Patents

Literature

54results about How to "Solving Quality Control Issues" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

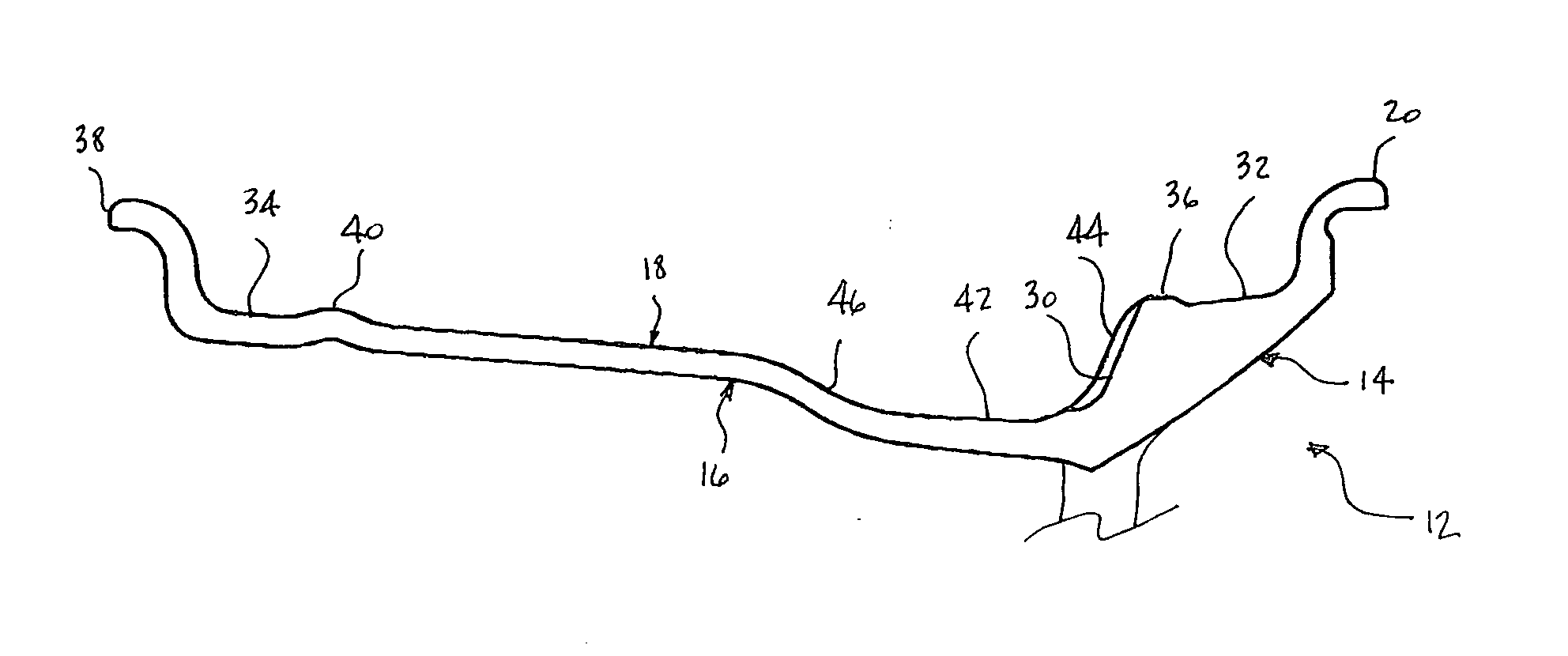

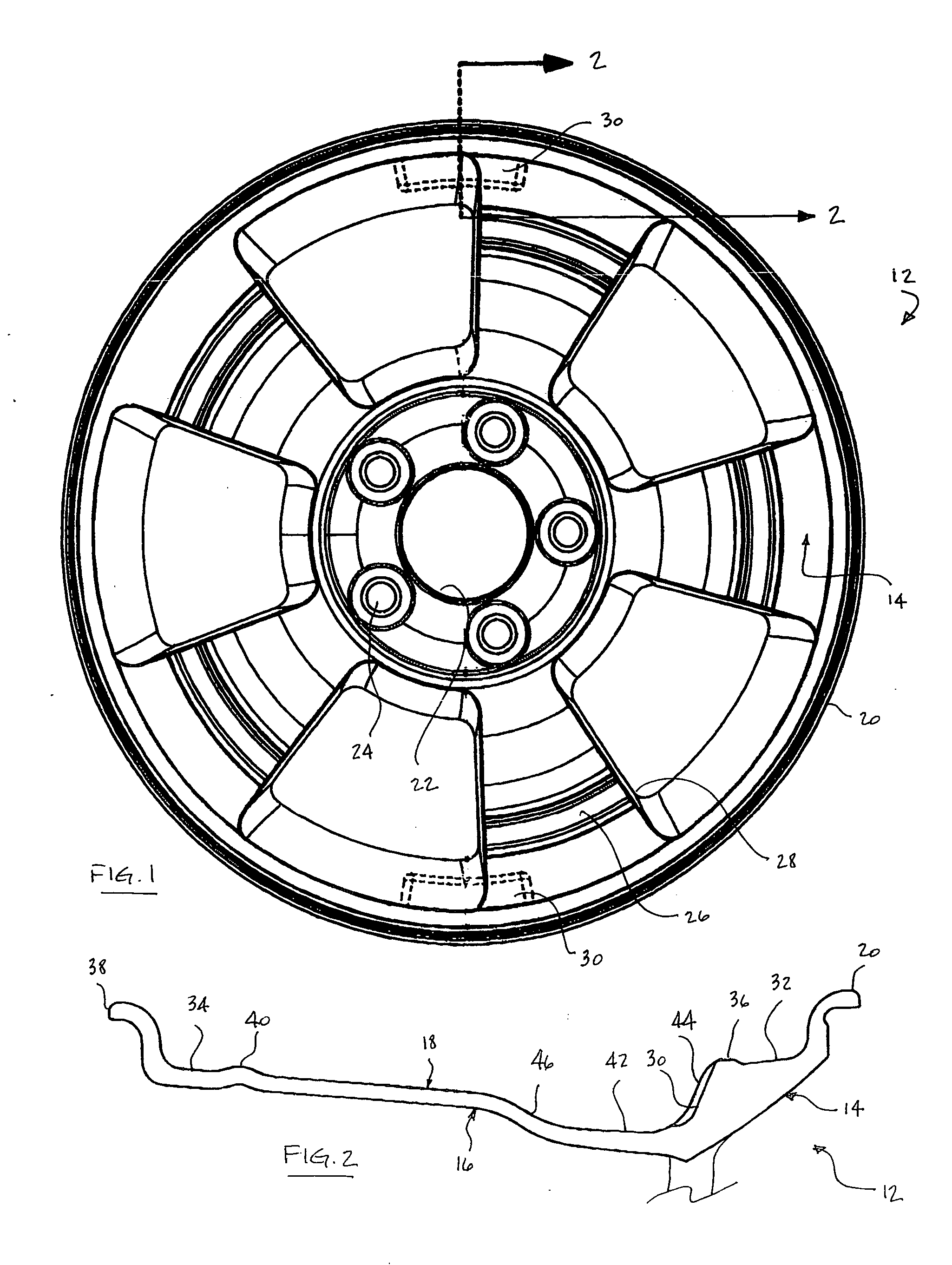

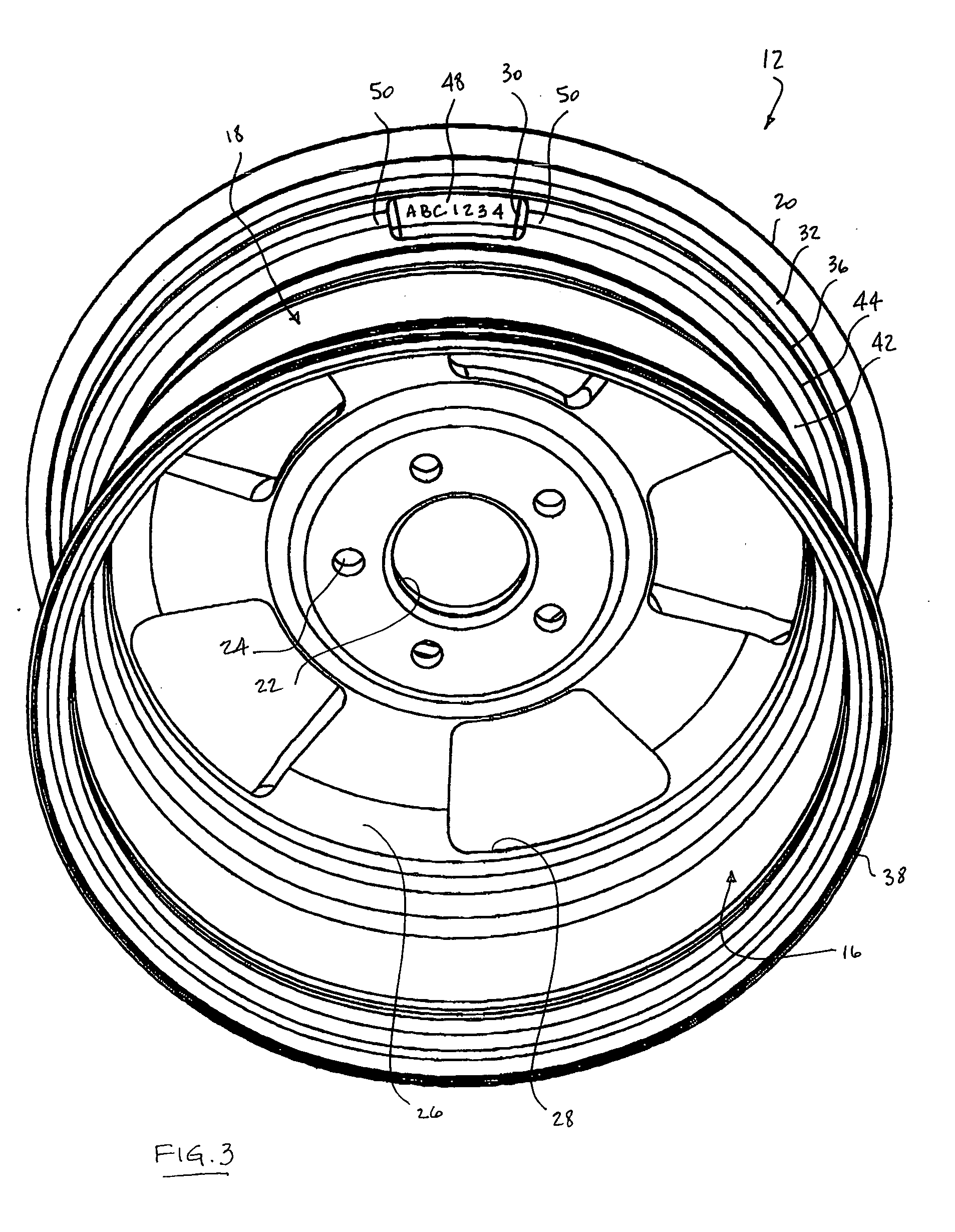

Wheel traceability system

InactiveUS20050285440A1Strict controlSolving Quality Control IssuesRimsDisc wheelsEngineeringMechanical engineering

An identifying mark is disposed in a cast-in recess that is formed in a raw casting that is subsequently transformed into an automotive roadwheel. The mark provides for a unique identification to thereby allow the progress of each wheel through its manufacturing process to be monitored and its manufacturing history to be memorialized. The same identifying mark may be relied upon by the auto manufacturer for similar purposes and by matching each wheel's ID to VIN of the vehicle to which it is mounted, the end user should remain traceable throughout the wheel's service life. The recess is positioned so as to protect the mark disposed therein during the manufacturing process as well during its end use.

Owner:SUPERIOR INDS INT

Cotton-like lining cloth and production process thereof

The invention relates to cotton-like lining cloth which is formed by blending viscose fibre / polyester staple fiber blended yarn serving as warp yarn and functional polyester filament serving as weft yarn, wherein the functional polyester filament can absorb and discharge moisture. In addition, a production process of the cotton-like lining cloth is further related. The production process includes the following steps: 1, warp yarn selection; 2 weft yarn selection; 3, weaving; 4, overflow desizing and bleaching processing or overflow desizing and bath dyeing processing; 5, dehydration; 6, scotching; 7, sizing; 8, coating calendaring; 9, perching volume classification; and 10, laboratory sample detection.

Owner:CPL NEW MATERIAL TECH CO LTD

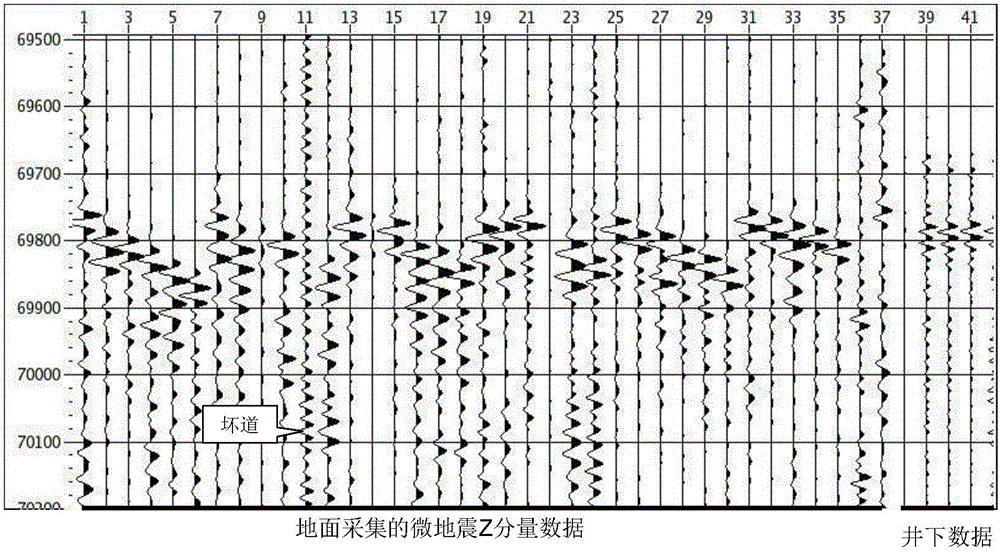

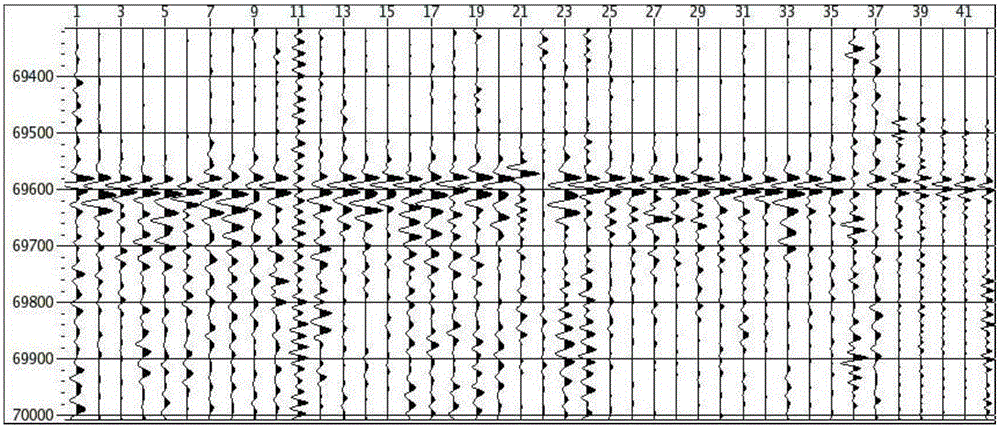

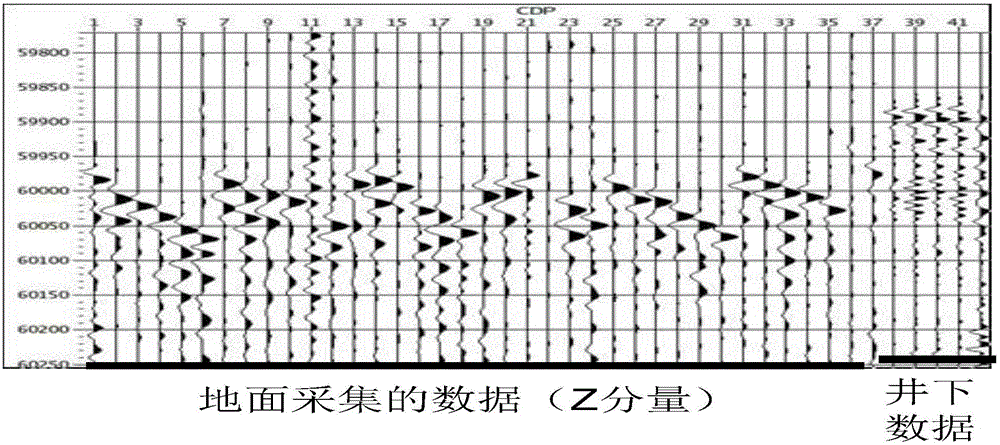

Quality control method for minor tremor positioning precision

ActiveCN105093297ASolving Quality Control IssuesSeismic signal processingNatural resourceNatural disaster

The invention belongs to the technical field of natural disasters, natural resources and environment prospecting, more particularly, to a quality control method for minor tremor positioning precision. The method comprises the following steps: marking positions according to a hypocentral location coordinate obtained from minor tremor monitoring and a measuring point coordinate; using given speed parameters and underground space structure information to obtain the travel time between the two; conducting NMO treatment on minor tremor signals to obtain a gather array after correction; taking the amplitude of sub-waves in a minor tremor before lamination as a benchmark to mark the amplitude of sub-waves after lamination. If the two are consistent, it proves that a good lamination effect has been achieved, or rather to say that a minor tremor has been precisely positioned. If not, it proves poor precision. The technical solutions of the method can effectively control the positioning precision of a minor tremor.

