Patents

Literature

81results about How to "Save raw material cost" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Wear resistant steel cast and method for manufacturing the same

InactiveCN101469390AImprove effective measuresThe chemical composition formula is reasonableWear resistantManganese

The invention provides a novel martensite and bainite wear-resistant casting steel material and a manufacturing method thereof. The material is characterized in that the material is formed by taking C, Cr and Mo alloy elements with lower content as main constituents and assisting with a small amount of V, Ti, B and RE alloy elements. The material can obtain a microscopic structure consisting of tempered martensite, lower bainite and a small amount of remaining austenite after heat treatment, which ensures that the material has higher toughness and good wear resistance, can bear larger shock and violent impact, also has good abrasion resistance against grinding aids, has the comprehensive mechanical property superior to those of high and middle manganese austenite casting steel, and is an ideal material for manufacturing spare parts used in severer environment.

Owner:张莹

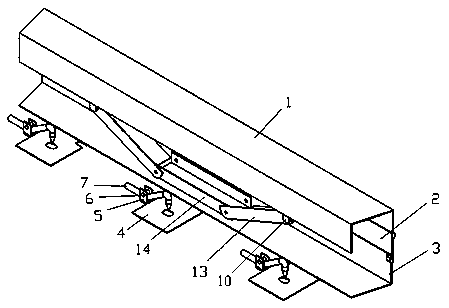

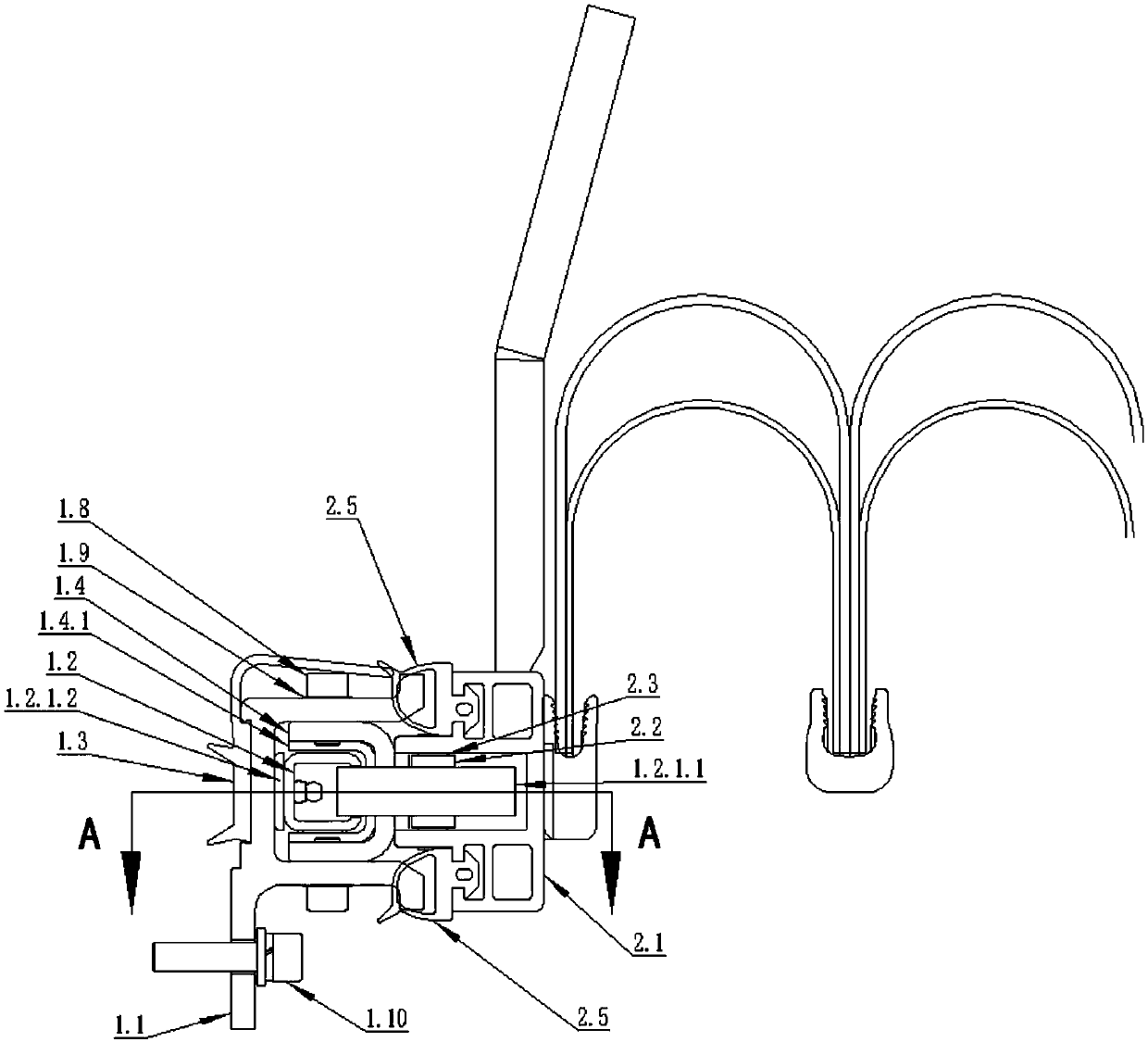

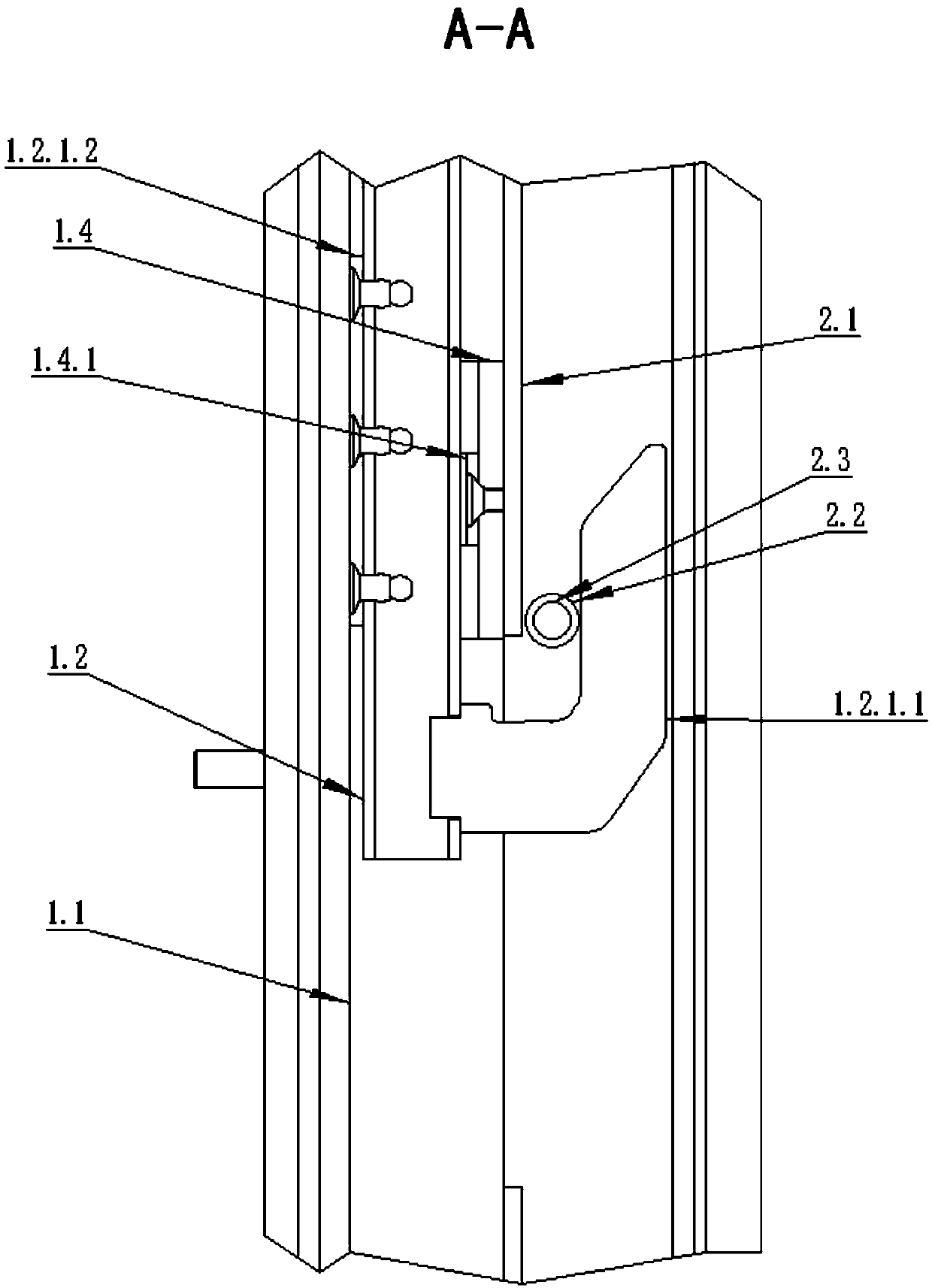

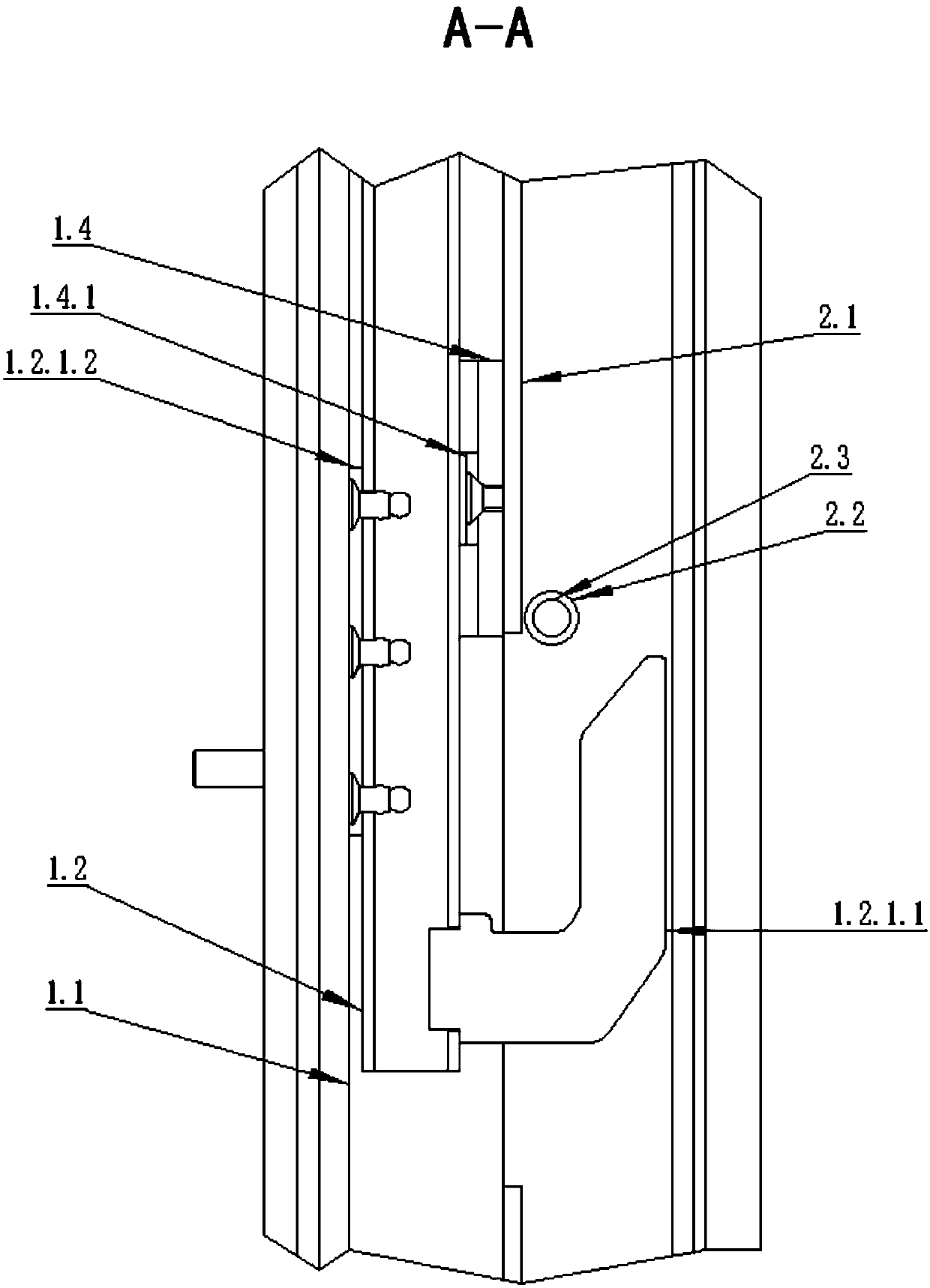

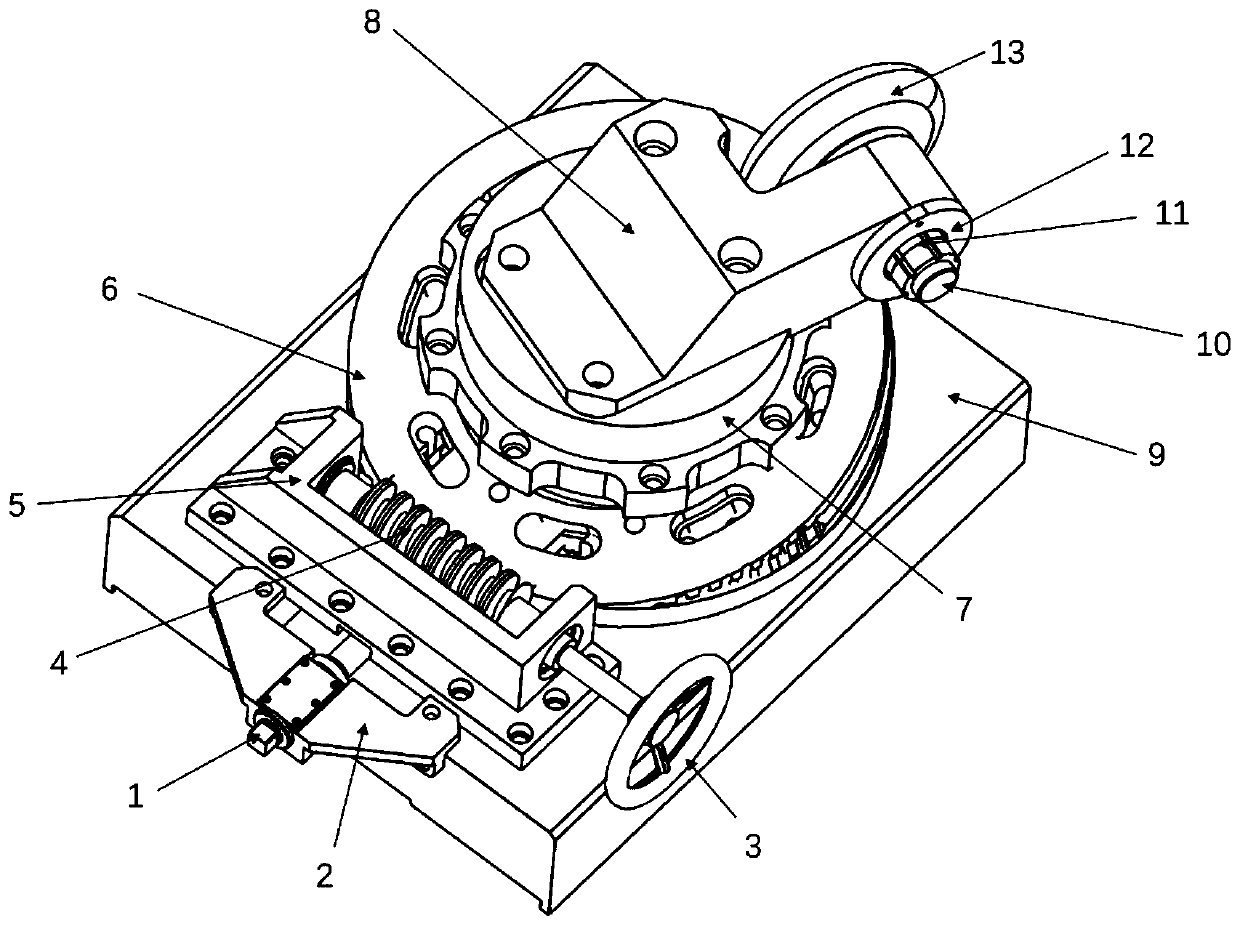

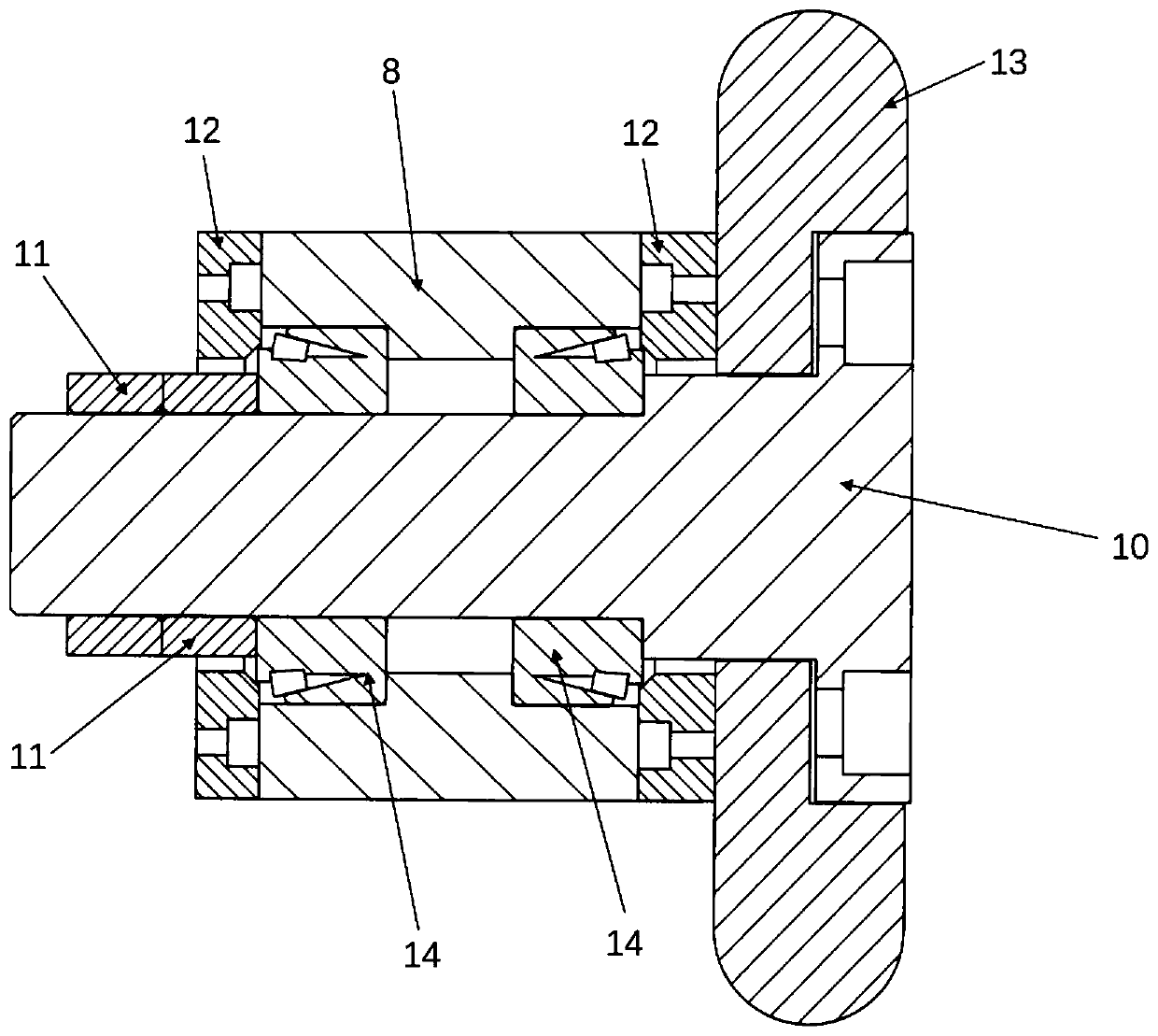

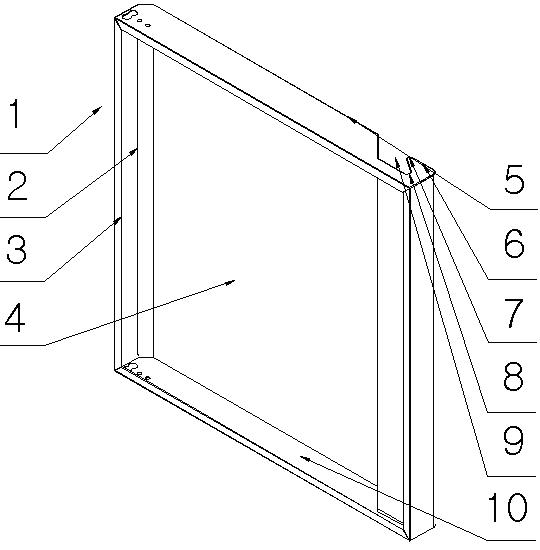

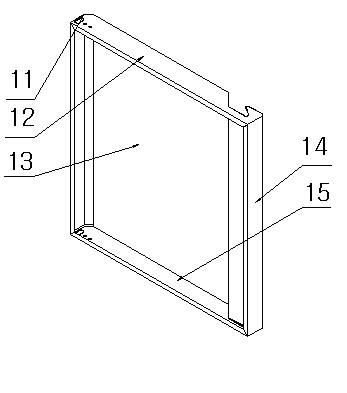

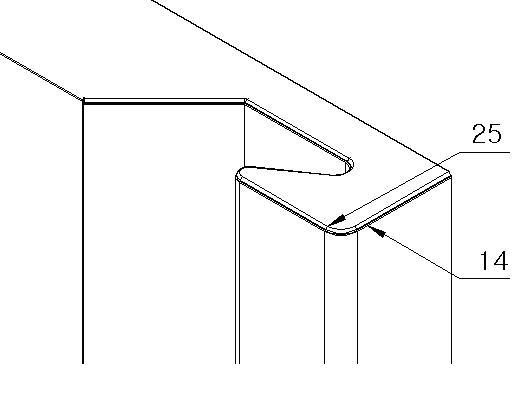

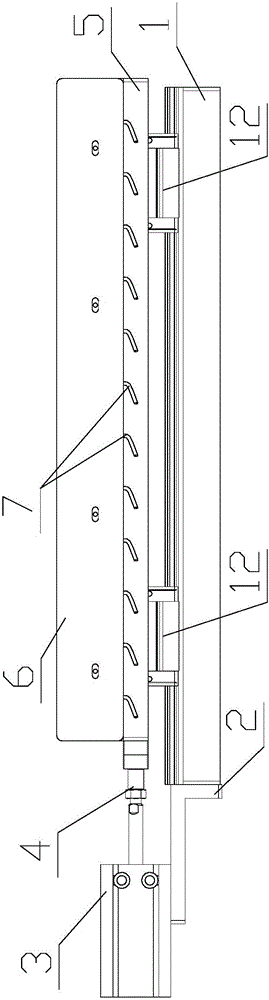

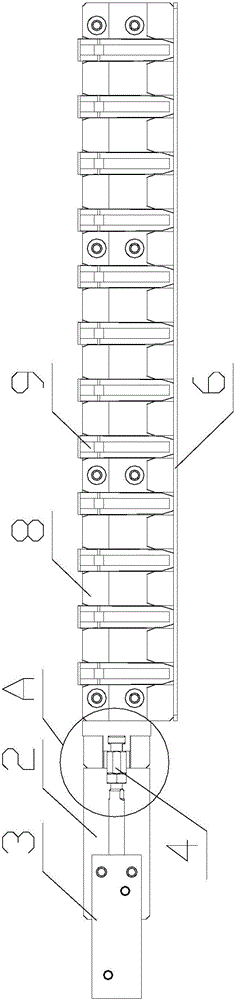

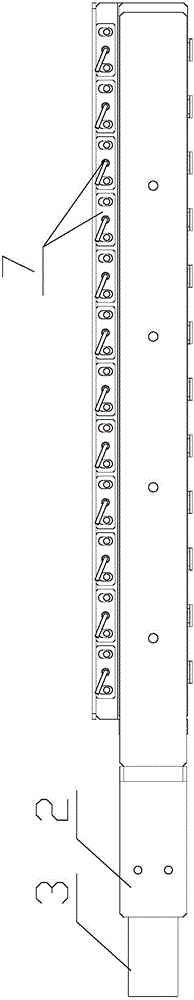

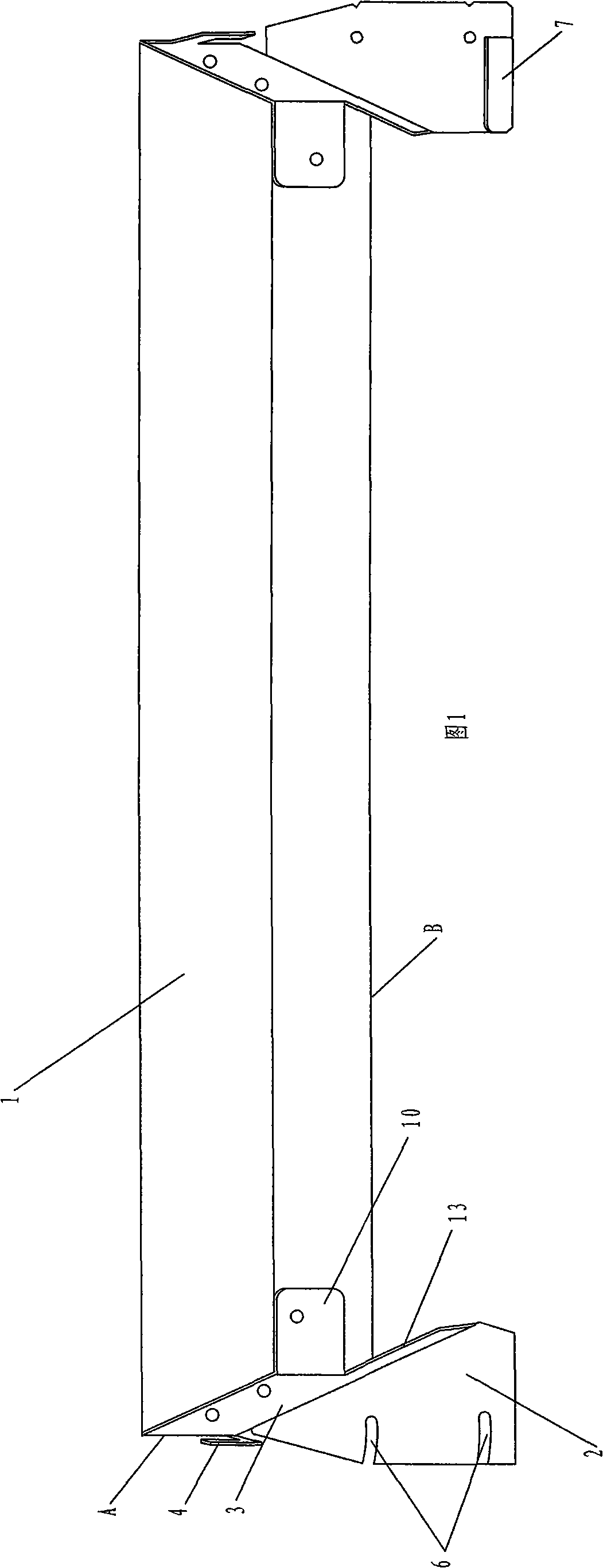

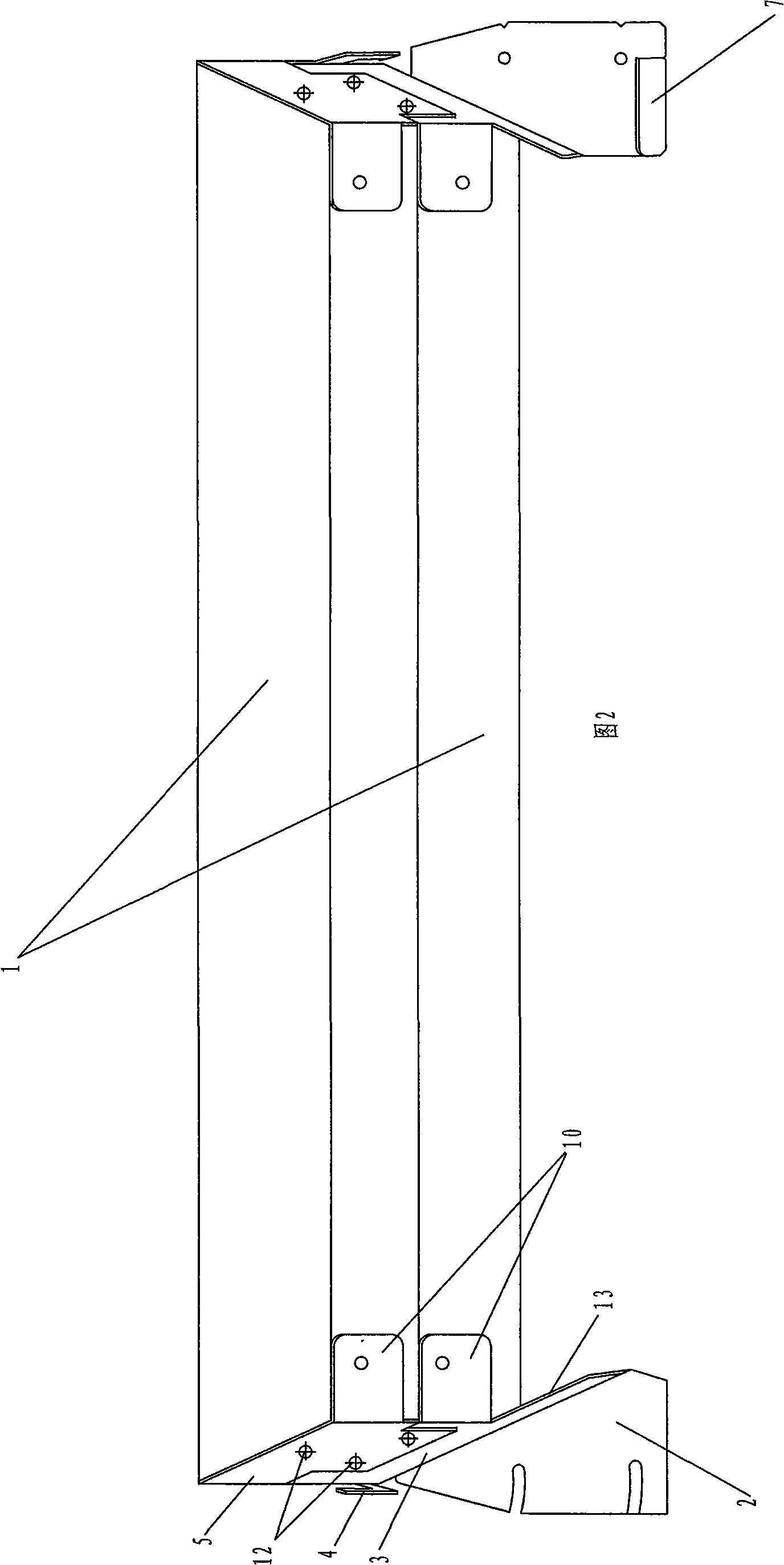

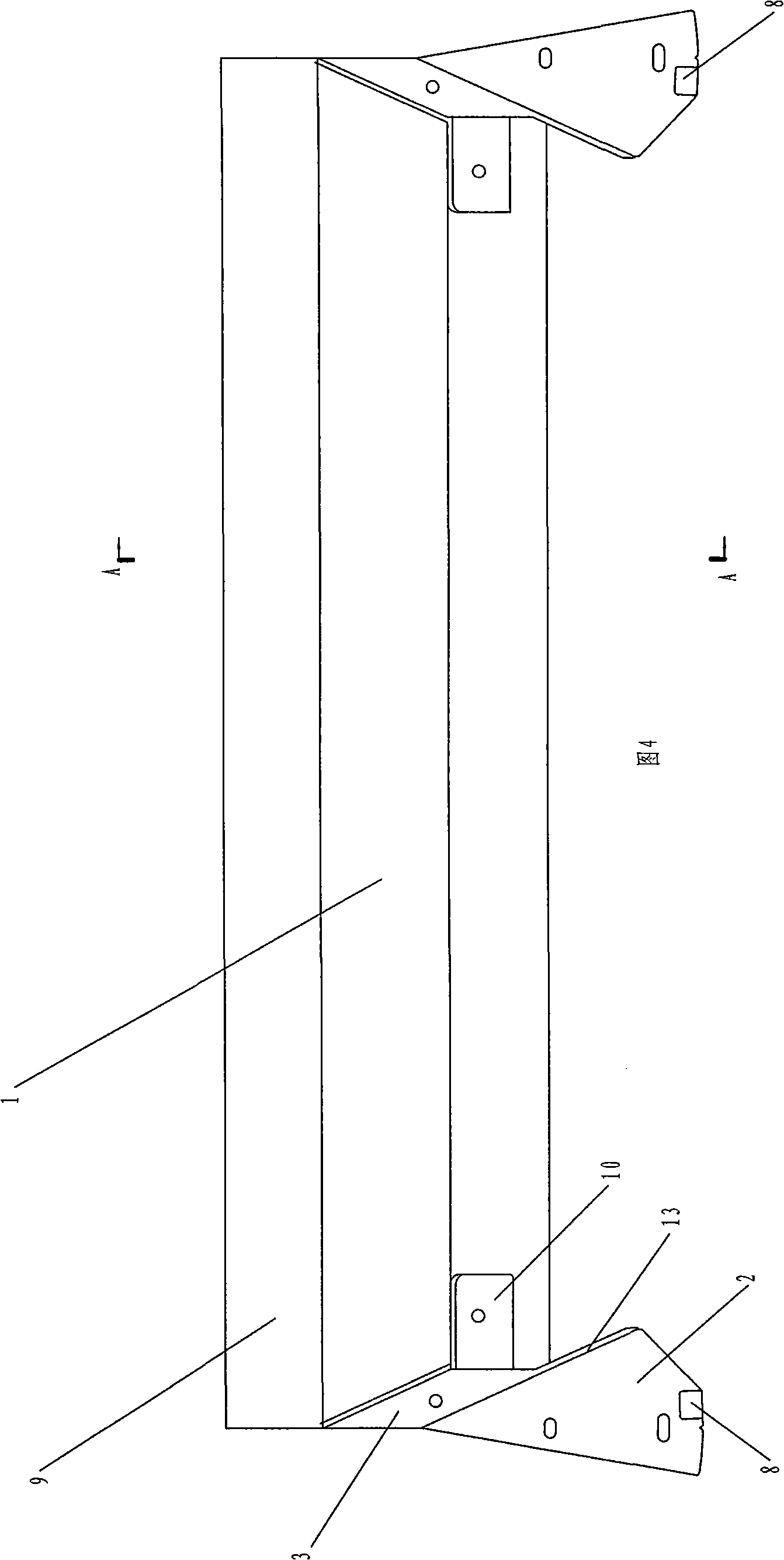

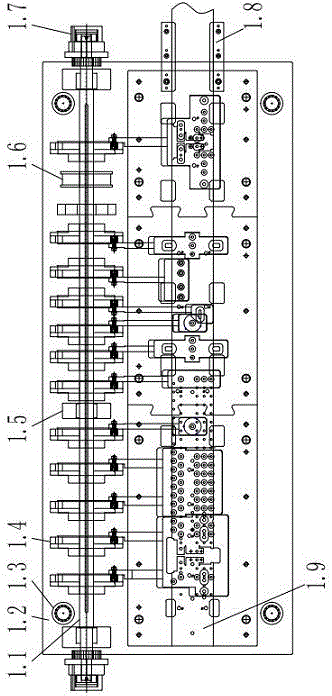

A loc mechanism for a vehicle body frame of a through-road

PendingCN109094591ASimple structureEasy to operateAxle-box lubricationRailway bodiesLocking mechanismCore component

A loc mechanism for a vehicle body frame of a through-road comprises a vehicle body frame and a butt joint frame As the core components of the whole locking mechanism, the vehicle body frame comprisea car body frame, a connecting rod, a car body frame sealing strip, a guide seat, a positioning pin, a handle, a base, a mounting bolt, a combined seal gasket and a car body fastener, and the car bodyframe is pre-fixed on the end surface of the car body through the car body fastener; The docking frame is formed to provide a fixed connection interface for the locking mechanism, and is located on the end face of the through channel, and comprises a docking frame, a rotating shaft, a fixed shaft, a push-pull handle and a docking frame sealing strip. 