Composition of keeping ice house and horticulture production fresh and its manufacturing technics

A manufacturing process and a technology for horticultural products, which are applied in the field of compositions for maintaining the freshness of cold storage and horticultural products and their manufacturing processes, and can solve problems such as dust in formability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

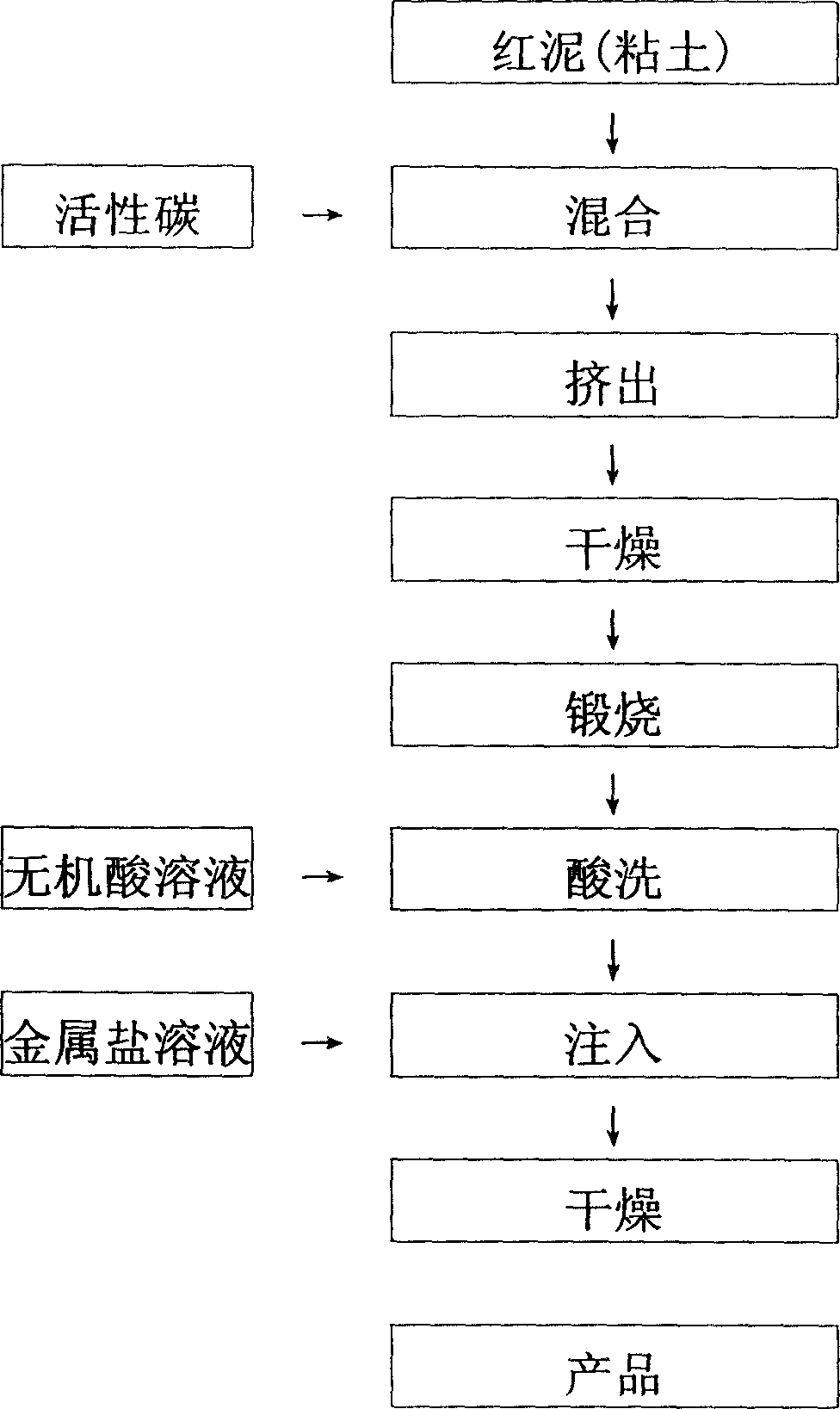

Method used

Image

Examples

example 1

[0043] The moisture content of by-product red mud (moisture content 40% by weight (weight), solid basis 6.0kg) and activated carbon powder (below 200 orders, 4.0kg) is adjusted to 35% by weight and then put into a kneading mixer, After mixing at 80 rpm for 30 minutes, shape was formed with 5mm die extruder.

