Single-waterway split cold crucible for induction melting and manufacture method thereof

A technology of induction smelting and production methods, applied in crucible furnaces, furnaces, lighting and heating equipment, etc., can solve the problems of high processing difficulty, overall scrapping, material waste, etc., and achieve the effect of low difficulty, low difficulty and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0072] Embodiment 1, the crucible piece has a small horizontal hole, and is assembled by welding the horizontal tube:

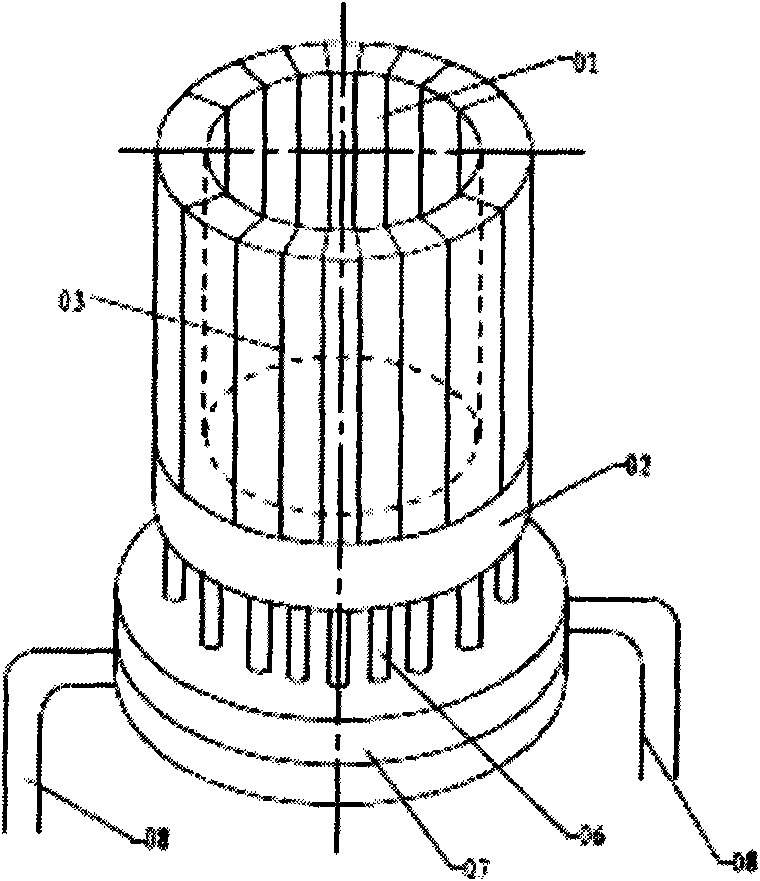

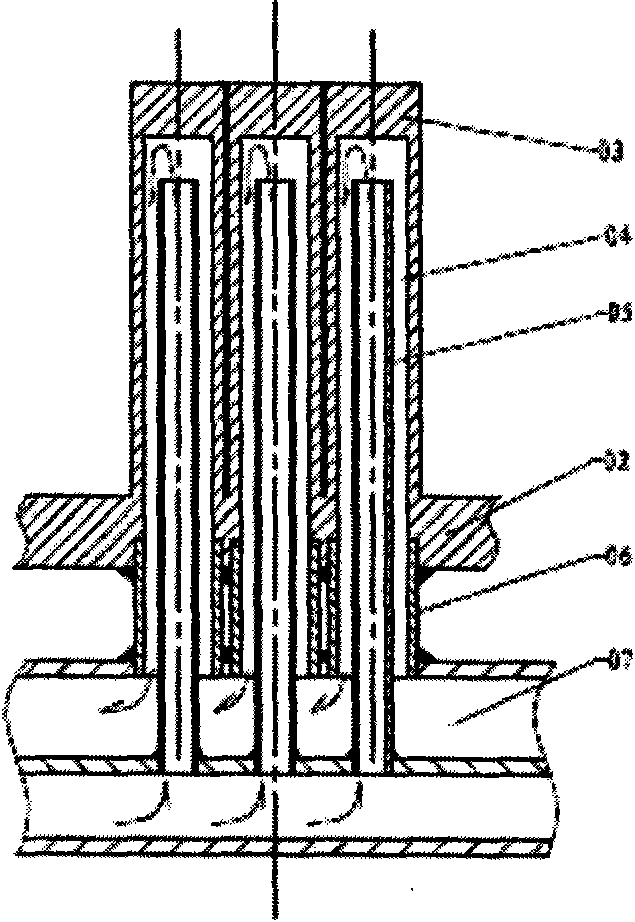

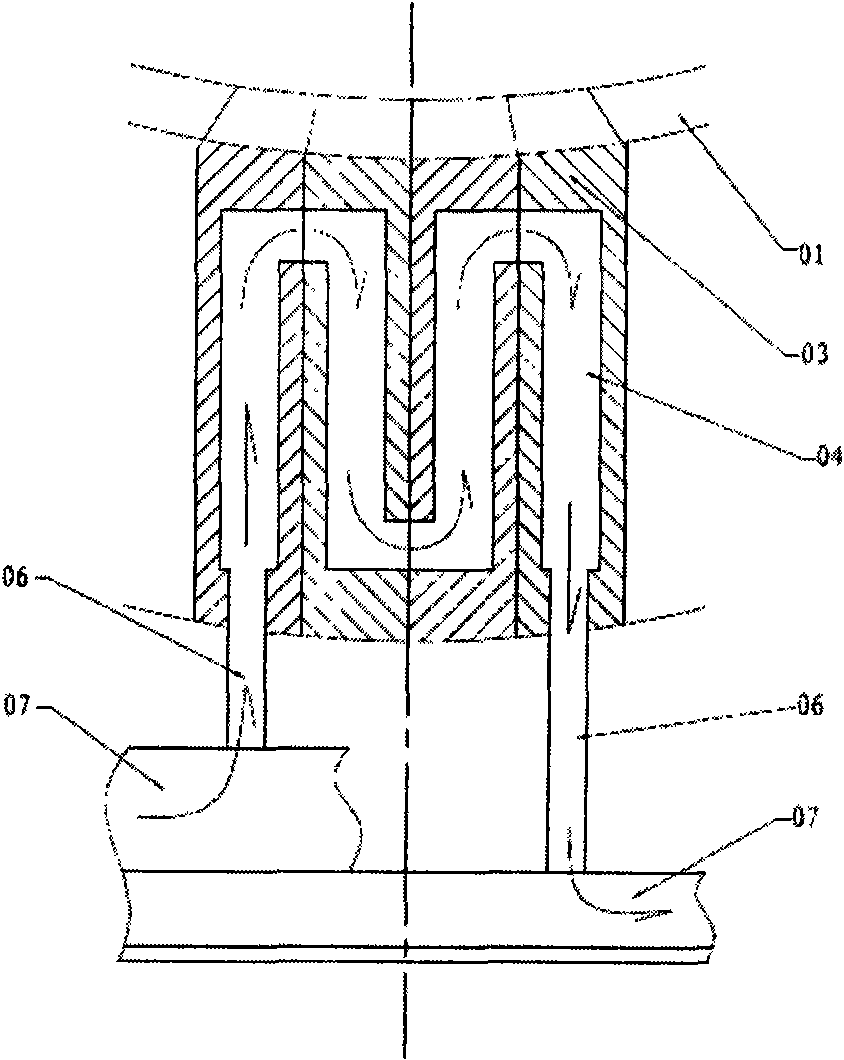

[0073] The crucible has a circular cross-section, an internal channel pattern, and is divided into 18 petals. It is assembled through the horizontal hole by welding. The crucible wall and the crucible bottom are in an integrated structure. The inner wall of the crucible bottom (02) is conical and the bottom surface is flat.

[0074] The blanks of the crucible pieces are cut from a thick copper plate, a total of 18 pieces, including the shape of the crucible bottom (02). Drill a deep hole (12) upwards from the bottom surface of the crucible sheet, and the distance between the upper end of the deep hole and the upper end surface of the crucible sheet is about 20mm. according to Figure 5b , d and Figure 6c Proceed to process and assemble the crucible pieces in the indicated manner: for a set of 6 pieces, for two of them a cross hole (16) is machined at one e...

Embodiment 2

[0076] Embodiment 2, the crucible piece has a small horizontal hole, and is assembled through the horizontal hole by means of a mechanical seal:

[0077] The crucible has a circular cross-section, an internal channel pattern, the crucible wall is divided into 16 petals, the bottom of the crucible is a split structure, and is divided into 8 petals according to the radiation direction, there is no injection port, the upper surface is a conical surface, and the lower surface is a plane.

[0078] Crucible wall making:

[0079] 1) Making crucible pieces: copper rods with rectangular cross-sections are made according to Figure 4 Cut in the manner shown, the length of the crucible blank is equal to the height of the crucible wall, a total of 16 pieces. A step is welded on the inner wall of the lower end of each crucible piece for installing the crucible bottom. A deep hole is drilled upwards from the bottom surface of the crucible sheet, and the distance between the upper end of t...

Embodiment 3

[0093] Embodiment 3, using mechanical seals to assemble through horizontal holes:

[0094]The crucible has a circular cross-section, an inner channel pattern, and the crucible wall is divided into 16 petals. The bottom of the crucible is a split structure, which is divided into 8 petals according to the radiation direction, with a betting port and a cone shape.

[0095] These are substantially the same as the cold crucible of embodiment two, but there are also differences in structure: a. the bottom of the crucible (02) is directly contained in the lower end surface of the crucible wall (01), so the end of the crucible sheet (03) does not process steps, But this makes aqueduct (06) have to connect from the outer wall of crucible wall;

[0096] Crucible wall production process:

[0097] 1) Make the crucible piece: Except that the upper end of the crucible piece needs to be reserved for assembling the crucible (26) when cutting the blank, and the step is not made at the lower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com