A preparation method of tungsten-nickel alloy target material for electrochromic glass coating

An electrochromic glass, tungsten-nickel alloy technology, applied in metal processing equipment, metal material coating technology, sputtering coating and other directions, can solve the discoloration and coating quality is not stable enough, high cost, low yield of color-changing glass and other problems, to achieve the effect of stable discoloration, increased sintering density and high density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

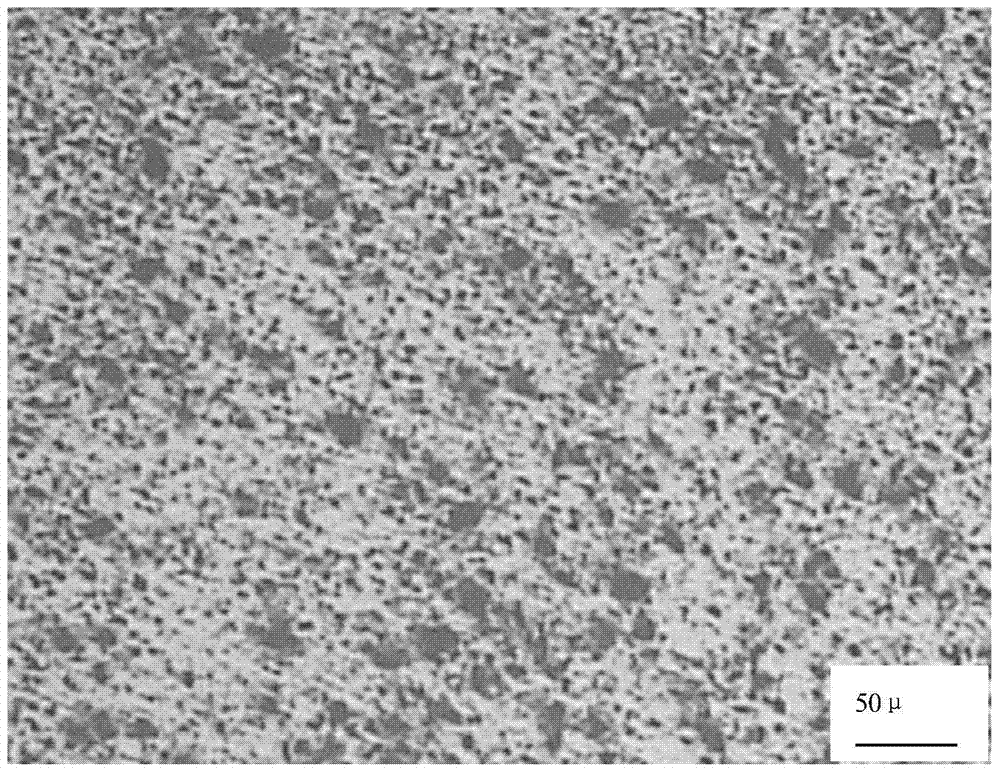

[0026] (1) Each component is weighed according to the following weight percentages: 40% of tungsten powder with purity ≥ 99.999% and an average Fischer particle size of 5.0 μm, 50% of nickel powder with a purity of ≥ 99.95% and an average Fischer particle size of 5.0 μm, and a purity of 10% of tungsten trioxide powder ≥99.95% with an average Fibonacci particle size of 5.0 μm;

[0027] (2) Place the above-mentioned components in a V-shaped mixer and mix them uniformly at a speed of 20r / min to obtain 40% by mass of high-purity tungsten (W), 50% by mass of nickel (Ni), and tungsten trioxide (WO3) 10% by mass mixed powder;

[0028] (3) Put the above mixed powder into a vacuum hot-pressing sintering mold, then put it into a vacuum hot-pressing sintering furnace, raise the temperature to 1430°C at a rate of 5°C / min, pressurize to 35MPa, and hold for 120min for vacuum hot-pressing sintering. After vacuum hot pressing and sintering, turn off the heating power and cool down with the f...