Owner:CHINA UNITED COALBED METHANE +1

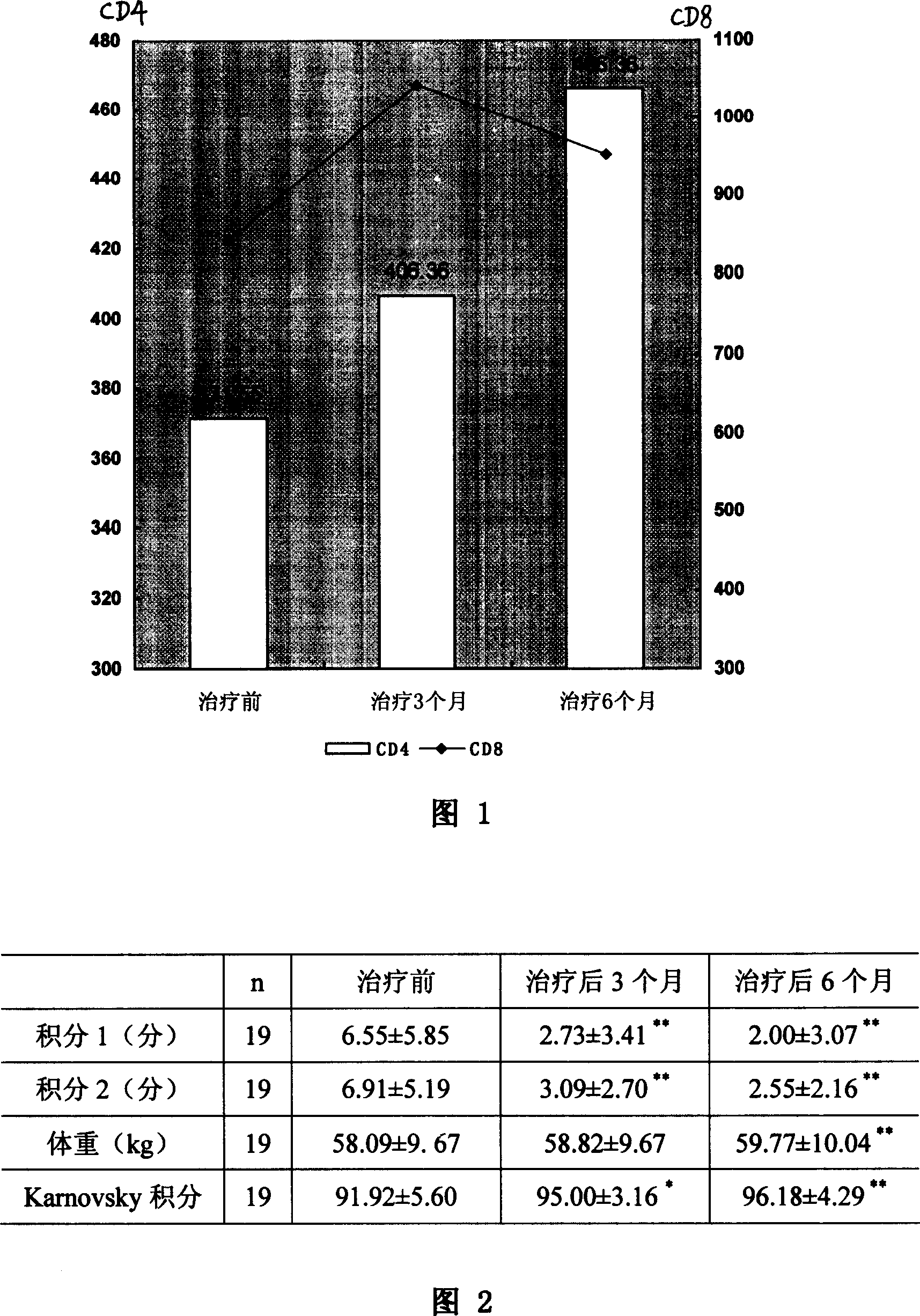

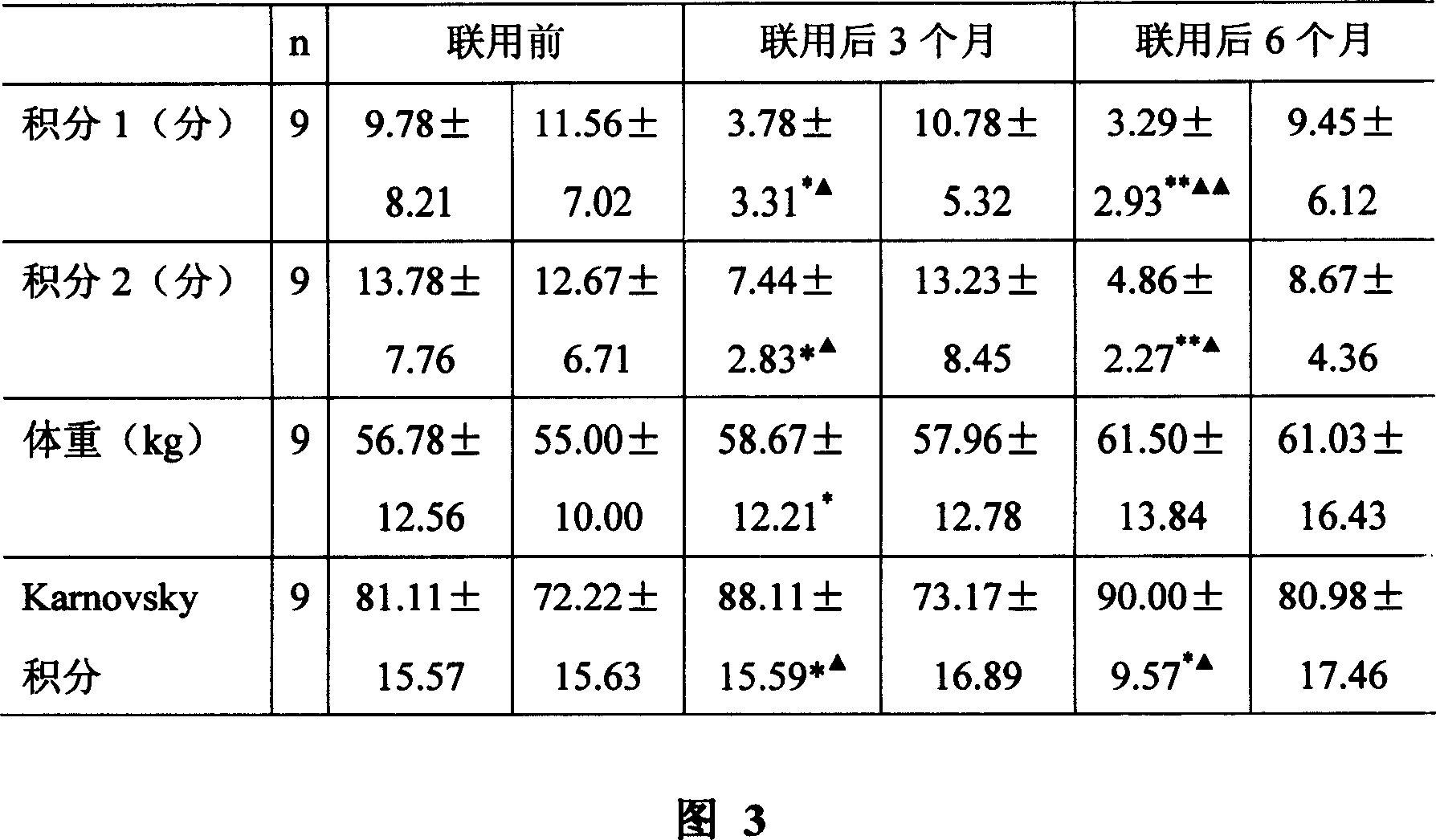

Medicine composition for preventing and treating AIDS and its prepn process and use

The present invention discloses one kind of medicine composition for preventing and treating AIDS and its preparation process and use. The medicine composition consists of active ingredient and auxiliary ingredient, and may be prepared into granule, tablet, capsule, oral liquid or injection. It has the functions of inhibiting the copying of HIV, promoting immunologic reconstruction of the AIDS patient, delaying disease and clinical complication, and synergizing and attenuating in high efficiency retrovirus resisting therapy. The present invention has wide application foreground.

Owner:广州中医药大学热带医学研究所

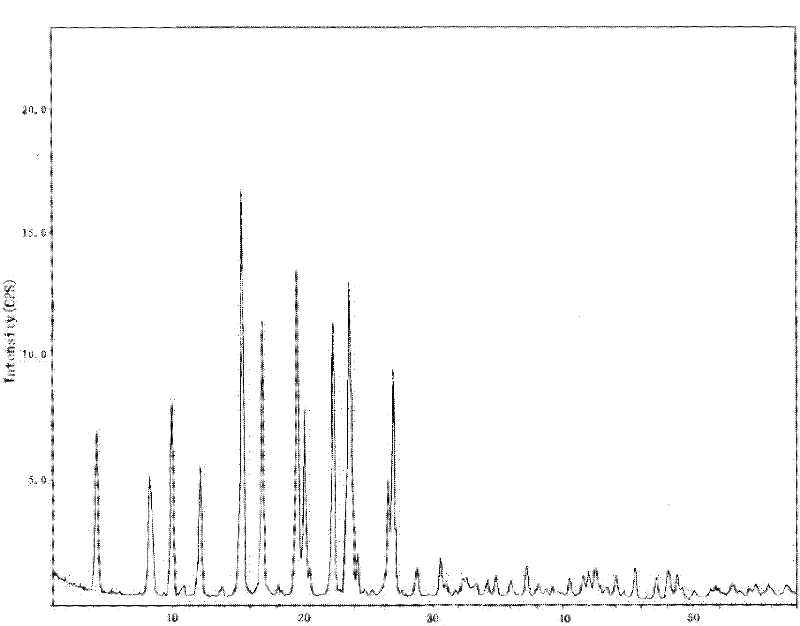

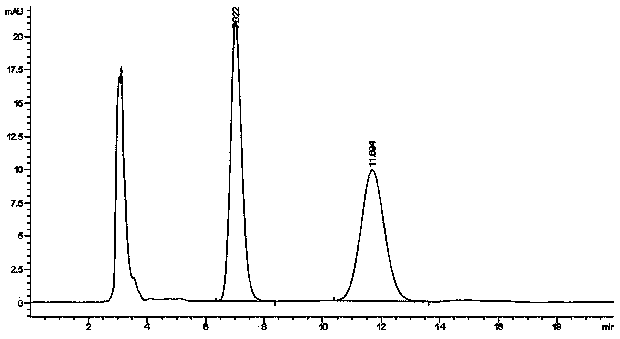

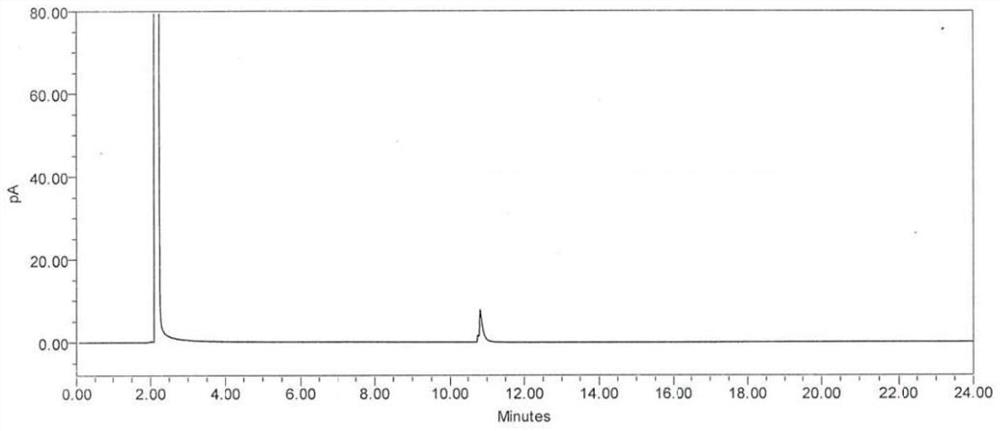

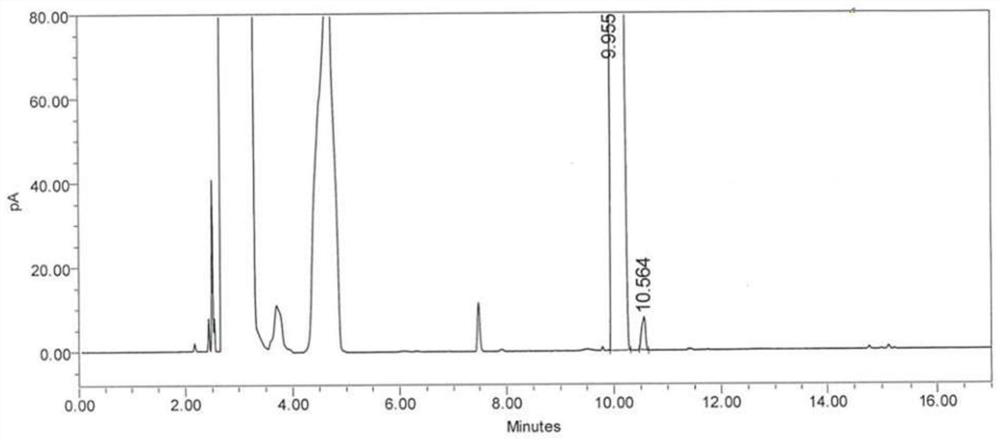

Bushy knotweed leaf fingerprint HPLC method and its use in bushy knotweed leaf capsule quality control

ActiveCN106018629AHigh separation of chromatographic peaksSolving Quality Control IssuesComponent separationGoniothalamusHplc method

The invention provides a bushy knotweed leaf fingerprint HPLC method. The method comprises preparation of a sample to be detected and HPLC detection of the sample. The method can simultaneously detect 12 index components such as gallic acid, chlorogenic acid, ferulic acid, polydatin, rutin, isoquercitrin, quercitrin, resveratrol, quercetin, rheum emodin, chrysophanol and physcion in bushy knotweed leaf raw drugs and their products. The bushy knotweed leaf fingerprint HPLC method has a chromatographic peak resolution, realizes retention time stabilization of different samples and solves the bushy knotweed leaf capsule quality control problems.