12 loc hooks and that rotate shaft on the buttjoint frame are driven to be matched or separated by pulling two handle, so that the through-way and the end face of the car body are quickly connected and unknitted, the operation is convenient andquick, and the maintenance efficiency of the through-way is improved.

Owner:丹纳威奥贯通道系统(青岛)有限公司

Multifunctional seedling culture matrix block prepared from plant straw and preparation method of seedling culture matrix block

InactiveCN105367300AAvoid harmReduce pollutionAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersFiberBiology

The invention relates to a multifunctional seedling culture matrix block prepared from plant straw and a preparation method of the seedling culture matrix block. The matrix block takes plant straw compost or turfy soil as a main material, miscellaneous Al2O3*nH2O powder, phosphorus diamine, efficient water-absorbent resin and plant growth-promoting and disease-resisting bacillus are added, the peripheral surface is coated with an elastic and degradable fiber net prepared from polylactic acid, a small hole I is formed in the center of the upper surface of the seedling culture matrix block and used for accommodating seeds, and multiple small holes II are formed around the small hole I and used for accommodating controlled-release fertilizer. The seedling culture matrix block can be applied to centralized and advance seedling culture before field transplantation in case of transplantation and can be implanted in a field through direct ditching, and the matrix block immediately meets requirements of water absorption and germination of the seeds after absorbing water. The seedling culture matrix block is widely applied to seedling culture for forest fruits, crops, flowers, plants and vegetables, can be transplanted in the field and a greenhouse in one step and can also be directly embedded in the field, the plastic culture hole cost is saved, a large quantity of crop straw is consumed, environmental pollution is reduced, the soil fertility is enhanced, and the matrix block has the very bright popularization prospect and the significant social and economic benefit.

