Concentrated garment washing solution and preparation method

A technology for laundry detergent and parts by mass is applied in chemical instruments and methods, detergent compounding agents, detergent compositions, etc., to achieve the effects of high economic and social benefits, solution of dissolution problems, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The preparation method of concentrated laundry detergent described in the application comprises the steps:

[0032] (The production process is all produced at room temperature, no heating is required, the stirring speed is set according to the different reactor equipment, and the ultimate goal is to completely stir and dissolve the raw materials)

[0033] 1. Take the deionized water according to a certain mass ratio, add it to the chemical material kettle, and then add anionic surfactant, isomeric alcohol ether surfactant, nonionic surfactant, and amphoteric surfactant in sequence according to a certain mass ratio. The ionic surfactant is stirred until completely dissolved to obtain a mixed solution A;

[0034] 2. Add benzisothiazolinone, essence, and deionized water to the mixed solution A according to a certain mass ratio, and stir evenly to obtain a mixed solution B;

[0035] 3. Add biological enzymes to the mixed solution B according to a certain mass ratio, and st...

Embodiment 1

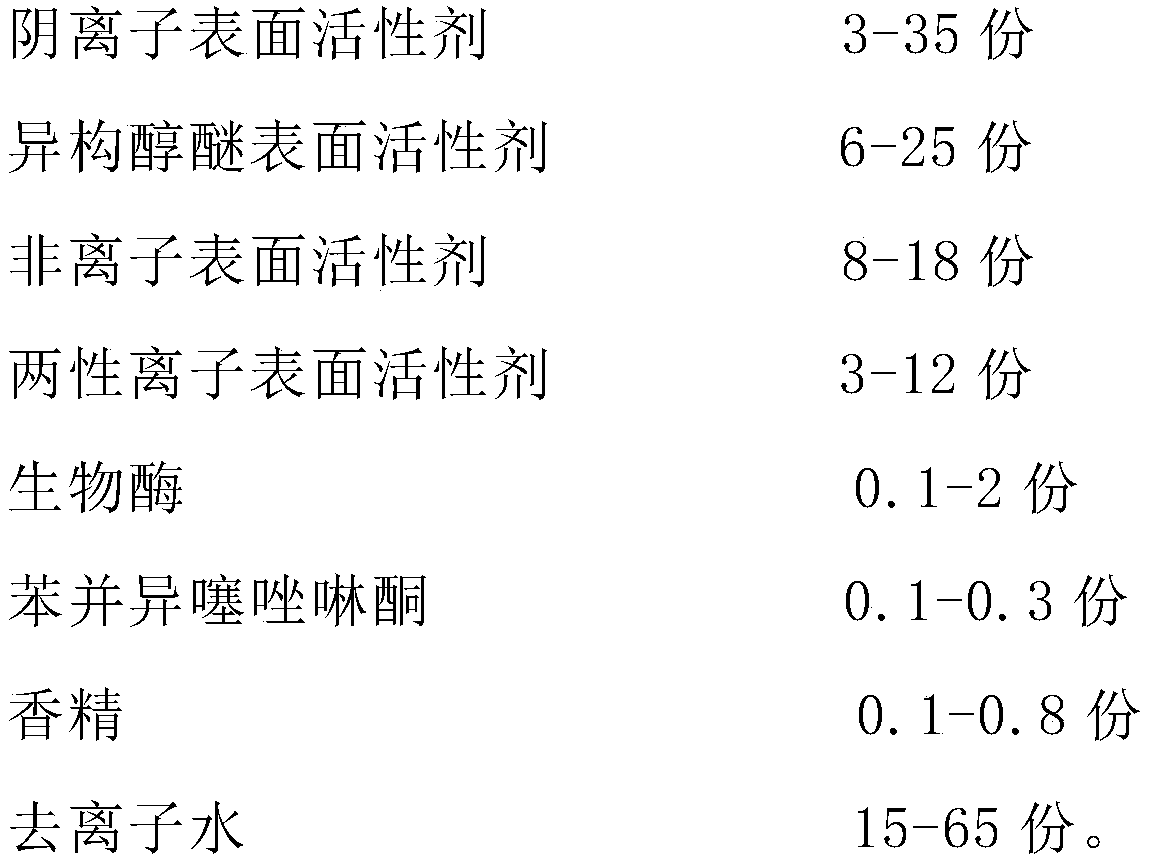

[0039] A solvent-free enzyme-added low-foam concentrated laundry detergent, comprising the following components and parts by mass:

[0040]

[0041] The detergency of the detergent of this embodiment is measured according to the test conditions of GB / T13174: the concentration of standard laundry detergent is 2‰, after the sample concentration is diluted 3 times and 4 times respectively, and then washed by 2‰ aqueous solution, the washing results are as follows:

[0042]

[0043] The foam measurement of the detergent of the present embodiment is by the standard method stipulated by the state: Roche method; 2‰ aqueous solution to measure the foam, the washing results are as follows:

[0044]

Embodiment 2

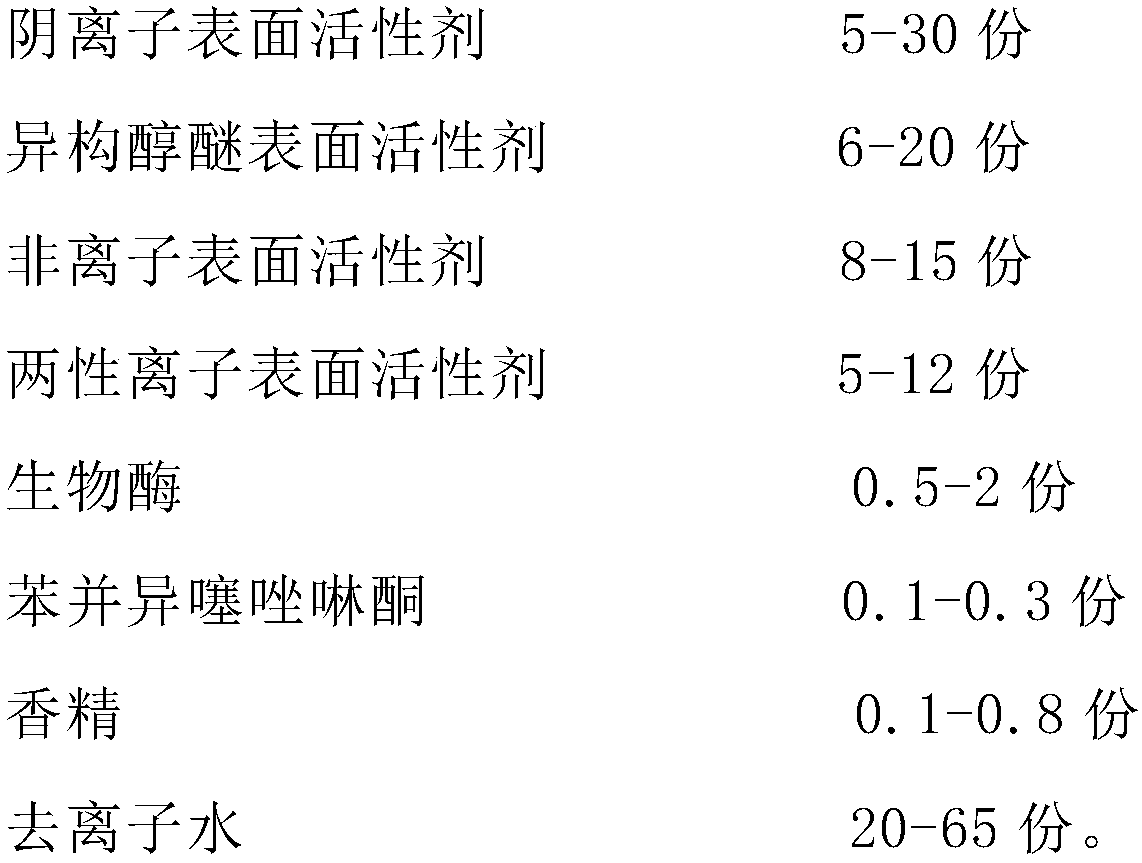

[0046] A solvent-free enzyme-added low-foam concentrated laundry detergent, comprising the following components and parts by mass:

[0047]

[0048]The detergency of the detergent of this embodiment is measured according to the test conditions of GB / T13174: the concentration of standard laundry detergent is 2‰, after the sample concentration is diluted 3 times and 4 times respectively, and then washed by 2‰ aqueous solution, the washing results are as follows:

[0049]

[0050] The foam measurement of the detergent of the present embodiment is by the standard method stipulated by the state: Roche method; 2‰ aqueous solution to measure the foam, the washing results are as follows:

[0051]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com