Sliding formwork construction method

A construction method and slip-form technology, which are applied in the fields of formwork/template/work frame, on-site preparation of building components, construction, etc., can solve problems such as lack of summary, achieve fast construction progress, reduce on-site processing and welding, reduce Effects of Environmental Pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The technical solution of the present invention is further described below in conjunction with the accompanying drawings, but the scope of protection is not limited to the description.

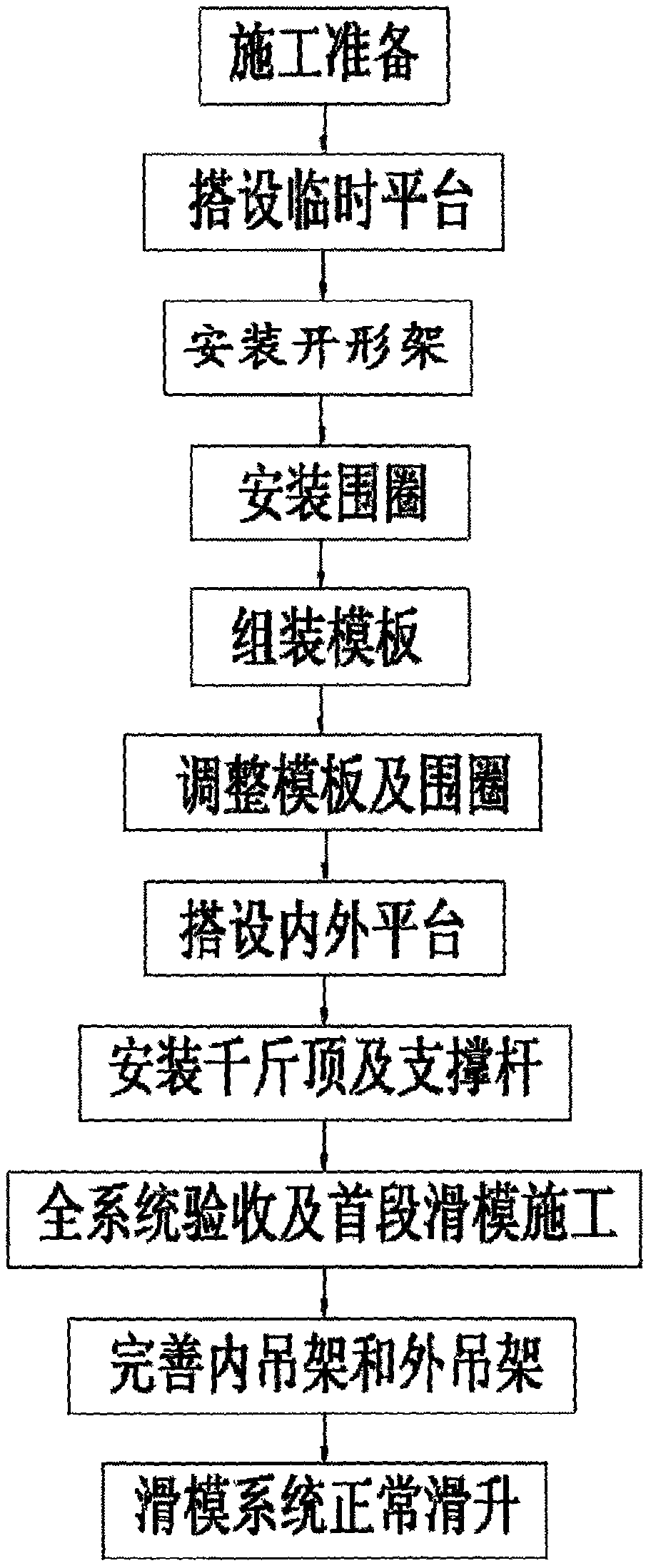

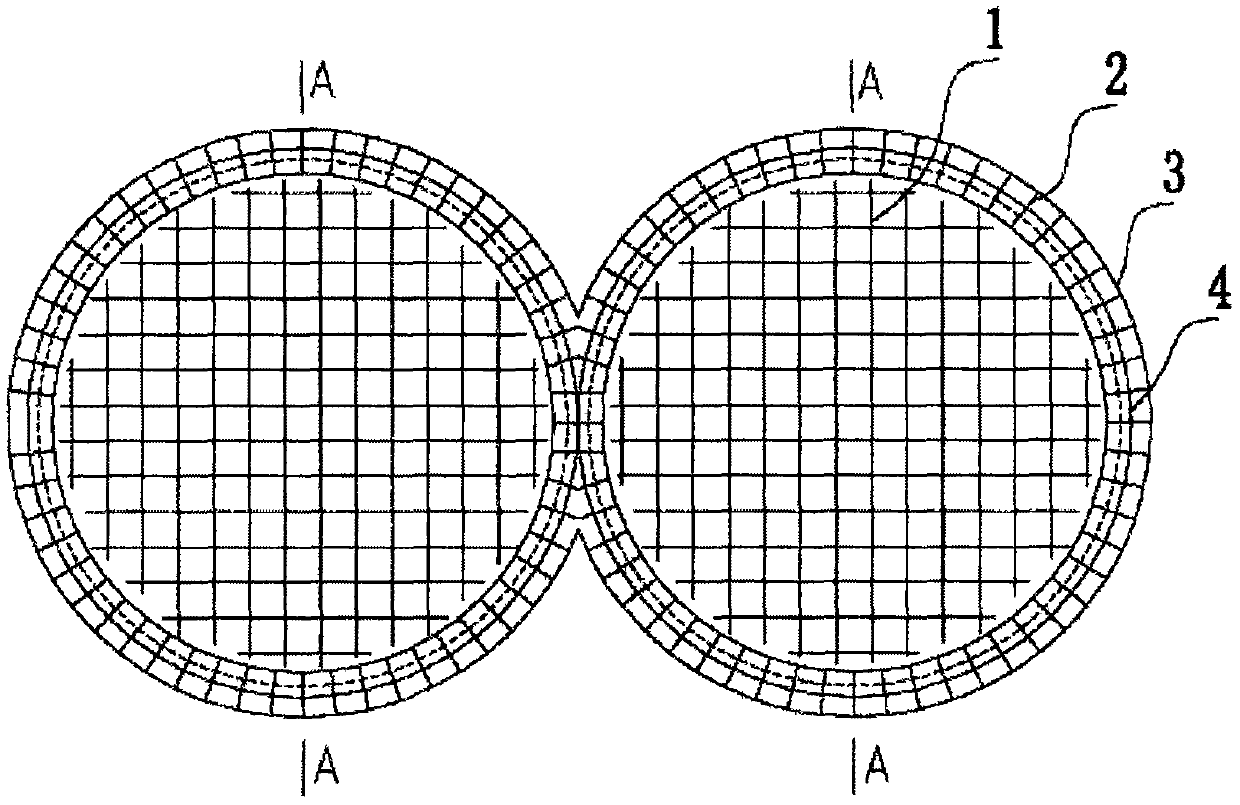

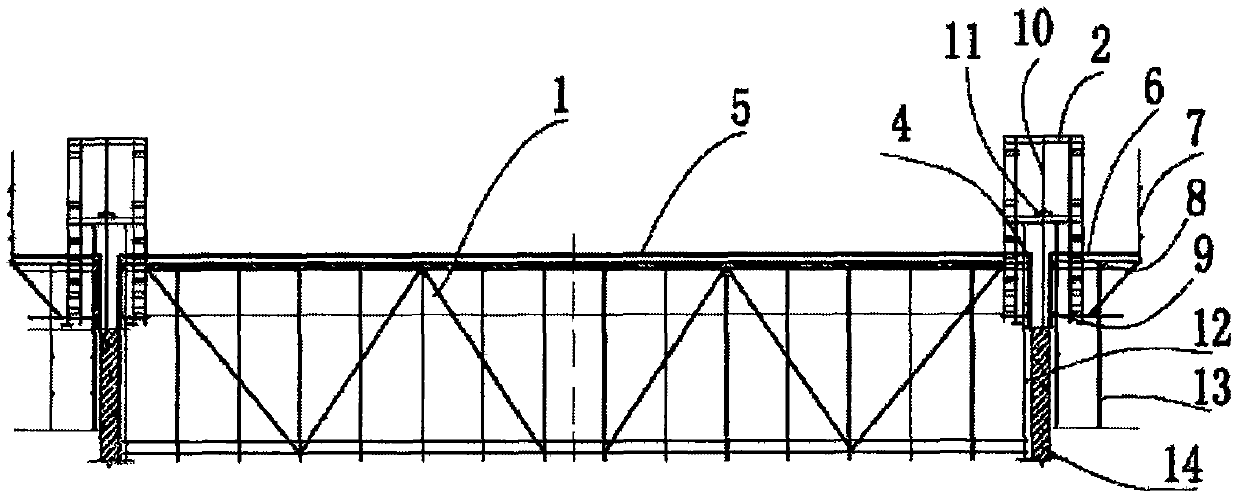

[0047] like Figure 1 to Figure 6 As shown, a hydraulic slipform construction method for a reinforced concrete straight tube high-rise structure, the specific method includes the following steps: a, erecting a temporary platform; b, installing an open frame 2; c, installing an enclosure 3; d, assembling a formwork 4; e. Adjust template 4 and enclosure 3; f. Set up inner platform 5 and outer platform 6; g. Install jack 11 and support rod 10; h. Acceptance of the whole system and construction of the first section of sliding form; i. Improve inner hanger 12 and the outer hanger 13; j, the sliding form system slides up normally.

[0048] The inner platform 5, the outer platform 6, the inner hanger 12, the outer hanger 13, the opening frame 2, the guardrail 7, the template enclosure 9 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com