Electrochromism film with stable performance and preparation method thereof

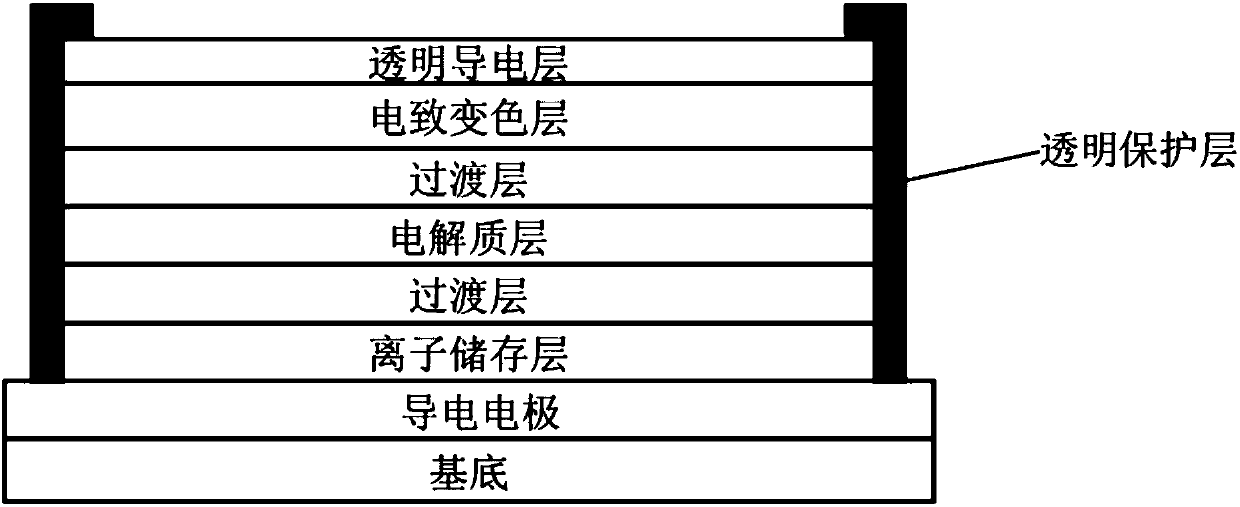

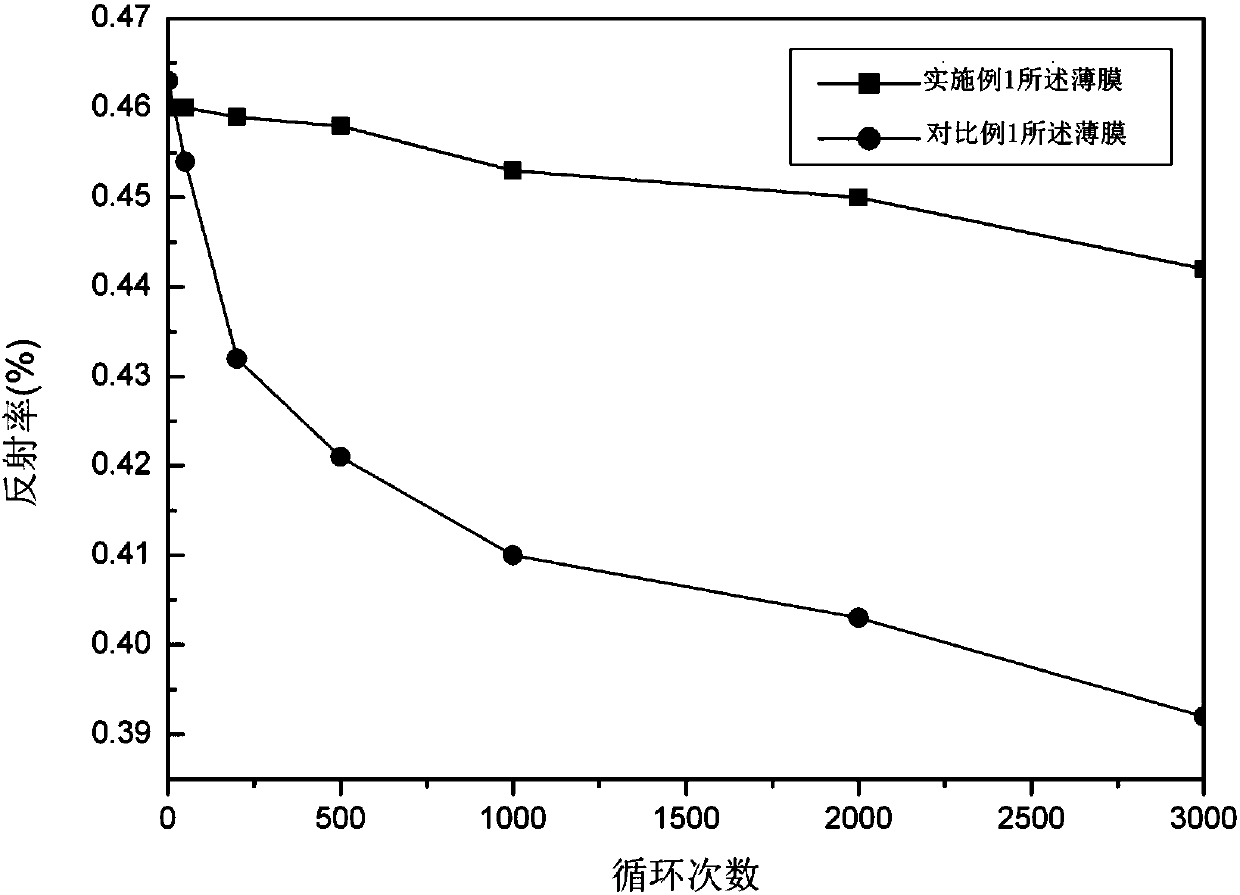

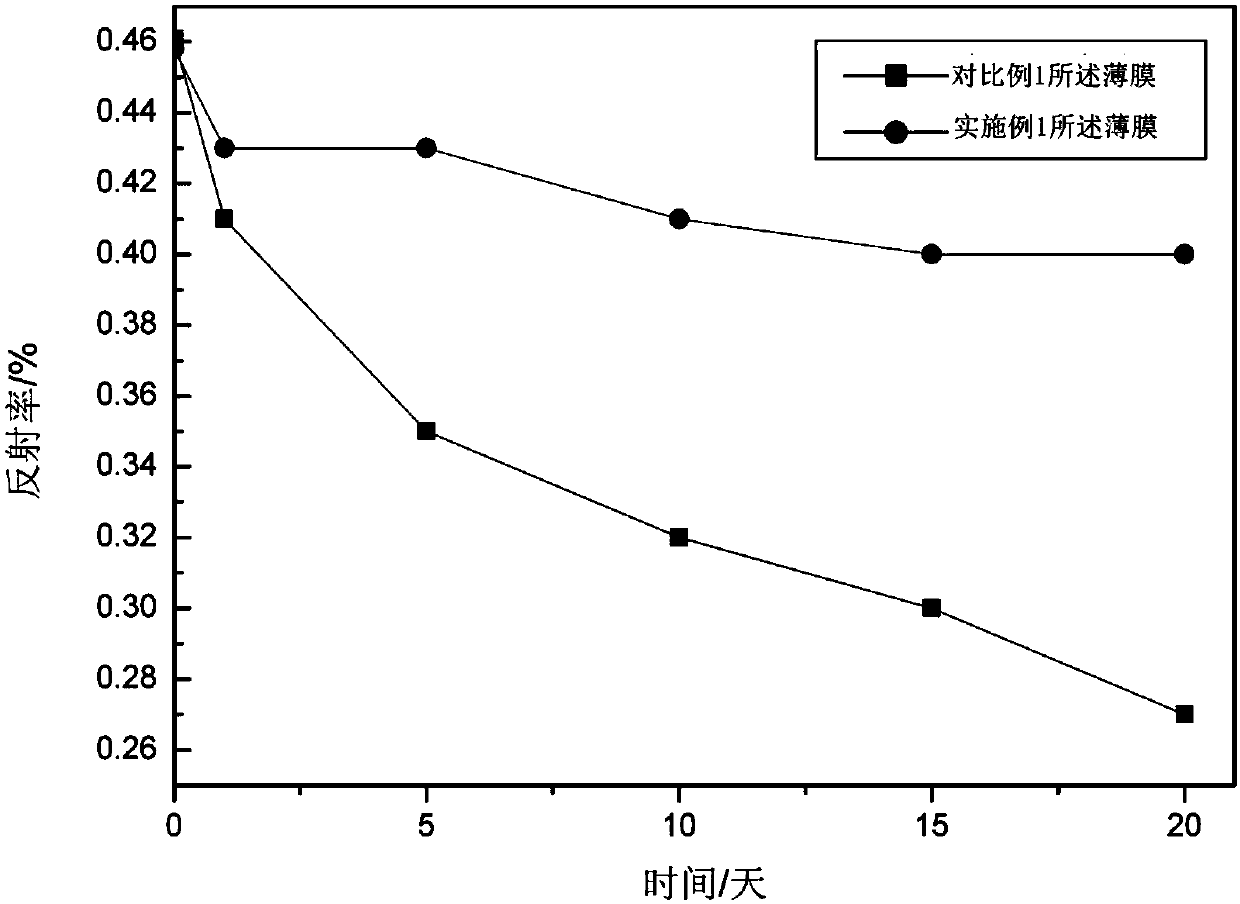

An electrochromic and electrochromic layer technology, applied in nonlinear optics, instruments, optics, etc., can solve the problems of reduced cycle stability of the color-changing film, easy generation of leakage current, degradation of color-changing performance, etc., to improve the effect of coloring memory , Good cycle stability and environmental stability, stable discoloration performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A method for preparing an electrochromic thin film with stable performance, the steps of the method are as follows:

[0038](1) The substrate is made of a flexible polyimide film with a thickness of 125 μm, and the substrate is mounted on a fixture and placed in a clean vacuum sputtering chamber, where the background vacuum degree in the vacuum sputtering chamber is less than 3×10 -3 Pa, the sputtering pressure is 1Pa;

[0039] (2) Deposit an aluminum film on a polyimide film substrate with a thickness of 200 nm by means of roll-to-roll magnetron sputtering. A high-purity aluminum (99.9%) target is used as the target material, argon gas is used as the working gas, the argon gas flow rate is 100 sccm, the tape transport speed is 0.3 m / min, and the working power is 10000 W.

[0040] (3) Preparation of NiO by reactive sputtering method x Thin film: a magnetic metal nickel target is used as the target material, the sputtering power is 90W, and Ar and O are used 2 The mix...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com