Owner:云南海沣药业有限公司

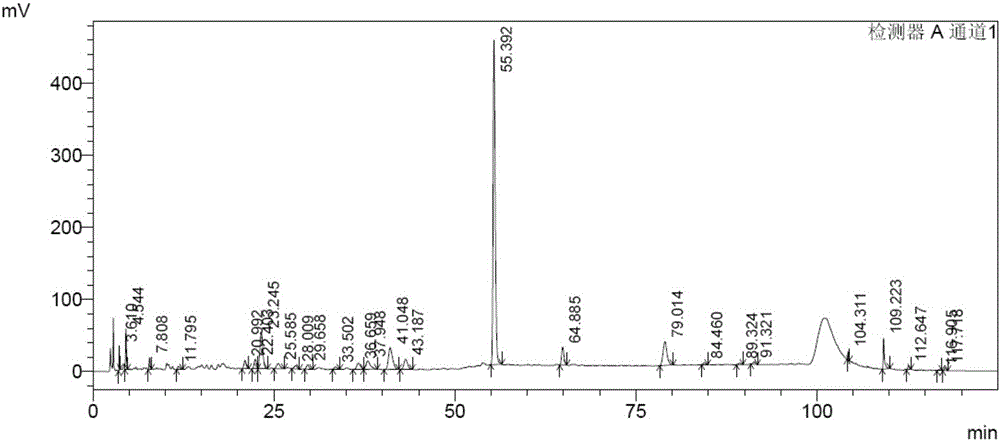

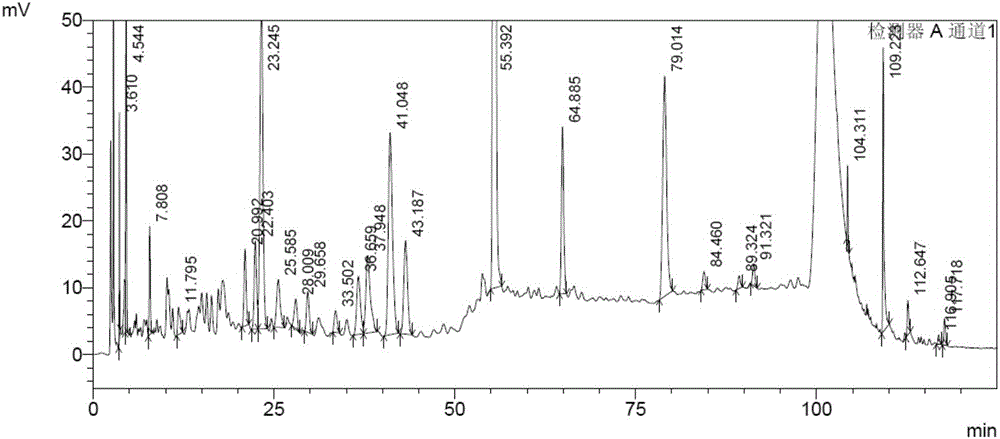

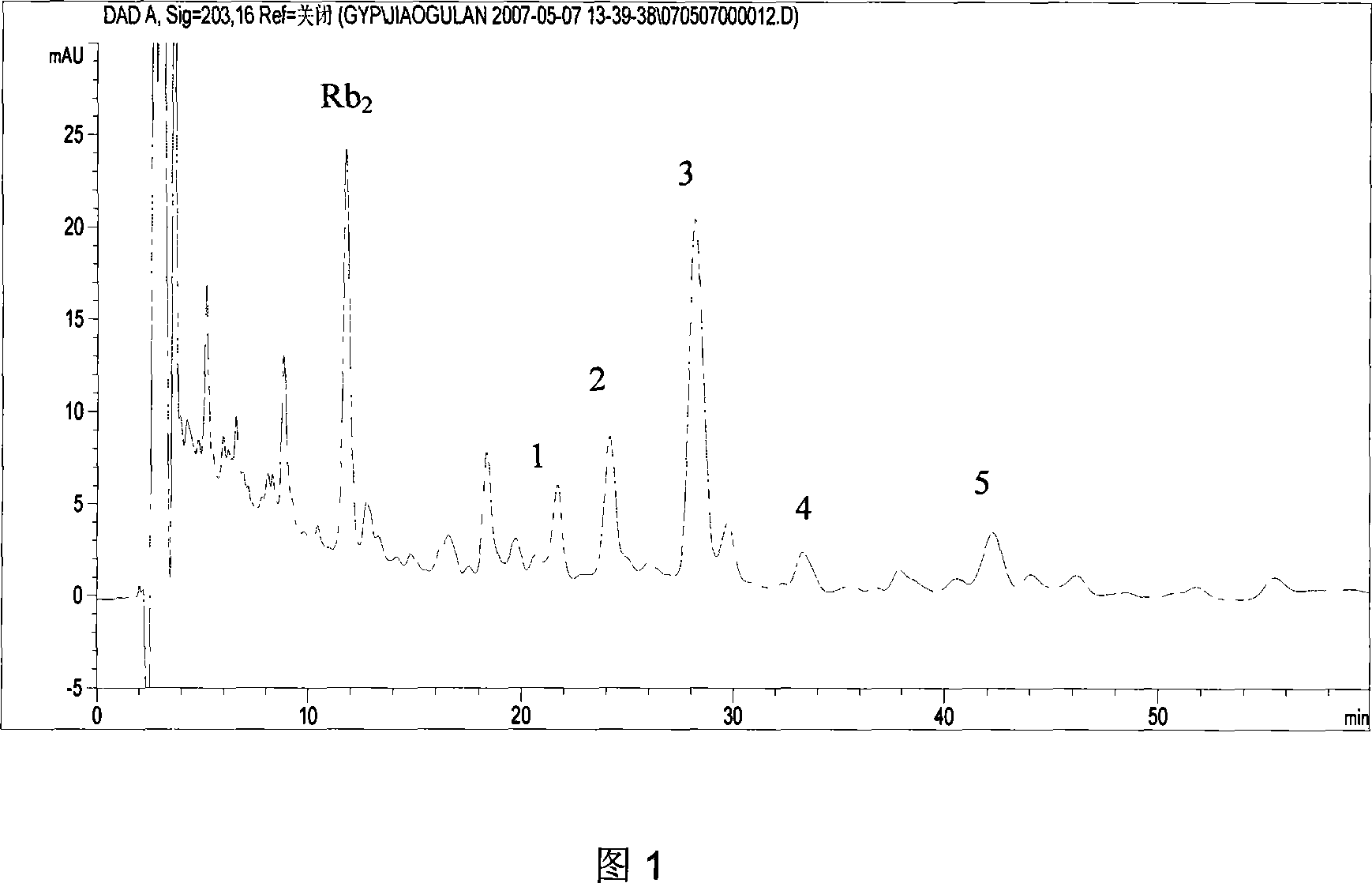

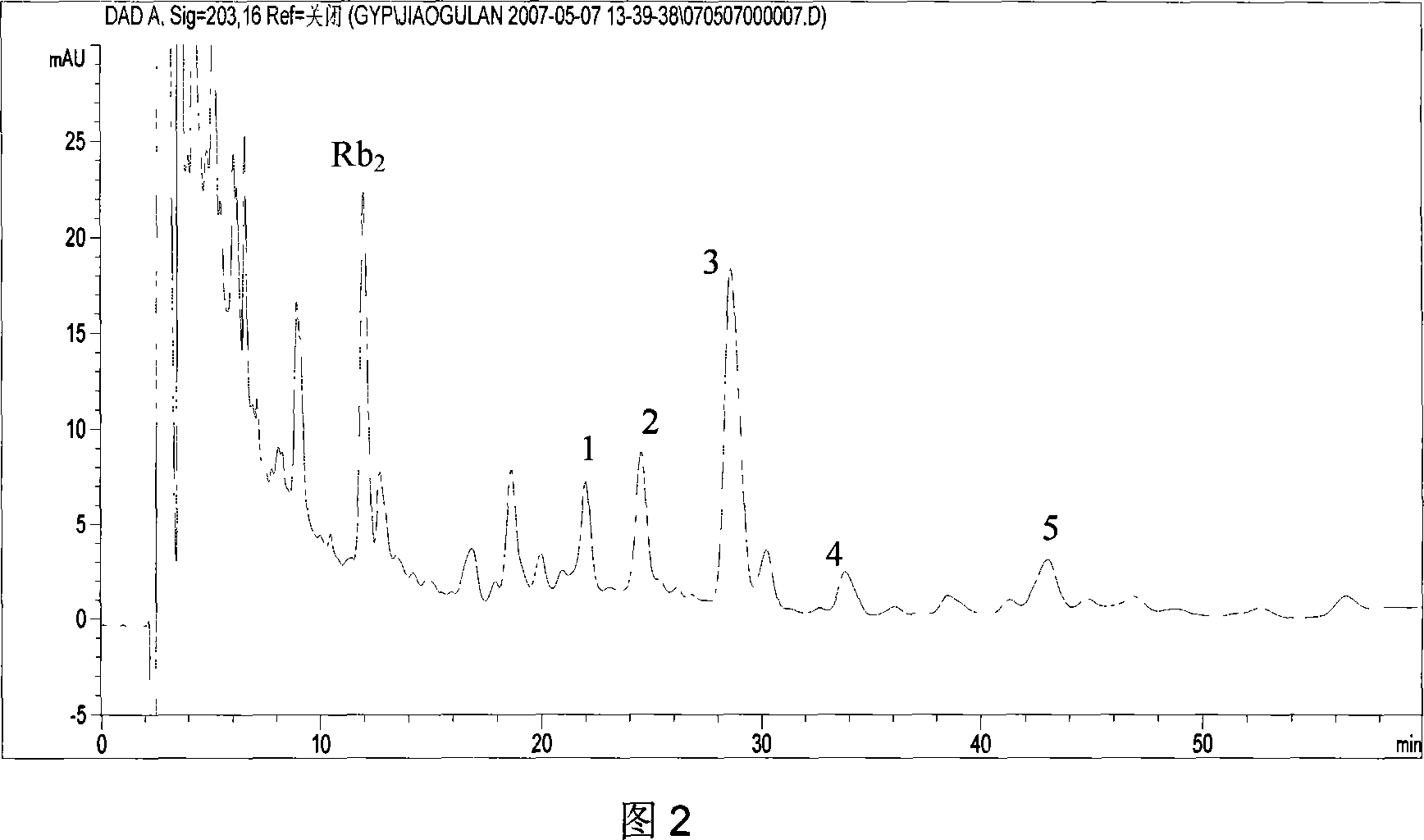

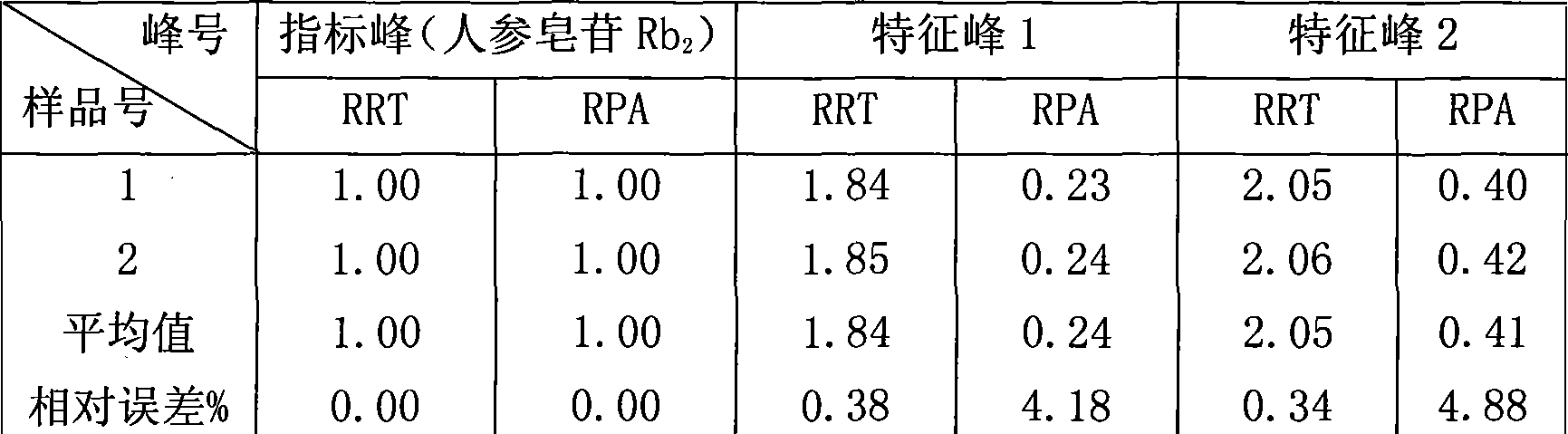

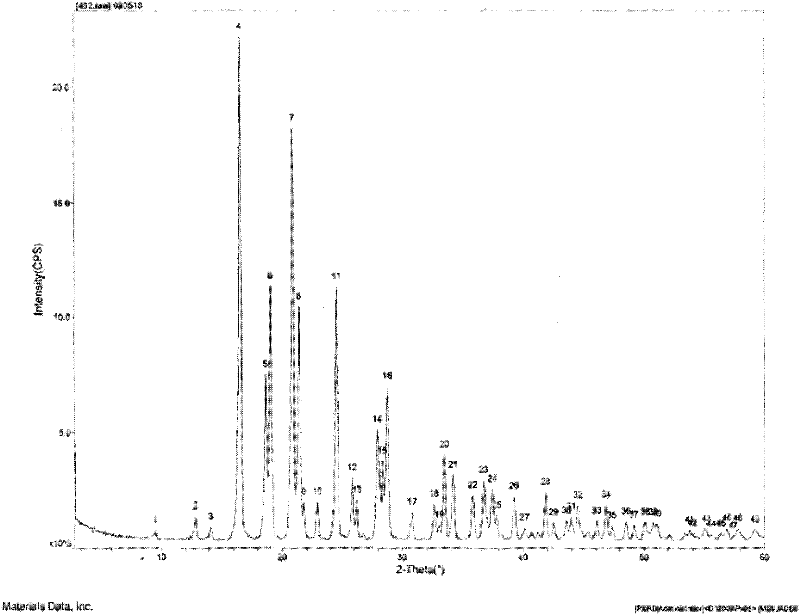

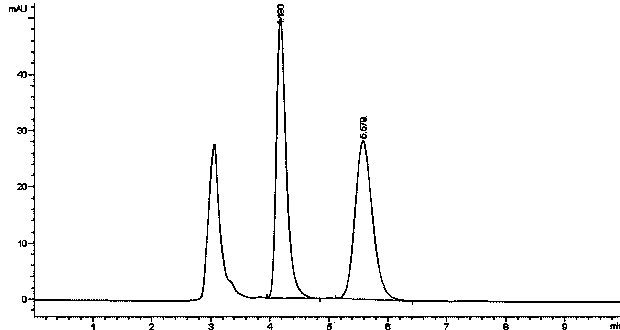

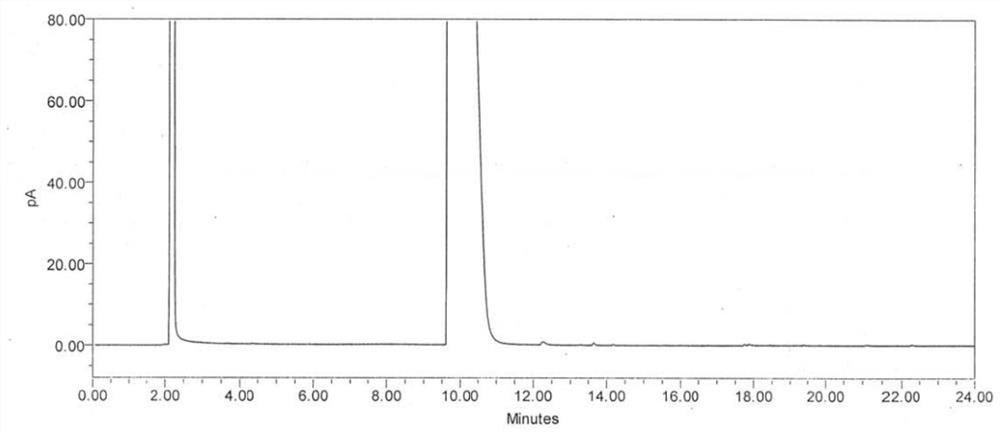

Fingerprint quality control method of gynostemma pentaphylla medicine added with internal standard

ActiveCN101078713ASolving Quality Control IssuesEfficient identificationComponent separationTesting medicinal preparationsHplc fingerprintInternal standard

The invention relates to a quality control method for fingerprint of herba gynostemae medicinal materials with internal standard in it, comprising (1) measuring method for fingerprint of herba gynostemae medicinal material, (2) building standard fingerprint, (3) comparing HPLC fingerprint of sample with reference fingerprint according to technology demand of quality control of fingerprint that similarity of six common peaks calculated is not smaller than 0.9. The invention is provided with high sensitivity, good reproducibility, strong specialization and reliable method. It can evaluate quality of herba gynostemae medical material scientifically and effectively. It can be applied in quality control in practical production and can satisfy the demand of identification and quality control for enterprise medicinal material.

Owner:SHANGHAI MODERN CHINESE TRADITIONAL MEDICINE TECH DEV

Detection method for tablets capable of relaxing muscles and stimulating blood circulation

InactiveCN102552616ASolving Quality Control IssuesHeavy metal active ingredientsComponent separationHerbal preparationsFluid phase

The invention belongs to the field of pharmacy and relates to a detection method for Chinese herbal preparation of tablets capable of relaxing muscles and stimulating blood circulation, in particular to a detection method for tablets capable of relaxing muscles and stimulating the blood circulation. The detection method adopts a thin layer chromatography method to identify rhizoma cibotii and cortex periplocae in products, and uses a high efficiency liquid chromatography method to measure the content of hydroxysafflor yellow which is a main constituent of red flower. The detection method is quick in speed, high in accuracy and capable of effectively controlling quality of tablets capable of relaxing muscles and stimulating the blood circulation.

Owner:JIANGXI JEMINCARE GRP CO LTD +1

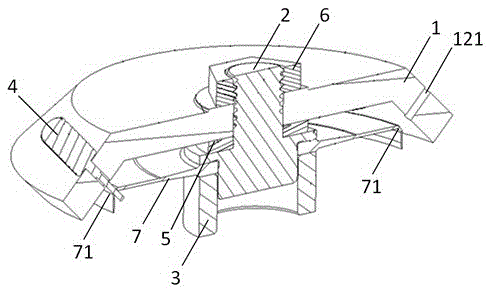

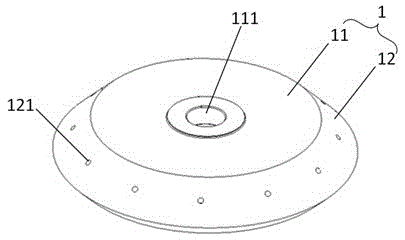

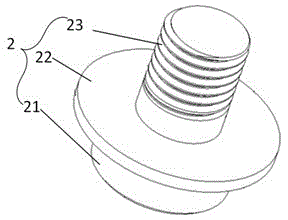

Multi-inclined-hole position degree testing device of disc thin-walled member

InactiveCN105547078ALower skill requirementsAvoid handlingMechanical measuring arrangementsBatch processingSoftware engineering

The present invention discloses a multi-inclined-hole position degree testing device of a disc thin-walled member. The device comprises a positioning base. A positioning shaft is installed on the positioning base. A gasket sleeves the positioning shaft. A test disk and a positioning shaft upper end are fixed through a nut. A test pin goes through the guide hole on the test disk and the inclined hole to be tested on a disc-shaped thin-walled member to be tested. The multi-inclined-hole position degree testing device has the advantages of simple structure, easy carrying, easy operation, efficient testing, and low skill demand of an inspector, the testing can be implemented between the inclined-hole processing sequences of the disc thin-walled member, the handling process of a member to be tested of finished product testing is avoided, the quality control problem in a product batch processing line is solved, the detection time is saved, and the detection efficiency is improved.