Owner:SHANDONG AGRICULTURAL UNIVERSITY

Yarn spinning method of heat-accumulation and heating fiber blended and bulked double-layered-structure yarns

The invention discloses a yarn spinning method of heat-accumulation and heating fiber blended and bulked double-layered-structure yarns. The yarn spinning method comprises the following steps: selection of raw materials and a blending ratio; a blended yarn spinning process; a yarn spinning process; a vinylon dissolving process. The formation of hollow parts of the double-layered-structure yarns actually comprises two aspects that in one aspect, the hollow parts are formed through dissolving water-soluble vinylon with hot water; in the other aspect, in a hot water treatment process, an irreversible heat shrinkage rate generated by high shrinkage acrylic fibers is more than a heat shrinkage rate generated by outer wrapping short fibers, so that the bulkiness and the hollow degree are also increased on the basis of previous hollow parts.

Owner:徐州银宇纺织有限公司

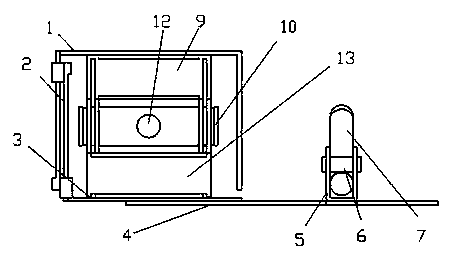

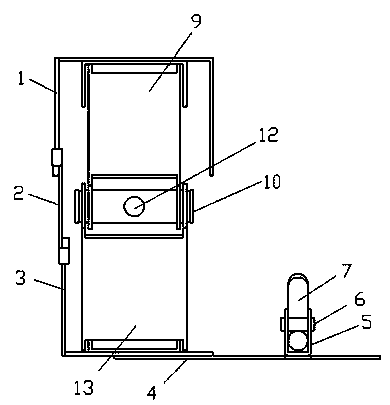

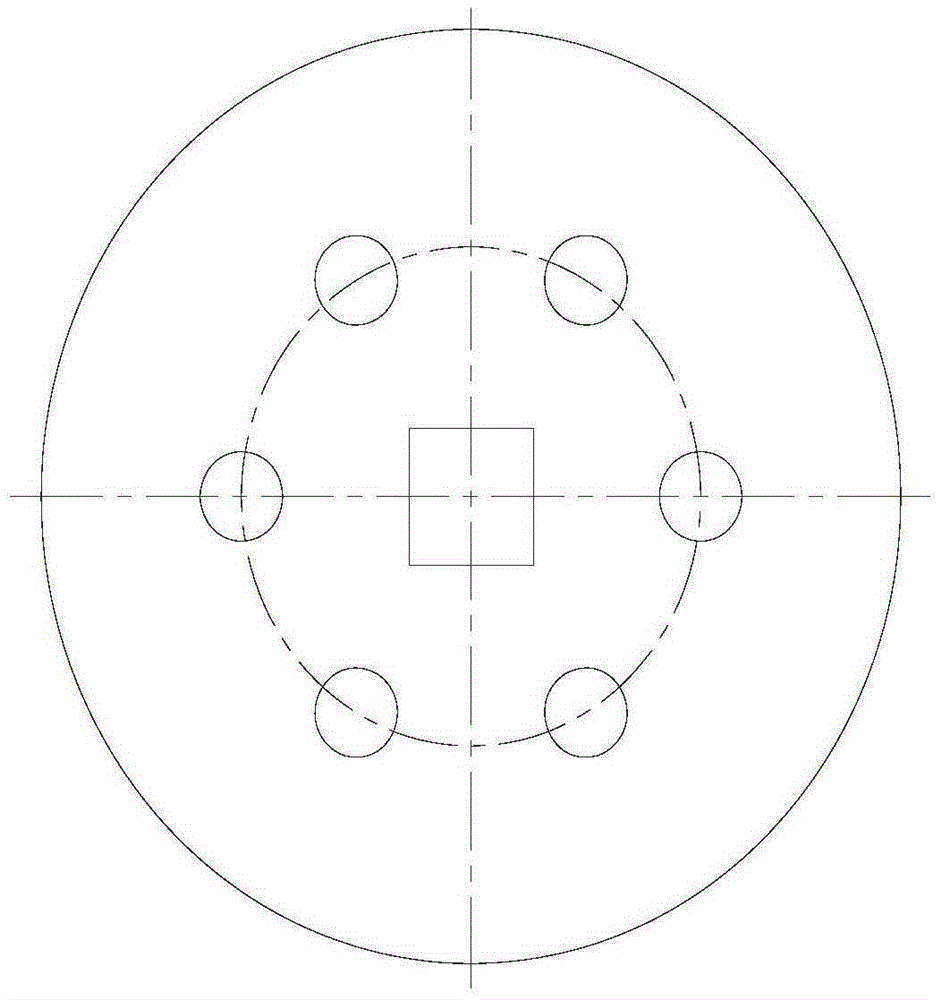

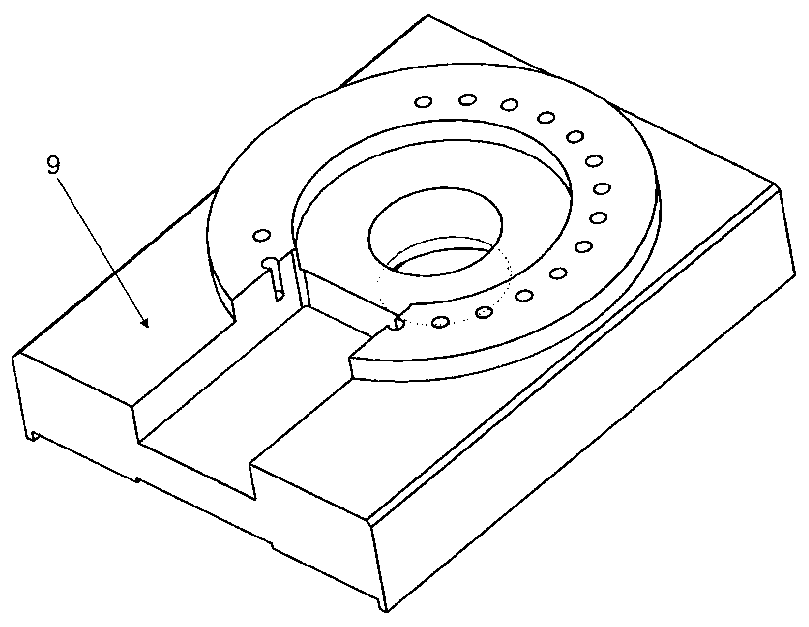

Spinning wheel angle adjusting device used for paired wheel spinning equipment

InactiveCN110090885AMeet the requirements of contact angleFulfil requirementsEngineeringRotating disc

The invention discloses a spinning wheel angle adjusting device used for paired wheel spinning equipment. The problems that the mold cost of existing mold spinning equipment is high, universality is poor, and the manufacturing period is long are solved. A fixed groove is formed in a spinning wheel sliding table to be used for fixing a locking bolt seat; a jacking lead screw is mounted in the locking bolt seat; a worm bearing pedestal is connected with the spinning wheel sliding table through bolts; a hand wheel is mounted at one end of a worm; the worm cooperates with a worm wheel, and the spinning wheel angle is controlled by the worm and the worm wheel together; a rotating disc and the worm wheel are fixed, and synchronous motion is guaranteed; a spinning wheel frame is mounted on a spinning wheel seat, and a spinning wheel is mounted on a spinning wheel shaft inserted into the spinning wheel frame; bearing grooves capable of containing bearings are machined in the spinning wheel frame, the two bearings are mounted in the spinning wheel frame, and normal rotating of the spinning wheel shaft is guaranteed; spinning wheel sealing covers are mounted at the two ends of the spinning wheel frame; and axial locating of the spinning wheel shaft is achieved through a locking nut mounted at the tail end. The spinning wheel angle adjusting device is used for angle adjusting of a horizontal paired wheel spinning machine.

Owner:HARBIN INST OF TECH

Refrigerator door and processing method thereof

InactiveCN102564021AUnique appearanceBeautiful appearanceDomestic cooling apparatusLighting and heating apparatusRefrigerator carLap joint

The invention relates to a refrigerator door and a processing method thereof. A door body is integrally formed by the aid of an integral plate via working procedures of plate shearing, corner cutting and flanging, bending and welding. A door handle of the refrigerator door is provided with a longitudinal and inwards recessed groove, an outer door buckle of the door handle is arranged on the outer side of the groove, and an inner door buckle of the door handle is disposed on the inner side of the groove. The refrigerator door is processed by the aid of the integral plate, surfaces are in lap joint, the refrigerator door is high in strength and not easy to deform, is integrally chamfered, accordingly is steady but not heavy, and realizes excellent visual impact for people. The processing method has the advantages that process is simple, rivet welding process is omitted, and raw materials and labor cost are saved.

Owner:济南宇翔制冷设备有限公司

Preparation method for N-methyl-4-nitrophthalimide

The invention discloses a preparation method for N-methyl-4-nitrophthalimide. The preparation method comprises: firstly cooling fuming concentrated nitric acid to 5-8 DEG C, dropwise adding concentrated sulfuric acid and preparing the mixed acid at 10-15 DEG C; mixing N-methylphthalimide with concentrated sulfuric acid at 0 DEG C with stirring, then dropwise adding the mixed acid, and reacting for 3-4 h; using an extracting agent to extract a nitrated compound obtained in the reaction; layering, separating an upper-layer organic phase and a lower-layer sulfuric acid mother solution; recovering the upper-layer organic phase to obtain N-methyl-4-nitrophthalimide, performing centrifugation filtering and drying to obtain a finished product; and removing water in the lower-layer sulfuric acid mother solution through a drying agent, concentrating and applying to mixing of the mixed acid in the subsequent batch of the nitration reaction. According to the preparation method, by selecting proper low-temperature processing, acid adding sequence, molar ratio of reaction raw materials and the extracting agent, the yield and the purity are improved. The preparation method helps to reduce generation of by-products, improve the operation environment and reduce production cost.

Owner:HUBEI XINZHOU CHEM

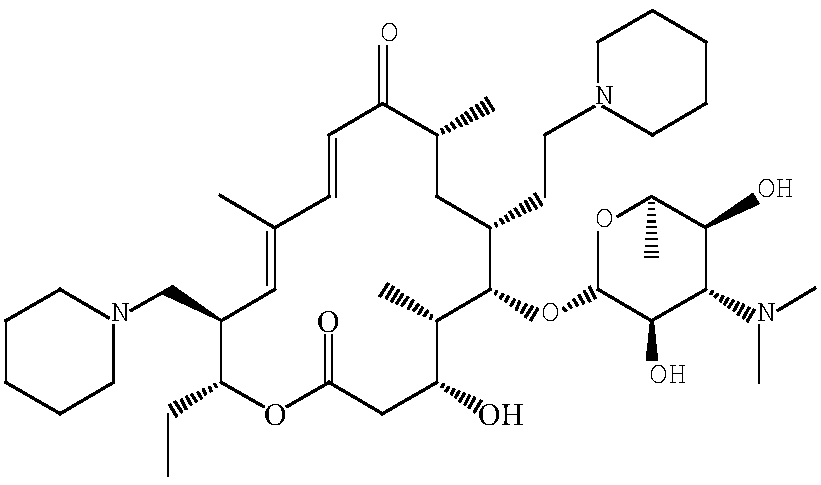

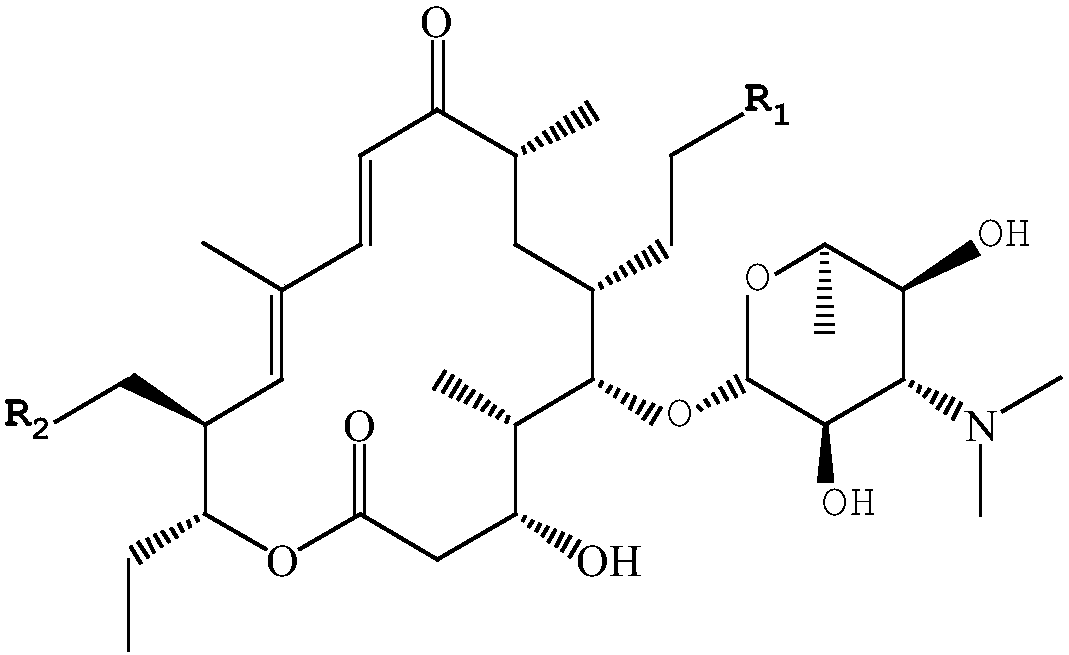

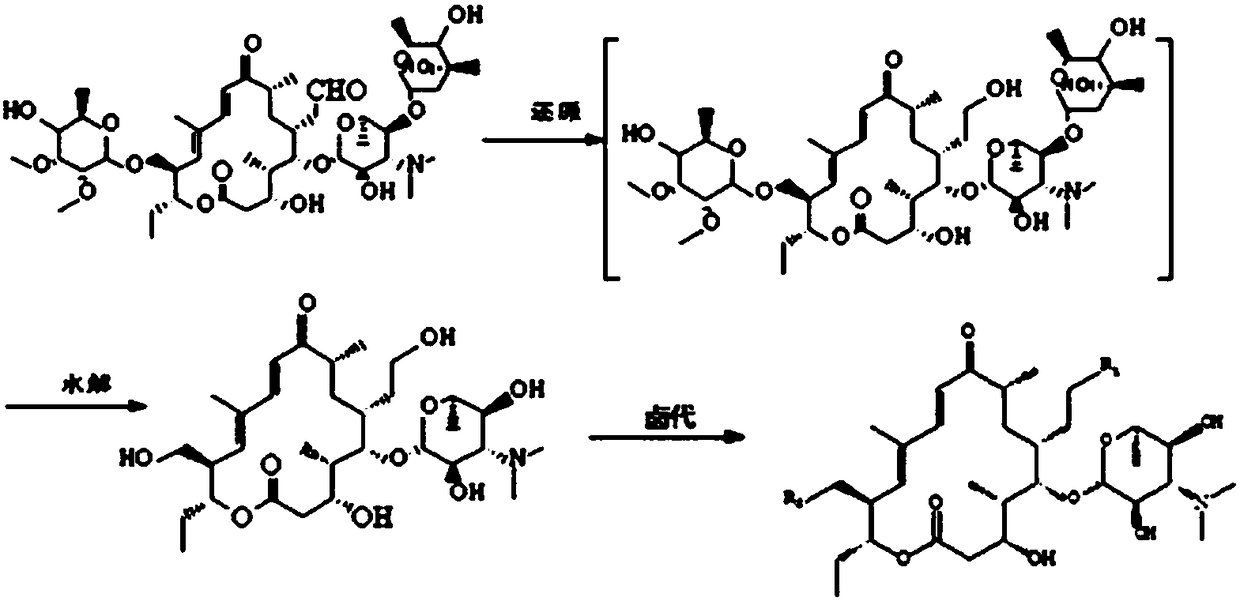

Synthetic method of 20,23-dipiperidine-5-O-carbomycin amine glycosyl-tildipirosin

InactiveCN108264529AThe synthesis process is simpleSave raw material costSugar derivativesSugar derivatives preparationCarbomycinGlycosyl

The invention discloses a synthetic method of 20,23-dipiperidine-5-O-carbomycin amine glycosyl-tildipirosin. The synthetic method comprises the following steps: (1) adding 20,23- dihalo-5-O-carbomycinamine glycosyl-tildipirosin, piperidine and potassium carbonate in a reaction container, carrying out heating refluxing for 4-5 h while stirring, after fluxing is finished, filtering an obtained mixing system, adding purified water in filtrate, fully stirring and then standing for layering, and separating to obtain an organic layer; (2) adding pure water in the organic layer again, adjusting pH value to be 2-3, standing for layering, separating to obtain a water layer, cooling the water layer to the temperature of 0 DEG C, adjusting pH value to be 8.0-8.5, standing for layering, separating toobtain a water phase, extracting the water phase by using an organic solvent to obtain an organic phase, removing the organic solvent, filtering, and concentrating till the product is dry to obtain acrude product; and (3) refining the crude product to obtain the 20,23-dipiperidyl-5-O-carbomycin amine glycosyl-tildipirosin. By the method, the 20,23- dihalo-5-O-carbomycin amine glycosyl-tildipirosin is directly used as a starting material, the route for synthesizing tildipirosin is greatly simplified, and the synthesizing cost is reduced.

Owner:湖北回盛生物科技有限公司

Silicon carbide green body and production process thereof

ActiveCN102219520ASave processing and costReduce processing costsCeramic shaping apparatusHydroxypropylmethyl celluloseGypsum

The invention discloses a silicon carbide green body and a production process thereof. The green body is prepared by carrying out extrusion molding on a main material silicon carbide and auxiliary materials, wherein the auxiliary materials are powdered graphite with a gain size of 3500 meshes, hydroxypropyl methyl cellulose with a gain size of 80 meshes and powdered poval with a gain size of 160 meshes. The process is a green body forming method in which reaction-sintered silicon carbide square beam and roller rod products are changed through extrusion molding. The process has the advantages that compared with the traditional method in which a square beam green body is produced by virtue of grouting molding, in the process disclosed by the invention, the granularity of the selected raw materials is relative coarse, thus the machining process and cost of micro-powder are saved, the machining cost of the raw materials is reduced, simultaneously, the manufacturing expenditure and raw material cost of a gypsum mould are saved, the operation process is simplified, and the work efficiency is improved.

