Method for judging whether internal and external color difference exists in cone yarn

A technology of bobbin yarn and color difference, applied in the textile field, can solve the problems of increased manufacturing cost of grey fabrics or ready-made garments, color difference inside and outside, high cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

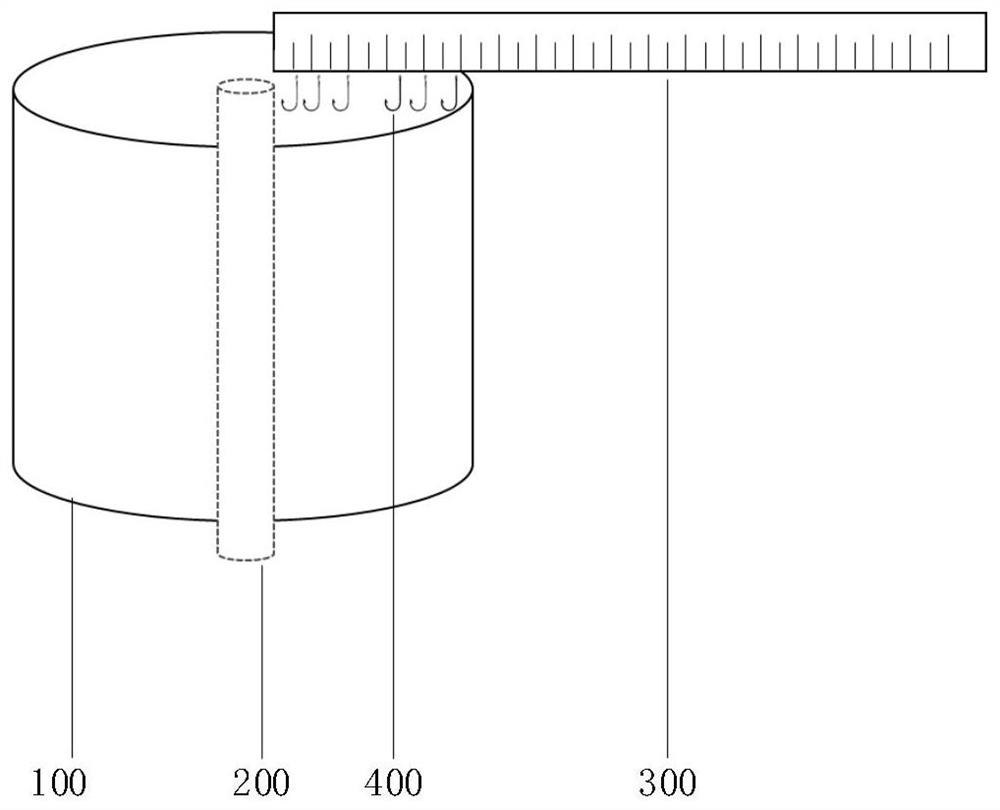

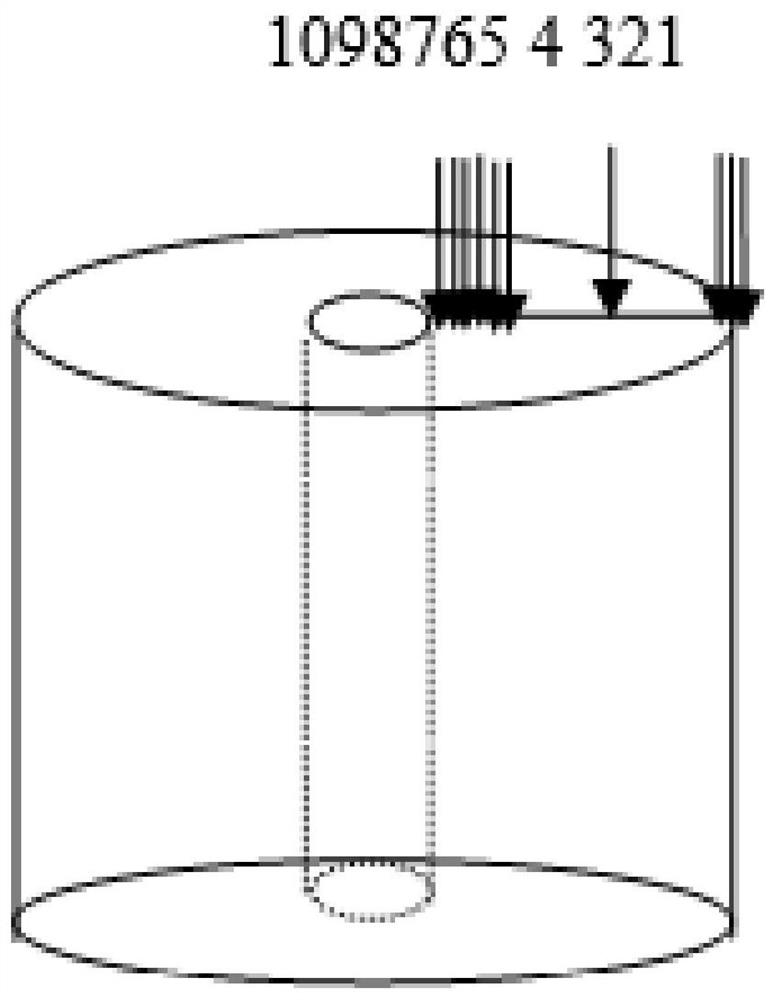

[0070] In this embodiment, the bobbin is subjected to layering treatment, and the number of layers is 10 layers. Specifically adopt figure 1 In the corresponding way, the bobbin is layered, and the bobbin is divided into 10 layers, including the innermost layer (1 layer), the second inner layer 5 layers, the middle layer (1 layer), the second outer layer 2 layers and the outermost layer (1 story). 10 layers layered as figure 2 shown. For ease of description, the 10 layers of yarns are numbered 1, 2, 3, 4, 5, 6, 7, 8, 9, and 10 from outside to inside. The layer thickness of each layer is shown in Table 1, wherein, the thickness of the middle layer is the layer thickness between the second inner layer yarn and the second outer layer yarn with the smallest distance. Further, when layering the bobbins, the inner layer yarns are layered from the inside to the outside, and the outer layer yarns are layered from the outside to the outside.

[0071] The sock knitting machine is ...

Embodiment 2

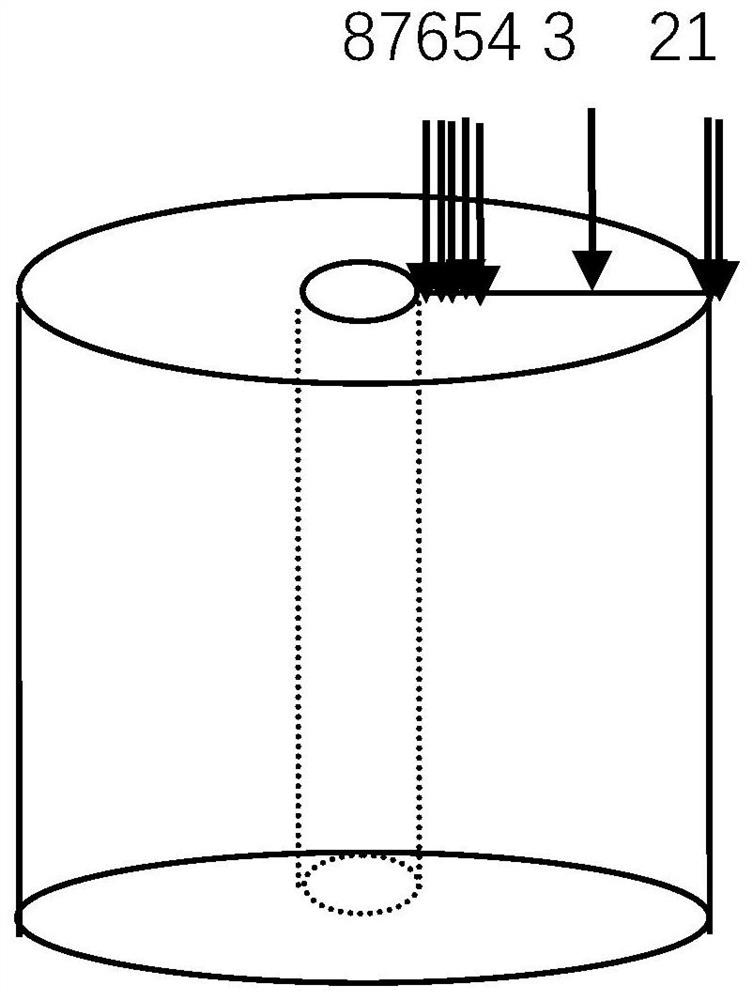

[0075] In this embodiment, the bobbins are processed in layers, and the number of layers is 8 layers. Specifically adopt figure 1 In the corresponding way, the bobbin is layered, and the bobbin is divided into 8 layers, including the innermost layer (1 layer), the second inner layer 4 layers, the middle layer (1 layer), the second outer layer 1 layer and the outermost layer (1 story). 