Owner:CHINA NTAIONAL NUCLEAR TIANJIN MACHINERY

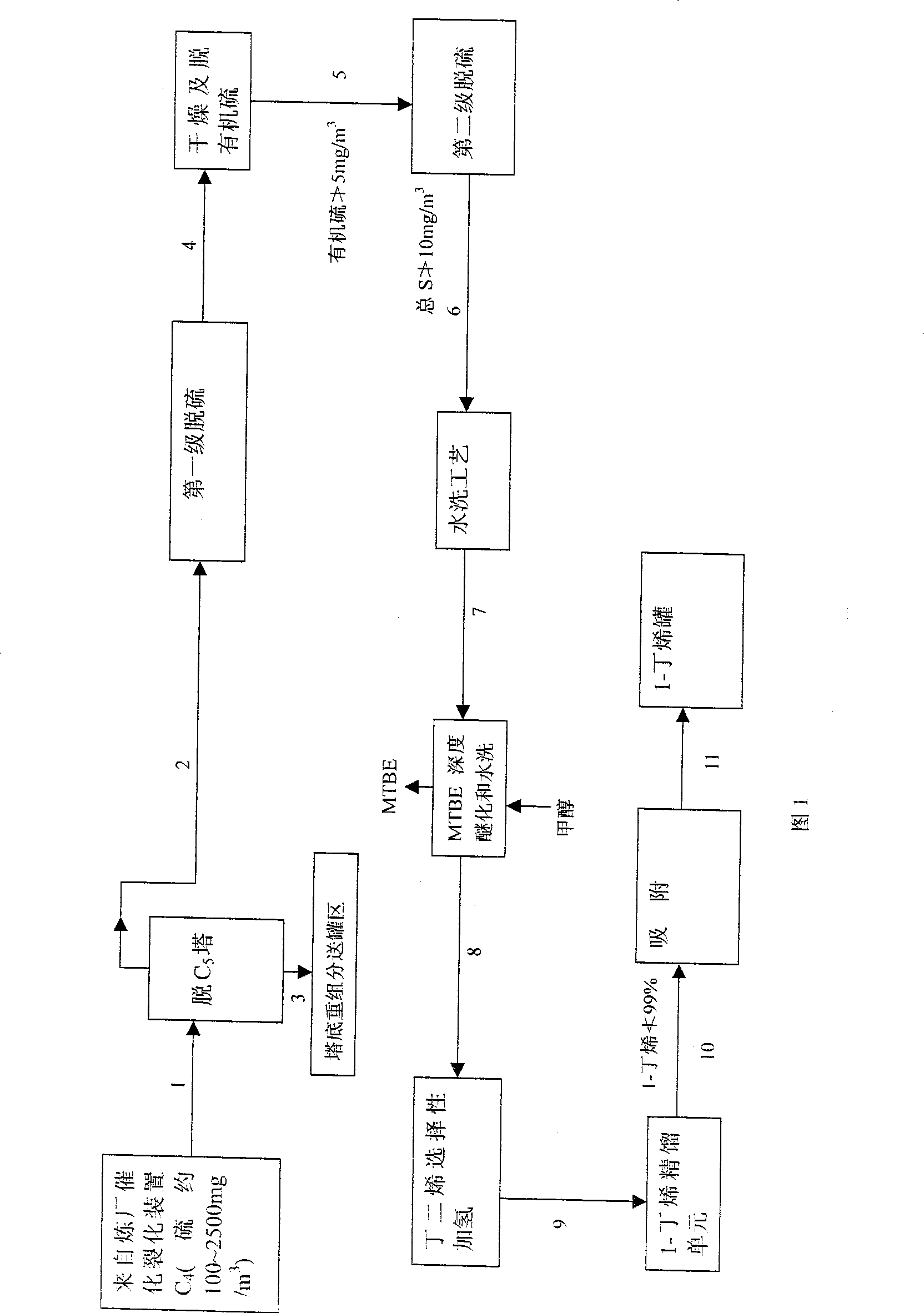

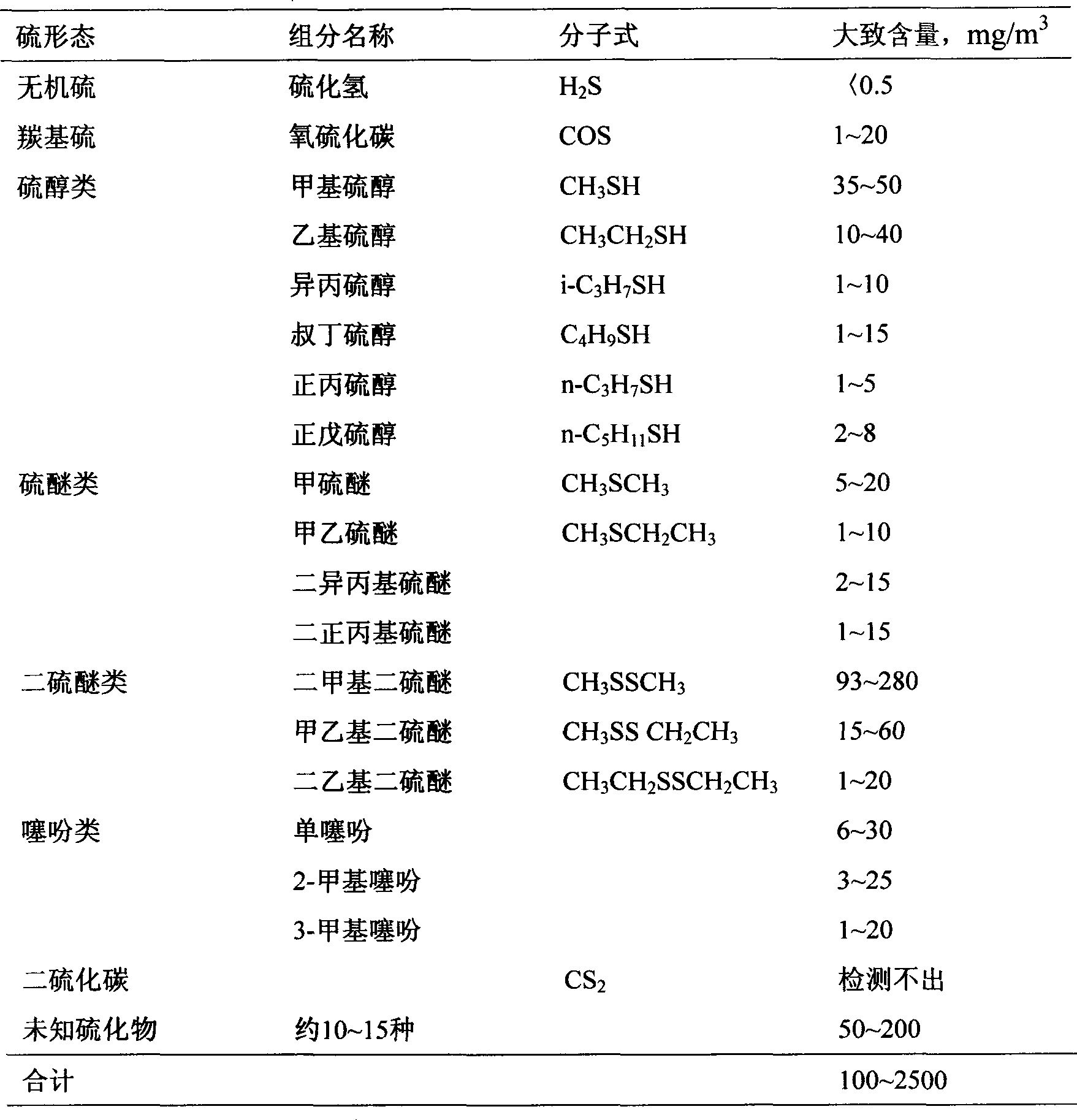

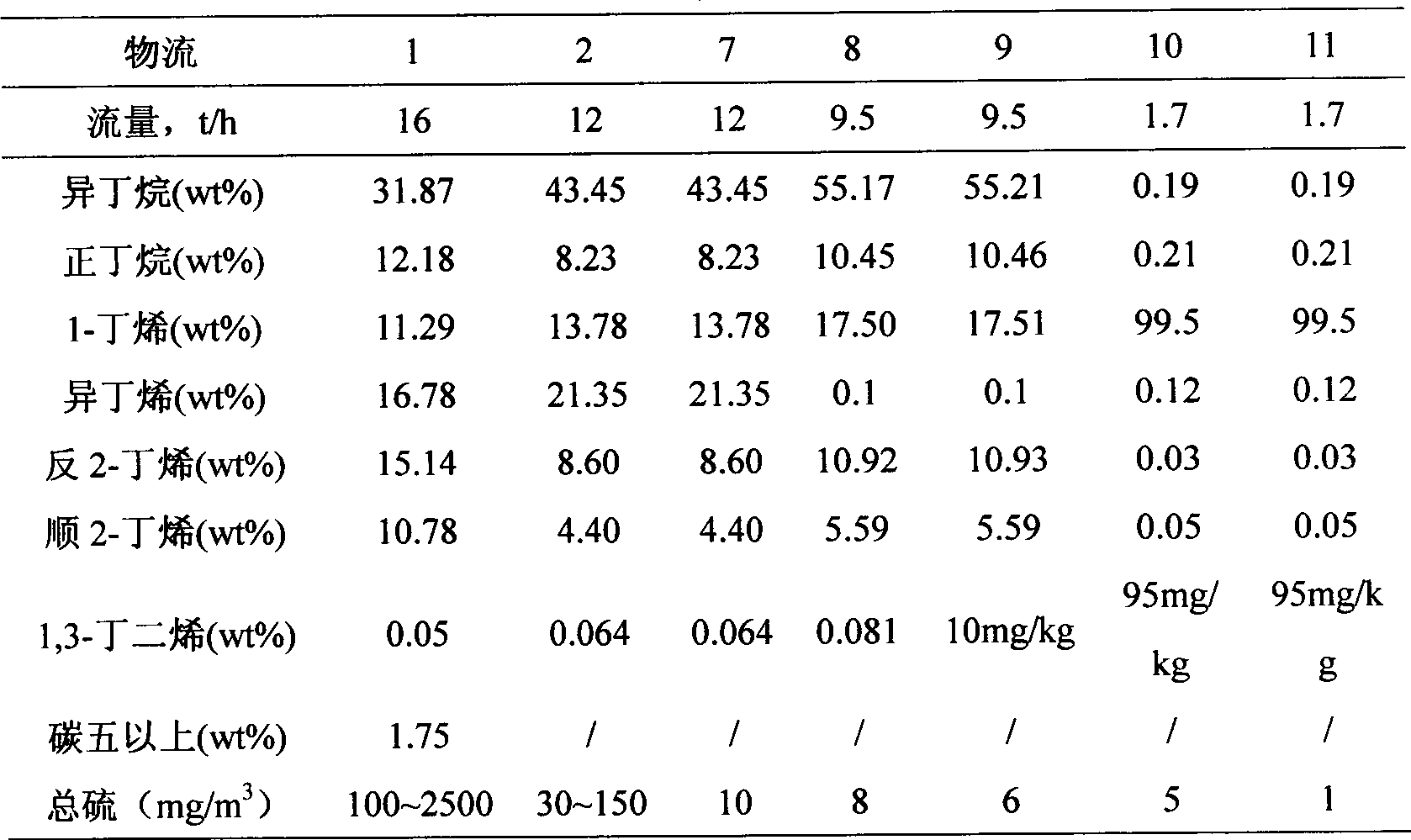

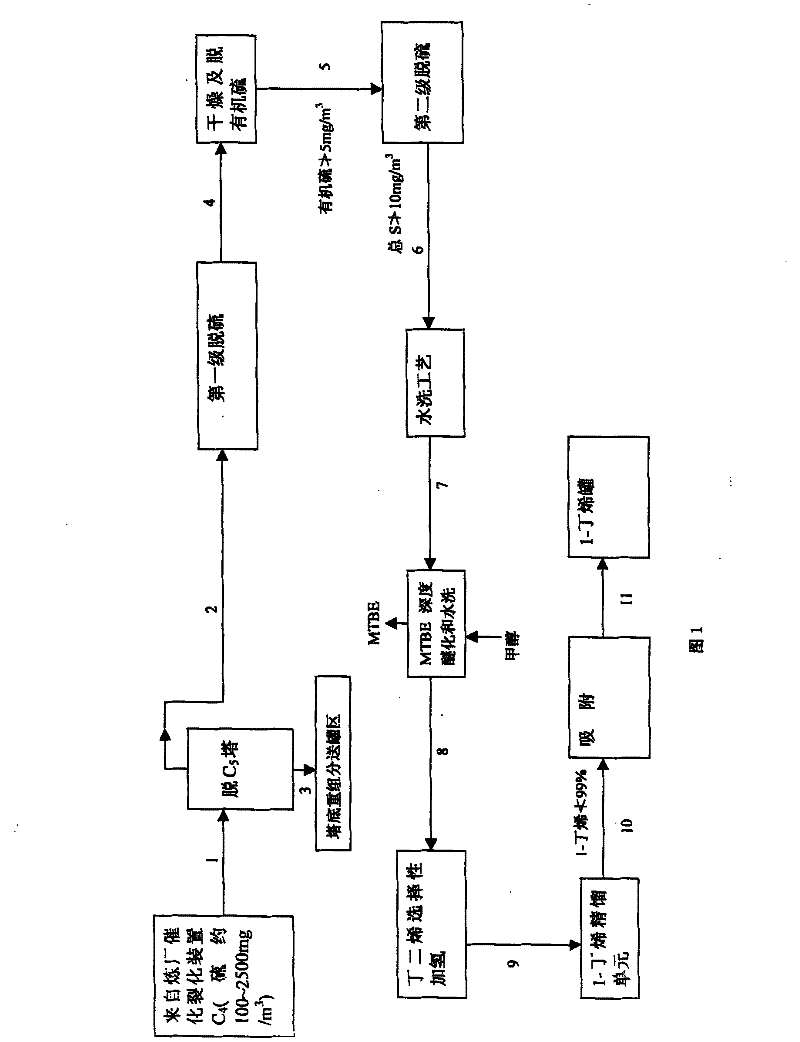

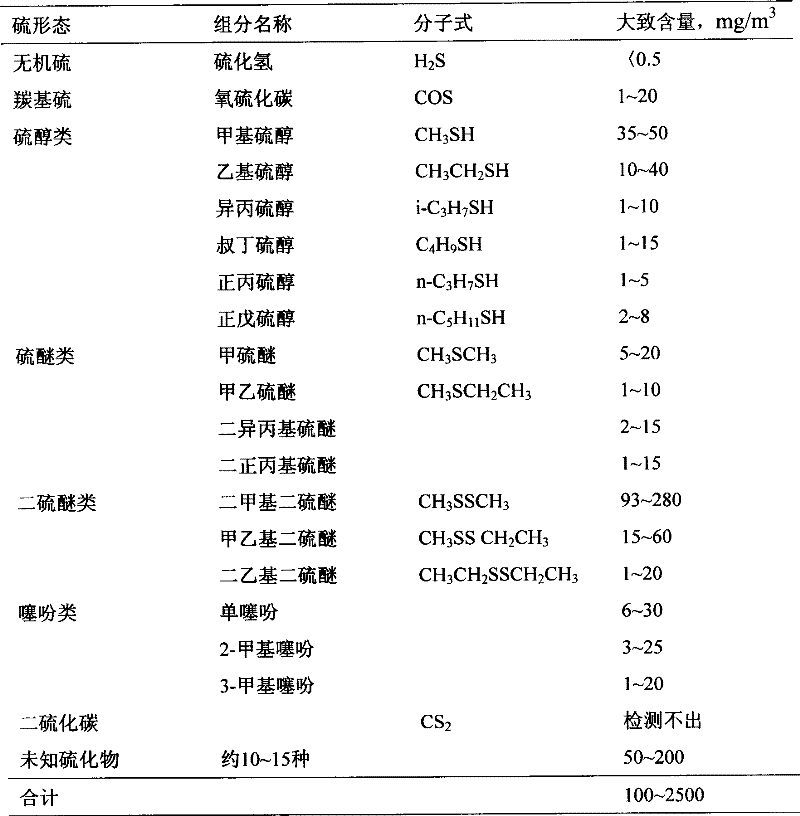

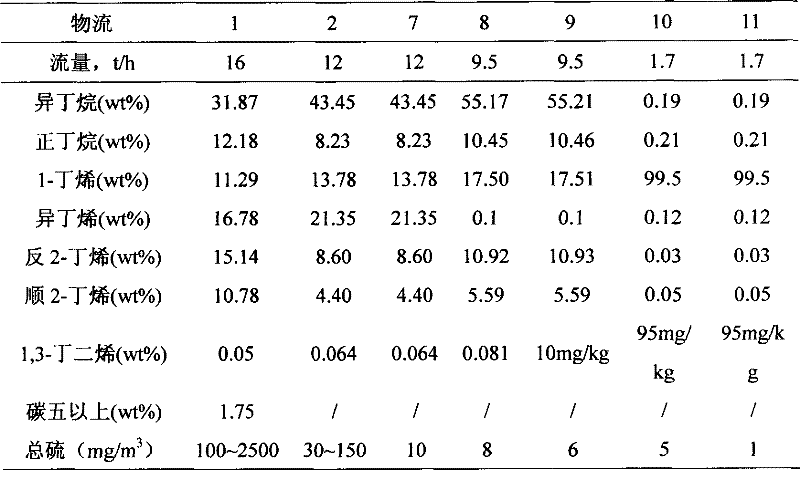

Method for preparing polymer grade 1-butene by high sulfur content four carbon compounds catalysis from refinery

ActiveCN101362671ADoes not affect activityLow costDistillation purification/separationChemical modification purification/separationMolecular sievePurification methods

The invention relates to a method for producing polymer grade 1-butene from C4 catalyzed by high sulfur in a refinery, which is a purification method for C4 catalyzed by the high sulfur that is the by-product of refinery process in petrochemical industry. The invention discloses that coarse desulfurization of the C4 catalyzed by a high sulfur refinery is carried out in a de-C5 tower, and at least desulfurizing, drying, organic sulfur removing and washing are carried out by a water scrubber and a reactor, thereafter, material flow enters the reactor and etherification is carried out for removing isobutene, as well as hydrogenation is added selectively and removing diene. Then the material flow is separated by a distillation column, and adsorbed by a molecular sieve in the reactor, so as to obtain the polymer grade 1-butene with the purity of the 1-butene to be over 99 percent, wherein, the total sulfur content is less than 2mg / m<3>. By adopting the invention, the mixed C4 with high sulfur is desulfurized at first until the sulfur content is less than 10mg / m<3>, and then enters different reactors, and the catalyst activity is not affected, thus leading the 1-butene to achieve polymer grade standard finally. The production technique of the invention is characterized by short process, easy operation, and the like, and has the advantages of environmental sanitation, safe production and comparatively low cost.

Owner:CHINA PETROLEUM & CHEM CORP

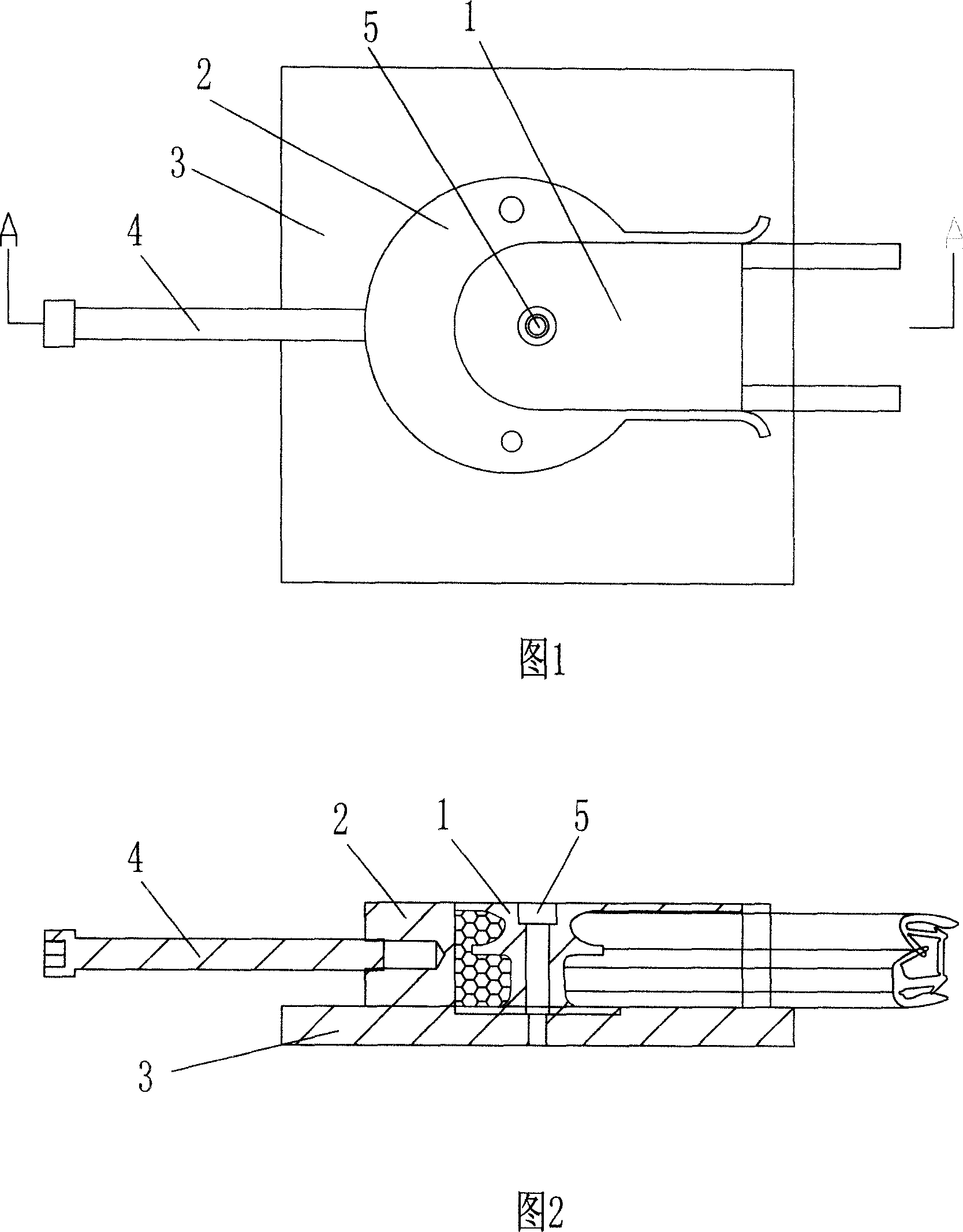

Thormobend shaping method of rubber sealing strip for automobile door window and its mould

ActiveCN100999132ASave processing feeSolving Quality Control IssuesDomestic articlesVulcanizationMechanical engineering

The present invention discloses a thermobending setting method of glass guide channel rubber weather strip for automobile door and window and its mould. Said method includes the following steps: (a), marking out on the position of rubber weather strip extruded and vulcanized by rubber extruding machine and said position can be thermally bent; (b), positioning the rubber weather strip on the setting mould, heating and vulcanizing; and (c), taking out said rubber weather strip, naturally cooling so as to implement thermobending setting operation. Said mould includes bending-setting mould, movable mould and lower template.

