Lifting type reversing position intelligent adjusting rail guided vehicle

A technology for rail trucks and intelligent adjustment, applied in the field of rail trucks, can solve problems such as unstable operation of rail trucks, and achieve the effects of easy processing, reduced processing costs, and reduced errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

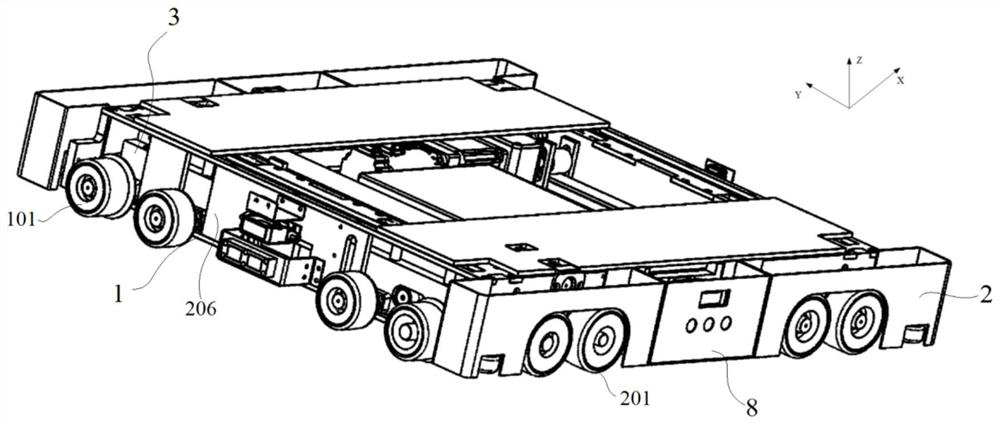

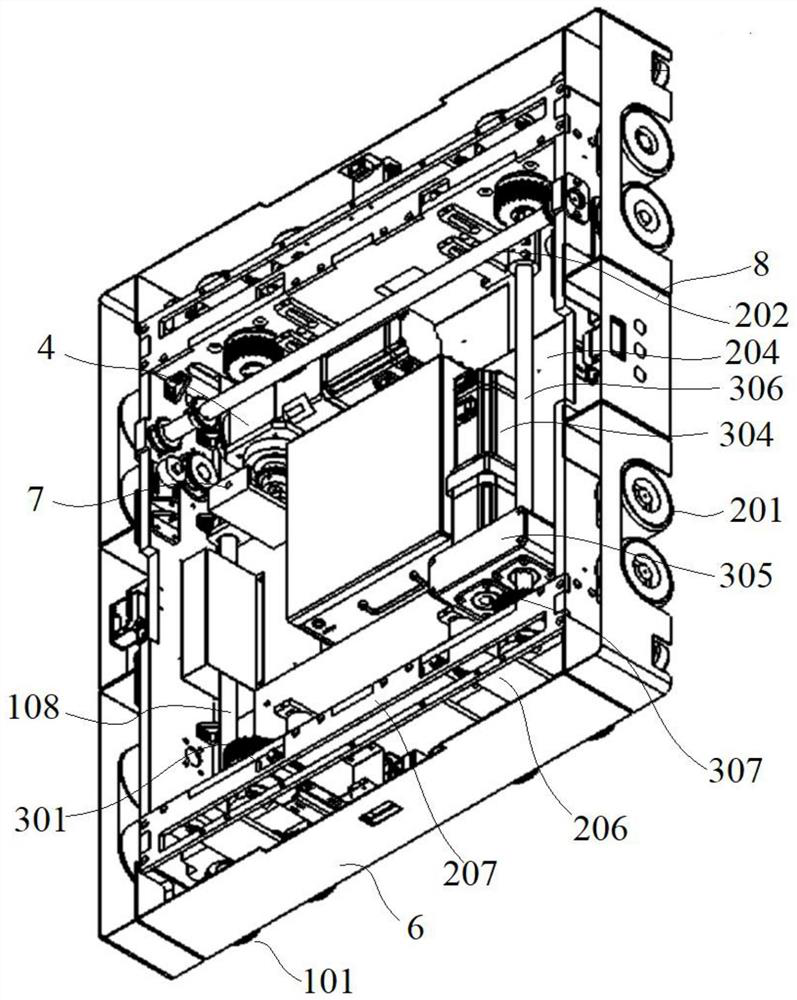

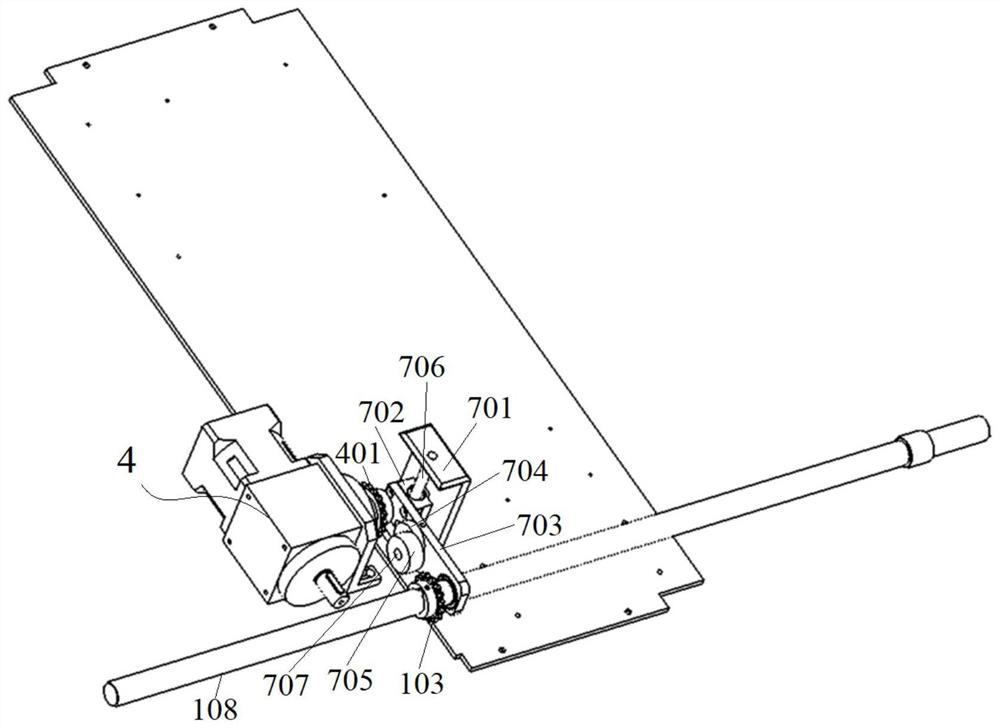

[0051] The embodiment of the present application provides a lifting type reversing position intelligent adjustment rail transport vehicle, which solves the technical problem in the prior art that the chain between the crossbar and the motor is out of joint or the crossbar is bent and deformed, resulting in unstable operation of the rail transport vehicle.

[0052] The technical solution in the embodiment of the present application is to solve the above-mentioned technical problems, and the general idea is as follows:

[0053] A chain adaptive adjustment mechanism is designed. The chain adaptive adjustment mechanism can automatically adjust the tightness of the chain, so that the chain is always in a tense state, and ensures the stable transmission of the driving force of the traveling wheel of the rail transport vehicle.

[0054] At the same time, the chain adaptive adjustment mechanism can also provide lateral support for the middle part of the cross bar to relieve the bending...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com