Dressing and smelting method for high-silt content copper oxide ores

A technology for oxidized copper ore with high mud content, applied in flotation, process efficiency improvement, solid separation, etc., can solve problems affecting the quality of concentrate, low quality of ore slime, difficult to remove, etc., and achieve strong process adaptability , High copper recovery rate, less environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

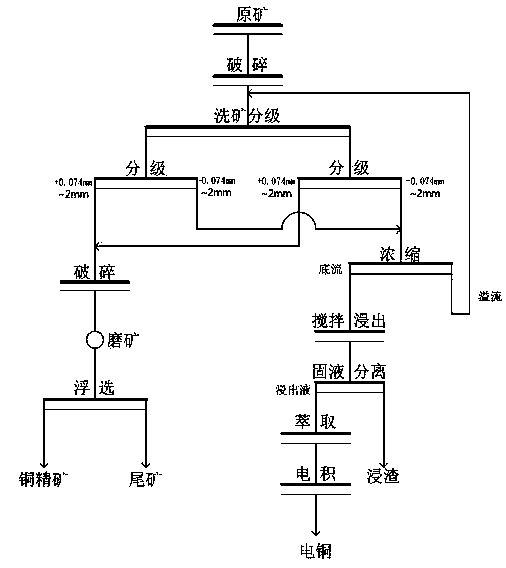

[0016] Implementation mode one: if figure 1 As shown, the raw material is a copper oxide mine in Yunnan, with a geological reserve of 35,000 metal tons and a raw ore copper grade of 0.81%. The main copper minerals are malachite, a small amount of chrysocolla, chalcopyrite, bornite, and chalcocite etc., the copper oxidation rate is 73.45%, and the -0.01mm content accounts for 11.56%, which is a high-mud copper oxide ore.

[0017] Adopt the concrete implementation of this invention as follows:

[0018] (1) After the raw ore is crushed to 60mm by the jaw crusher, the ore is washed by a trough washing machine to obtain coarse and fine grains, and the coarse and fine grains are separated by vibrating screen and water for further washing Classification, +1mm coarse grains and -1mm fine grains are obtained, of which the yield of +1mm coarse grains is about 59.31%, and the yield of -1mm fine grains is about 40.69%. The +1mm coarse grains are used in the grinding and flotation syste...

Embodiment approach 2

[0022] Implementation mode two: if figure 1 As shown, the specific steps of this embodiment are:

[0023] (1) The copper oxide ore containing 20wt% mud and 72wt% copper oxidation rate is crushed, washed and classified into coarse-grained pulp and fine-grained pulp without mud. 12wt% copper concentrate and tailings; the copper concentrate can be sold directly to the smelter, and the tailings are stored in the tailings dam. The dividing point between coarse-grained pulp and fine-grained pulp is 0.074mm. The concentration of coarse pulp is 80wt%, and the concentration of fine pulp is 5wt%.

[0024] (2) The fine-grained ore pulp is concentrated, and the overflow water is returned to the ore washing operation in step (1). The underflow is concentrated to 30wt% and then acid leached. The underflow leaching adopts stirring leaching. The acid used for leaching is sulfuric acid. The concentration of the acid is 120g / L, leaching for 1 hour, filtering (solid-liquid separation) and wa...

Embodiment approach 3

[0025] Implementation mode three: if figure 1 As shown, the specific steps of this embodiment are:

[0026] (1) The copper oxide ore containing 50wt% mud and 80wt% copper oxidation rate is crushed, washed and classified into coarse-grained pulp and fine-grained pulp without mud, and the coarse-grained pulp is obtained by grinding and flotation in the prior art 22wt% copper concentrate and tailings; the copper concentrate can be sold directly to the smelter, and the tailings are stockpiled in the tailings dam. The classification range of coarse pulp and fine pulp is 2mm. The concentration of coarse pulp is 92wt%, and the concentration of fine pulp is 45wt%.

[0027] (2) The fine-grained ore pulp is concentrated, and the overflow water is returned to the ore washing operation in step (1). The underflow is concentrated to 60wt% and then acid is leached. The acid concentration is 30g / L, leached for 5 hours, filtered (solid-liquid separation), and the filter residue is washed, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com