Chord axis apparatus for stringed instrument and its manufacture method

A technology for stringed instruments and pegs, which is applied in the field of peg devices and its manufacture, can solve the problems of increasing the number of complex parts and high manufacturing costs, and achieve the effect of eliminating shaking and stable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

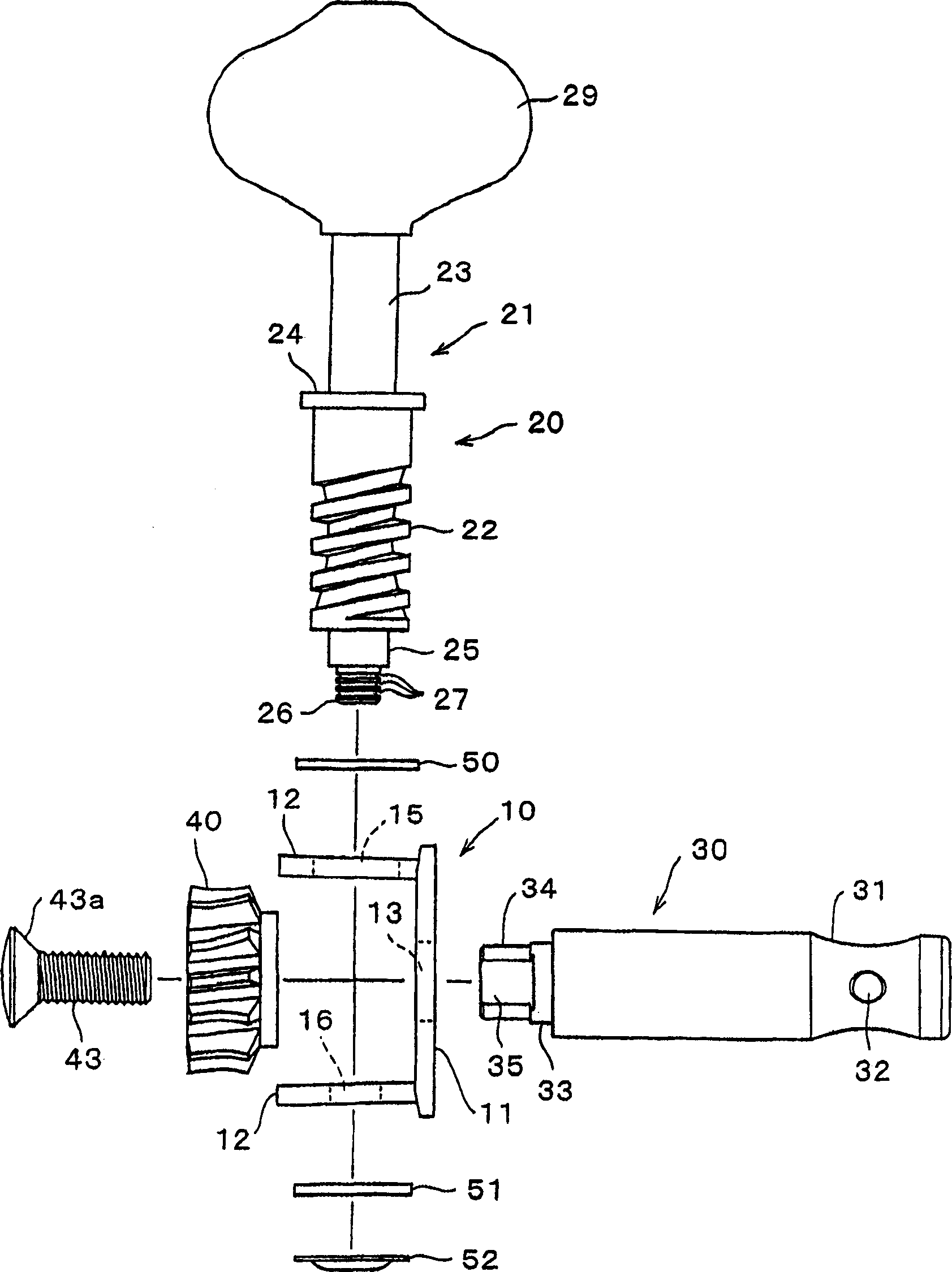

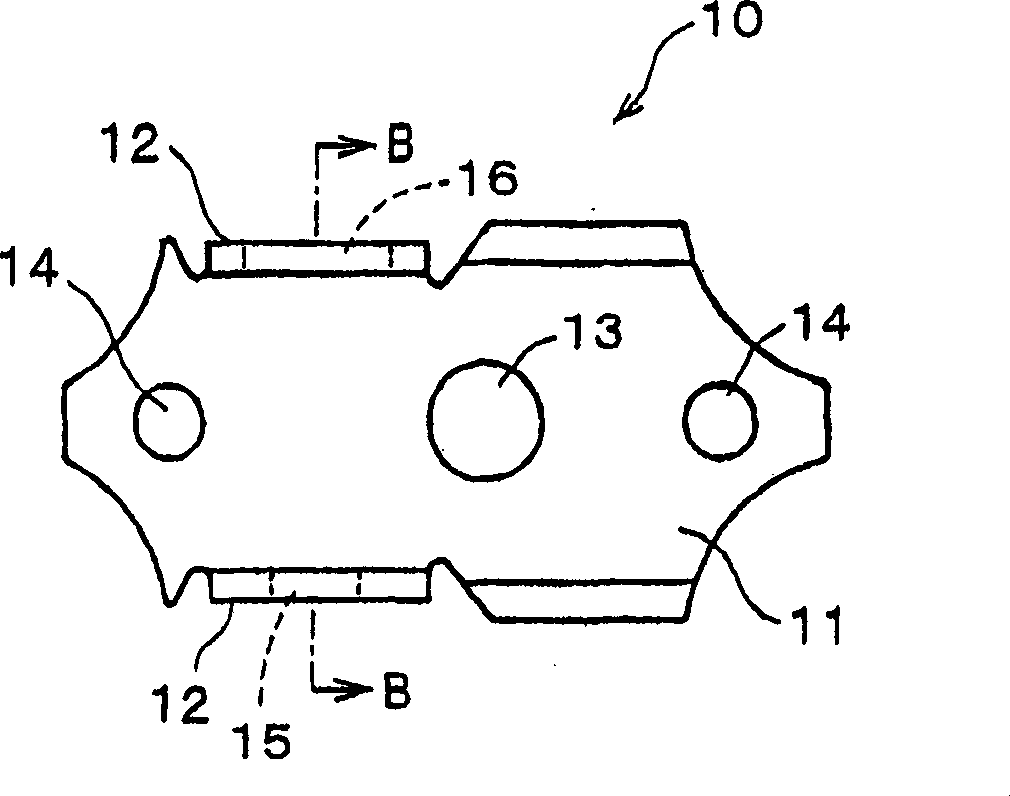

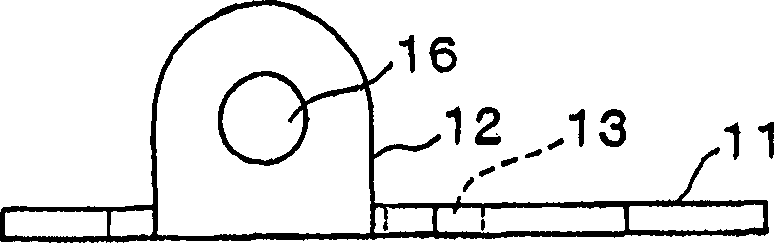

[0034] Below, refer to Figure 1 to Figure 6 Embodiments of the present invention will be described.

[0035] figure 1 It is an assembly plan view of the peg device of the embodiment. In the figure, numeral 10 is a main body, 20 is a worm gear assembly, 30 is a reel, and 40 is a worm gear. Hereinafter, these structures will be described in order, figure 2 is a plan view showing the main body 10 . As shown in the figure, the main body 10 has a substantially rectangular shape in plan view, and is composed of a flat base 11 and bearings 12 erected from both sides of the base 11 . In the base portion 11, a support hole 13 for freely rotatably supporting the reel 30 is formed. In addition, holes 14 for attaching the peg unit to the head of the classical guitar with screws are formed in the base portion 11 .

[0036] A large diameter hole 15 for freely rotatably supporting the base of the worm gear shaft assembly 20 is formed in one bearing 12, and a small diameter hole for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com