Embodiment 2

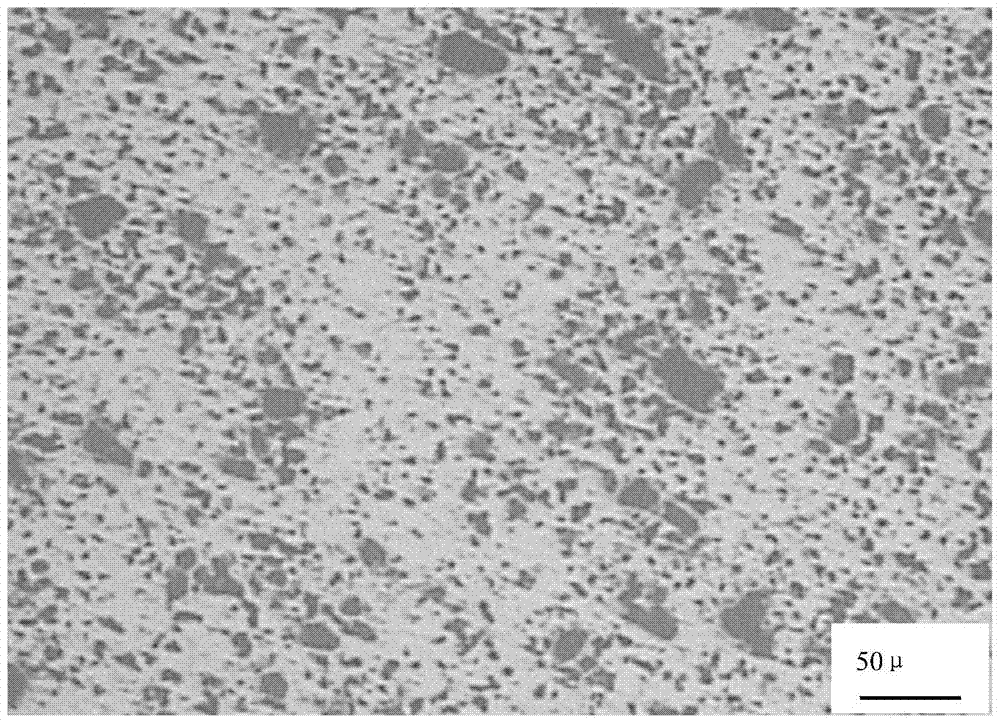

[0030] (1) Weigh each component according to the following weight percentages: 50% of tungsten powder with purity ≥ 99.999% and an average Fischer particle size of 5.0 μm, 40% of nickel powder with a purity of ≥ 99.95% and an average Fischer particle size of 5.0 μm, and a purity of 10% of tungsten trioxide powder ≥99.95% with an average Fibonacci particle size of 5.0 μm;

[0031] (2) Place the above-mentioned components in a V-shaped mixer and mix them uniformly at a speed of 20r / min to obtain 50% by mass of high-purity tungsten (W), 40% by mass of nickel (Ni), and tungsten trioxide (WO3) 10% by mass mixed powder;

[0032] (3) Put the above mixed powder into a vacuum hot-pressing sintering mold, then put it into a vacuum hot-pressing sintering furnace, raise the temperature to 1430°C at a rate of 5°C / min, pressurize to 35MPa, and hold for 120min for vacuum hot-pressing sintering. After vacuum hot pressing and sintering, turn off the heating power and cool down with the furnac...

Embodiment 3

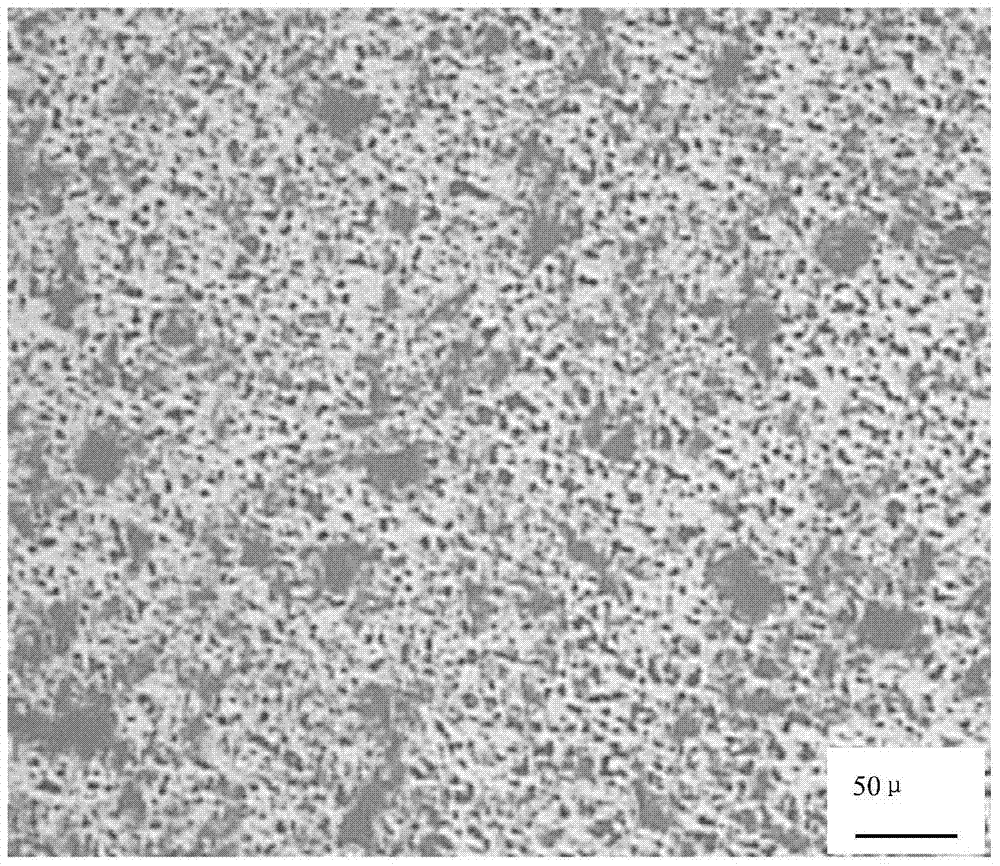

[0034] (1) Weigh each component according to the following weight percentages: 50% of tungsten powder with purity ≥ 99.999% and an average Fischer particle size of 5.0 μm, 30% of nickel powder with a purity of ≥ 99.95% and an average Fischer particle size of 5.0 μm, and a purity of 20% tungsten trioxide powder ≥99.95% with an average Fischer particle size of 5.0 μm;

[0035] (2) Place the above-mentioned components in a V-shaped mixer and mix them uniformly at a speed of 20r / min to obtain 50% by mass of high-purity tungsten (W), 30% by mass of nickel (Ni), and tungsten trioxide (WO 3 ) mixed powder with 20% by mass percentage;

[0036] (3) Put the above mixed powder into a vacuum hot-pressing sintering mold, then put it into a vacuum hot-pressing sintering furnace, raise the temperature to 1430°C at a rate of 5°C / min, pressurize to 35MPa, and hold for 120min for vacuum hot-pressing sintering. After vacuum hot pressing and sintering, turn off the heating power and cool down w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com