Scrap-free machining technology and device for lift truck scissor arm material

A technology of processing technology and processing equipment, applied in the direction of metal processing equipment, forming tools, manufacturing tools, etc., can solve the problems of not being able to adapt to mass production, the efficiency cannot be compared with mold production, and high consumables

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

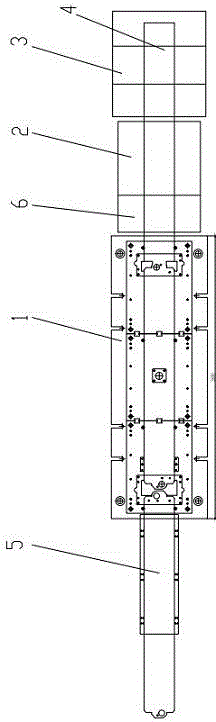

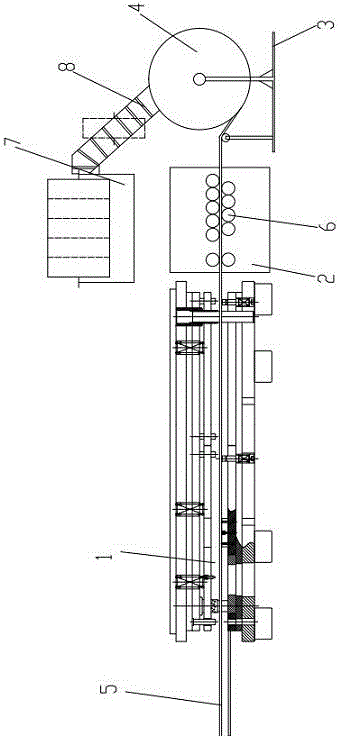

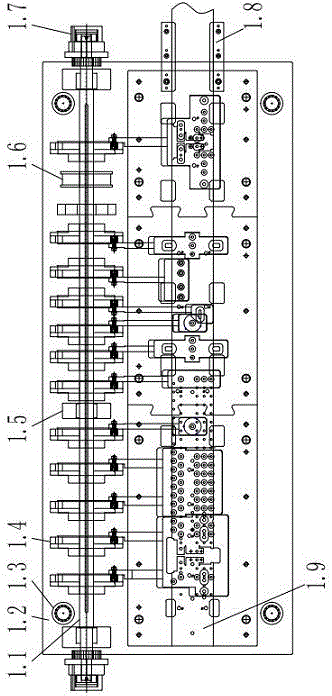

[0023] The invention specifically relates to a process and a processing device for processing scissor arms of a scissor arm without edge material. The process cooperates with the processing device to improve the product quality and production efficiency of the scissor arm of the lift truck before bending, and can greatly save materials.

[0024] For the scissor arm of the lift truck, the length of the front sheet is 2100mm, the width is 277mm, and the thickness is 3.0mm. The material is hot-rolled steel plate Q460-590C. The processing technology is as follows:

[0025] 1. Separating and cutting to length: Use the cutting machine 7 to cut the coiled material products entering the factory into rolls and cut to length to form a fixed-length coil with a width of 277mm, and position the two ends of the fixed-to-length coil 4 On the material frame 3, the support to the length coil material 4 is realized, and the length coil material 4 can be rotated and fed.

[0026] 2. Feeding: The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com