Round knitting liner sleeve for balls

A technology for gall sleeves and balls, applied in balls, knitting, weft knitting, etc., can solve the problems of labor-intensive and time-consuming, unstable quality and roundness, and achieve the effect of saving raw material costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

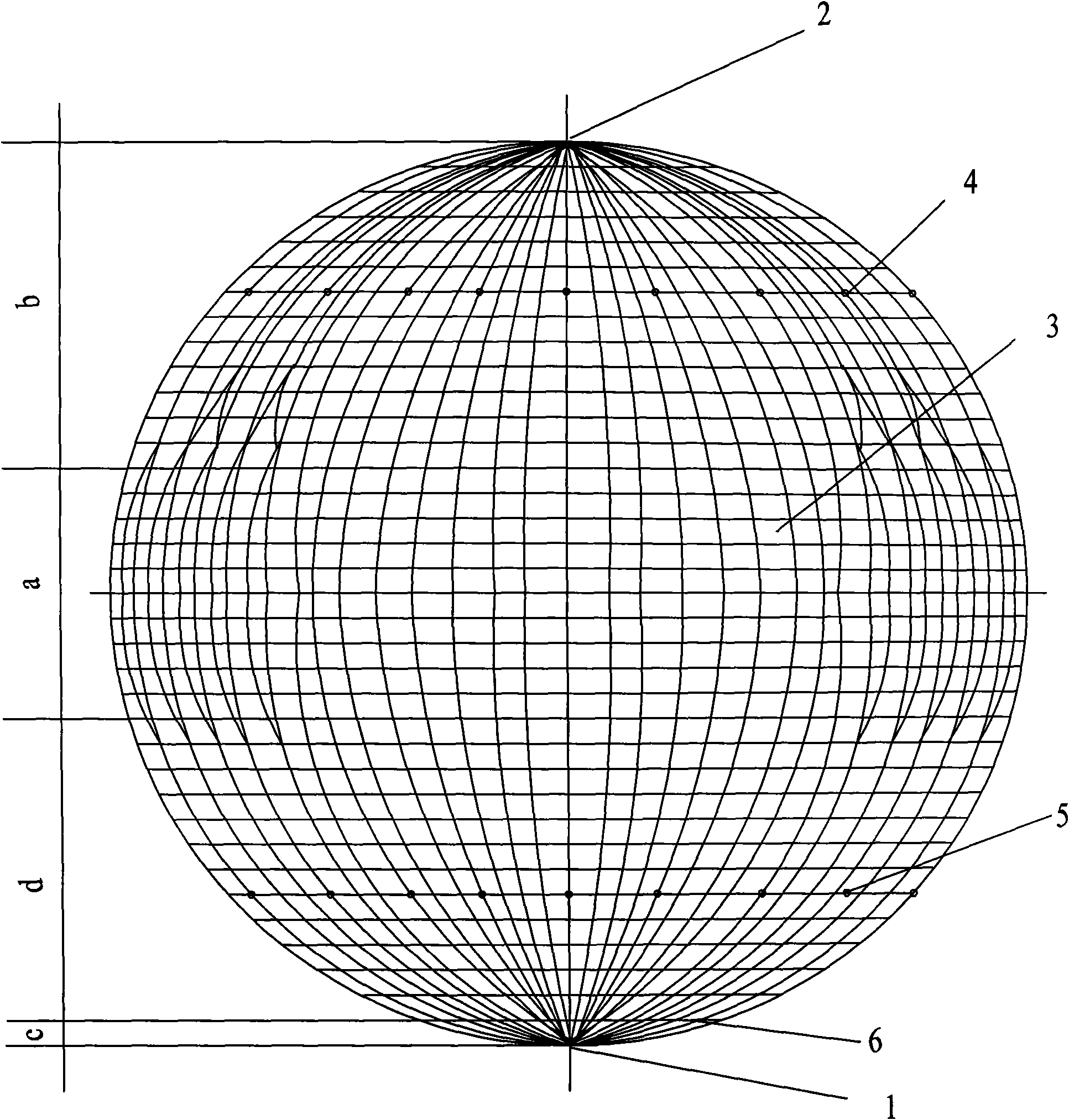

[0020] As shown in the figure: the sleeve is integrally woven into a spherical shape with yarn on a circular knitting machine; an annular flat needle area a is formed near the equator of the sleeve;

[0021] An annular gradually shrinking needle narrowing area b is formed on the side close to the north pole relative to the flat needle area a, and a gradually enlarged annular needle widening area d is formed on the side close to the south pole relative to the flat needle area a; The north pole of the sleeve forms the narrowing point 2, and the south pole of the sleeve forms the starting point 1, and the sleeve is densely covered with fine meshes 3 formed during the knitting process of the knitted product jersey fabric.

[0022] The yarns include T / C83 / 17, T / C85 / 15, T / C50S / 3 strands, T / C32S / 2 strands or T / C16S / 2 strands.

[0023] The method for weaving the ball full-circle knitted sleeve is characterized in that:

[0024] First use the yarn to form the starting point 1 on the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com