8 layers layered as image 3 shown. For ease of description, the eight layers of yarns are numbered 1, 2, 3, 4, 5, 6, 7, and 8 from outside to inside. The layer thickness of each layer is shown in Table 2, wherein, the thickness of the middle layer is the layer thickness between the second inner layer yarn and the second outer layer yarn with the smallest distance. Further, when layering the bobbins, the inner layer yarns are layered from the inside to the outside, and the outer layer yarns are layered from the outside to the outside.

[0076] The sock knitting machine is used for stitching ...

Embodiment 3

[0080] In this embodiment, the bobbin is subjected to layering treatment, and the number of layers is 6 layers. Specifically adopt figure 1 In the corresponding way, the bobbin is layered, and the bobbin is divided into 6 layers, including the innermost layer (1 layer), the second inner layer 2 layers, the middle layer (1 layer), the second outer layer 1 layer and the outermost layer (1 story). 6 layers layered as Figure 4 shown. For ease of description, the six layers of yarn are numbered 1, 2, 3, 4, 5, and 6 from outside to inside. The layer thickness of each layer is shown in Table 3, wherein, the thickness of the middle layer is the layer thickness between the second inner layer yarn and the second outer layer yarn with the smallest distance. Further, when layering the bobbins, the inner layer yarns are layered from the inside to the outside, and the outer layer yarns are layered from the outside to the outside.

[0081] The hosiery machine is used for splicing and w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com