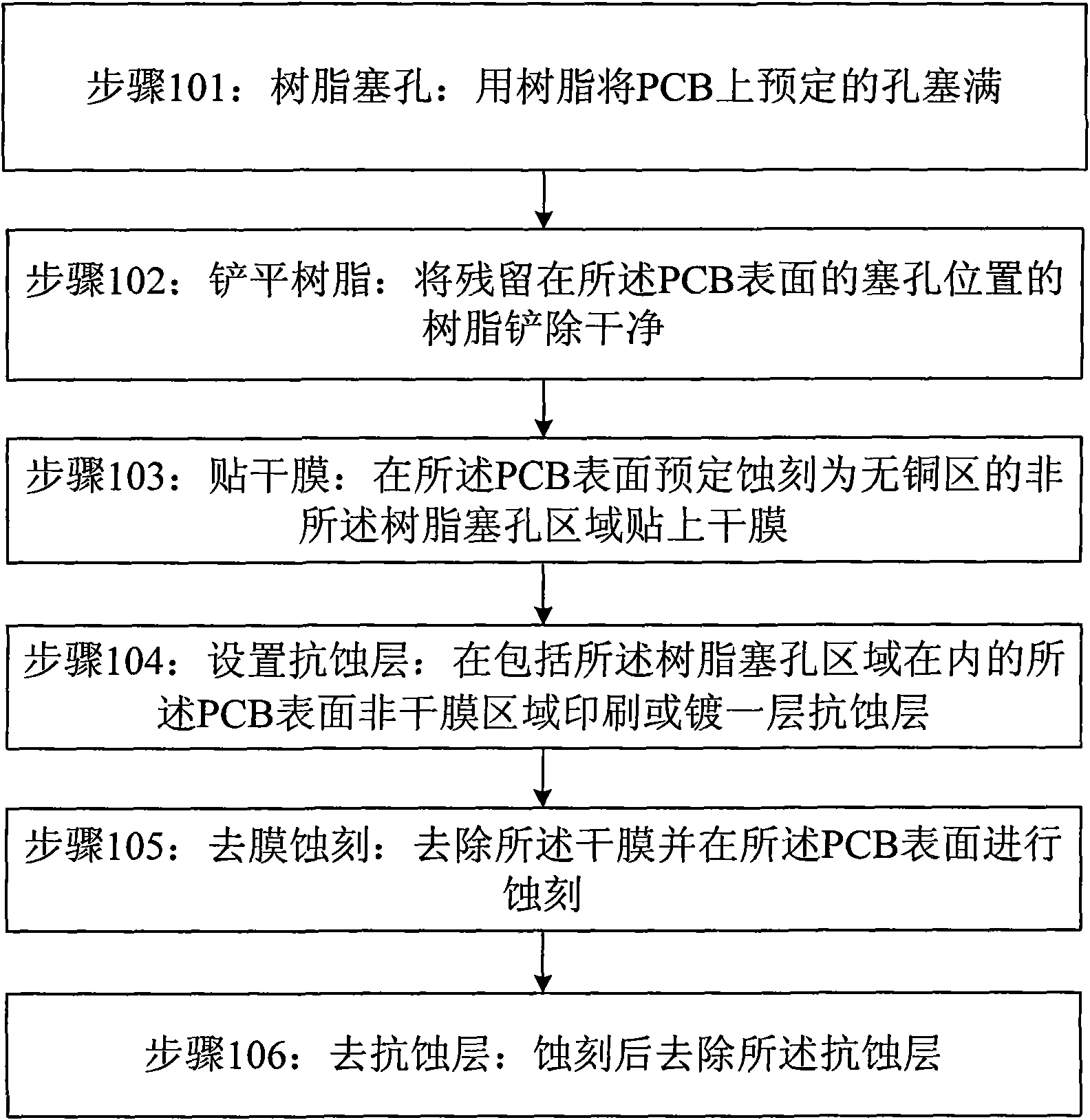

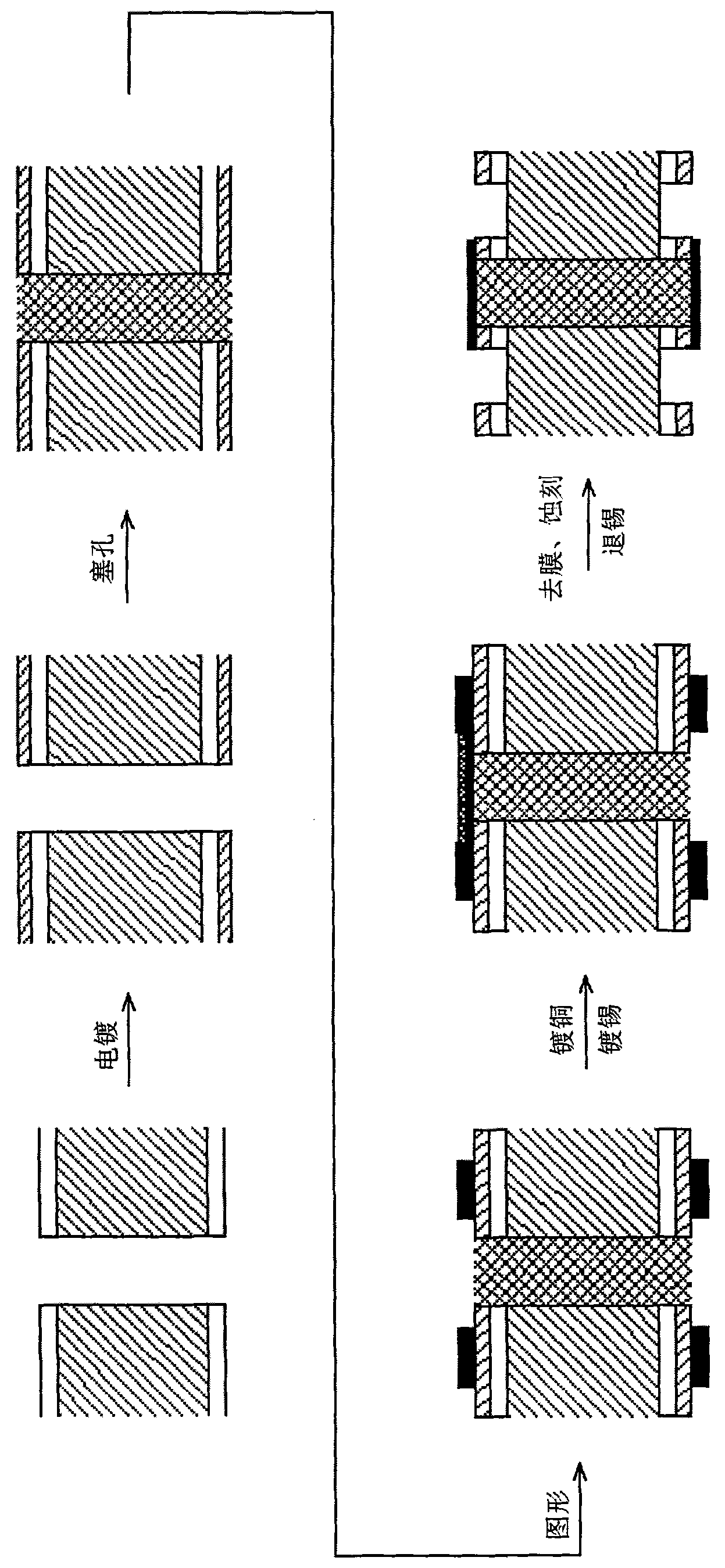

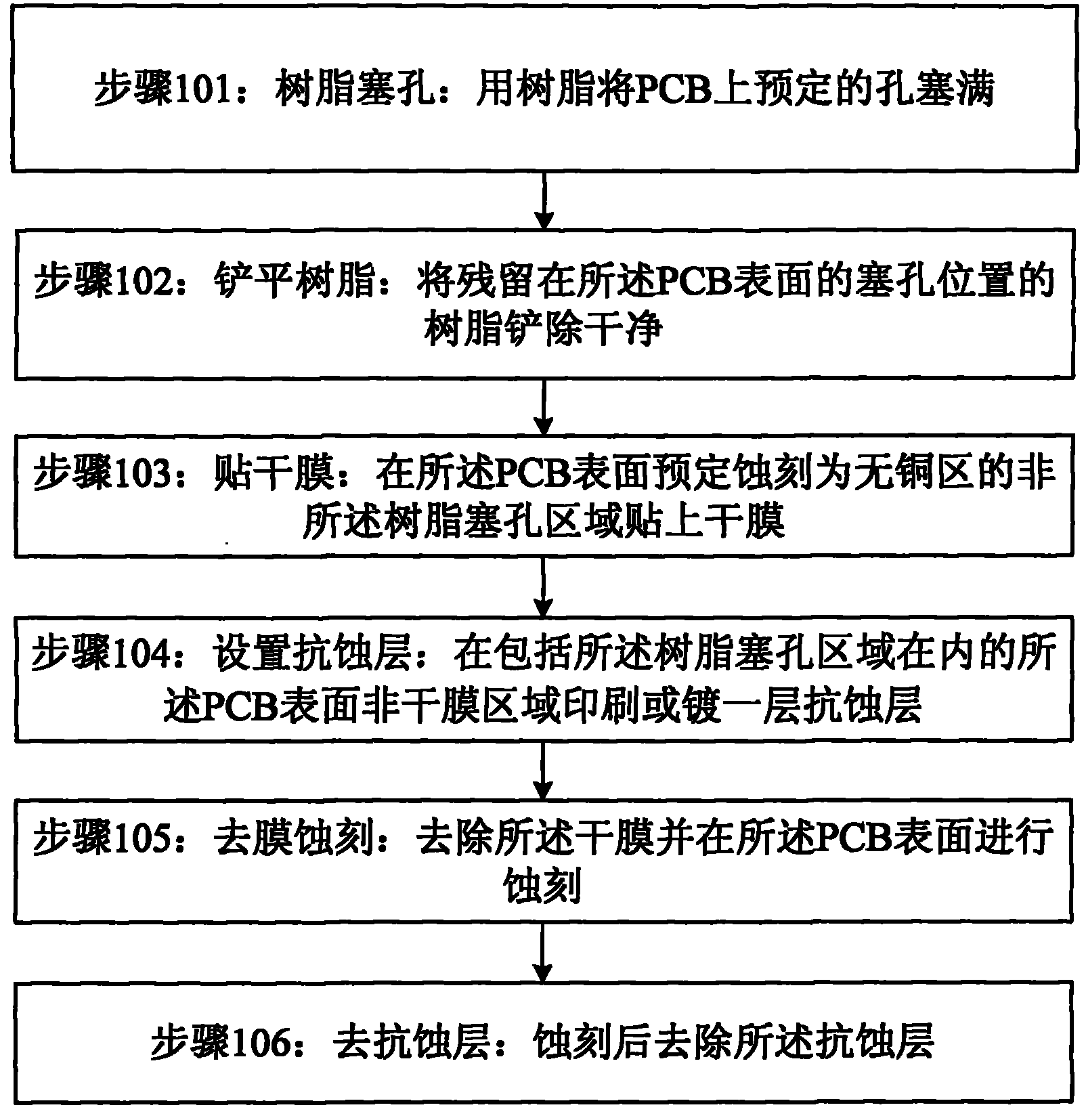

[0029] see figure 1 as well as figure 2 , the PCB processing method embodiment of the present invention mainly comprises the following steps:

[0030] Step 101: Resin plugging holes: filling predetermined holes on the PCB with resin;

[0031] Step 102: leveling the resin: removing the resin remaining at the plug holes on the surface of the PCB;

[0032] Step 103: Sticking a dry film: sticking a dry film on the area of the PCB surface that is not scheduled to be etched as a copper-free area, but not the resin plug hole area;

[0033] That is, paste a dry film on the surface of the PCB that will be etched as a copper-free area;

[0034] Step 104: setting a resist layer: printing or plating a resist layer on the non-dry film area of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com