Double-layer steel net mineral cotton perlite sandwich composite lightweight wall plate

A lightweight wallboard, perlite technology, applied in building components, buildings, building structures, etc., can solve problems affecting technical performance and safe service life, poor thermal insulation, sound absorption and sound insulation, transportation, construction difficulties, etc. problems, to achieve the effect of easy and fast handling and installation, good sound absorption performance, and good sound insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

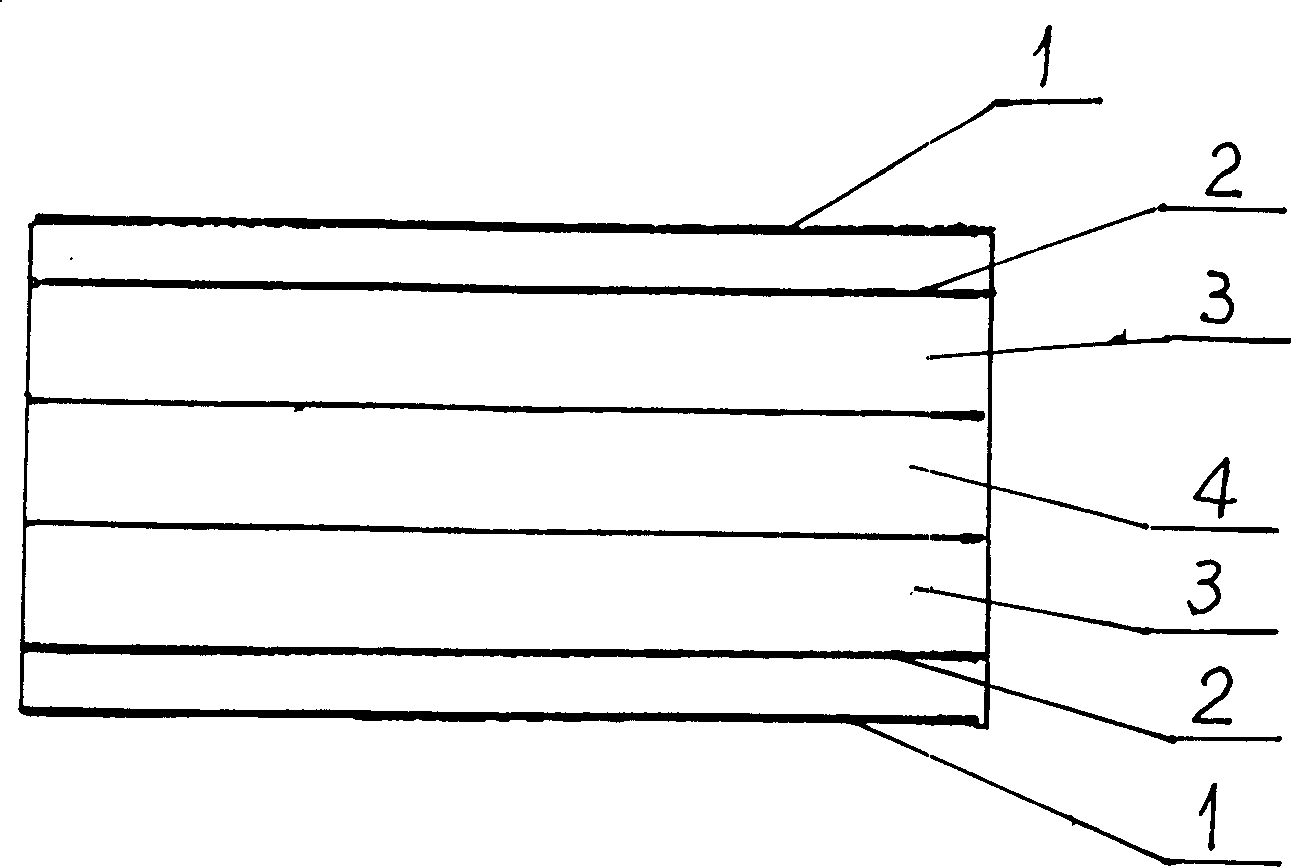

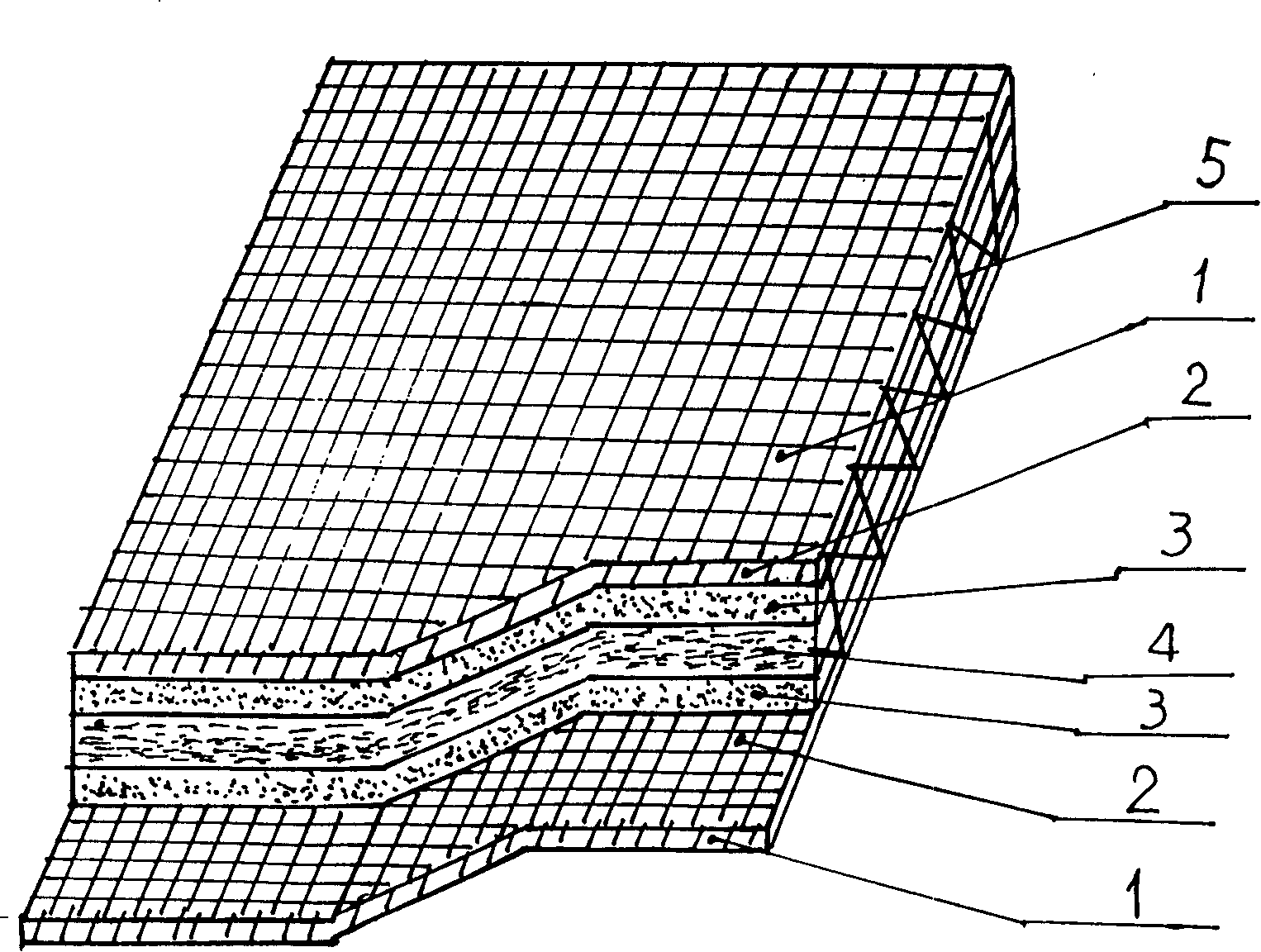

[0011] See figure 1 , figure 2 The upper and lower layers of this double-layer steel mesh mineral wool perlite sandwich composite lightweight wallboard are respectively double-layer steel mesh, one layer is φ2.0 galvanized steel mesh 1, and the other layer is φ1.5 Galvanized steel mesh 2, the middle core layer is composed of perlite slats 3, mineral wool slats 4, and perlite slats 3. The upper layer of double-layer steel mesh and the lower layer of double-layer steel mesh sandwich the composite middle core layer Tightly connect and fix it into the core board of the net frame. The upper and lower double-layer steel mesh sides are connected and fixed by galvanized steel wire welded into a V-shaped multifilament 5, and the upper and lower layers are sprayed with cement. The component formed after the mortar is the new wall.

PUM

| Property | Measurement | Unit |

|---|---|---|

| flame retardant | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com