Side forms for paving asphalt concrete pavement

A technology of asphalt concrete and paving, applied to roads, roads, buildings, etc., can solve the problems of waste of asphalt concrete material costs, processing costs and transportation costs, increase construction workload, increase additional burdens, etc., to save the edge Effects of cutting operations, reducing construction workload, and saving raw material costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

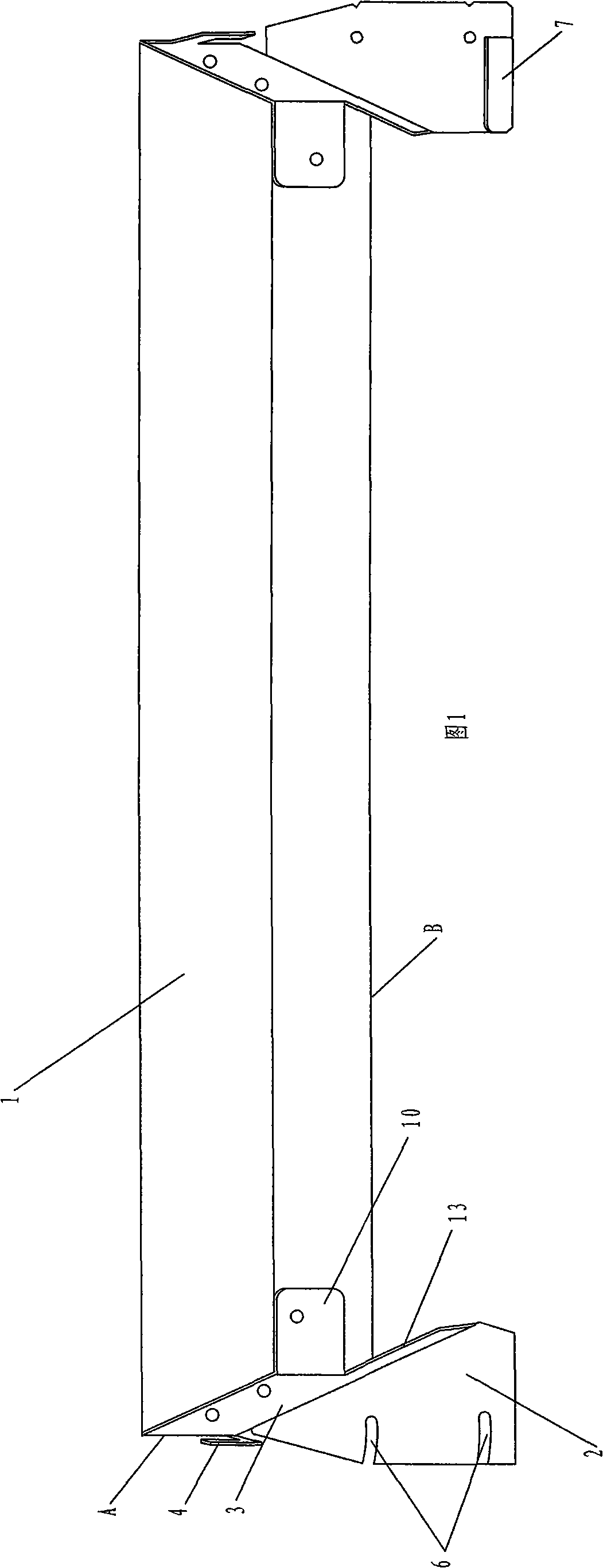

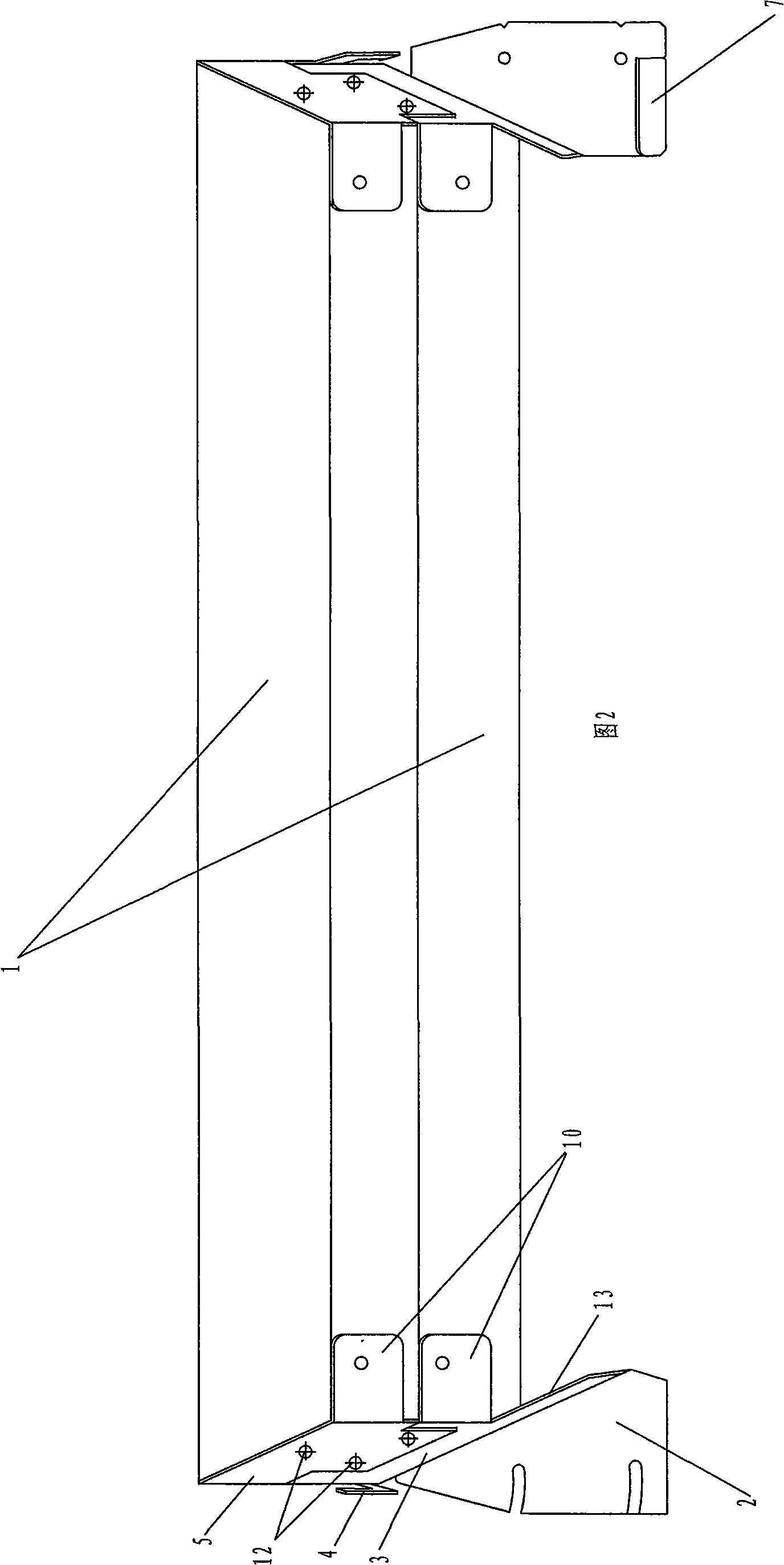