Owner:SHANDONG JINHONG NEW MATERIAL CO LTD

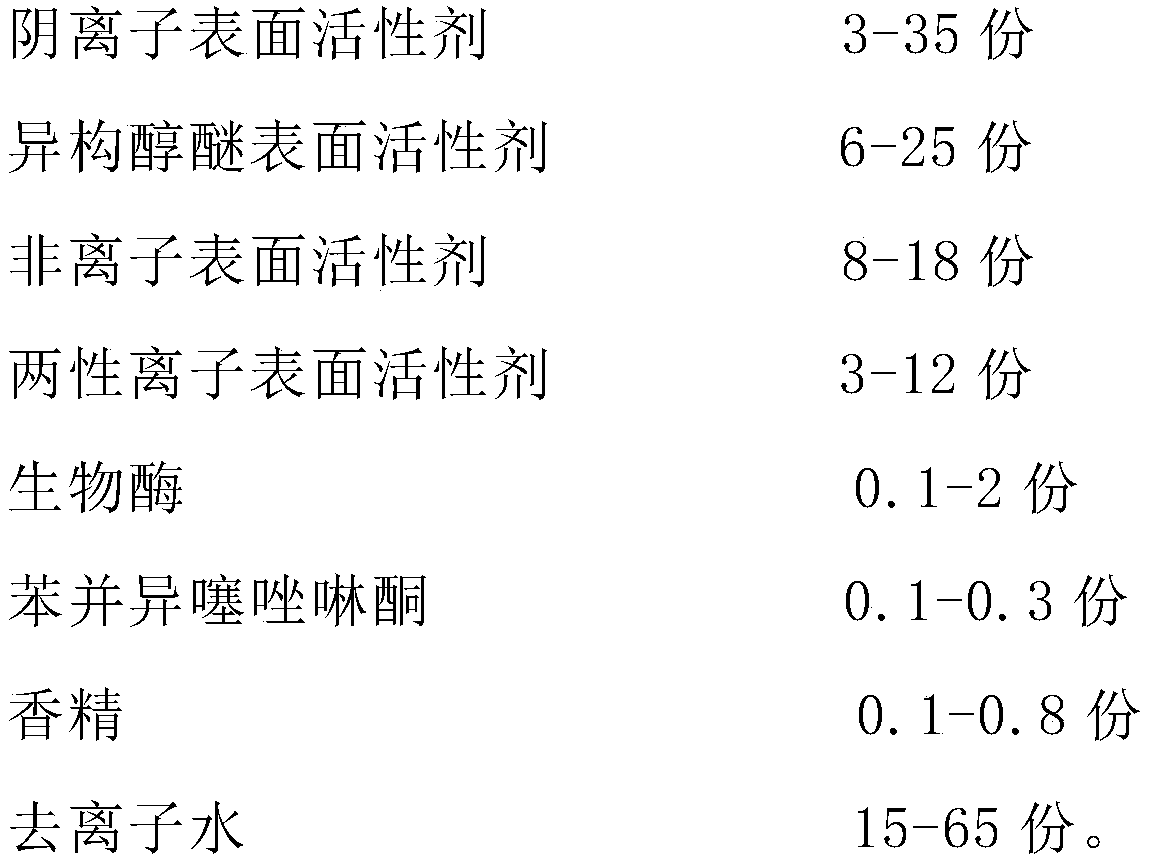

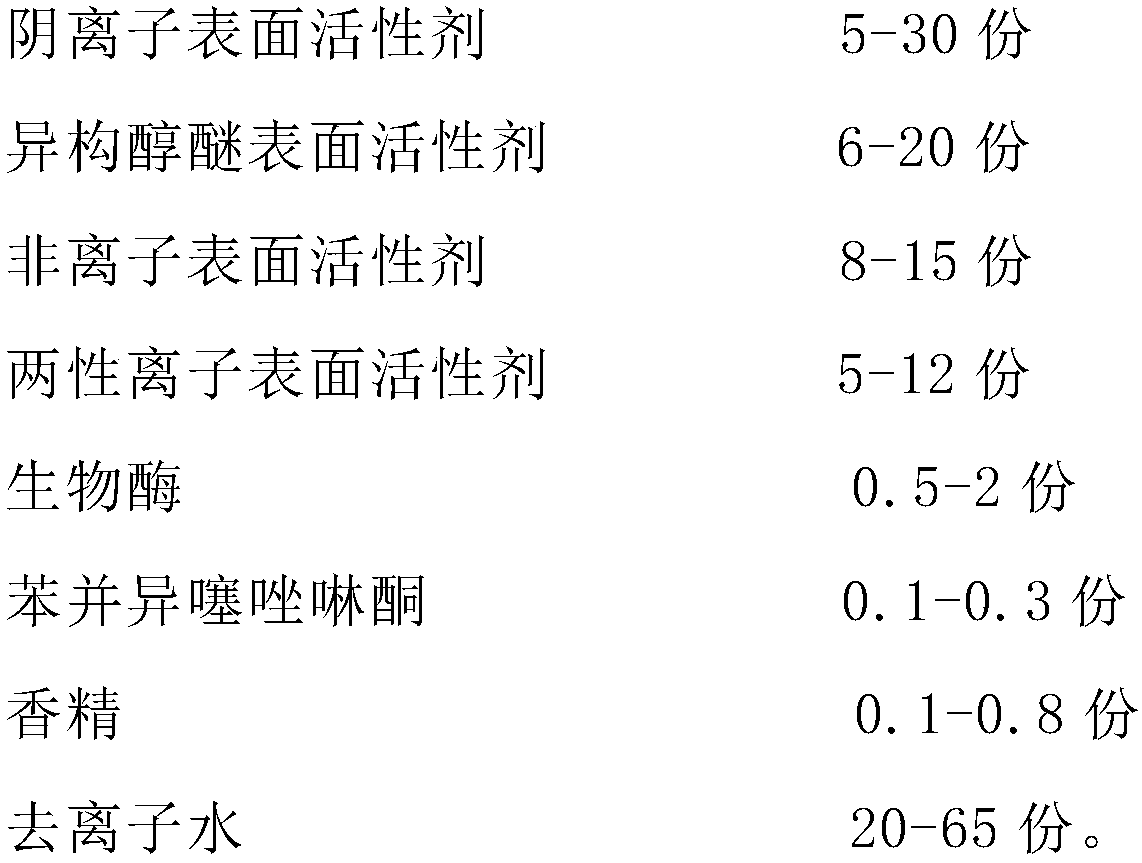

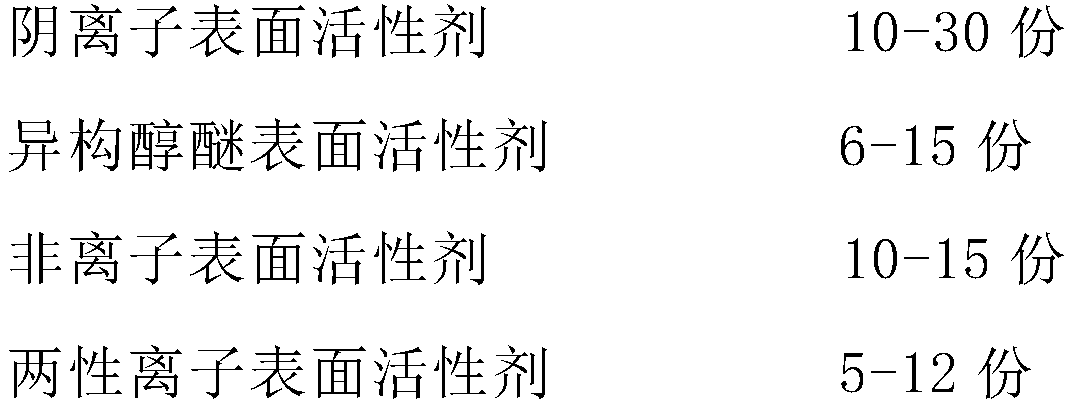

Concentrated garment washing solution and preparation method

InactiveCN107603771ASolve dissolveIncrease enzyme activityOrganic detergent compounding agentsAmpholytes/electroneutral surface-active compoundsAlcoholBenzisothiazolone

The invention provides a concentrated garment washing solution, which is prepared from the following main components in parts by mass: 3 to 35 parts of anionic surfactant, 6 to 25 parts of isomeric alcohol ether surfactant, 8 to 18 parts of nonionic surfactant, 3 to 12 parts of zwitterionic surfactant, 0.1 to 2 parts of biological enzyme, 0.1 to 0.3 part of benzisothiazolone, 0.1 to 0.8 part of essence and 15 to 65 parts of deionized water. The concentrated garment washing solution provided by the invention is excellent in washing effects, friendly to a human body and an environment, green andenvironmentally friendly.

Owner:BEIJING REWARD HOME CARE CHEM

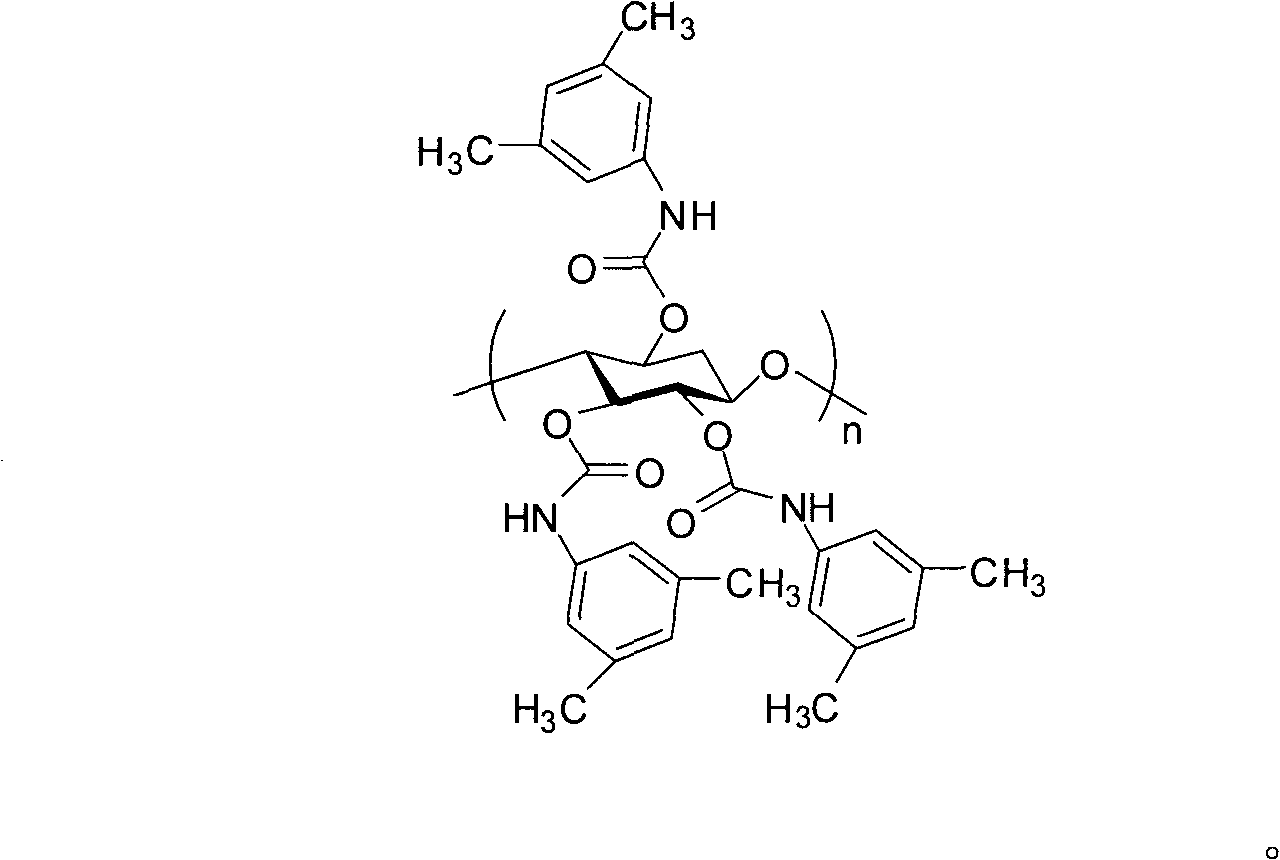

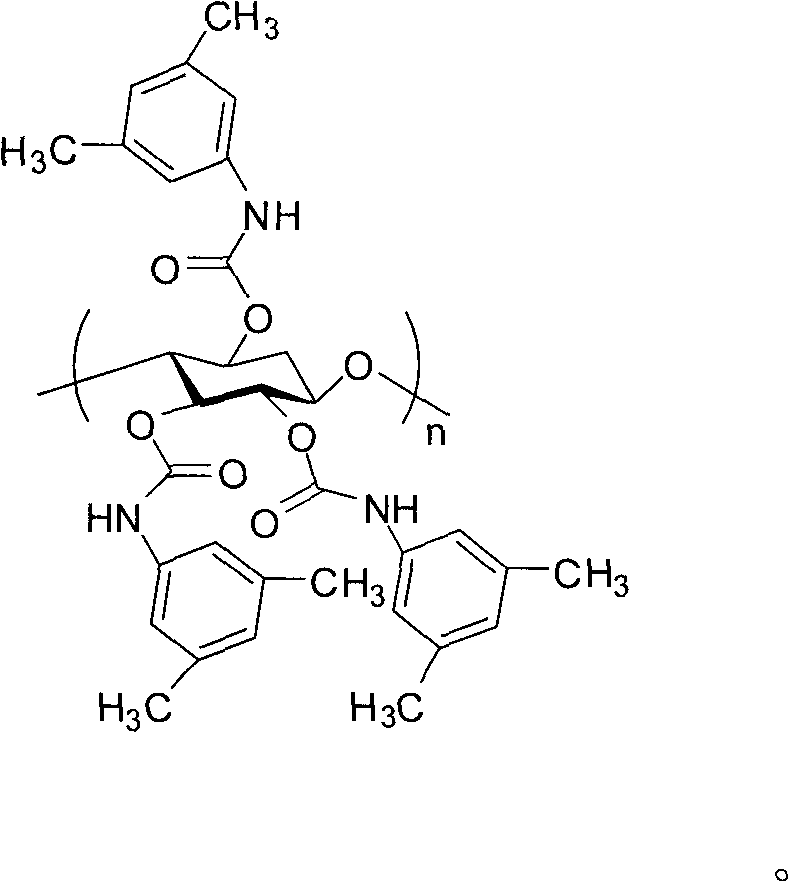

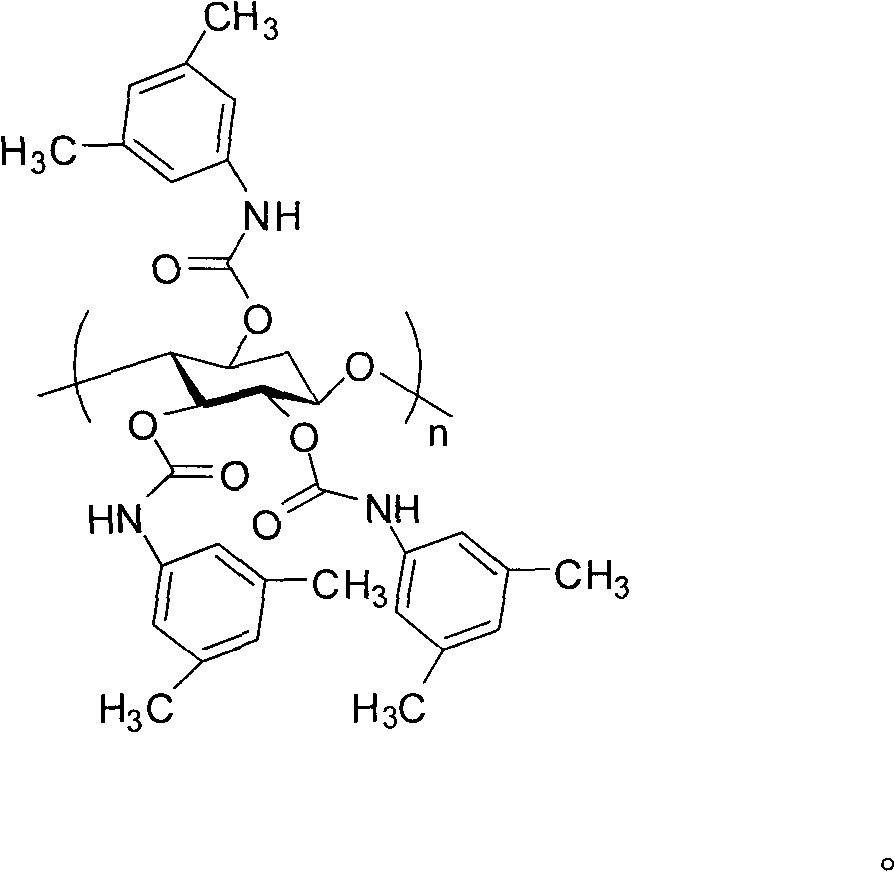

Synthesis and application of large-grain diameter chiral stationary phase

InactiveCN101811034ASave raw material costReduce resistanceOther chemical processesOrganic compound preparationStationary phaseSilica gel

The invention relates to the synthesis of a large-grain diameter chiral stationary phase, wherein a synthetic method uses silica gel with the grain diameter of 40-60mum to prepare coating type and bonding type cellulosic derivative chiral stationary phases with the coating volume ratio of 18-25 percent and obtaines better chiral separation for propranolole hydrochloride enantiomers under a positive-phase condition. Because the filling aperture is large, gaps among fillings are large, reducing the resistance for a mobile phase, thereby effectively preventing the defects of high column pressure, easy blockage, shorter life and the like of a small-grain diameter chiral column and simultaneously effectively lowering the raw material expense of a silica gel matrix in the preparation of the chiral column.