Owner:萨固密渝锦(重庆)橡塑制品有限公司

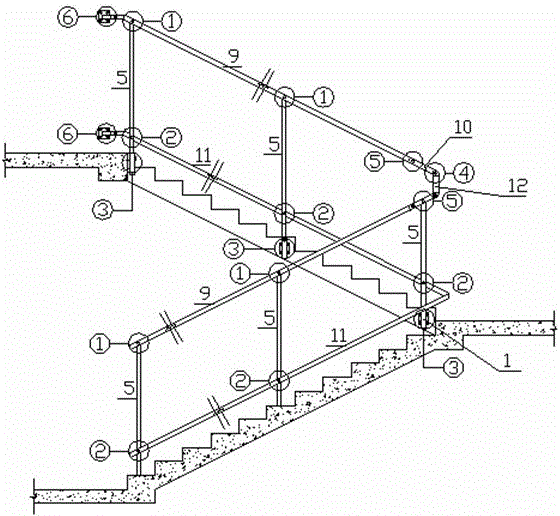

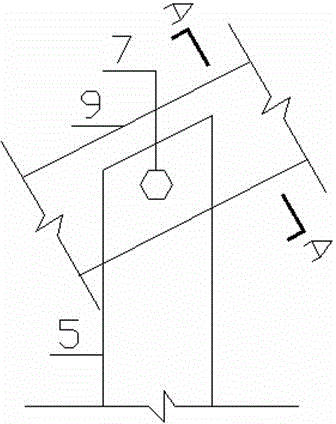

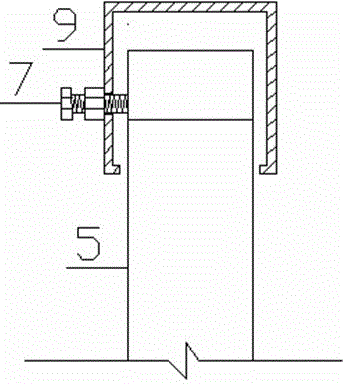

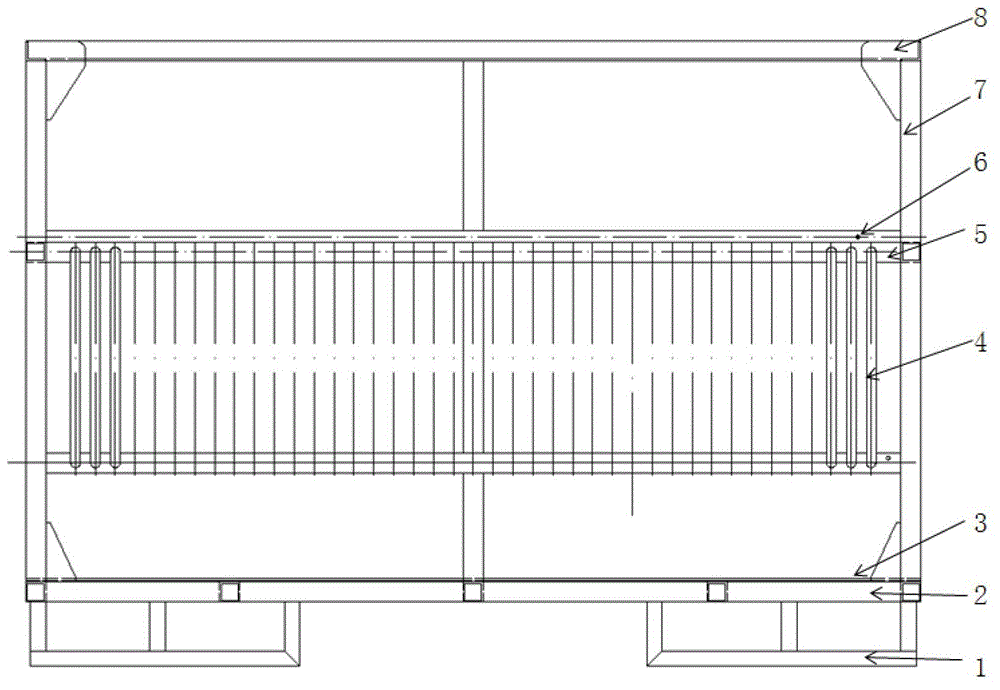

Temporary guard railing for stair

ActiveCN104533102AEase of mass productionStable supportBuilding material handlingStairway-like structuresVertical projectionBrick

The invention discloses a temporary guard railing for a stair. The temporary guard railing for the stair comprises a base and a vertical column; poles are connected to the upper end of the vertical column, and lever posts are connected to the lower part of the vertical column; the base is connected to the side surface of the suspended end of each stair section through an expansion; the base, the poles and the lever posts are all locked to the vertical column through bolts; a telescopic rods are locked to the end parts of adjacent poles through the bolt; sleeves, the poles, the lever posts and the telescopic rods of an upper stair section and a lower stair section are positioned in the same vertical projection plane; a connecting rod is hinged between adjacent telescoping rods through the bolt. The temporary guard railing for the stair has the beneficial effects that the structure is simple, and the design is reasonable; the temporary guard railing is arranged on the side surface of each stair section and is not needed to be dismounted during paving face bricks and stones, and therefore, the protection effect is effectively achieved in the period before erecting a formal guard railing, and as a result, the safety is improved.

Owner:THE FIRST COMPARY OF CHINA EIGHTH ENG BUREAU LTD

Tool for automobile door protective plate

ActiveCN102963621ASolving Quality Control IssuesEasy to operateContainers to prevent mechanical damageDamagable goods packagingQuality controlEngineering

The invention discloses a tool for an automobile door protective plate, which comprises a frame, wherein the frame consists of a bottom frame, upright columns and angle steel; the bottom frame, the upright columns and the angle steel are connected in sequence; a guard device and a limiting device are arranged in the frame; and the protective range of the guard device is adjustable. The tool can effectively perform quality control during transport and storage of door outer plates, is easy and convenient to operate and improves the work efficiency. Besides, the tool has the advantages of simple manufacture process, long service life, low maintenance cost and wide application range, can satisfactorily perform quality control during transport and storage of the door outer plates, reduces the reworking capacity, provides convenience for worker's operation and increases the work efficiency.

Owner:盐城佳杰传动科技有限公司

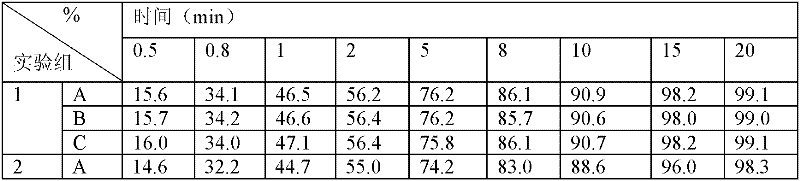

Brand-new oral solid pharmaceutical composition and preparation method thereof

ActiveCN102335178AReduce dosageSolving Quality Control IssuesOrganic active ingredientsOrganic chemistryOlmesartanLevamlodipine

The invention discloses a brand-new oral solid pharmaceutical composition. The pharmaceutical composition is an oral preparation prepared from hydrochlorothiazide, l-amlodipine, olmesartan medoxomil and pharmaceutically acceptable auxiliary materials, and the oral preparation comprises but is not limited to tablets or capsules. The composition comprises the following raw materials in parts by weight: 5-25 parts of hydrochlorothiazide, 2.5-5 parts of l-amlodipine, 20-40 parts of olmesartan medoxomil, 40-120 parts of microcrystalline cellulose, 30-90 parts of pregelatinized starch, 15-40 parts of low-substituted hydroxypropyl cellulose, 10-45 parts of crosslinked polyvinylpyrrolidone, 3-8 parts of silica and 1-2 parts of magnesium stearate. The pharmaceutical composition disclosed by the invention has the advantages of scientific and reasonable prescription, low auxiliary material content and high bioavailability, and is a drug of first choice for treating hypertension.

Owner:HAINAN JINRUI PHARMA CO LTD

Detection method of liver-strengthening syrup Chinese medicinal preparation

InactiveCN102552800ASolving Quality Control IssuesComponent separationDigestive systemTraditional medicineThin-layer chromatography

The invention belongs to the field of pharmacy, and relates to a detection method of a liver-strengthening syrup Chinese medicinal preparation, in particular to a detection method of liver-strengthening syrup. In the detection method, Chinese angelica and white paeony root in a product are identified with a thin layer chromatography. The detection method disclosed by the invention has a quick speed and high accuracy, and can be used for effectively controlling the quality of liver-strengthening syrup.

Owner:JIANGXI JEMINCARE GRP CO LTD +1

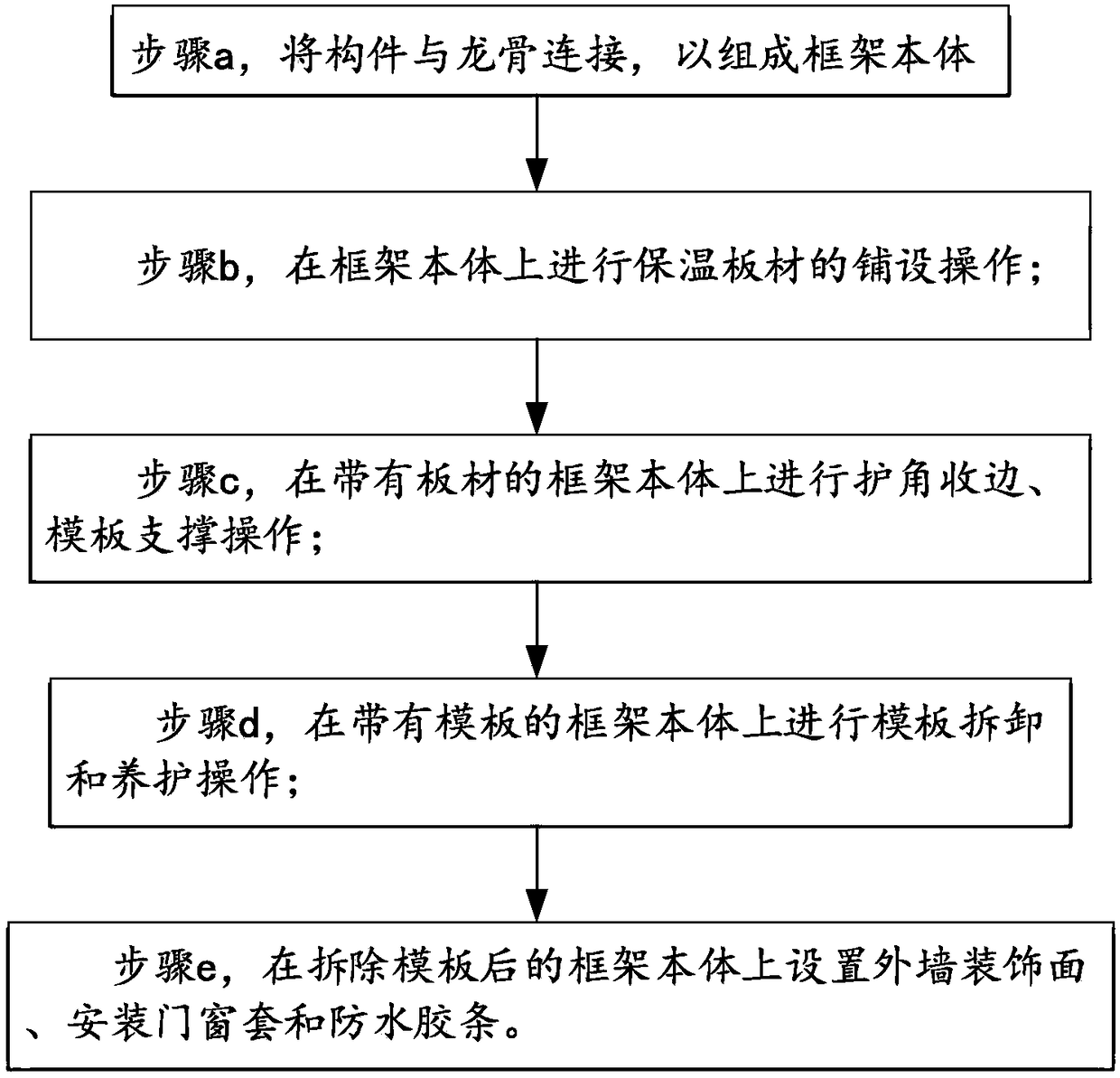

Wall manufacturing method

The invention discloses a wall manufacturing method. The method comprises the following steps that 1, a component and a keel are connected to form a frame body; 2, a heat preservation board is laid onthe frame body; 3, corner protection edge forming and template supporting operations are performed on the frame body with the board; 4, template disassembling and maintaining operation is performed on the frame body with the template; 5, an exterior wall decoration face is arranged on the frame body with no template, and a door and window sleeve and a waterproof adhesive strip are installed; themethod can be applied to the technical field of fabricated walls, the total output of a production line can be effectively improved, the actual market requirement can be effectively met, the production technology can be optimized, the labor intensity of workers is effectively lowered, the utilization rate of raw materials can be effectively increased, quality control in the wall production processcan be achieved, the production wall quality can be effectively ensured, and anti-seismic, anti-wind-pressure and heat preservation and other properties of the wall can be greatly improved.

Owner:BEI JING NEW BUILDING MATERIALGRP

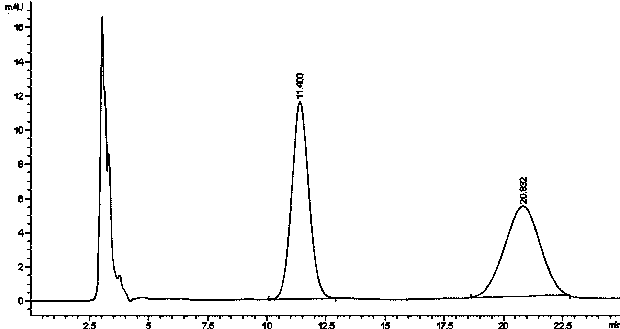

High performance liquid chromatography splitting method for Boc hydroxyl adamantane amino acid

InactiveCN103913526ASolving Quality Control IssuesPracticalComponent separationChemistryChromatography column

The invention discloses a high performance liquid chromatography splitting method for Boc hydroxyl adamantane amino acid. A high performance liquid chromatograph is adopted, a straight-chain starch type chiral column is used as a chromatographic column, and mixed liquid of normal hexane and ethyl alcohol or normal hexane and isopropanol is used as a flowing phase; the flowing speed of the flowing phase is controlled to be 0.60-1.20 mL / min; chromatographic separation is performed under conditions that the temperature of the chromatographic column is 25-40 DEG C, the sample injection amount is 5-20 microliters, and the detection wavelength is 210-260 nm; according to the volume percentage, a ratio of the normal hexane to the ethyl alcohol (or isopropanol) is (70-90 percent):(10-30 percent). Separation and measurement of the R and S type Boc hydroxyl adamantane amino acid in a Boc-hydroxyl adamantane amino acid despinner are effectively realized, and the separation degree is up to 3.25-4.57.