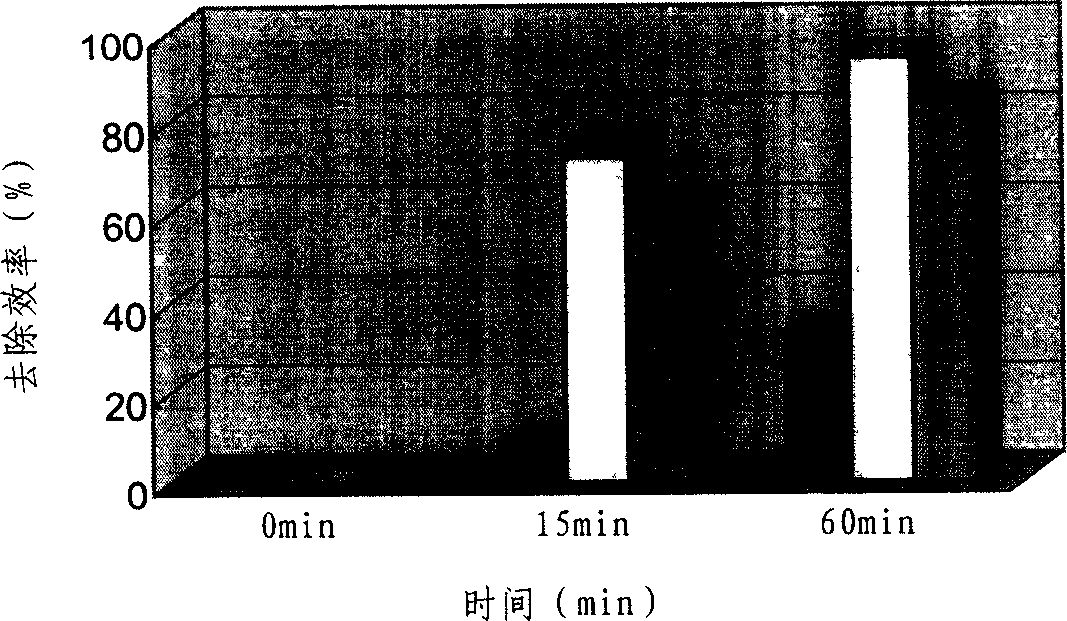

[0044] Put the extruded shaped body into a drier, dry it at 105°C for 2 hours, and after calcining it at 950°C for 2 hours, put the calcined object (9.5kg) into 5% by weight hydrochloric acid solution (45 liters ) for 2 hours, the temperature was 60°C, then the shaped body and the solution were separated, and the shaped body was washed with 100 liters of water, followed by injecting 10% by weight ferric chloride solution for 4 hours with a solid basis of 1:1 under the condition of maintaining 40°C. The solid and the solution were separated, washed with drained water, and finally dried in a fluidized bed dryer at 90°C for 4 hours to obtain 18.5 kg of shaped bodies.

example 2

[0046] The moisture content of by-product red mud (moisture content 40% by weight (weight), solid basis 6.2kg) and activated carbon powder (below 200 orders, 4.3kg) is adjusted to 35% by weight and then put into a kneading mixer, After mixing at 80 rpm for 30 minutes, shape was formed with 5mm die extruder.

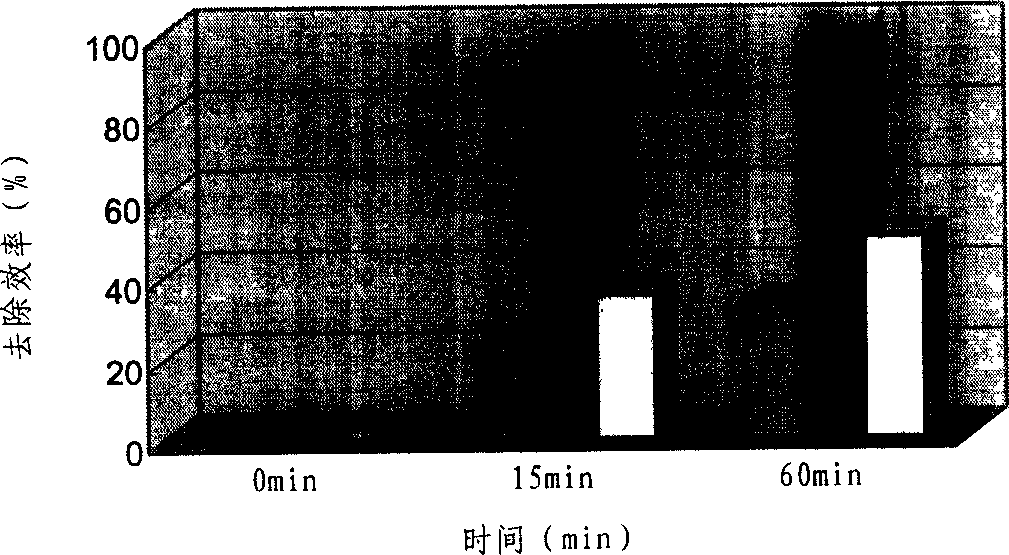

[0047] Put the extruded molded body into a drier, dry it at 105°C for 2 hours, and calcinate it at 950°C for 2 hours, then put the calcined object (9.9kg) into 5% by weight sulfuric acid solution (45 liters ) for 2 hours, the temperature was 60°C, and then the shaped body and the solution were separated, and the shaped body was washed with 100 liters of water, and then kept at 40°C with a 1:1 solid basis to inject 10% by weight copper sulfate solution for 4 hours. The solid and the solution were separated, washed with drained water, and finally dried in a fluidized bed dryer at 90°C for 4 hours to obtain 18.8 kg of shaped body.

example 3

[0049] The moisture content of by-product red mud (moisture content 40% by weight (weight), solid basis 6.0kg) and activated carbon powder (below 200 orders, 4.0kg) is adjusted to 35% by weight and then put into a kneading mixer, After mixing at 80 rpm for 30 minutes, shape was formed with 5mm die extruder.

[0050] After putting the extruded molded body into the drier, dry it at 105°C for 2 hours, and then calcined it at 950°C for 2 hours. liter) for 2 hours, the temperature was 60°C, then the shaped body and the solution were separated, the shaped body was washed with 100 liters of water, and then maintained at 40°C with a 1:1 solid basis to inject a 10% by weight lead sulfate solution for 4 hours. The solid and the solution were separated, washed with drained water, and finally dried in a fluidized bed dryer at 90°C for 4 hours to obtain 18.4 kg of shaped body.

[0051] differentiate

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com