Owner:王荣

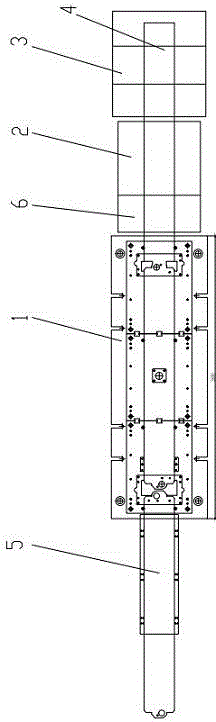

Staggering discharging device of adjusting box

PendingCN106044177APrecise positioningGuaranteed uptimeConveyorsControl devices for conveyorsEngineeringMechanical engineering

Owner:梁启明

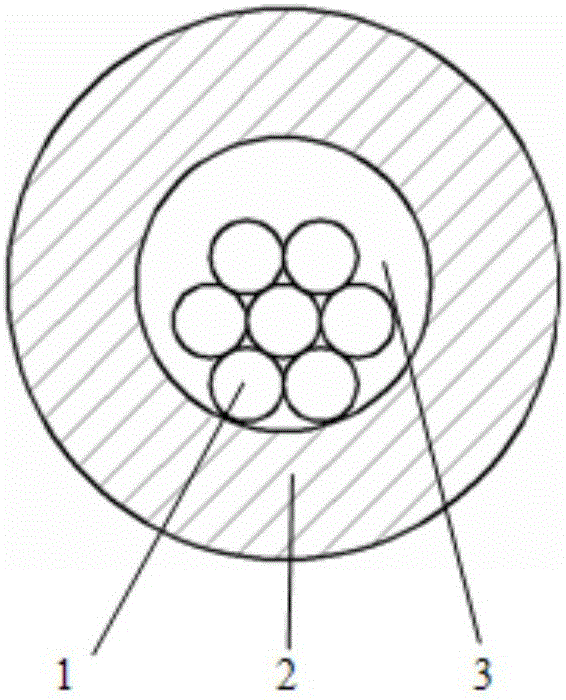

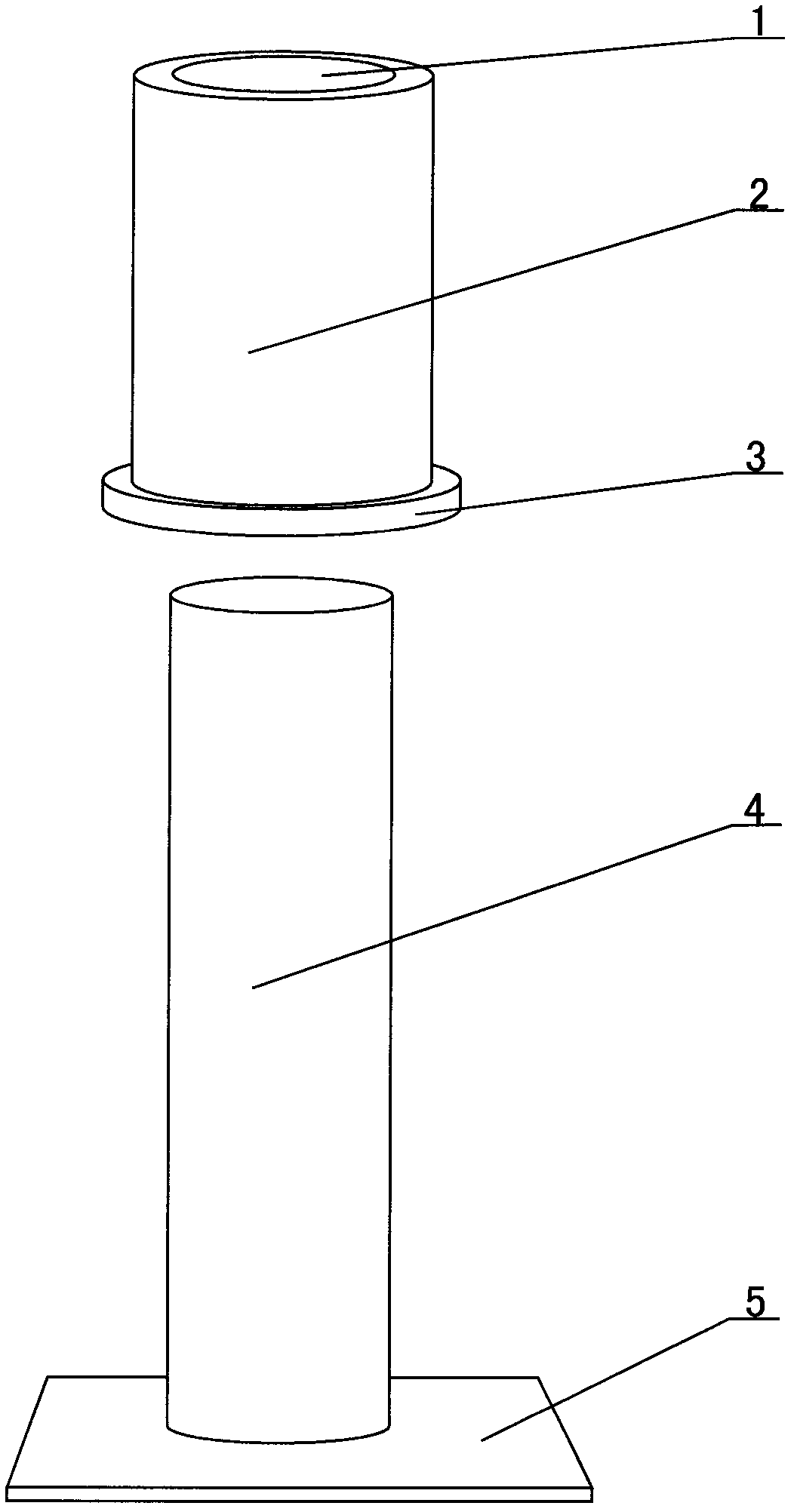

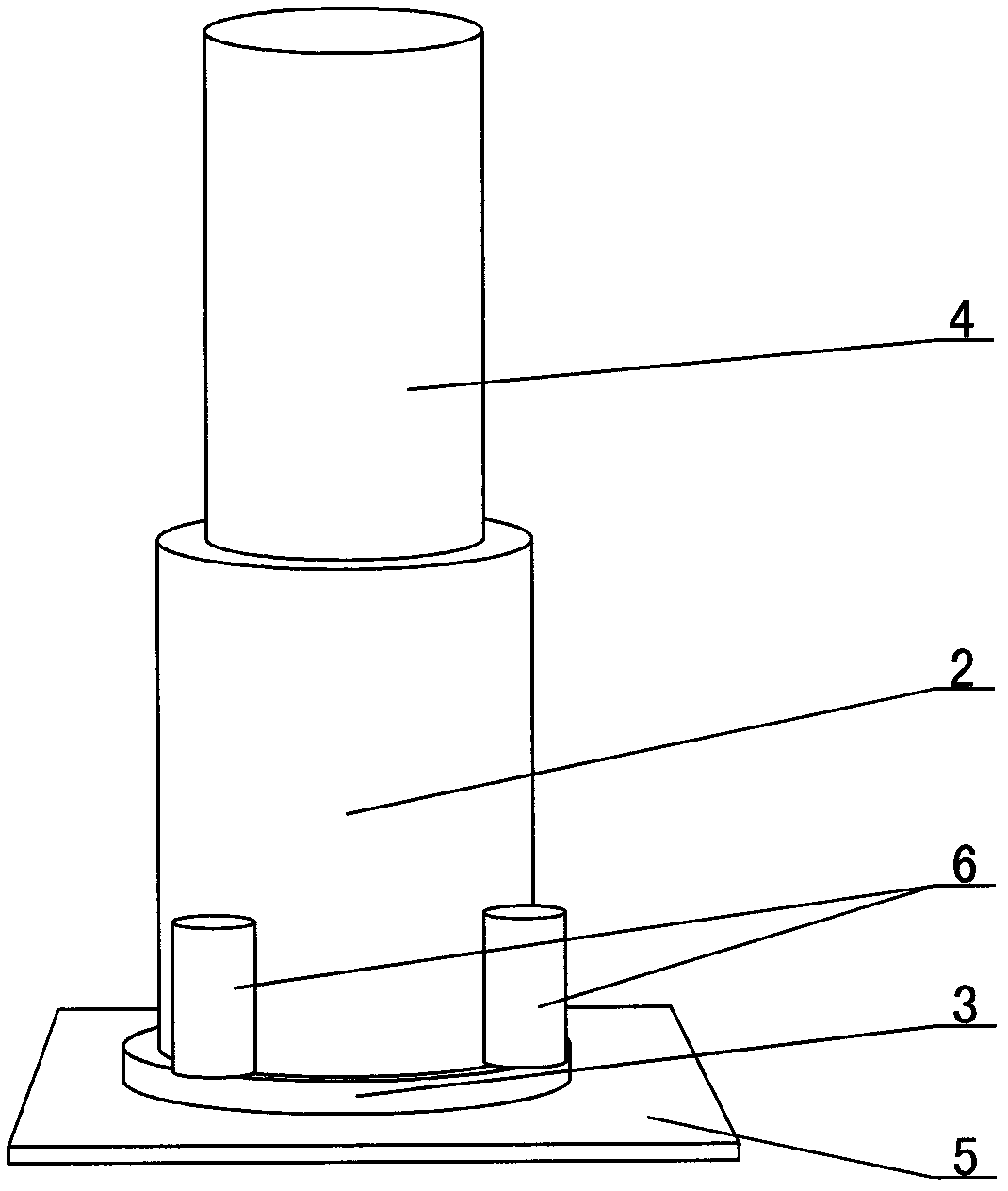

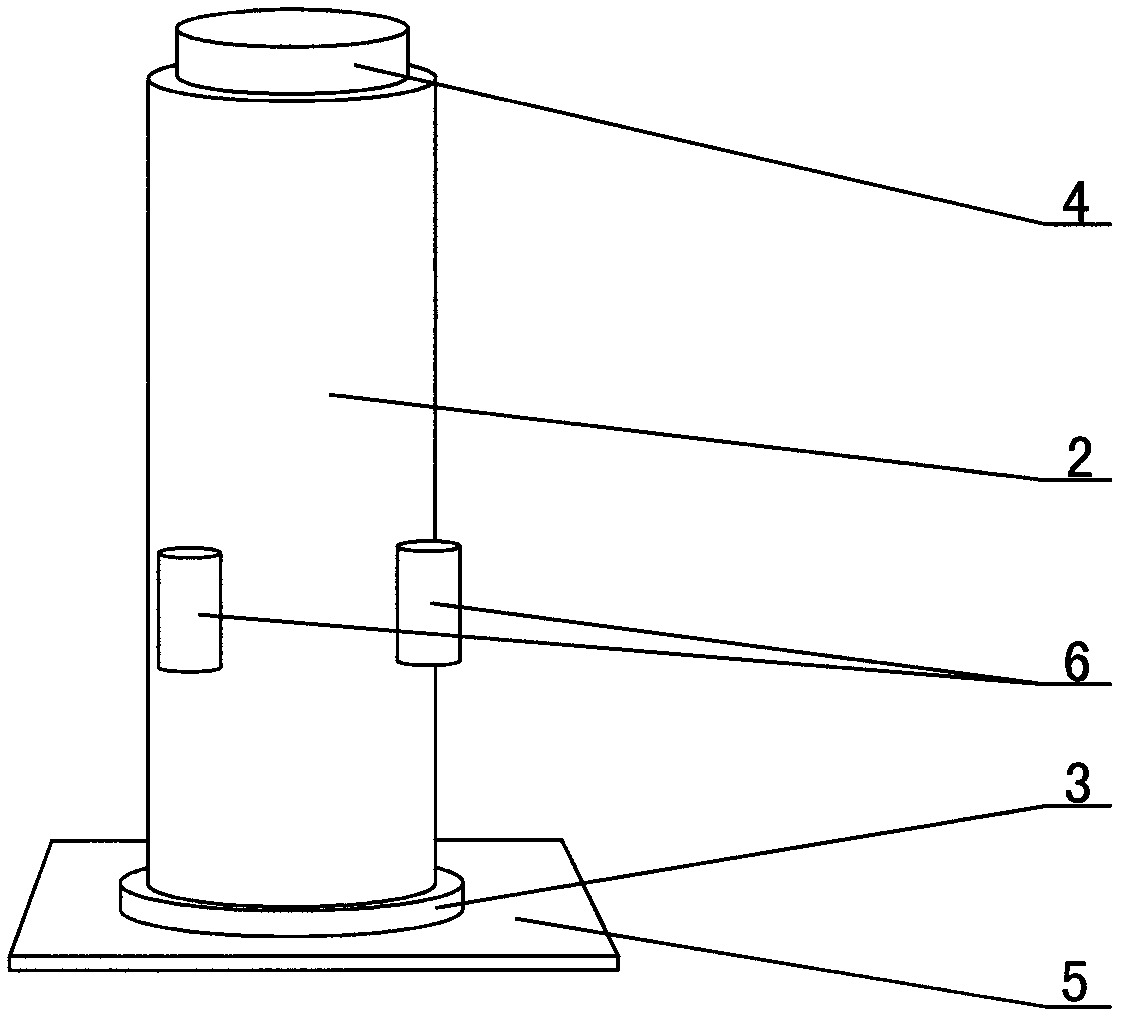

Integral copper crucible and method for producing copper crucible by integral forging and rotary pressing

The invention discloses an integral copper crucible and a method for producing the copper crucible by integral forging and rotary pressing, and relates to a copper crucible and a machining method. A barrel (2) has a circular structure; one end of the barrel (2) with the circular structure is provided with a flange plate (3); the flange plate and the barrel are integrated; and an inner through hole (1) with the same hole diameter is formed from one end of the barrel, which is provided with the flange plate (3), to the other end of the barrel (2). Rotary pressing equipment is involved in the method for producing the copper crucible, and a blank is uniformly pressed by a mandrel (4) and a rotary pressing mechanism and is deburred and ground to form the copper crucible. By the method for machining the copper crucible by integral forging, the finished copper crucible does not have any weld joint, the defect of unperceivable cracks or rupture at the later stage of using the copper crucible is effectively overcome, and raw material cost, forging cost and machining cost are greatly reduced.

