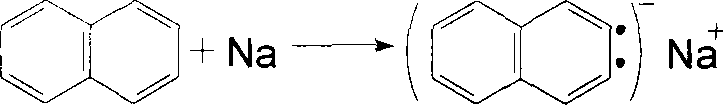

Method for measuring active concentration of sodium naphthalin treatment solution

A technology for treating liquid and sodium naphthalene, which is applied in the field of sodium naphthalene complexes, can solve the problems of no effective detection method, etc., and achieve the effect of reasonable method design, fast analysis speed and good reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] Under the condition of isolating air and moisture, use dichloroethane to react with sodium naphthalene treatment solution at a reaction temperature of 40°C and a reaction time of 5 minutes. Add 50ml tertiary pure water, adjust the pH to 6 with sulfuric acid, and extract the resulting product with water. Sodium chloride, the extraction time is 1min, the sodium chloride in the aqueous solution is titrated with silver nitrate standard solution, and the concentration of sodium naphthalene treatment solution activity is calculated based on the consumption of silver nitrate standard solution V1. Sodium naphthalene treatment solution and dichloroethane The weight-to-volume ratio is 0.2:2,

[0052] Calculation of activity concentration of sodium naphthalene treatment solution:

[0053] X=(V1-V2)×C / m=(6.98-0.02)×0.1010 / 0.2051=3.43mol / kg

Embodiment 2

[0055] Under the condition of isolating air and water vapor, use trichloroethane as a dechlorination agent to react with sodium naphthalene treatment solution, reaction temperature 70℃, reaction time 15min, add 50ml tertiary pure water, adjust the pH value to 10 with nitric acid, The sodium chloride produced by water extraction, the extraction time is 5 minutes, the sodium chloride in the aqueous solution is titrated with silver nitrate standard solution, and the active concentration of sodium naphthalene treatment solution is calculated according to the consumption of silver nitrate standard solution V1. The weight-to-volume ratio of trichloroethane is 2:2,

[0056]Calculation of activity concentration of sodium naphthalene treatment solution:

[0057] X=(V1-V2)×C / m=(7.89-0.03)×0.1010 / 2.005=0.40mol / kg

Embodiment 3

[0059] Under the condition of isolating air and water vapor, use chloroform as a dechlorinating agent to react with sodium naphthalene treatment solution at a reaction temperature of 50°C and a reaction time of 10 minutes. Add 50ml tertiary pure water, adjust the pH to 10 with acetic acid, and use water The sodium chloride produced by extraction, the extraction time is 5 minutes, the sodium chloride in the aqueous solution is titrated with silver nitrate standard solution, and the active concentration of sodium naphthalene treatment solution is calculated according to the consumption of silver nitrate standard solution V1. The weight-to-volume ratio of methyl chloride is 1:2,

[0060] Calculation of activity concentration of sodium naphthalene treatment solution:

[0061] X=(V1-V2)×C / m=(7.86-0.05)×0.1010 / 1.012=0.78mol / kg

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com