Thormobend shaping method of rubber sealing strip for automobile door window and its mould

A technology of rubber sealing strips and glass woolen grooves, which can be applied to home appliances, other home appliances, applications, etc. It can solve the problems of color difference at the corners, wrinkles at the corners, and high design costs, so as to improve the pass rate and speed up the development cycle. , The effect of saving processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

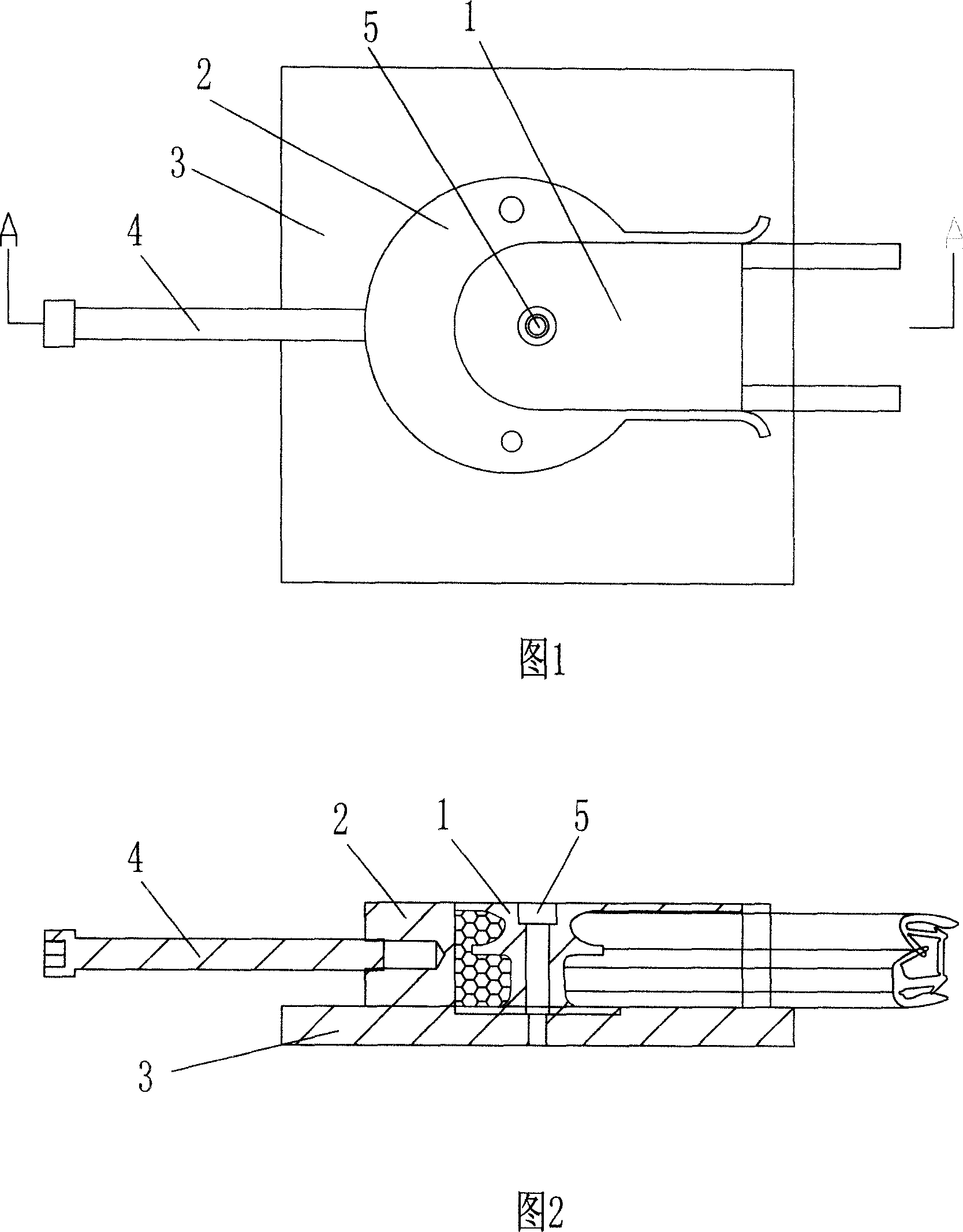

[0024] Below in conjunction with accompanying drawing, the present invention is further described, as shown in Fig. 1, Fig. 2:

[0025] A method for hot-bending forming of a glass woolen rubber sealing strip for automobile doors and windows, comprising the following steps:

[0026] a) Extrude, pull, vulcanize and cool at 280°C with a rubber extruder, and cut the rubber sealing strip with a vulcanization degree of 70% to 80% to the required length, and draw a line on the part to be bent;

[0027] b) Position the rubber sealing strip on the forming mold according to the marked position, heat to 240-260°C, and vulcanize for 4-8 minutes;

[0028] c) Open the mold, take out the rubber sealing strip, let it cool down naturally, and complete the hot-bending forming of the rubber sealing strip.

[0029] The scribed line in the described step a is to locate the scribed line by the model.

[0030] The heating in the step b is on a flat vulcanizing machine, pressurized, heated and vulc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com