Owner:SHANGHAI INSTITUTE OF TECHNOLOGY

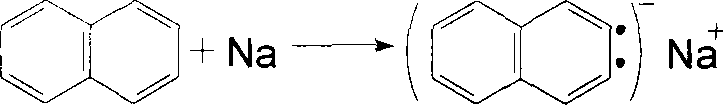

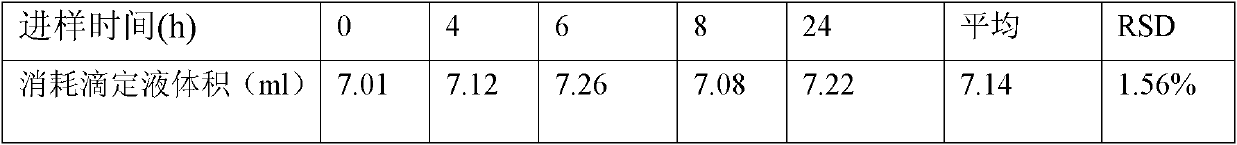

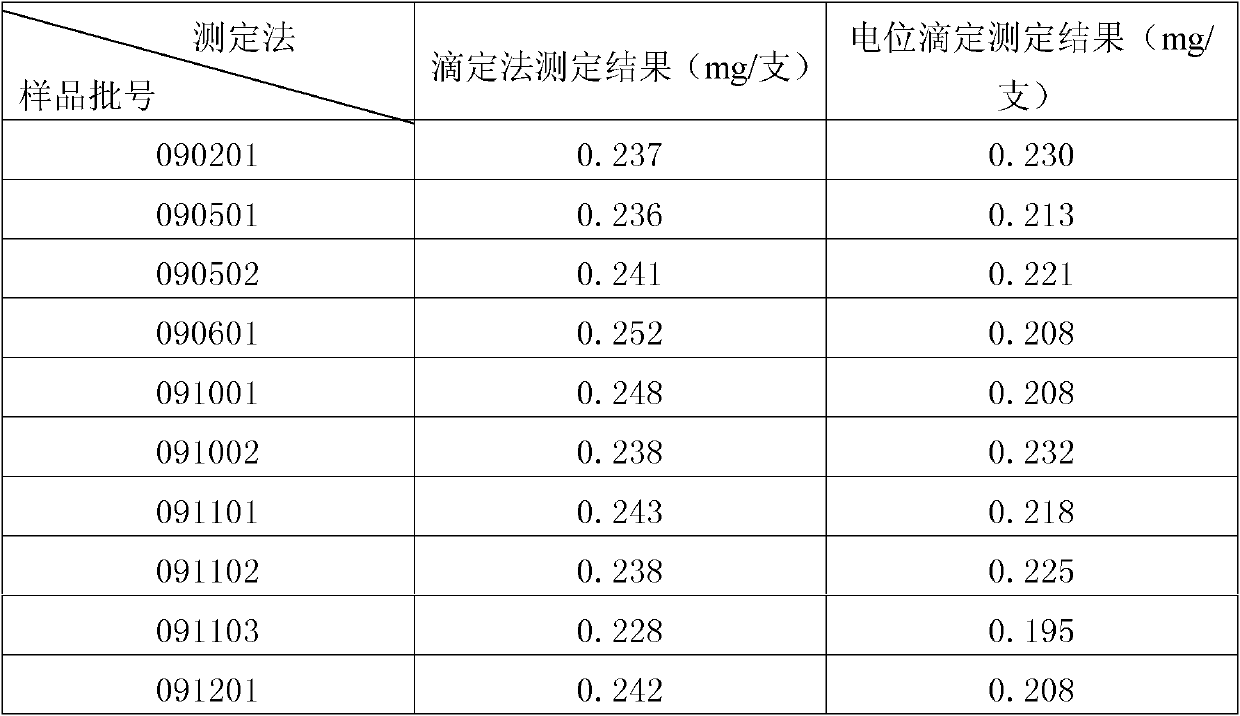

Method for measuring active concentration of sodium naphthalin treatment solution

InactiveCN101246153ASimple requirementsEasy to measureChemical analysis using titrationSpecial data processing applicationsRelative standard deviationReaction temperature

The invention discloses a testing method of sodium-naphthalene solution active concentration. In the absence of air and water, hydrochloric ether is used as dechlorinating agent to act with sodium-naphthalene solution, reaction temperature is 40-70 DEG C, reaction time is 5-15 minutes, sodium chloride is generated, at pH 6-10, sodium chloride is generated with water extraction, extraction time is 1-5 minutes, titrate sodium chloride in water solution with silver nitrate titrating solution, sodium-naphthalene solution active concentration is calculated according the consumption of silver nitrate standard solution. The invention has advantages of scientific test principle, reasonable design method, simple acquired method, simple test operation, which can be completed within 10-15 minutes and fast analysis speed, the relative standard deviation is less than 2%, the test result has good reproduction quality, and the test method is effective and practical.

Owner:JUHUA GRP +2

Door guard plate tool appliance for vehicle

ActiveCN102975963ASolving Quality Control IssuesEasy to operateContainers to prevent mechanical damageDamagable goods packagingManufacturing technologyQuality control

The invention discloses a door guard plate tool appliance for a vehicle. The door guard plate tool appliance comprises a framework, wherein the framework is formed by a bottom frame, uprights and angle steels, wherein the bottom frame, the uprights and the angle steels are sequentially connected, the framework is internally provided with a protecting device and a limiting device, and the size of a protecting region of the protecting device is adjustable. According to the door guard plate tool appliance disclosed by the invention, the quality control of over a door outer plate workpiece during a transporting and storing processes can be effectively solvedrealized, the operation is simple and convenient, and the working efficiency is increased; meanwhile, the door guard plate tool appliance has the advantages that the manufacturing technology is simple, the service life is long, and the maintenance cost is low; the application range is wide, the quality control of over the door outer plate workpiece during the transporting and storing processes can be effectively better solvedrealized, and the repairing workload can be reduced; and the operation is convenient for a worker, and the working efficiency is increased.

Owner:盐城东方兴达农业发展有限公司

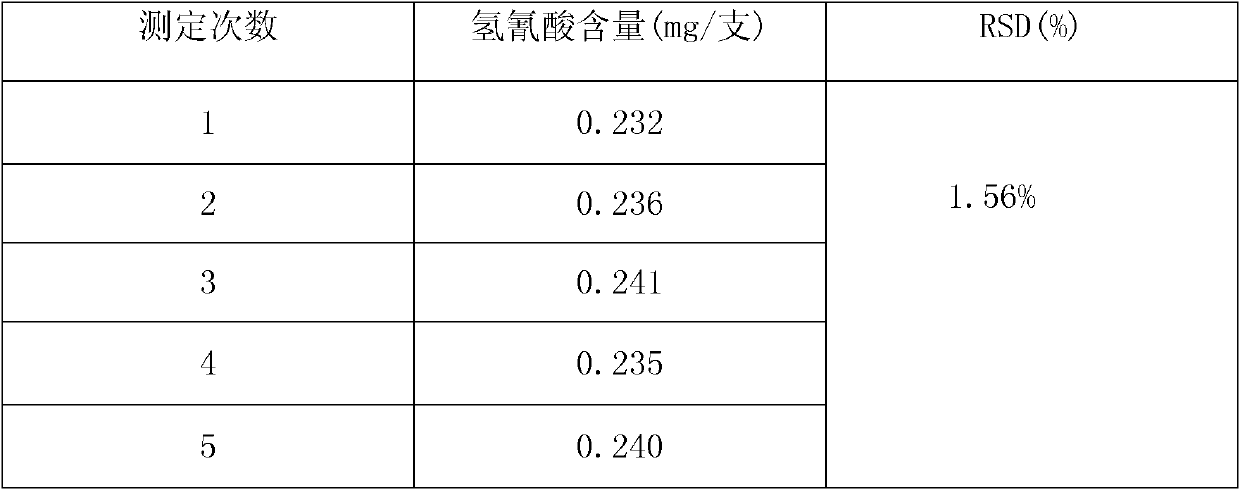

Quality detection method for Chinese herbal preparation of fritillary bulb extract oral liquid

InactiveCN102552662ASolving Quality Control IssuesComponent separationReptile material medical ingredientsHerbal preparationsPharmaceutical drug

The invention belongs to the field of pharmacy and relates to a detection method for Chinese herbal preparation of fritillary bulb extract oral liquid, in particular to a detection method for the fritillary bulb extract oral liquid. The detection method comprises an identification method of medicine constituents and a content measurement method of hydrocyanic acid. The detection method is quick in speed and high in accuracy.

Owner:JIANGXI JEMINCARE GRP CO LTD +1

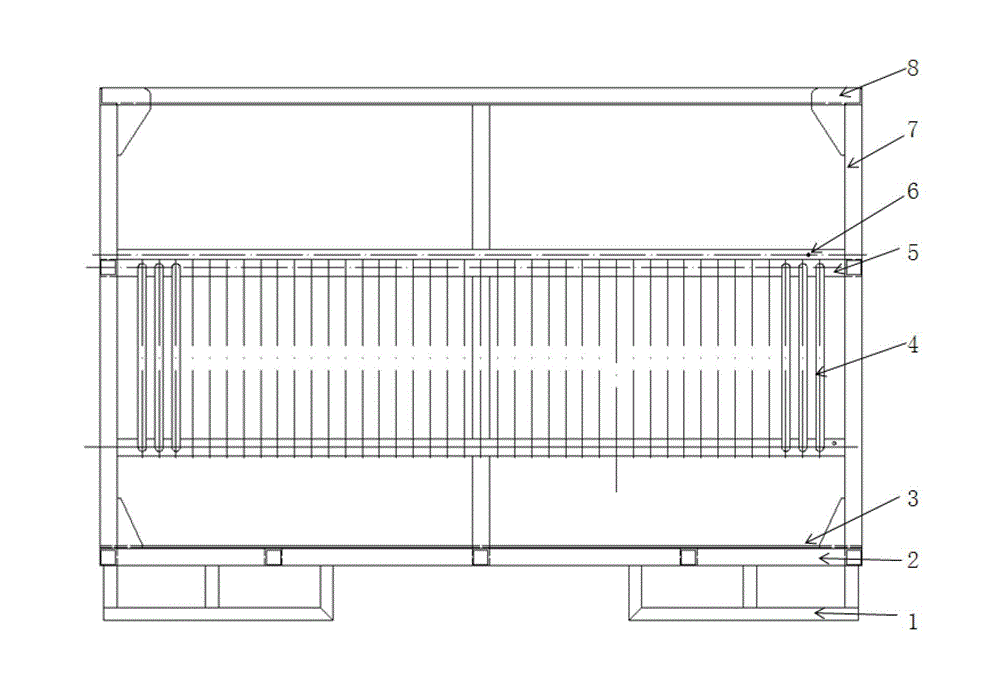

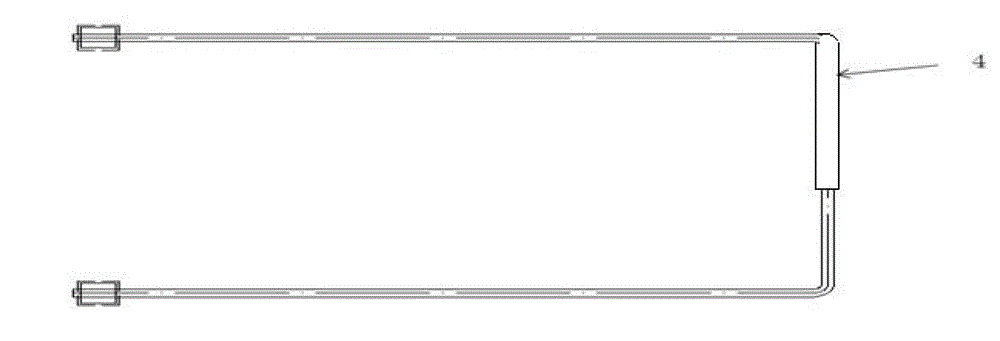

Beam-type supporting frame aperture multi-geometric tolerance detection device

InactiveCN106403778ALower skill requirementsSkill Requirement SolvedMechanical clearance measurementsProduction lineEngineering

The present invention discloses a beam-type supporting frame aperture multi-geometric tolerance detection device. The device comprises a handle and two checking sticks, a big cover plate is arranged at the lower portion of the handle, and the front side plate and the back side plate are parallel to each other and are both in vertical connection with the bottom surface of the big cover plate; and the front side plate and the back side plate are L-shaped plate structure, free ends are respectively provided with a front side plate through hole and a back side plate through hole, and the one sides of the free ends of the front side plate and the back side plate are respectively provided with linings. The beam-type supporting frame aperture multi-geometric tolerance detection device can be configured for checking of the beam-type supporting frame aperture multi-geometric tolerance, is simple in structure, convenient to carry, easy to operate, effective in checking and not high in the checkers' skill requirement, can enforce the checking prior to entering an assembly line so as to solve the quality control problem of products in batch on the assembly line, save the detection time and improve the detection efficiency.

Owner:CHINA NTAIONAL NUCLEAR TIANJIN MACHINERY

Quality detection method for medicine (named as Er bao concentrated decoction)

InactiveCN102552751AAvoid product qualitySolving Quality Control IssuesComponent separationDigestive systemHerbal preparationsPharmacy

The invention belongs to the field of pharmacy and relates to a detection method for Chinese herbal preparation of medicine (named as Er bao concentrated decoction), in particular to a detection method for the medicine (named as Er bao concentrated decoction). The detection method uses a thin layer chromatography method to identify radix pseudostellariae, poria cocos, Chinese yam and radia paeoniae alba in products and adopts a high efficiency liquid chromatography method to measure the content of paeoniflorin which is a main constituent of the radia paeoniae alba. The detection method is quick in speed, high in accuracy and capable of effectively controlling quality of the medicine (named as Er bao concentrated decoction).

Owner:JIANGXI JEMINCARE GRP CO LTD +1

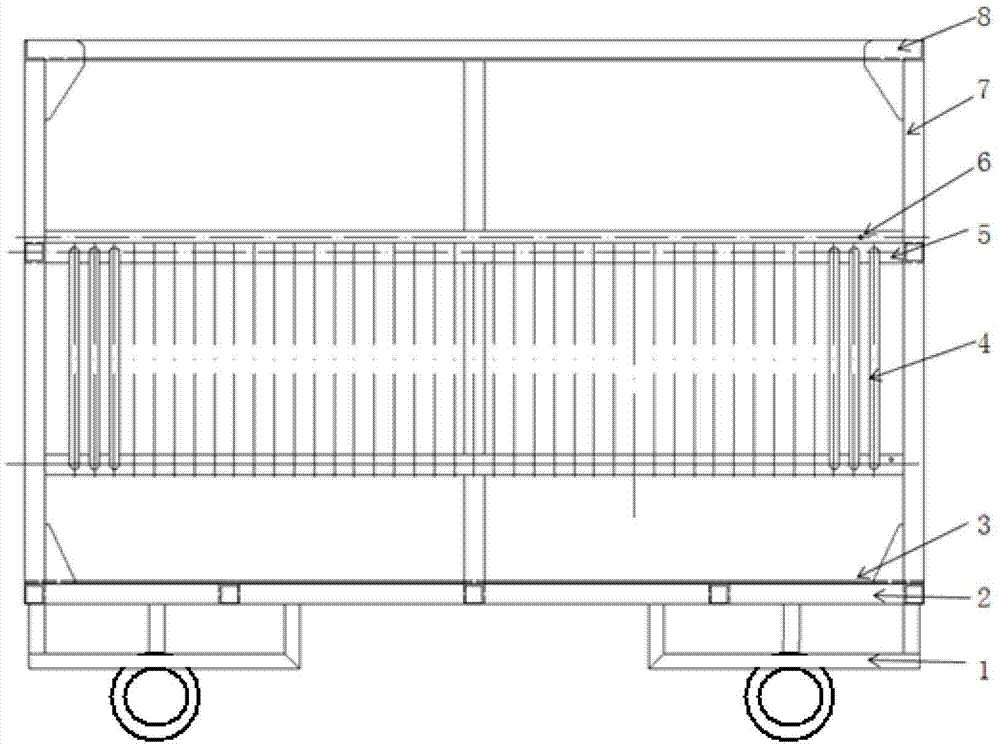

Movable workstation tool in vehicle production process

InactiveCN103085047ASolving Quality Control IssuesEasy to operateWork tools storageOther workshop equipmentIn vehicleEngineering

The invention discloses a movable workstation tool in the vehicle production process. The movable workstation tool comprises a frame, wherein the frame consists of a bottom frame, upright posts and steel angles; the bottom frame, the upright posts and the steel angles are connected in turn; a protective device and a limiting device are arranged in the frame; standing feet are arranged on the lower part of the bottom frame; movable devices are arranged on the lower parts of the standing feet; the protective device is a U-shaped gear lever; and the gear lever generally has a U shape which is opened transversely. By the movable workstation tool in the vehicle production process, quality control during transport and storage of outer plate workpieces of doors can be realized effectively; the movable workstation tool is easy and convenient to operate; and the work efficiency is improved. Simultaneously, the workstation tool is also simple in manufacturing process, long in service life, low in maintenance cost and wide in application range; the quality control during the transport and storage of the outer plate workpieces of the doors can be realized well; the workload of repair is reduced; workers can operate the movable workstation tool conveniently; and the work efficiency is improved.

Owner:WUHU SHUNCHANG AUTO PARTS

Method for separating and detecting 1, 2-propylene glycol enantiomer by gas chromatography

PendingCN113848257AReduce usageImprove stabilityComponent separationChromatographic separationAlcohol

The invention provides a rapid, efficient and environment-friendly pre-column derivatization gas chromatography separation and determination method for enantiomer impurities of (S)-1, 2-propylene glycol of alcohol compounds (such as dapagliflozin synthesis raw materials), and effectively overcomes the technical defects of peak trailing in the chromatographic separation process of 1, 2-propylene glycol and incapability of accurately quantifying trace impurities in the 1, 2-propylene glycol.