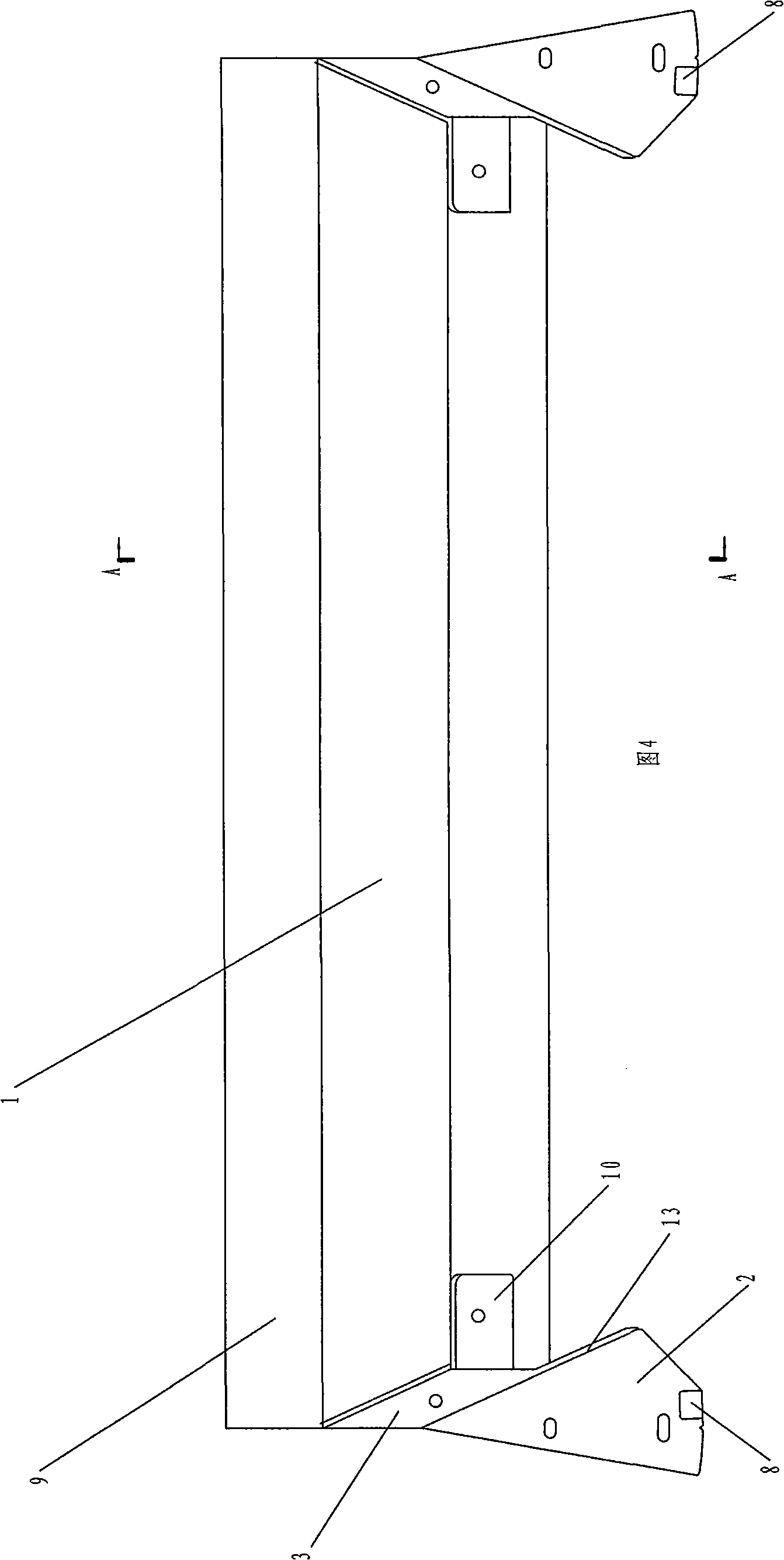

[0027] Refer to accompanying drawing 1. The inner surface A of the straight long strip 1 in the side mold is the forming sealing mold surface in contact with the edge of the asphalt concrete layer, the bottom surface B is the placement surface in contact with the roadbed, and the inner surface A is vertical to the bottom surface B. The vertical plate 3 in the fixed clamping plate on the two wedge-shaped ends is attached to the wedge-shaped end and connected by connecting screws 12. The bottom plate 2 at the lower end of the vertical plate 3 is formed by folding back the lower extension plate surface of the vertical plate, and the bottom plate 2 is parallel to the bottom surface B, Perpendicular to the vertical board 3, there are nail holes reserved on the board surface. Matching positioning cards for docking alignment are also provided between the fixed clamping plates at both ends. Straight body elongated block 1 can be the wooden block that load-bearing is strong, light in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com