Production device for preparation of isooctane by isobutane and butene alkylation reaction

A technology for an alkylation reactor and a production device, which is applied in the fields of organic chemistry, hydrocarbons, hydrocarbons, etc., can solve the problems of inability to guarantee the design ratio of isobutane, waste of resources, environmental pollution, etc., and achieve energy saving The effect of consumption, saving resources and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

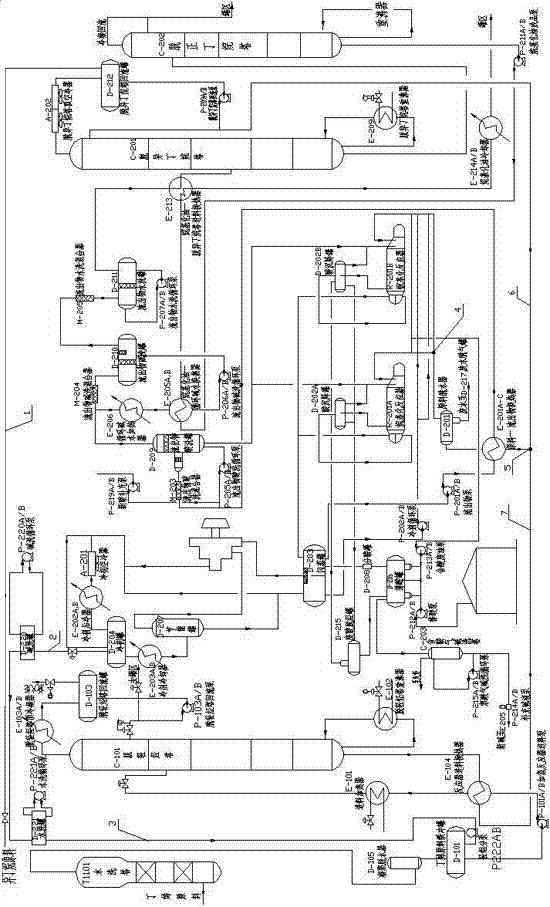

[0025] As shown in the figure, a production device for preparing isooctane by the reaction of isobutane and butene includes a raw material dehydrator D201, a raw material-effluent heat exchanger E201AC, and a raw material-effluent heat exchanger connected to the feed end of the alkylation reactor in sequence. Reactor feed heat exchanger E104, light hydrocarbon removal tower C101, butene feed heater E101, butene feed buffer tank D101;

[0026] It also includes the flash tank D203, the effluent pickling tank D209, the effluent alkali washing tank D210, the effluent washing tank D211, and the feedstock of the alkylation oil-removing isobutane tower, which are sequentially connected to the discharge end of the alkylation reactor. Heat exchanger E213, de-isobutane tower C201, de-n-butane tower C202, heat exchanger, n-butane product oil tank; among them, the upper part of the de-isobutane tower C201 is connected to the back-flow tank D212 of the de-isobutane tower. The butane tower ref...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com