Beam-type supporting frame aperture multi-geometric tolerance detection device

A technology of shape and position tolerance and detection device, which is applied in the direction of measuring device, mechanical measuring device, and mechanical device, can solve the problems of shape and position tolerance, research and design of rare inspection devices, etc., achieve convenient operation, save detection time, The effect of improving detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

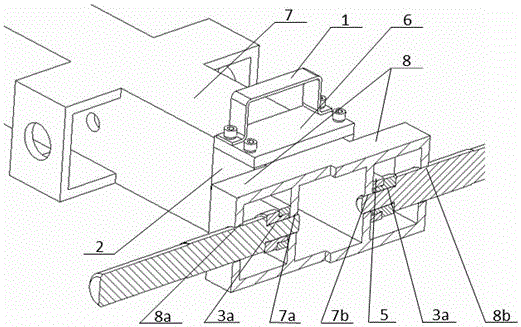

[0033] The multi-shape tolerance detection device of the beam support frame aperture of the present invention will be described in detail below in conjunction with the drawings and embodiments of the description:

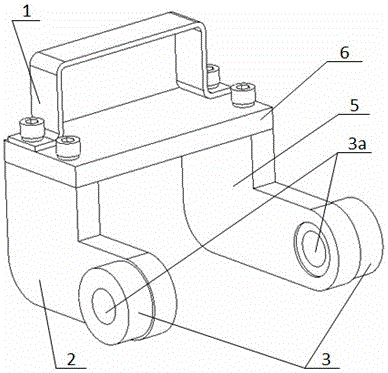

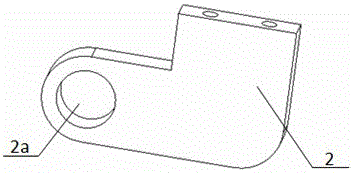

[0034] like Figure 1~6 As shown, a multi-shape tolerance detection device for the aperture of a beam support frame includes a handle 1 and two inspection rods 4, a large cover plate 6 is arranged under the handle 1, and the front side plate 2 and the rear side plate 5 are parallel to each other and Both are vertically connected to the bottom surface of the large cover plate 6; the front side plate 2 and the rear side plate 5 are all in an L-shaped plate structure, and the free ends respectively form the front side plate through hole 2a and the rear side plate through hole 5a, and the front side plate 2 and the side opposite to the free end of the rear side plate 5 are provided with a bushing 3 .

[0035] The large cover plate 6 is arranged horizontally.

[0036] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com