Owner:陈普选

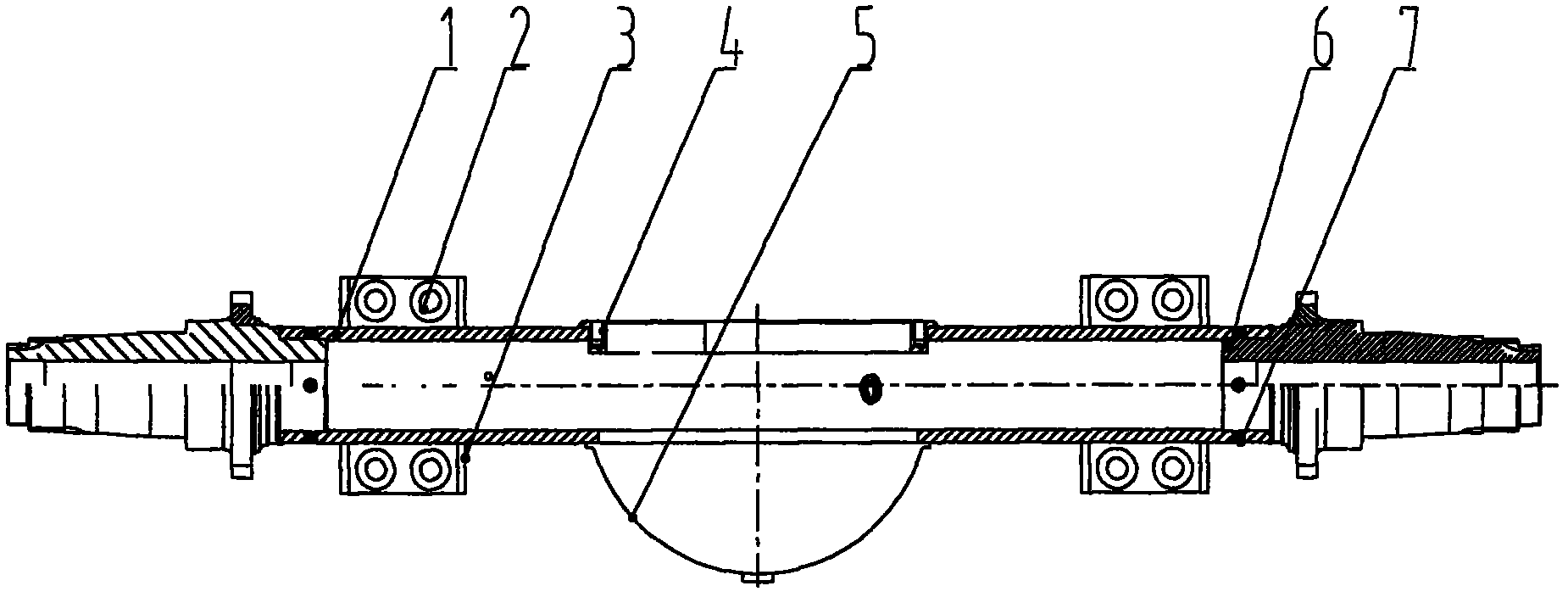

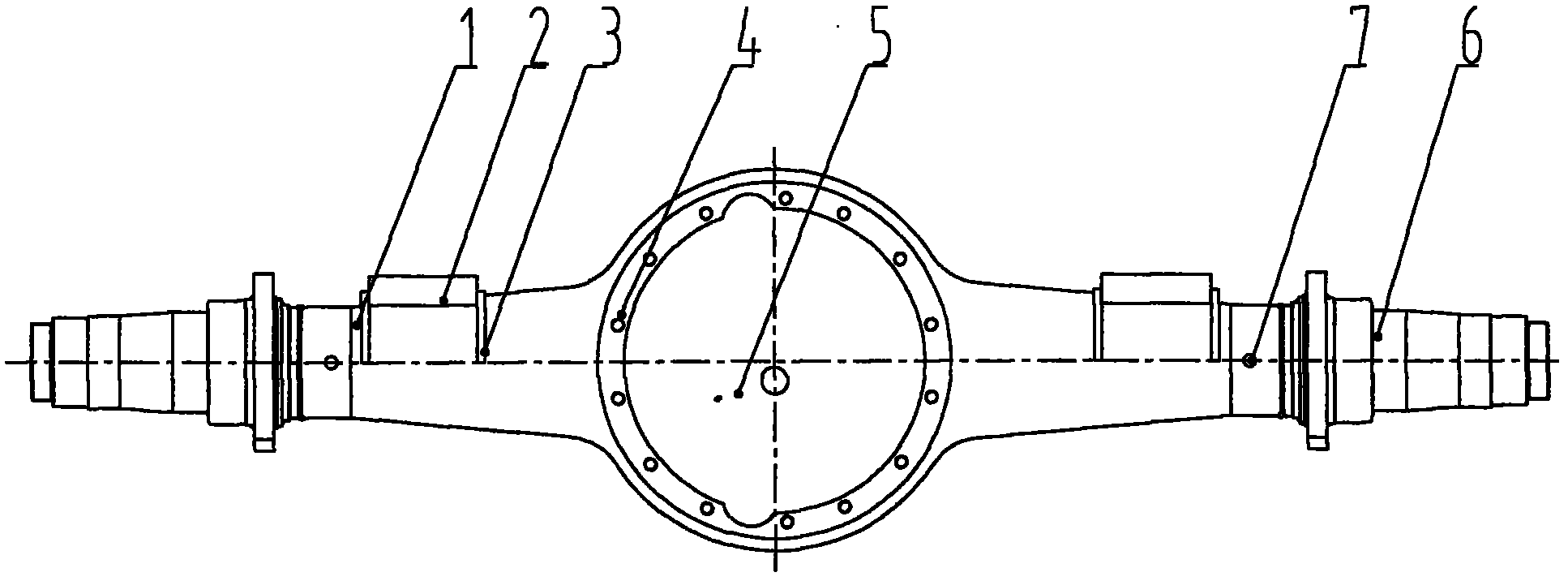

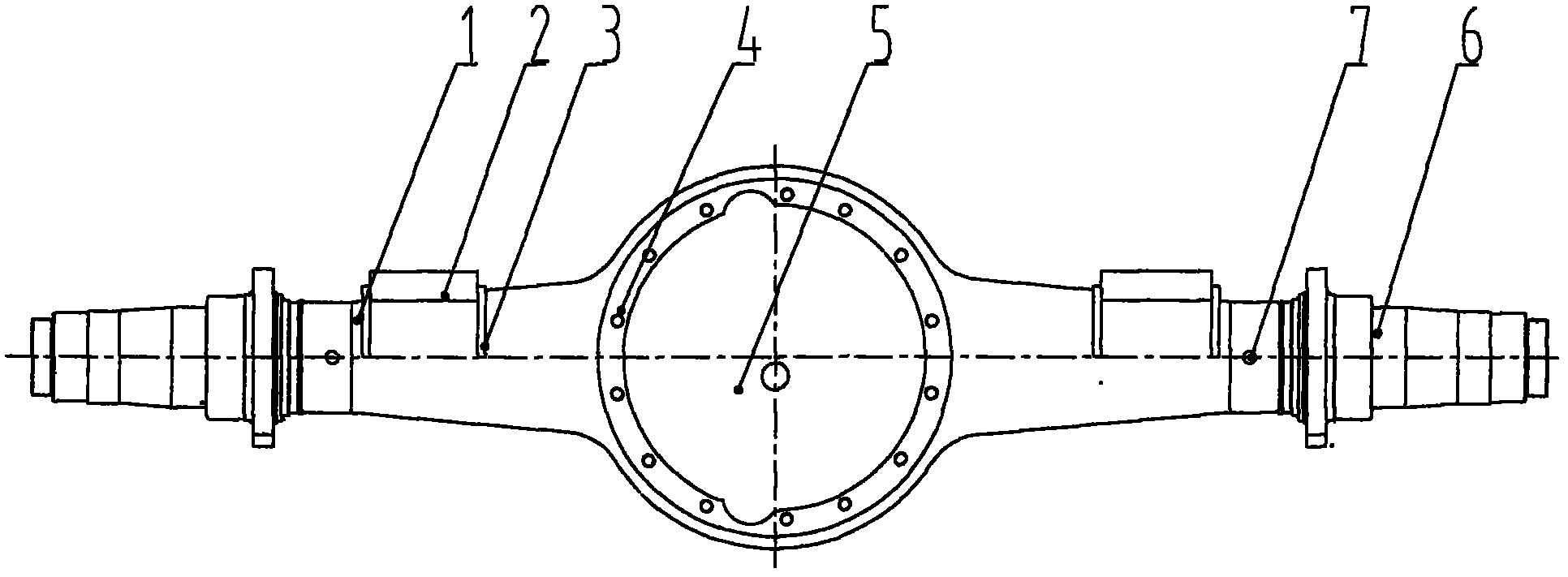

Manufacturing method of driving axle housing of heavy load road roller

ActiveCN102407733AIncrease profitSimple structureAxle unitsRolling resistance optimizationAgricultural engineeringHeavy load

The invention provides a manufacturing method of a driving axle housing of a heavy load road roller, which improves the strength and rigidity of the driving axle housing and can be used on a heavy load road roller more than 20 tons; the manufacturing method also improves the material utilization, reduces the weight and reduces the production cost, and simultaneously improves the production efficiency, reduces the rejection rate and makes the process simple and convenient, so that the driving axle housing can be processed easily. The driving axle housing is composed of an axle housing, a support, rib plates, a flange, a bottom cover, axle ends and a welding rivet; both ends of the axle housing are connected with the axle ends symmetrically, the welding rivet is fixed at the connection part of the axle ends and the two ends of the axle housing; the rib plates are arranged at the inner sides of axle ends symmetrically and the support is fixedly connected with the inner sides of the rib plates; the flange is arranged at the middle part of the axle housing and the bottom cover is fixedly connected at one side of the flange. The process method of a road roller driving axle housing comprises sequentially accomplished steps of axle housing pressing, welding, shot blasting, acid cleaning, phosphating, washing, under-coating vanishing, processing, hot pressing of axle end, correcting and welding-on. The driving axle housing provided by the invention has the advantages of simple structure, and prolonged service life, is easy to produce, and is convenient and fast to manufacture.

Owner:洛阳路通重工机械有限公司

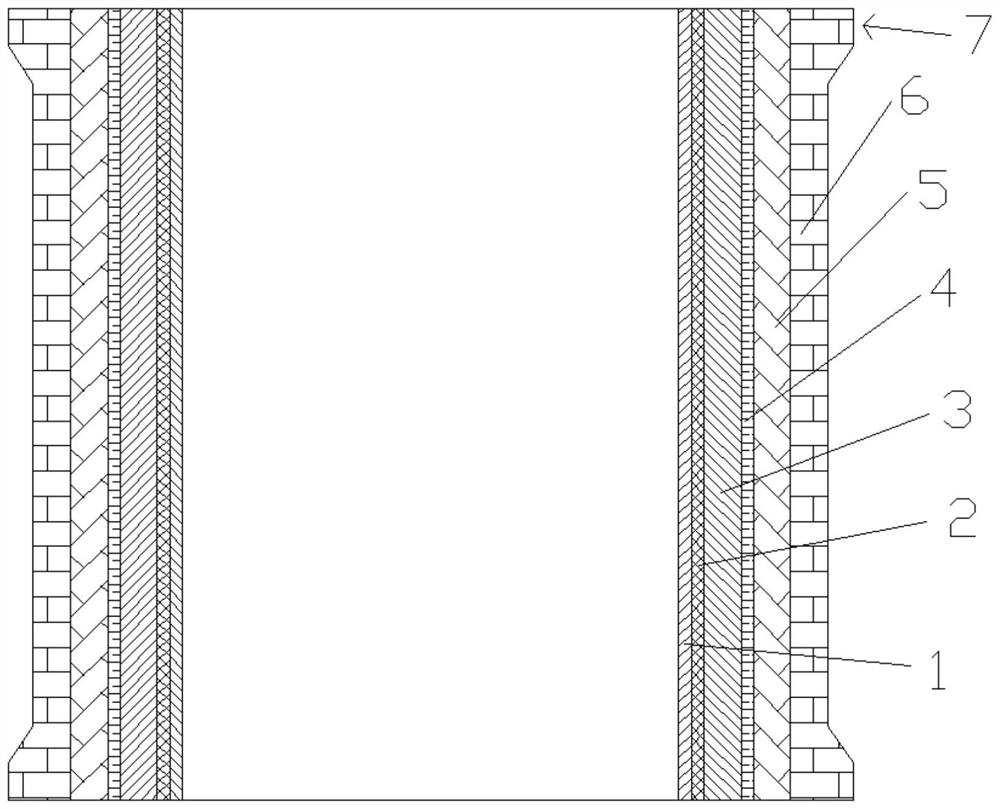

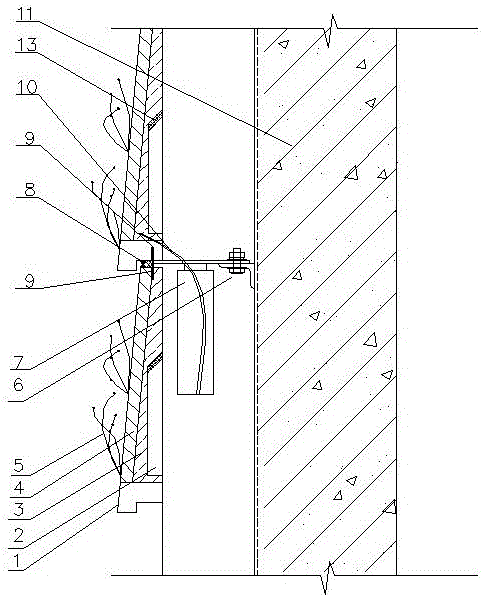

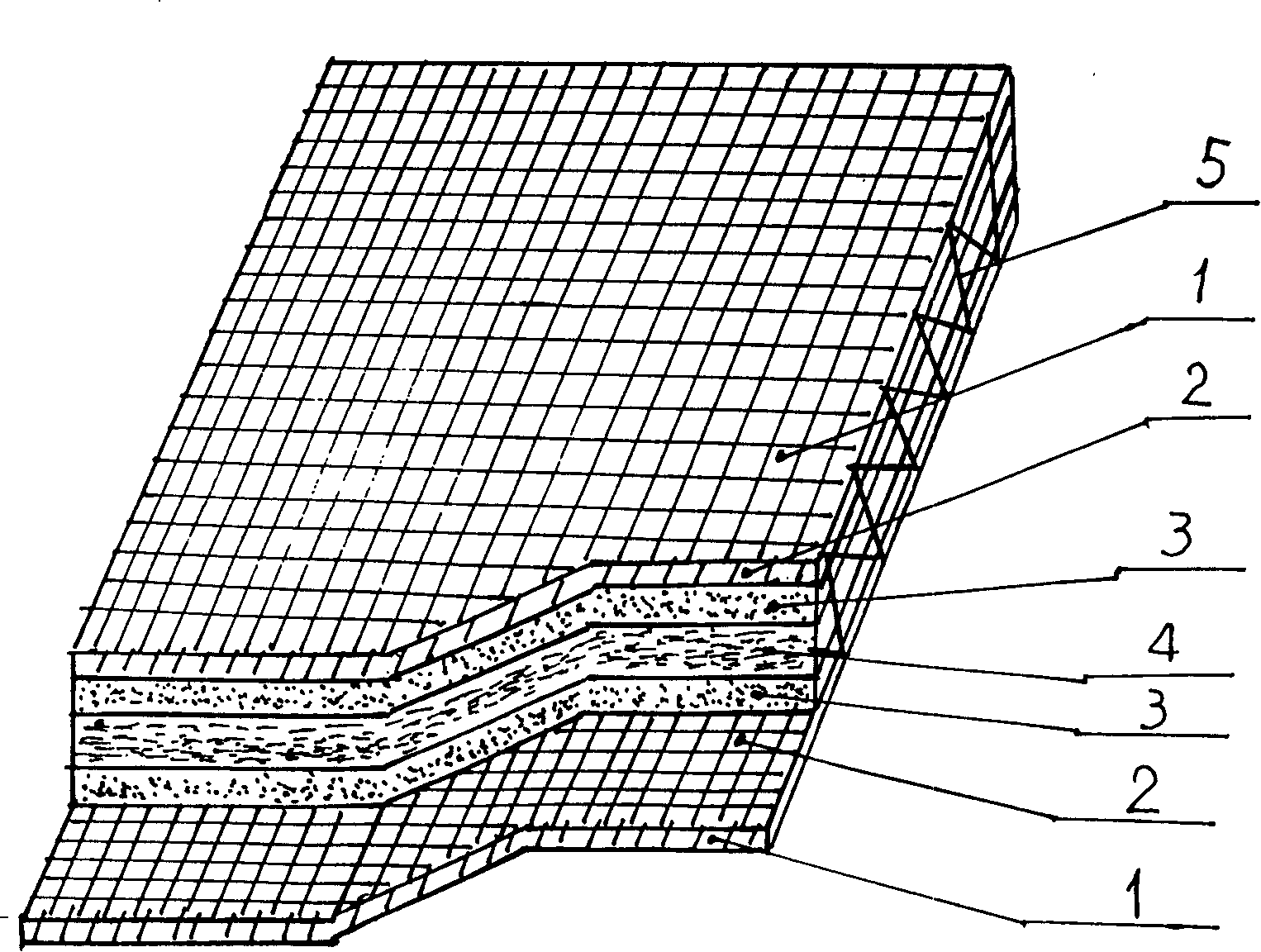

Plant growing type exterior wall hanging plate system

InactiveCN105971210ASolve self-importanceSolve functionCovering/liningsGeneral water supply conservationEngineeringWater pipe

A planting-type external wall hanging board system, which relates to the technical field of construction engineering. The invention includes a box-type hanging board positioned on the outside of a wall through a pendant. A vegetation layer, a water-absorbing layer, and a built-in water tank are arranged in the box-type hanging board. The upper end of the box is provided with an opening, the opening is covered with a filter layer, at least one end of the water-absorbing layer is arranged in the built-in water tank, and planting holes are distributed on the surface of the box-type hanging board; a closed external water tank is arranged between the wall and the box-type hanging board, An aqueduct is arranged between the water-absorbing layer and the external water tank. Drought-tolerant plants can be grown in the planting hole, the moisture required by the plants is provided by the water-absorbing layer, and the rainwater is collected by the built-in water tank and the external water tank, without artificial regular watering. The invention solves the shortcomings of dry-hanging stone material such as heavy weight and single function, and realizes the multi-functionality of the product, but enables the hanging board to have the function of growing plants.

Owner:YANGZHOU UNIV

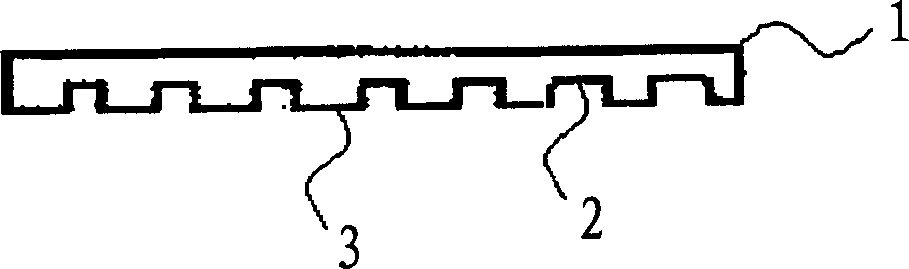

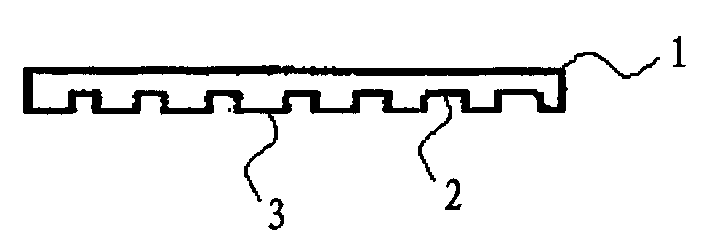

Side forms for paving asphalt concrete pavement

InactiveCN101275382ASave raw material costSave processing feeRoads maintainenceRoad surfaceProtection layer

An asphalt concrete pavement laying used side mould, pertains to the road building molded board facilities technique field, which is used to omit side section incising operation in the construction. The side mould is configured with a stretched body long stick in the middle part and fixing catch plates on the both ends, both ends of the stretched body long stick is in wedge shape, whose inner surfaces are perpendicular to the bottom face, risers of the fixing catch plates are connected with the wedge shape terminal, holes are nailed on the motherboard, and a matched locator card is provided between the two fixing catch plates. The locator card can clamp wires small riser, the inner surface of the stretched body long stick can be additively sticked with a rubber plate, and the external surface can be covered with a protection layer. The order suitable side section can be directly formed in the process of using the invention to lay the asphalt concrete pavement, thereby omitting the side section incising operation, thus the asphalt concrete raw material cost, processing charges and carriage charges can be saved; the construction operation amount can be reduced, the construction period can be cut short, and can be used as a side section molding molded board facilities in the asphalt concrete laying construction.

Owner:张军 +1

A high-efficiency solar cell for double-sided use and a preparation method thereof are provided

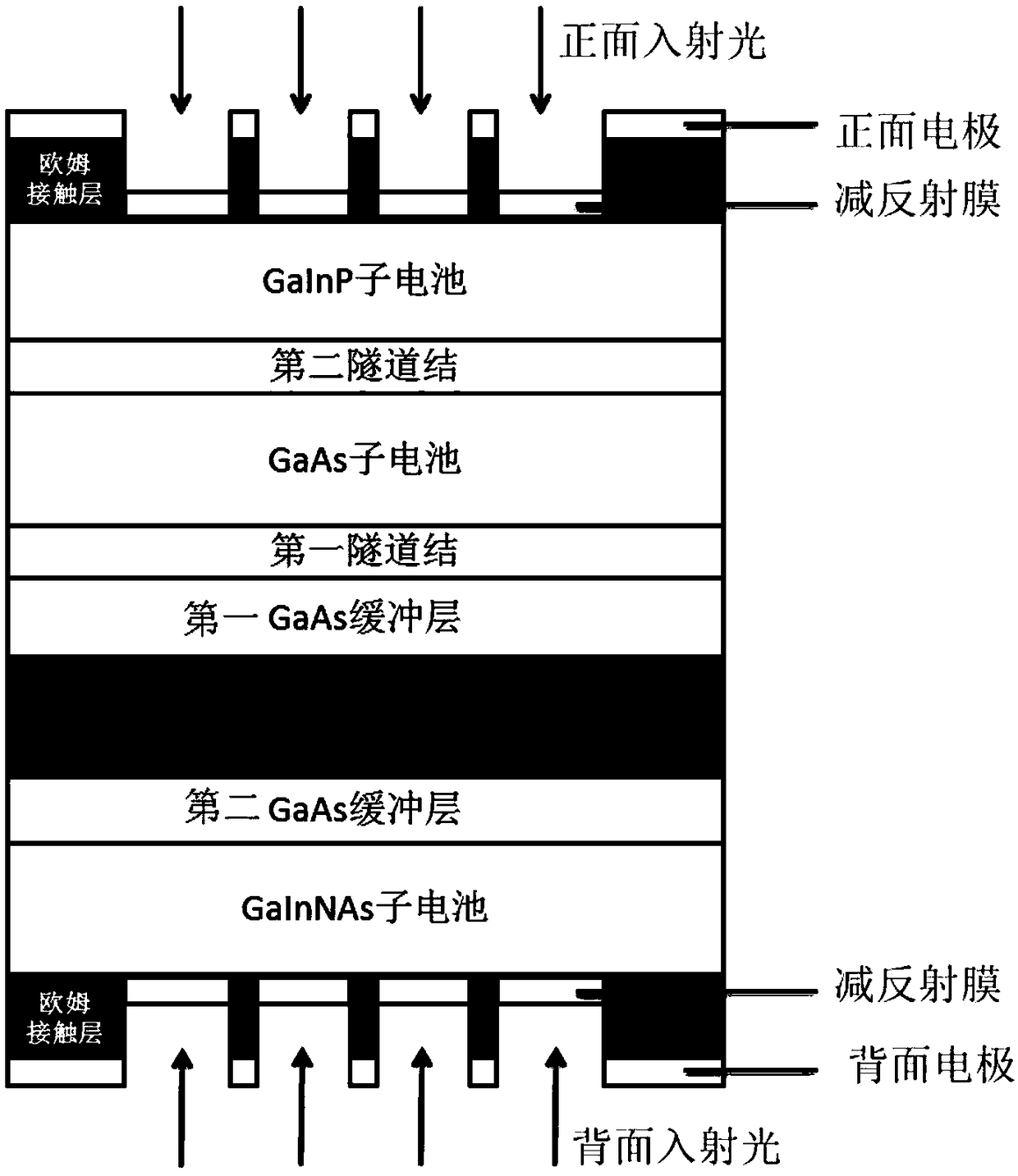

InactiveCN109148622AIncrease profitImprove photoelectric conversion efficiencyFinal product manufacturePhotovoltaic energy generationChemical vapor depositionTunnel junction

A high-efficiency solar cell for double-sided use and a preparation method thereof are disclosed. A metal organic chemical vapor deposition technology or molecular beam epitaxy growth technology is adopted to sequentially grow a first GaAs buffer layer, first tunnel junction, GaAs sub-cell, second tunnel junction, GaInP sub-cell and n-type GaAs cap layer with high doping concentration on the uppersurface of a GaAs substrate, a second GaAs buffer layer, GaInNAs sub-cell and n-type GaAs cap layer with high doping concentration are sequentially grown on the lower surface of the GaAs substrate, GaInP / GaAs / GaInNAs three-junction battery are obtained, and the upper and lower surfaces of the GaInP / GaAs / GaInNAs three-junction battery are photoetched, an antireflection film is deposited, electrodes are prepare and subsequent battery chips are manufactured; The invention can make the band gap structure of the battery more matched with the solar spectrum, improve the overall open-circuit voltageof the GaAs multi-junction battery, absorb and utilize the incident light on the back of the battery, and finally improve the photoelectric conversion efficiency of the battery.

