Staggering discharging device of adjusting box

A technology of discharging device and adjusting box is applied in the field of dislocation discharging device of adjusting box and discharging device of adjusting box of infusion set, which can solve the problems of increasing raw materials for manufacturers, production cost, large volume of feeding device and complicated structure, etc. , to achieve the effect of saving raw materials and production costs, smooth operation, and accurate positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

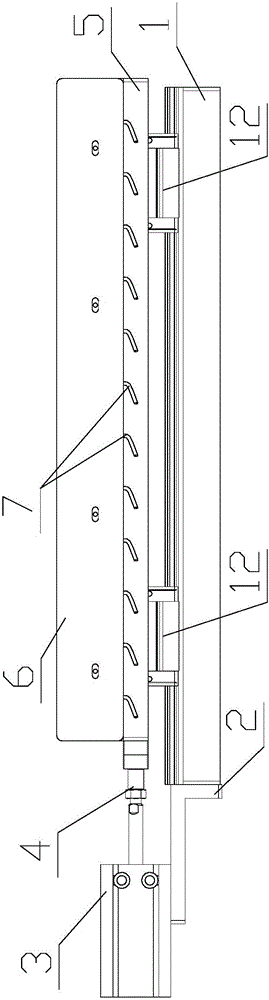

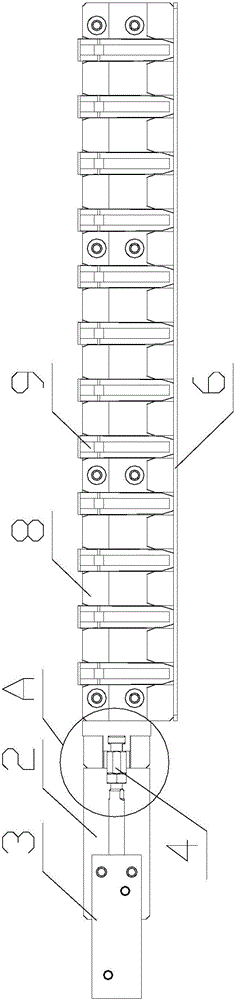

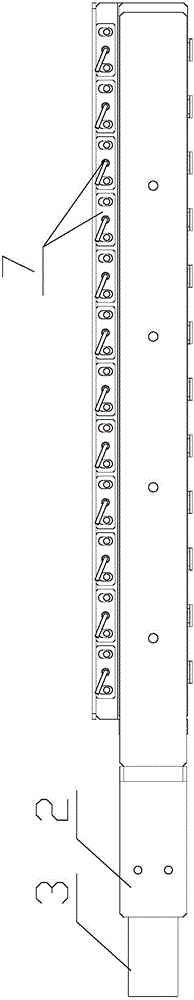

[0037] Embodiment: a kind of adjustment box misalignment discharging device, such as Figure 1~6 As shown, the guide rail installation plate 1 is included, the guide rail installation plate 1 is cuboid, the cylinder 3 installation plate 2 is fixed on the guide rail installation plate 1, and the cylinder 3 installation plate 2 is fixed on one of the end faces of the guide rail installation plate 1 with the smallest area. The cylinder 3 mounting plate 2 is L-shaped, the width of the cylinder 3 mounting plate 2 is consistent with the guide rail mounting plate 1, the shorter side of the cylinder 3 mounting plate 2 is fixed with the cylinder 3 mounting plate 2, and the cylinder 3 mounting plate 2 is installed for The height of the horizontal plane where the cylinder 3 is installed is higher than the height of the horizontal plane for installing the linear guide rail 10 on the guide rail mounting plate 1; as figure 1 As shown, a cylinder 3 is fixed on the mounting plate 2 of the cyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com