Refrigerator door and processing method thereof

A processing method and technology for freezer doors, which are used in lighting and heating equipment, household appliances, household refrigeration devices, etc., can solve problems such as unsightly, unsightly, and uncomfortable freezer doors, save raw materials and labor costs, and have a beautiful appearance. , the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Below in conjunction with accompanying drawing, the present invention is described in detail

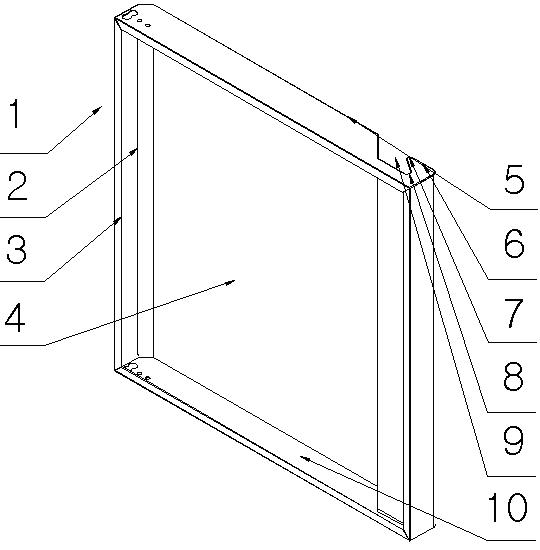

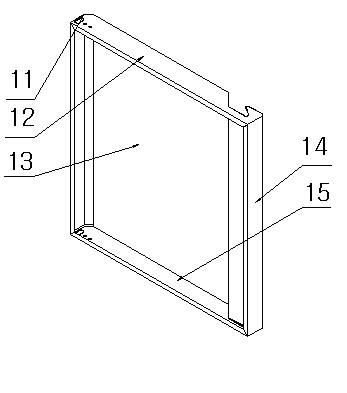

[0039] Such as Figure 1-3 Shown is a structural schematic diagram of a door outer panel 1 of a freezer door, which is formed by punching, bending and welding a whole sheet of stainless steel uncoiled material. The door outer panel 1 is composed of a visible surface 4, a door handle 6 located at the front end of the visible surface, a door edge 2 located at the rear end of the visible surface, a door upper side head 5 and a door lower side head 10 located at the visible surface and the lower end .

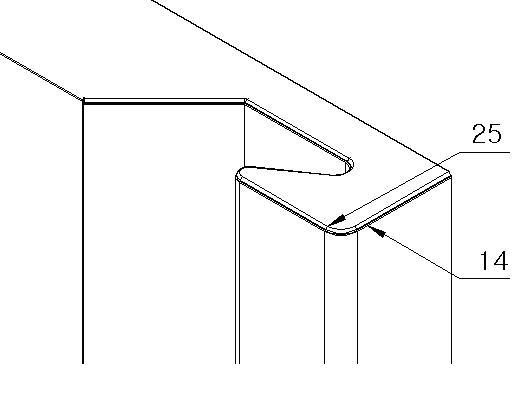

[0040] The door handle is provided with a longitudinal inward recessed groove 9, the outside of the groove 9 is the door handle outer handle 7, and the inner side is the door handle inner handle 8, the door handle outer handle and the door handle inner The angles of the clasping hands are respectively 35 degrees, and the radius of the arc chamfer at the end is 8mm. The outer han...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com