Owner:ZHONGSHAN DEHUA CHIP TECH CO LTD

Method for making soybean milk

InactiveCN102246861AMiniaturizationAvoid overflowing spacesBeverage vesselsMilk substitutesSlurrySoybean meal

The invention discloses a method for making soybean milk, which is used for making soybean milk in volume A. The method comprises: adding soybeans and liquid in volume accounting for 1 / 5 to 2 / 3 of the volume A, which are used for making the soybean milk in volume A into a soybean milk container before grinding and pulping; grinding the soybeans and pulping to form mixed liquid; and adding liquid into the soybean milk container till the volume A. Compared with the prior art, the method has the advantages that: only a small amount of liquid is added for grinding the soybeans and pulping before the grinding and pulping and finally the liquid is added till the set volume of the soybean milk, so the total volume of boiled milk during pulping is small; the need of preserving large space for rising milk and overflowing foam in a soybean milk cup is obviated; the need of using a soybean milk cup of which the volume is far more (more than 2.5 times) bigger for required volume A of soybean milk like in the prior art is obviated; and under the condition of making soybean milk at the same concentration, the soybean milk container is only required to be 20 to 50 percent bigger than required soybean milk, so the machine body of the soybean milk maker is smaller, and raw material and transport cost are saved.

Owner:MIDEA GRP CO LTD

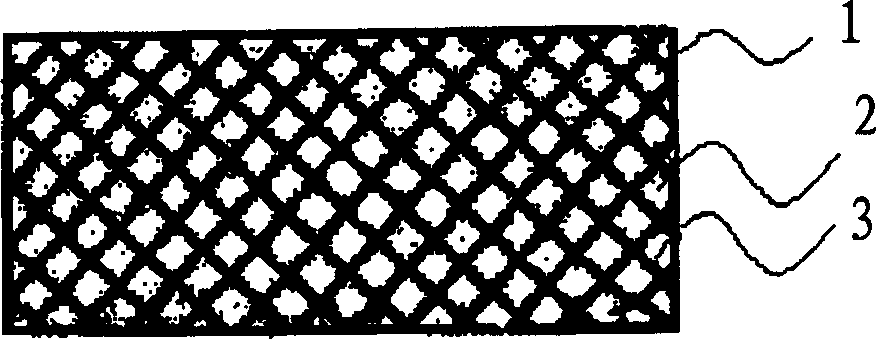

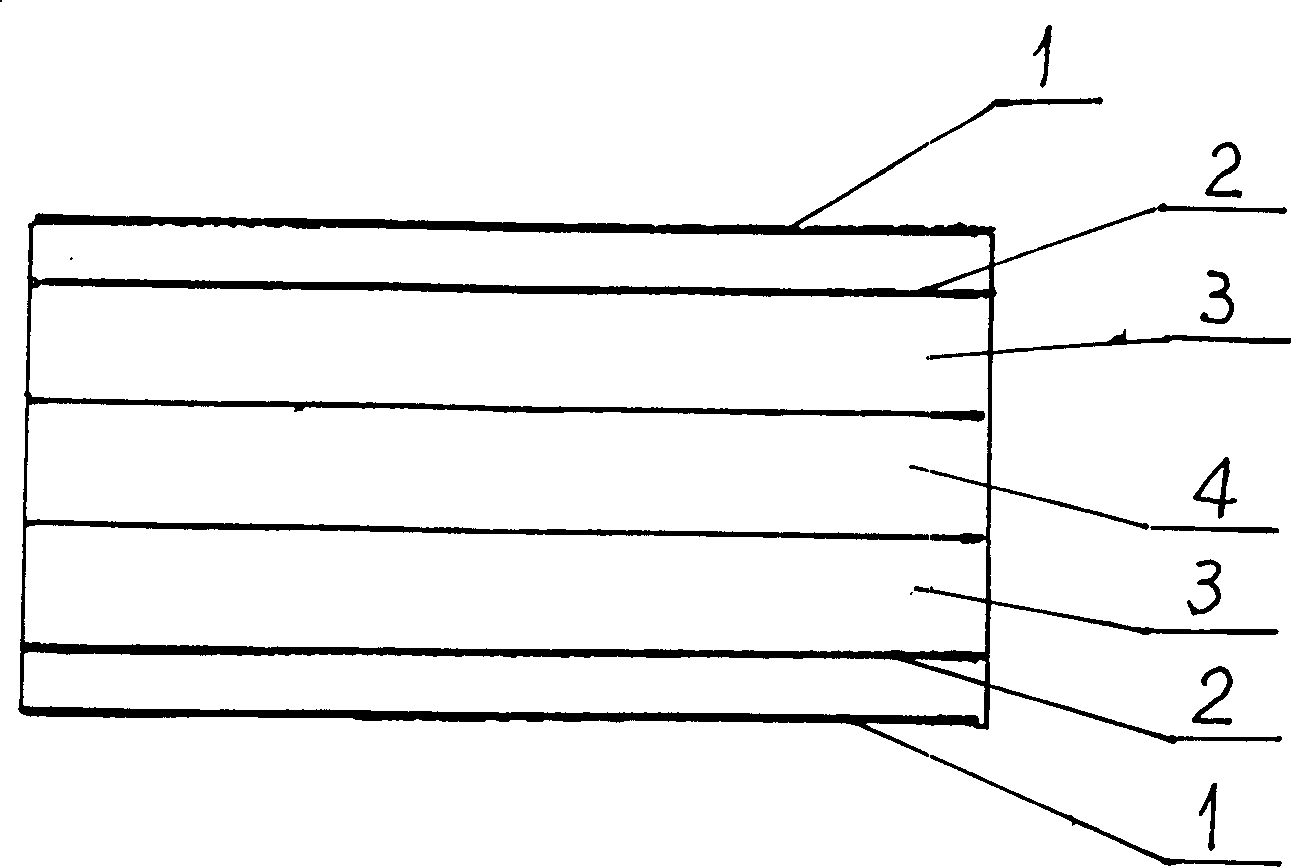

Double-layer steel net mineral cotton perlite sandwich composite lightweight wall plate

InactiveCN101191359ALight weightCondensation effect is strongBuilding componentsNon toxicitySandwich board

The present invention relates to a double-deck steel mesh mineral cotton perlite sandwich compound light wallboard; an upper cover coat and a lower cover coat are both double-deck steel meshes; a middle sandwich layer consists of a perlite lath, a mineral cotton lath and a perlite lath which are compounded; the compound middle sandwich layer is clamped and fixedly connected to form a grid sandwich board through the double-deck steel meshes of the upper cover coat and the lower cover coat. The invention has light volume weight, heat preservation, heat insulation, shock resistance, good sound absorption effect, non-toxicity and non-radioactivity, firmness, wear resistance, non-cracking and energy-saving and consumption-reducing performance, thereby the invention is an ideal fireproof and environment-friendly building material.

Owner:长沙市天心区广用珍珠岩建材厂

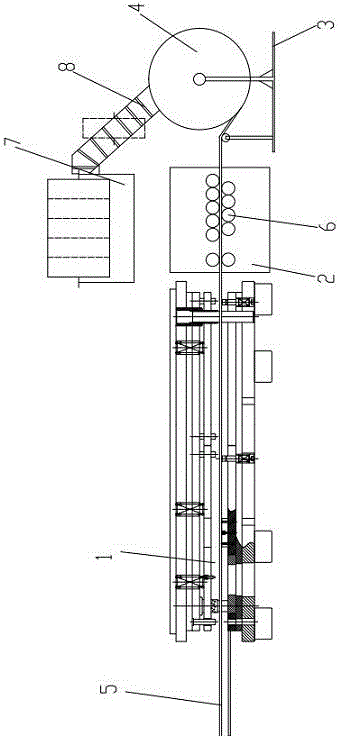

Scrap-free machining technology and device for lift truck scissor arm material

ActiveCN104308544AImprove consistencyHigh precisionShaping toolsOther manufacturing equipments/toolsStampingElectric machinery

The invention discloses a scrap-free machining technology and device for lift truck scissor arm material, belongs to the technical field of cold stamping die forming. The scrap-free machining technology comprises the following steps: scissoring at a fixed size, feeding, leveling and stamping; a press, a feeder and a material frame are matched for use; the feeder is positioned between the press and the material frame; the press, the feeder and the material frame are sequentially arranged; output and input ends of the press, the feeder and the material frame are sequentially connected; the material frame is a roll fixing device; the feeder is a roll-type feeding mechanism; a material guiding roll is driven by a motor; a leveling device is arranged on the feeder. Through the scrap-free machining technology and device for the lift truck scissor arm material, scrap-free lift truck scissor arm material machining can be reazlied, good product consistency, high precision, high efficiency and other advantages can be achieved; through the adoption of a die for stamping forming, a raw material adopts a roll of which the width is equal to that of a product, so that the product quality is ensured, the production efficiency is also improved by several times and the raw material and the machining cost are reduced.

Owner:CANGZHOU ORBON ELECTRICAL & MECHANICAL PROD MAKING

Method of lowering pH value and desulfurizing flue of sync process alkali preparing effluent

InactiveCN1548218ASave raw material costSave the initial construction feeDispersed particle separationWater/sewage treatmentLiquid wastePollution

The method of lower pH value and desulfurizing flue of sync process alkali preparing effluent includes the following steps: feeding the alkali preparing effluent and the flue into absorber for eliminating SO2 in boiler flue with the absorbing alkali preparing effluent and neutralizing the alkality of alkali preparing effluent simultaneously. The present invention treats the two main kinds of pollution, including alkali preparing effluent and flue with SO2, simultaneously in one set of apparatus, and can utilize the waste resource and low pollution treating cost.

Owner:TIANJIN BOHUA YONGLI CHEM IND

Yellowing-resistant ultraviolet (UV) cured varnish

The invention relates to the field of paints, and specifically relates to a yellowing-resistant UV-cured varnish. The varnish is composed of the following components in percentage by weight: 20 to 30% of six-functionality aliphatic acid modified polyester acrylate, 20 to 30% of four-functionality polyester acrylate, 15 to 30% of monomer, 2 to 5% of photoinitiator, 25 to 40% of diluent, and 0.5 to 2% of functional aid. The provided UV-cured varnish has the advantages of low cost, good yellowing resistance, simple production, and easy industrialization.

Owner:段晶晶

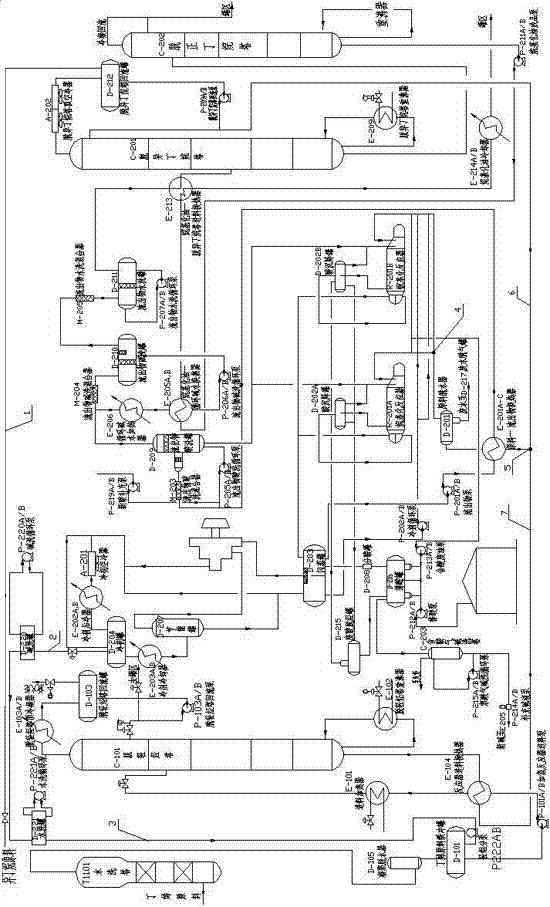

Production device for preparation of isooctane by isobutane and butene alkylation reaction

ActiveCN106854126AShort processReduce equipment loadHydrocarbonsHydrocarbon preparationChemistryIsobutane

The invention discloses a production device for preparation of isooctane by isobutane and butene alkylation reaction. The device includes a raw material dehydrator D201, a heat exchanger, a light hydrocarbon removing tower C101, a butene feed heater E101, and a butene raw material buffer tank D101 that are communicated with an alkylation reactor feed end in order, and also includes a flash tank D203, a pickling tank D209, an alkali washing tank D210, a washing tank D211, a deisobutanizer and a deisobutanizer C201 that are communicated with an alkylation reactor discharge end in order. Specifically, the upper part of the deisobutanizer C201 is communicated with a deisobutanizer return tank D212, an isobutane raw material conveying pipe is communicated with the return tank D212, a deisobutanizer reflux pump P209A / B sends the isobutane raw material and circulating isobutene back to the alkylation reactor through a pipeline and is communicated with a butene raw material convey pipe through a tee joint.

Owner:HUAIAN LIANLI CHEM CO LTD

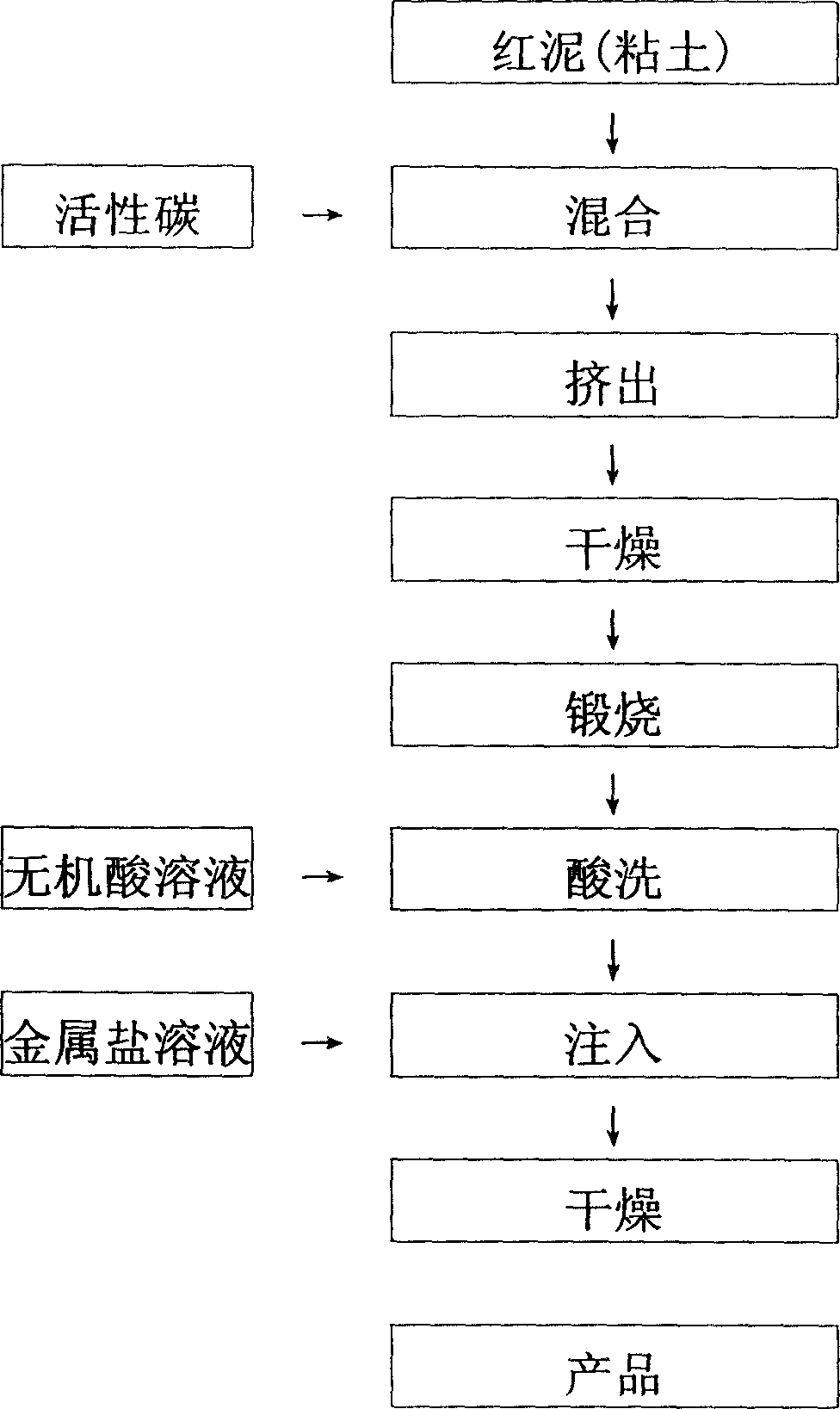

Composition of keeping ice house and horticulture production fresh and its manufacturing technics

InactiveCN1669636AGuaranteed freshnessImprove adsorption capacityOther chemical processesDeodrantsActivated carbonRed mud

The invention relates to a composition for ice house deodorizing and keeping horticulture product and food fresh by adsorbing ethene gas and its manufacturing technique. Particularly, the byproduct red mud generated by extracting bauxite from laterite is mixed with activated carbon, extruded and molded by an extruder, dried under 70-120 DEG C and calcined under 800-950 DEG C. The calcined product is washed by inorganic acid solution and added with 10-20wt% active metal salt immediately. The product can adsorb the plant hormone ethene which can rot the horticulture product to keep the product fresh.

