Multi-inclined-hole position degree testing device of disc thin-walled member

A technology for inspection devices and thin-walled parts, applied in the direction of measuring devices, mechanical devices, mechanical measuring devices, etc., can solve problems such as research and design of inspection devices that are rarely available, and achieve quality control problems, low skill requirements, and easy operation convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The following is a detailed description of a multi-slant hole position inspection device for a disc-type thin-walled part of the present invention in conjunction with the accompanying drawings and embodiments of the specification:

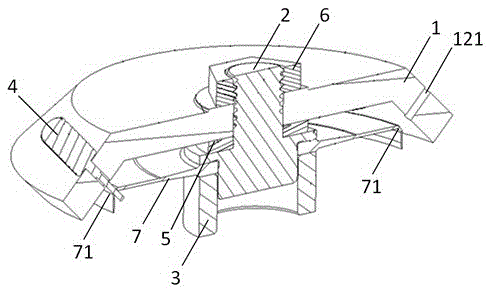

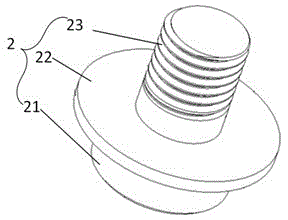

[0031] Such as figure 1 As shown in the figure, a multi-slope hole position inspection device for disc-type thin-walled parts includes a positioning base 3, a positioning shaft 2 is installed on the positioning base 3, a washer 5 is set outside the positioning shaft 2, and the inspection disc 1 is connected with the nut 6 and The upper end of the positioning shaft 2 is fixed; the inspection pin 4 passes through the guide hole 121 on the inspection plate 1 and the inclined hole 71 to be inspected on the disk-shaped thin-walled workpiece 7 to be inspected.

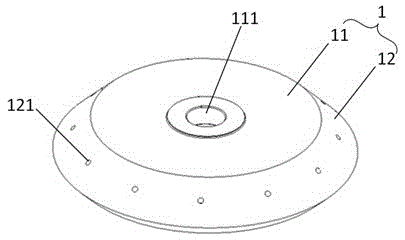

[0032] Such as figure 2 As shown, the inspection plate 1 is a plate-shaped structure with uniform thickness, formed by the plate surface 11 and the skirt 12 formed along the outer periph...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com