Owner:BEIJING SIHUAN PHARMA +3

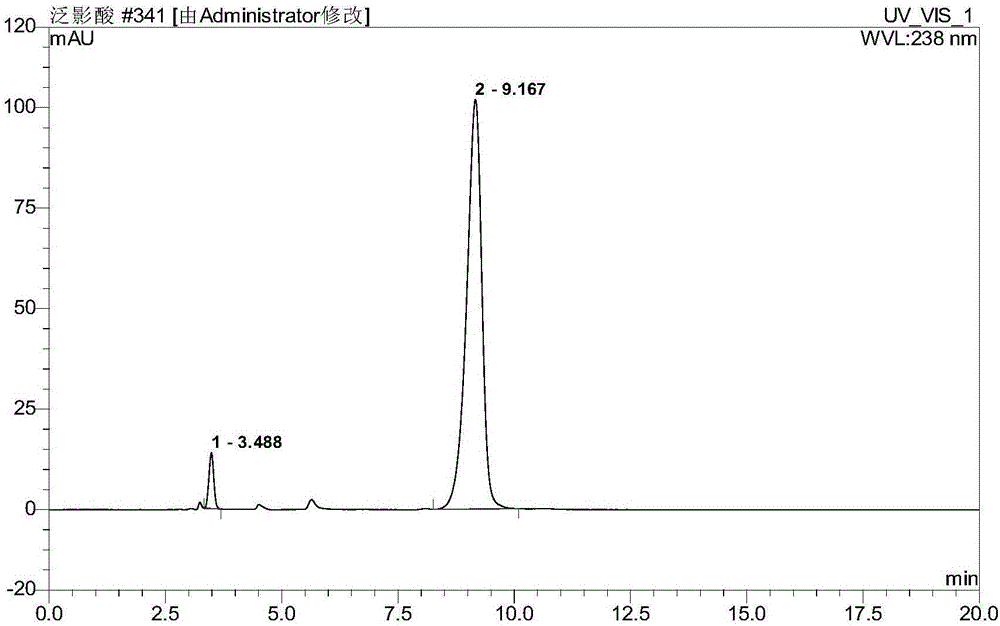

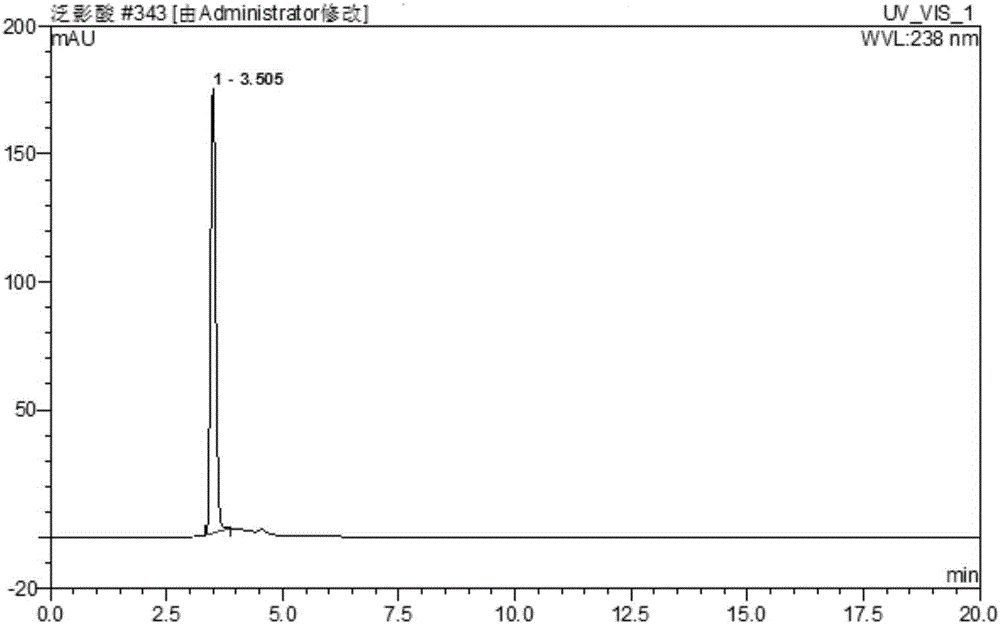

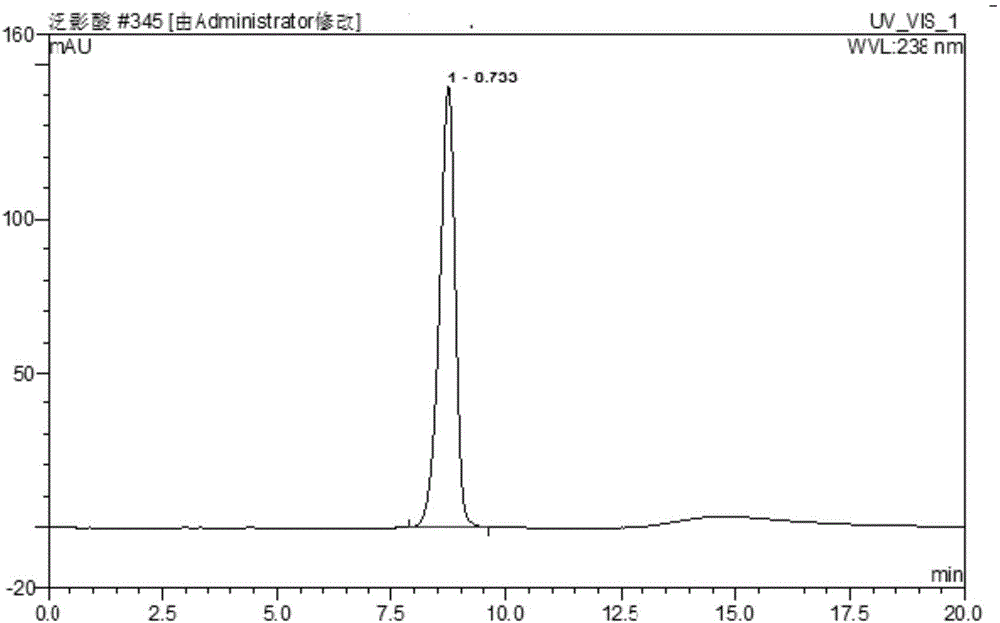

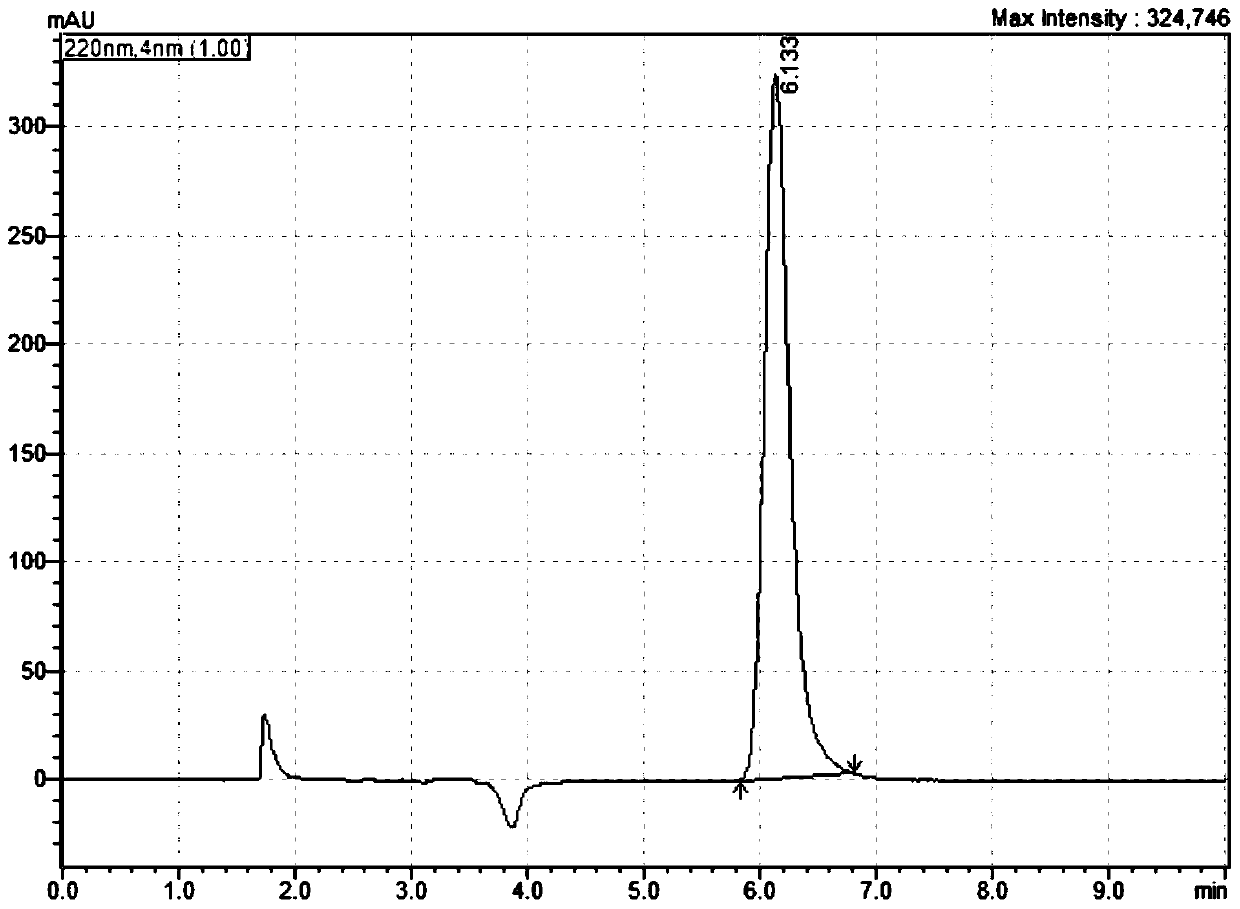

High performance liquid chromatography qualitative/quantitative analysis method for amidotrizoic acid active ingredient and application thereof

ActiveCN106841435ARapid determinationGuaranteed production effectComponent separationAmidotrizoic AcidPhosphoric acid

The invention discloses a high performance liquid chromatography analysis method for an amidotrizoic acid active ingredient. A core-shell type chromatographic column is used for the high performance liquid chromatography, acetonitrile and phosphoric acid-water are used as mobile phases, and separation is performed in an isocratic elution manner, wherein the pH value of the phosphoric acid water solution is 2.0, and the volume ratio of the acetonitrile to the phosphoric acid-water is 30:70. The high performance liquid chromatography analysis method disclosed by the invention can quickly determine the amidotrizoic acid active ingredient content, and can also detect raw materials and key intermediates in synthesis; and the detection result is accurate and reliable, thereby ensuring the production and quality of the amidotrizoic acid active ingredient.

Owner:SHANGHAI NEW HUALIAN PHARMA +1

Working position apparatus in automobile production process

InactiveCN102975189ASolving Quality Control IssuesEasy to operateWork tools storageQuality controlEngineering

The invention discloses a working position apparatus in an automobile production process, which comprises a frame. The frame consists of a bottom frame, a vertical column and an angle steel; the bottom frame, the vertical column and the angle steel are connected sequentially; and a protective device and a limiting device are arranged in the frame; the bottom end of the vertical column is connected with the bottom frame; the top end of the vertical column is connected with the angle steel; the vertical column is welded or riveted with the angle steel; and the protective device is a U-shaped catch lever, and the catch lever is substantially in a horizontal opened U shape. The working position apparatus can effectively solve the problem of quality control of transshipment and storage processes of outdoor panel workpieces, has simpleness and convenience in operation, and improves work efficiency, meanwhile the working position apparatus has a simple manufacturing process, long service life, low maintenance cost, and wide application range, can better solve the problem of quality control of transshipment and storage processes of the outdoor panel workpieces, reduces workload of repair, has simpleness in worker operation, and improves work efficiency.

Owner:WUHU SHUNCHANG AUTO PARTS

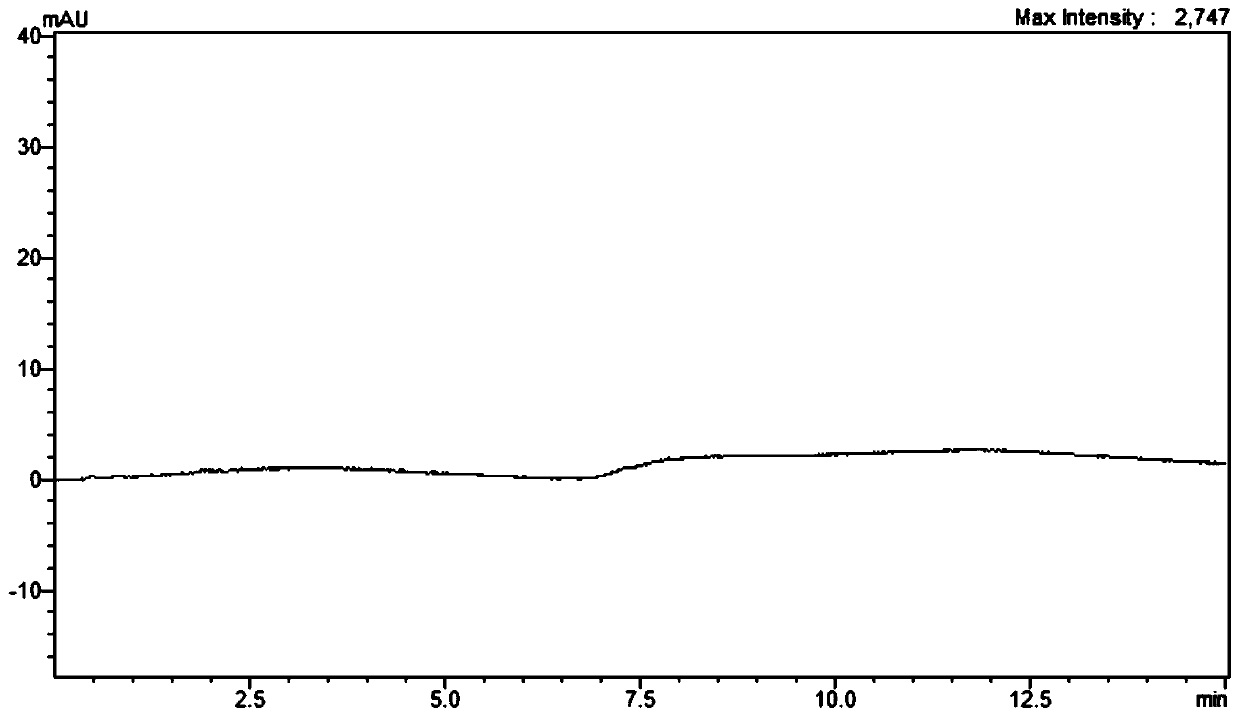

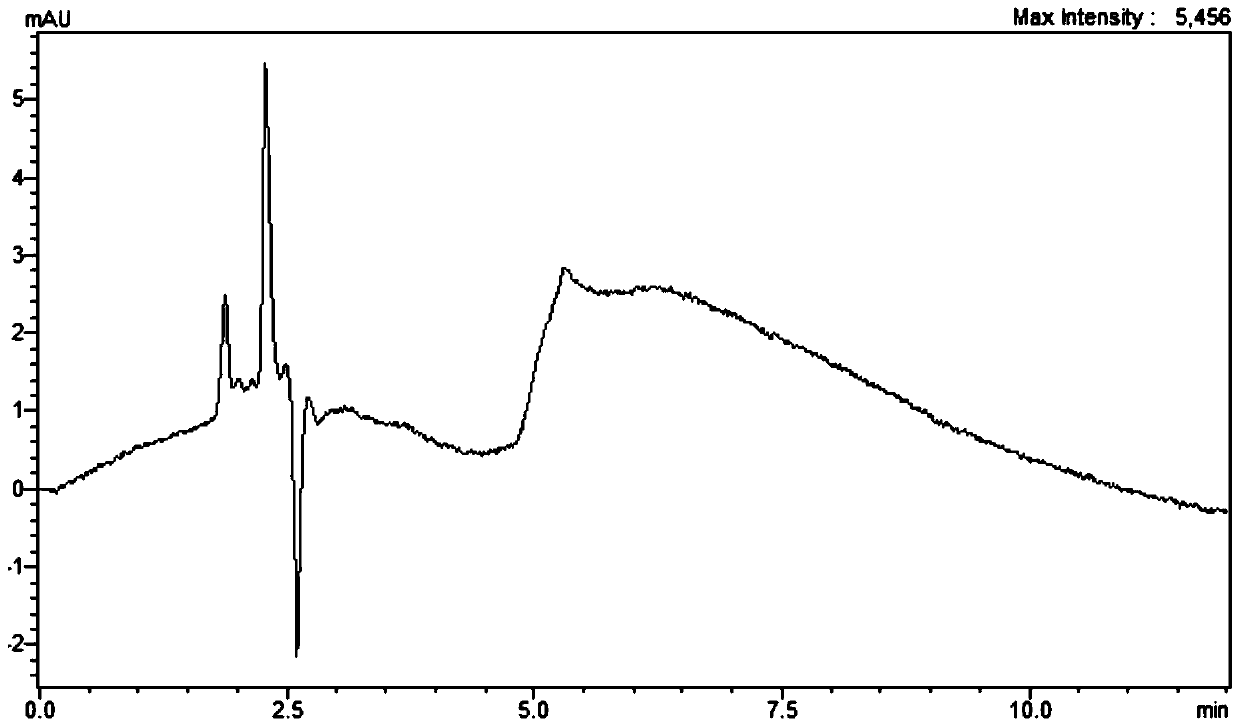

Method for detecting kasugamycin by high performance liquid chromatography

PendingCN111458433AAvoid damageValid reservationComponent separationColumn temperatureChromatography column

The invention relates to a method for detecting kasugamycin by high performance liquid chromatography, and belongs to the technical field of pharmaceutical analysis. Chromatographic conditions of themethod are as follows: a chromatographic column is Igeerre Virusil HILIC (Agela, 4.6mm*150mm, 5[mu]m), a mobile phase is an organic phase-water phase, an elution mode is isocratic elution, the flow rate is 1.0mL / min;, the detection wavelength is 220-245 nm, the column temperature is 40 DEG C, the sample size is 10[mu]L, a diode array detector is adopted as the detector, and isocratic elution is carried out. According to the method, an ion pair is prevented from being used as a mobile phase, so that the chromatographic column is prevented from being damaged; and kasugamycin can be effectively retained, so that interference of solvent peaks, inverted peaks and impurity peaks is avoided, and rapid and accurate detection can be realized.

Owner:JINGBO AGROCHEM TECH CO LTD

Method for preparing polymer grade 1-butene by high sulfur content four carbon compounds catalysis from refinery

ActiveCN101362671BDoes not affect activityLow costDistillation purification/separationChemical modification purification/separationPurification methodsDistillation

The invention relates to a method for producing polymer grade 1-butene from C4 catalyzed by high sulfur in a refinery, which is a purification method for C4 catalyzed by the high sulfur that is the by-product of refinery process in petrochemical industry. The invention discloses that coarse desulfurization of the C4 catalyzed by a high sulfur refinery is carried out in a de-C5 tower, and at least desulfurizing, drying, organic sulfur removing and washing are carried out by a water scrubber and a reactor, thereafter, material flow enters the reactor and etherification is carried out for removing isobutene, as well as hydrogenation is added selectively and removing diene. Then the material flow is separated by a distillation column, and adsorbed by a molecular sieve in the reactor, so as to obtain the polymer grade 1-butene with the purity of the 1-butene to be over 99 percent, wherein, the total sulfur content is less than 2mg / m<3>. By adopting the invention, the mixed C4 with high sulfur is desulfurized at first until the sulfur content is less than 10mg / m<3>, and then enters different reactors, and the catalyst activity is not affected, thus leading the 1-butene to achieve polymer grade standard finally. The production technique of the invention is characterized by short process, easy operation, and the like, and has the advantages of environmental sanitation, safe production and comparatively low cost.

Owner:CHINA PETROLEUM & CHEM CORP

A kind of cotton-like interlining and its production process

The invention relates to cotton-like lining cloth which is formed by blending viscose fibre / polyester staple fiber blended yarn serving as warp yarn and functional polyester filament serving as weft yarn, wherein the functional polyester filament can absorb and discharge moisture. In addition, a production process of the cotton-like lining cloth is further related. The production process includes the following steps: 1, warp yarn selection; 2 weft yarn selection; 3, weaving; 4, overflow desizing and bleaching processing or overflow desizing and bath dyeing processing; 5, dehydration; 6, scotching; 7, sizing; 8, coating calendaring; 9, perching volume classification; and 10, laboratory sample detection.

