Burner combined by a plurality of polygon prism cavity fire distributors

A technology of splitting flames and polygonal prisms, which is applied to burners, gas fuel burners, and combustion methods. It can solve the problems of reduced air mixing volume, excessive harmful gas content, and high harmful gas content, so as to avoid width changes and double support strength. , Improve the effect of burning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

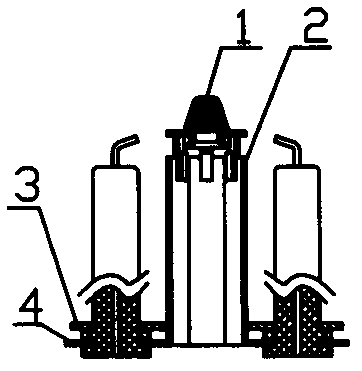

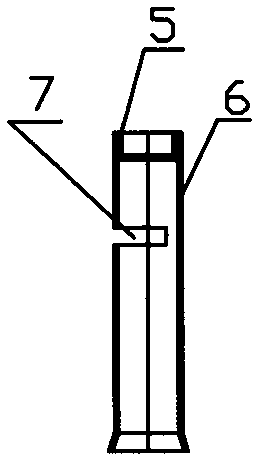

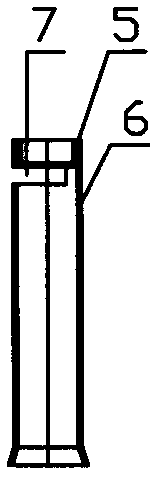

[0028] figure 1 , figure 2 , Figure 4 , Figure 5 , Image 6The combusted burner of multiple polygonal prism cavity fire distributors shown is lift type. It includes a center tube 2 located in the center and an outer ring tube 6 arranged in a ring around the periphery. The tops of the center tube 2 and the outer ring tube 6 are respectively equipped with a central fire distribution cover 1 and an outer ring fire distribution cover 5. The outer ring tube 6 The upper tube wall is partially cut to form a side port 7; the lower end of the central tube 2 and the outer ring tube 6 correspond to the position of the gas nozzle, and the proximity of the central tube 2 is equipped with an induction needle 8, an ignition needle, the central tube 2 and the outer ring tube 6 is a hexagonal prism, the through holes on the limit plate 9 or the tuyere plate 15 that the central tube and the outer ring tube pass through are corresponding hexagons, and the polygonal through holes limit the...

Embodiment 2

[0032] image 3 , Figure 7 , Figure 8 , Figure 9 , Figure 10 The burner combined with multiple polygonal prism cavity fire distributors shown is a fixed type. It includes a center tube 2 located in the center and an outer ring tube 6 arranged in a ring around the periphery. The tops of the center tube 2 and the outer ring tube 6 are respectively equipped with a central fire distribution cover 1 and an outer ring fire distribution cover 5. The outer ring tube 6 The upper tube wall is partially cut to form a side port 7; the lower end of the central tube 2 and the outer ring tube 6 correspond to the position of the gas nozzle, and the proximity of the central tube 2 is equipped with an induction needle 8, an ignition needle, the central tube 2 and the outer ring tube 6 is a hexagonal prism, the through holes on the limit plate 9 or the tuyere plate 15 that the central tube and the outer ring tube pass through are corresponding hexagons, and the polygonal through holes li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com