Owner:林栽信 +6

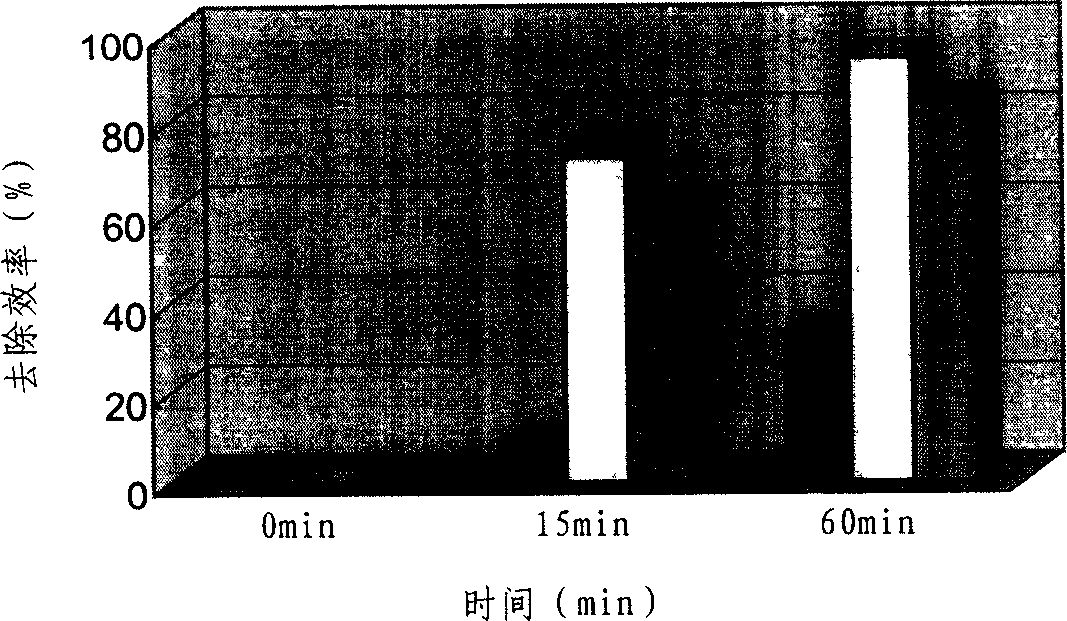

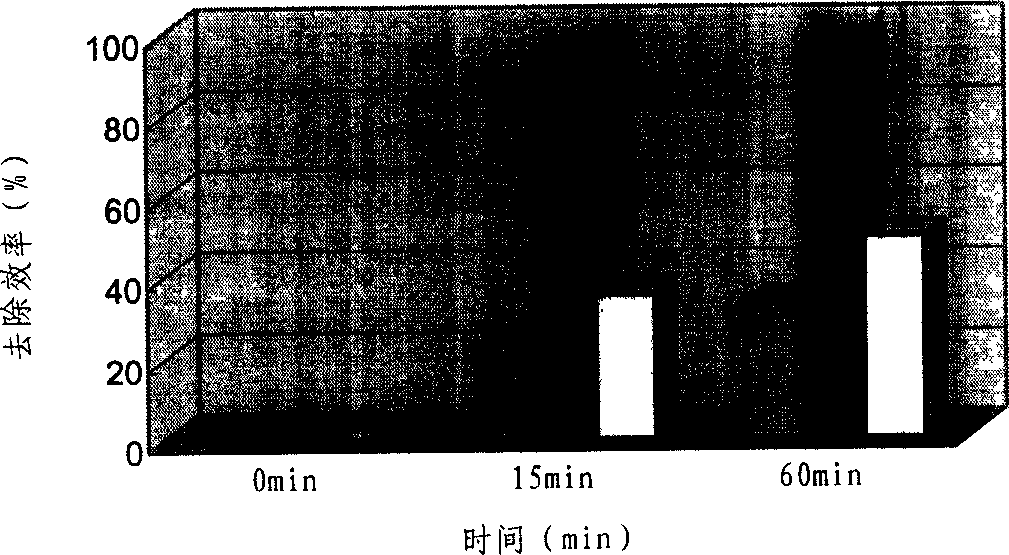

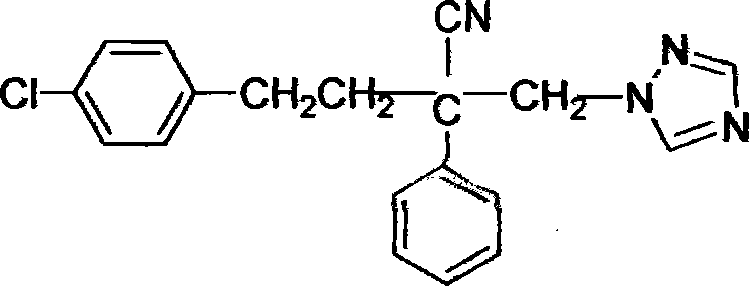

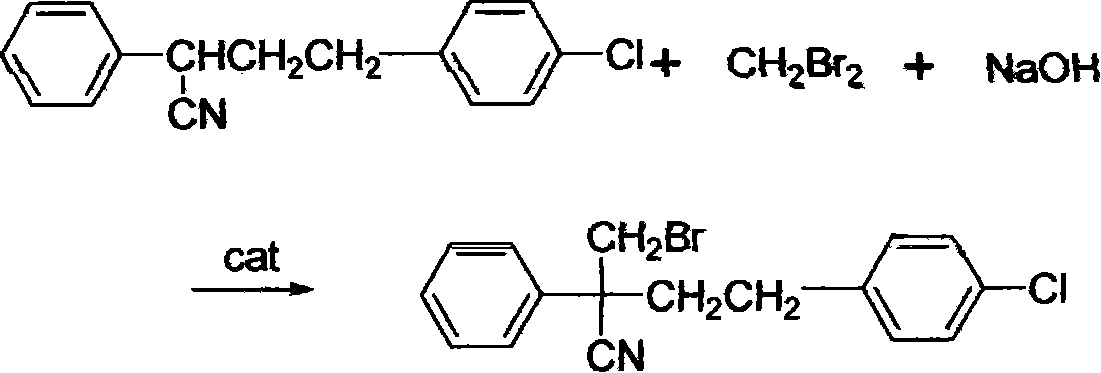

Method for preparing 2-bromomethyl-2-phenyl-4-(4-chlorophenyl)-butyronitrile

The invention relates to a 2-bromomethyl-2-phenyl-4-(4-chlorophenyl)-butyronitrile preparation method, which takes 2-phenyl-4-(4-chlorophenyl)-butyronitrile and dibromomethane as raw materials and sodium hydroxide as an acid binding agent, and the invention is characterized in that the reaction is processed with the existing of catalyst until the 2-phenyl-4-(4-chlorophenyl)-butyronitrile is completely converted into 2-bromomethyl-2-phenyl-4-(4-chlorophenyl)-butyronitrile, and when the reaction finishes, the reactant obtained from the reaction is settled stationarily and layered, after the alkali liquid layer is separated, the acquired liquid is 2-bromomethyl-2- phenyl-4-(4-chlorophenyl)-butyronitrile which can be used as the intermediate of nitrile benzenezole which is an agricultural fungicide. Application of solvent of dimethyl sulfoxide and extraction solvent of 1, 2-dichloroethane are avoided in the method, thereby reducing the cost, decreasing pollution and discharge of sewage and shortening the process, and the preparation method is environmental friendly, with prominent economic benefit.

Owner:JIANGSU FENGDENG PESTICIDE

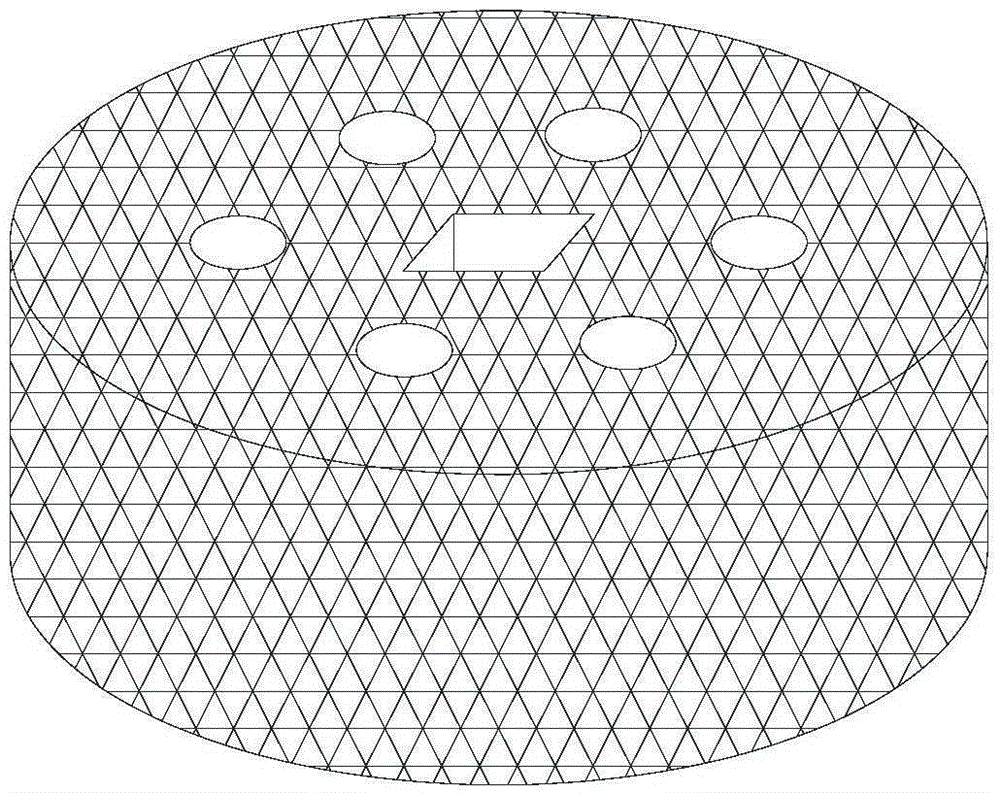

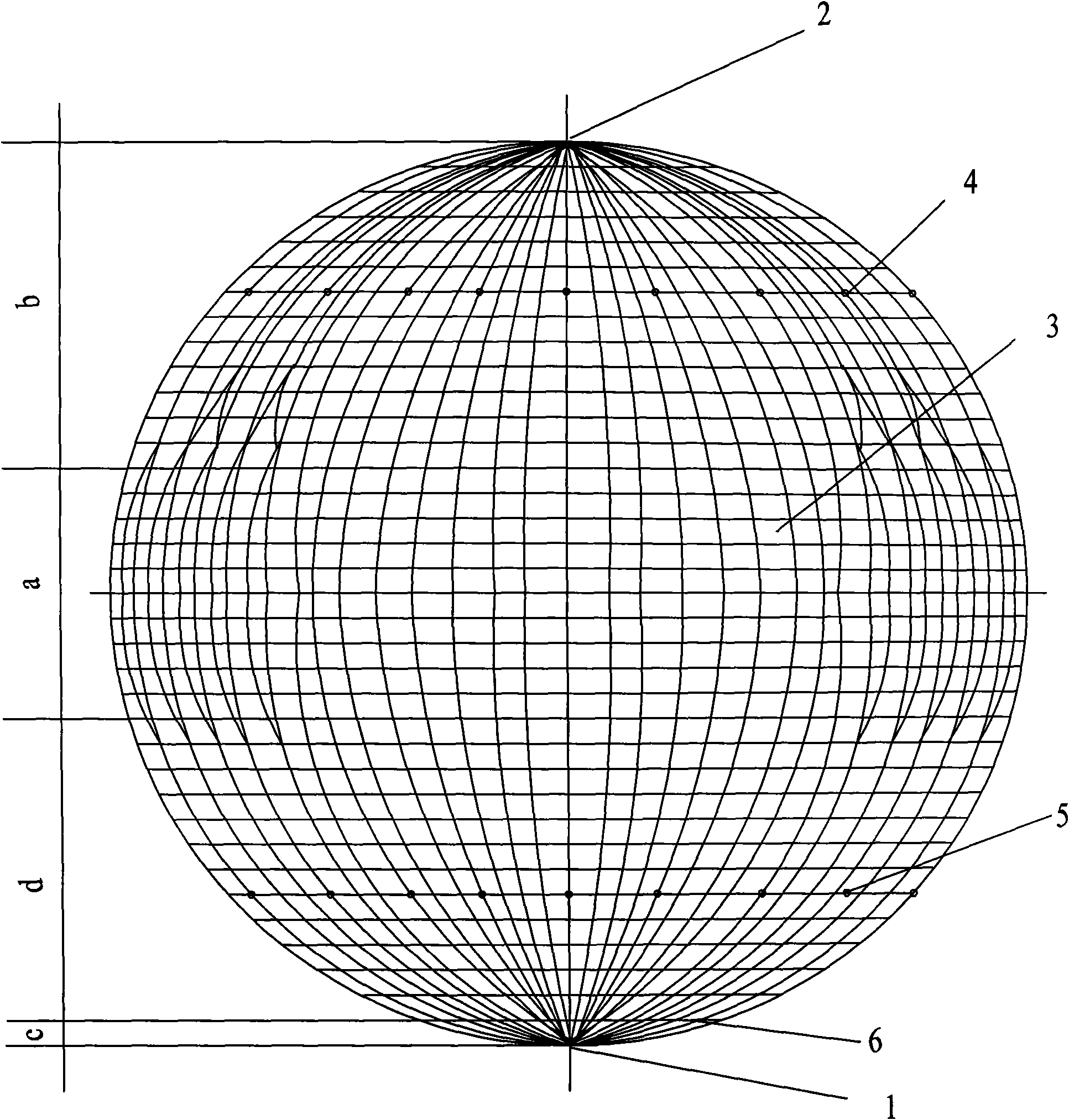

Round knitting liner sleeve for balls

The invention relates to a liner sleeve for ball sports facilities, in particular to a round knitting liner sleeve for balls. According to the scheme of the invention, the round knitting liner sleeve is characterized in that, the liner sleeve is integrally knitted into a sphere from yarn by a circular knitting machine; an annular plain knitted zone is formed near the equator of the liner sleeve; an annular and reducing narrowing zone is formed on one side corresponding to the plain knitted zone near the north pole; an annular and enlarging zone is formed on one side corresponding to the plain knitted zone near the south pole; a narrowing point is formed on the north pole of the liner sleeve, an increasing point is formed on the south pole of the liner sleeve, and fine meshes are densely distributed on the liner sleeve. The invention is capable of increasing the production efficiency and the product quality.

Owner:WUXI KAQI TEXTILE

Synthesizing process of 4-methoxy-alpha-[(3-methoxyphenyl)sulfo]-acetophenone

The invention relates to a synthesizing process of 4-methoxy-alpha-[(3-methoxyphenyl)sulfo]-acetophenone, belonging to the synthesizing technique of medical intermediates. The synthesizing process comprises the following steps of dissolving alpha-bromo-4-methoxyphenyl-acetophenone in ethanol, and obtaining the 4-methoxy-alpha-[(3-methoxyphenyl)sulfo]-acetophenone by adding the mixed liquid of potassium hydroxide solution and 3-methoxy-thiophenol ethanol solution. The invention has the advantages of convenient operation, low cost, high purity and high yield rate.

Owner:SHANDONG XINHUA PHARMA CO LTD

Thickness adjustable side formwork for pavement paving

InactiveCN103437266ASave raw material costReduce the amount of construction workRoads maintainenceRaw materialAsphalt concrete

The invention relates to a thickness adjustable side formwork for pavement paving, which belongs to the technical field of asphalt concrete pavement construction template equipment and is used for carrying out template supporting on the edge of a paved pavement. The invention adopts the technical scheme that the thickness adjustable side formwork comprises a formwork body, a fixing mechanism, a thickness adjusting mechanism and a side formwork clamp, wherein the formwork body is long strip-shaped and comprises an upper top plate, a connecting plate and a bottom plate; the fixing mechanism is connected to the bottom surface of the bottom plate; the fixing mechanism is connected and fixed with the ground; the thickness adjusting mechanism is positioned inside the formwork body and respectively connected with the lower surface of the upper top plate and the upper surface of the bottom plate. According to the invention, a neat edge part can be directly formed during the process of pavement paving, so that the edge part cutting operation is omitted, the raw material cost, processing cost and transport cost of asphalt concrete can be reduced, the construction quantity is reduced, the construction period is shortened and the cost is reduced. The thickness adjustable side formwork is scientifically and reasonably designed, fills up gaps at home and abroad, has a high practical value, is novel equipment of an edge part forming template facility in the asphalt concrete pavement construction and can be widely popularized and used in the industry.

Owner:SHIJIAZHUANG CHENQI TECH

Various cohesiveness magnetic pad composition and making method thereof

InactiveCN1385866ANoise isolationImprove vibration damping effectMagnetic materialsBuilding insulationsMagnetic dampingBromine

PURPOSE: Provided are a magnetic pad composition which shows various adhesion functions according to position to be applied, and a method for producing the same. CONSTITUTION: The magnetic pad composition comprises 18-27 wt% of blown asphalt, 45-65 wt% of bromine-based magnetite, 3-10 wt% of mica, 1-5 wt% of synthetic rubber based on nitrile butadiene rubber, 1-5 wt% of petroleum based adhesive resin, and 0.3-4 wt% of cellulose fiber. The method for producing the composition comprises the steps of (i) incorporating the magnetic damping sheet composition consisting of the components into magnetic pad, and (ii) extruding the pad comprising the composition.

Owner:HYUNDAI MOTOR CO LTD +1

Manufacturing method of large-diameter cylinder prefabricated body

PendingCN114013121AGuaranteed stabilityGuaranteed sturdinessLinings repairLayered productsFiberCarbon fibers

The invention discloses a manufacturing method of a large-diameter cylinder prefabricated body. The manufacturing method comprises the following steps: 1, preparing a special mold for the prefabricated body; 2, preparing a cylinder inner wall woven carbon cloth / net tire composite material needling unit layer; 3, preparing a first carbon fiber prepreg cloth isolation layer; 4, preparing a net tire / carbon fiber circulating unit layer; 5, preparing a second carbon fiber prepreg cloth isolation layer; 6, preparing a cylinder outer wall woven carbon cloth / net tire composite material needling unit layer; and 7, preparing a flange woven carbon cloth / net tire composite material needled layer to obtain a large-diameter cylinder prefabricated body with the diameter larger than 3 m. The annular sandwich design is adopted, a core heat insulation layer is wrapped, mechanical supporting of the prefabricated body in a furnace is achieved, the stability and firmness of the overall structure are guaranteed, the annular sandwich area is a low-density area and has excellent low-heat-conductivity performance and heat insulation effect, compared with a pure C / C prefabricated body structure, heat loss is greatly reduced, and the method is energy-saving, environment-friendly and extremely economical.

Owner:XIAN KANGBEN MATERIAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Synthesizing process of 4-methoxy-alpha-[(3-methoxyphenyl)sulfo]-acetophenone Synthesizing process of 4-methoxy-alpha-[(3-methoxyphenyl)sulfo]-acetophenone](https://images-eureka.patsnap.com/patent_img/8286e6ff-80a7-4927-9bd1-cbf59f7a37c9/GSA00000071259100011.PNG)