Thickness adjustable side formwork for pavement paving

An adjustable, side-form technology, applied in roads, roads, buildings, etc., can solve the problems of wasting asphalt concrete material costs, processing costs and transportation costs, burdening edge cutting costs, increasing construction workload, etc., to reduce construction work. The effect of the workload, saving the cost of raw materials, and shortening the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

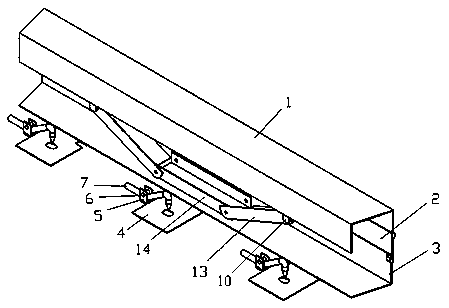

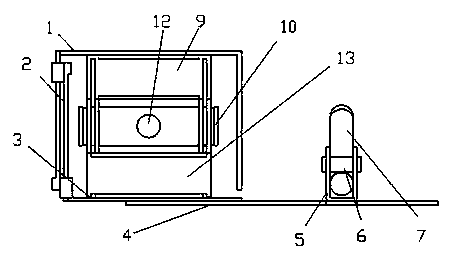

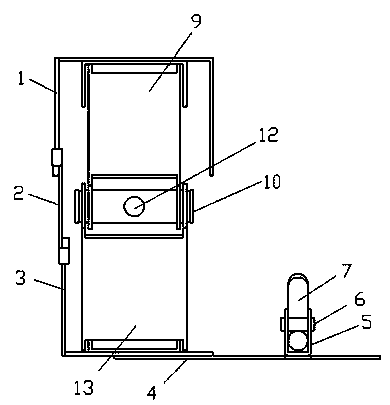

[0028] The invention includes a mold body, a fixing mechanism and a thickness adjusting mechanism.

[0029] Shown among the figure, mold body is made up of upper top plate 1, base plate 3 and connecting plate 2, and the mold body that upper top plate 1, base plate 3 and connecting plate 2 are formed is strip shape, and the mold body two ends become wedge-shaped or square. The upper top plate 1 is an inverted U-shaped plate, the bottom plate 3 is an L-shaped plate, and the connecting plate 2 is a vertical flat plate. The upper and lower ends of the two sides of the connecting plate 2 have relative barbs 15 respectively. The inner side is embedded in the barb 15 on the outer upper end of the connecting plate 2, the L-shaped outer surface of the bottom plate 3 is embedded in the barb 15 on the inner lower end of the connecting plate 2, and the upper top plate 1 is embedded in the inverted hook of the connecting plate 2. The bottom of the inner surface among the hook 15 has a limi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com