Owner:CPL NEW MATERIAL TECH CO LTD

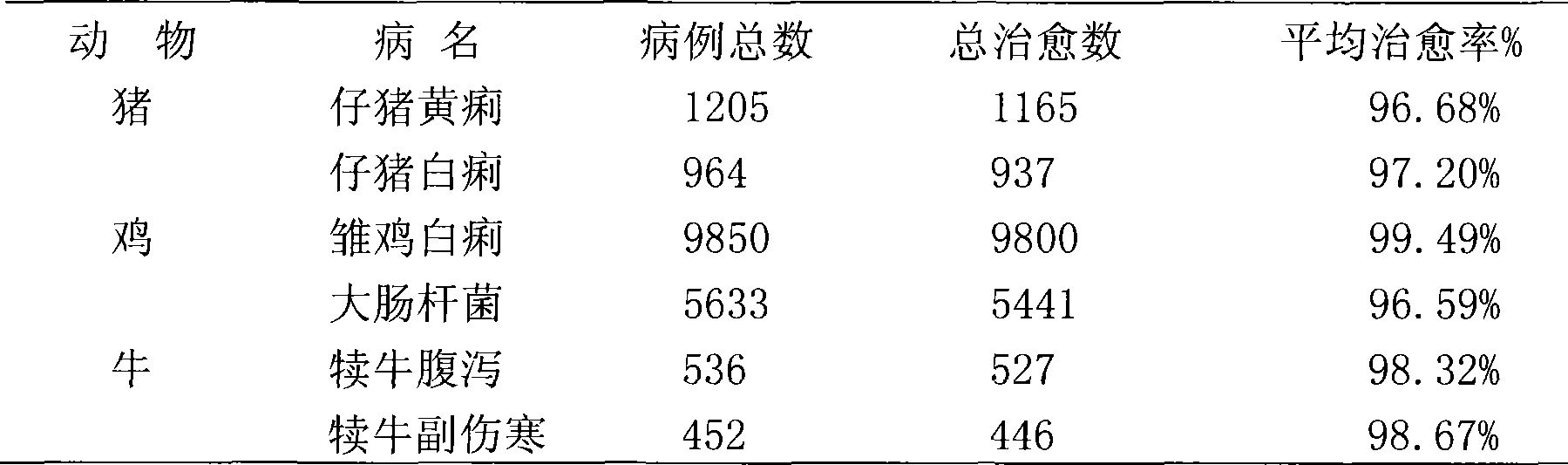

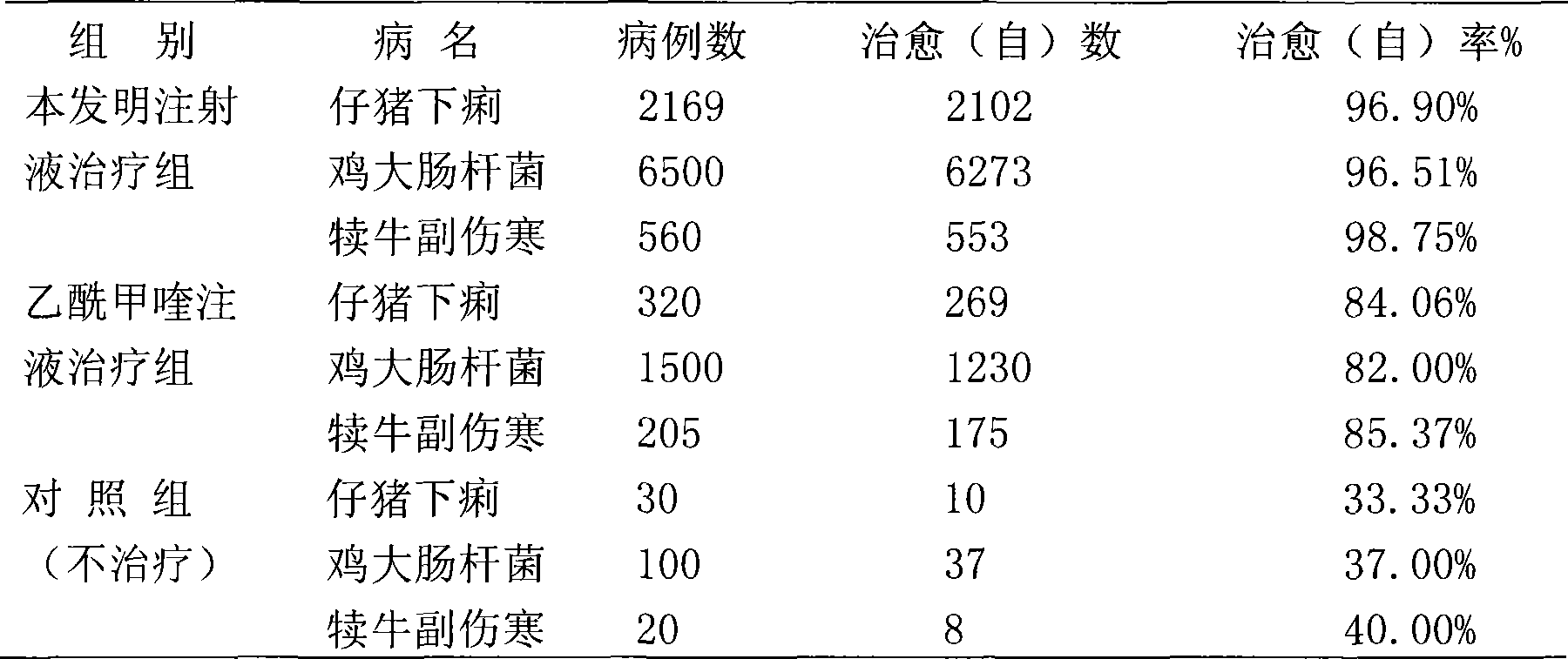

Compound mequindox injection for animals and preparation method thereof

InactiveCN101380300BNot easy to rule outAvoid interferencePharmaceutical delivery mechanismAntiinfectivesOrganic solventAtropine sulfate

Owner:陈建波

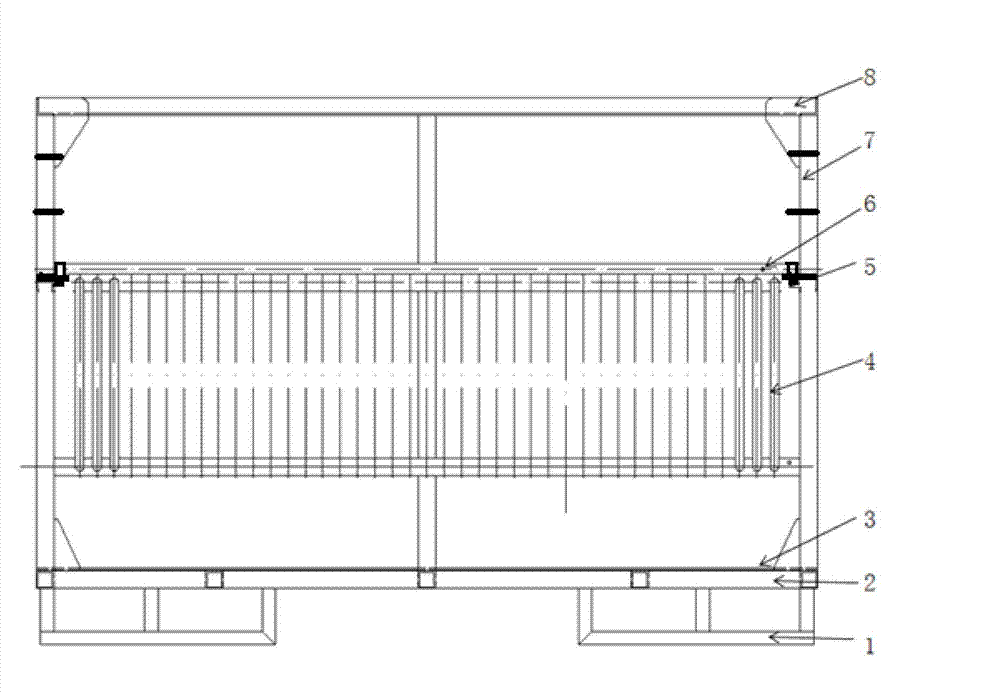

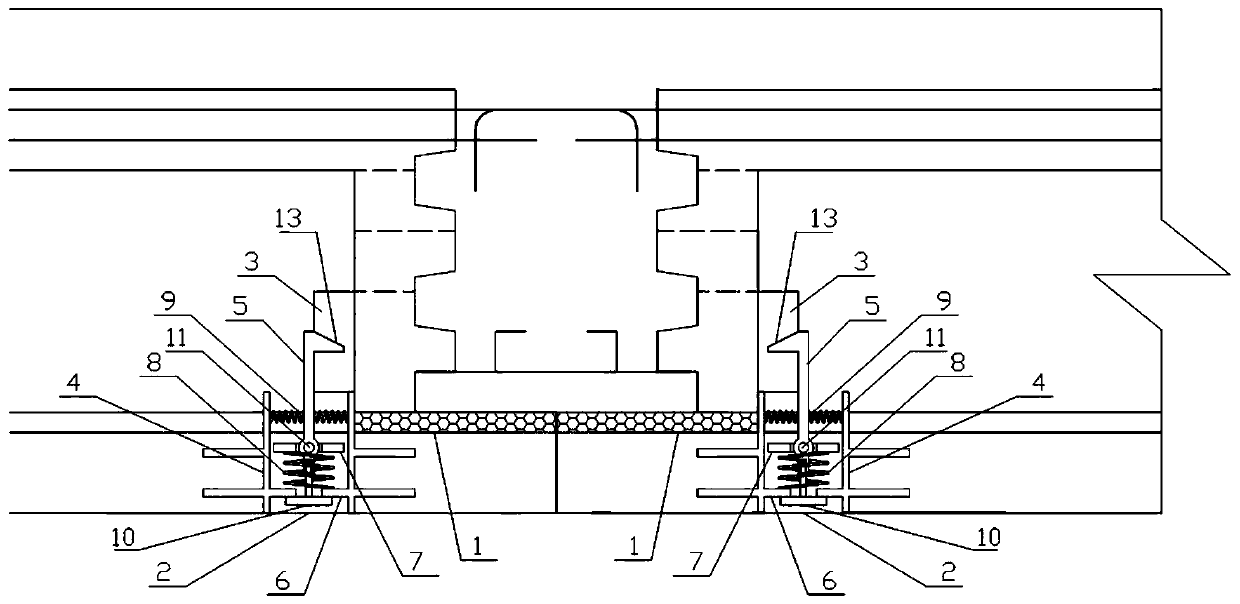

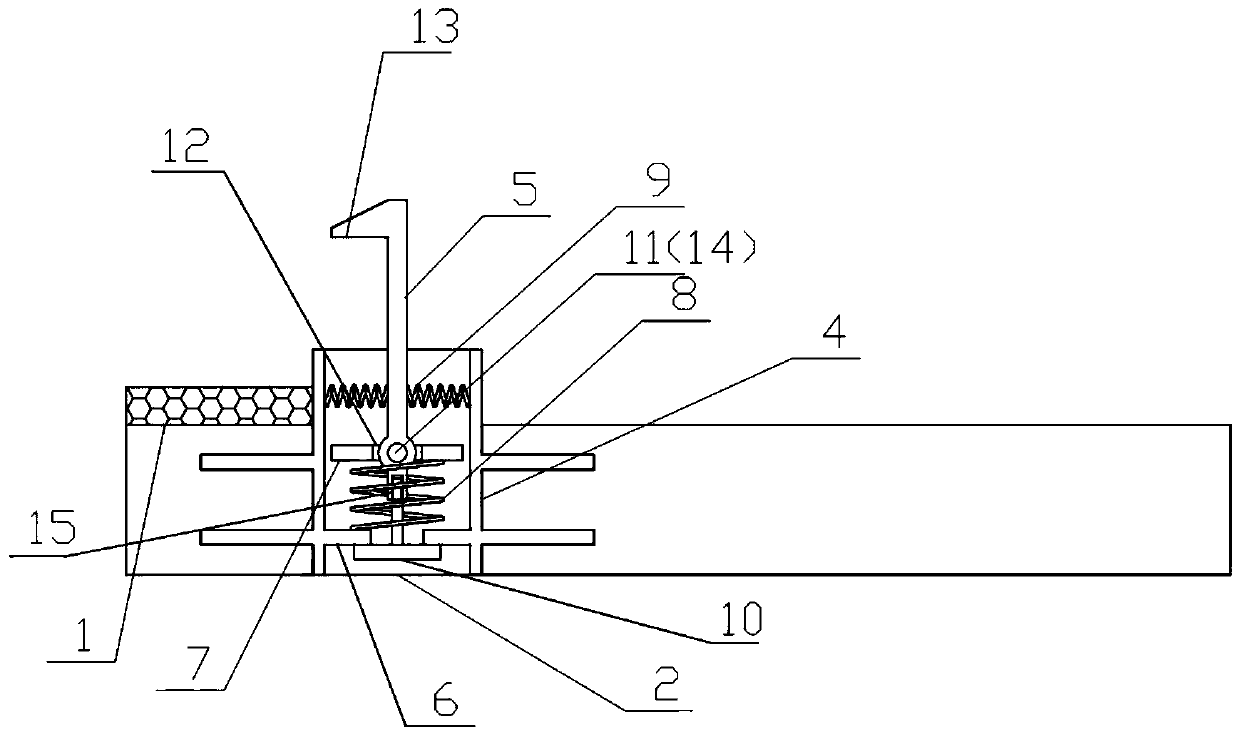

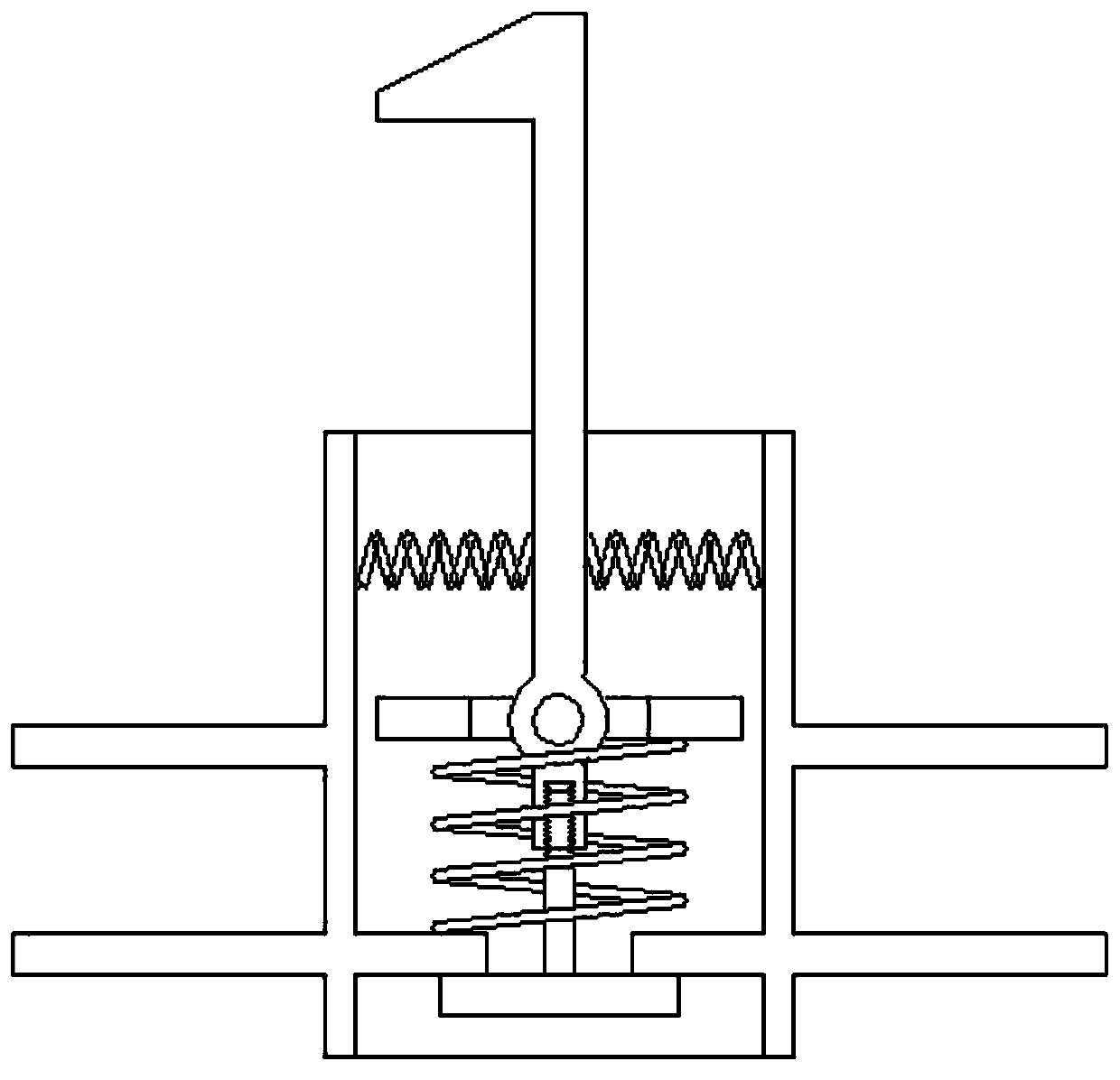

Convenient and fast installation device of rib-shaped floor system decorative bottom plate and using method

InactiveCN110130563AReduced footprintSolve the problem of high and lowCeilingsElectricityQuality control

The invention discloses a convenient and fast installation device of a rib-shaped floor system decorative bottom plate and a using method, and relates to the technical field of civil engineering. Theconvenient and fast installation device of the rib-shaped floor system decorative bottom plate comprises a steel sleeve, a fixed positioning disc is arranged in the inner cavity of the steel sleeve, aflexible material cushion is arranged on one side of the steel sleeve, a vertical rod with a hook is arranged at the top of the steel sleeve in a penetrating mode, a hook is arranged at the top of the vertical rod with the hook, a rotating shaft hole is formed in the vertical rod with the hook, and an elastic rotating shaft is arranged in the rotating shaft hole. According to the convenient and fast installation device of the rib-shaped floor system decorative bottom plate and the using method, water and electricity pipelines are placed in the height space of a ribbed beam to reduce the height occupied by a ceiling, the problem of low available floor height of current residential buildings is solved, factory prefabrication is used for solving the problem of product quality control, meanwhile a set of standard using methods is provided, and the problems that installation and disassembly of the decorative floor need commissioners to be responsible for, and pipeline maintenance in the later period is inconvenient are solved.

Owner:CHINA MCC17 GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com