Hydraulic slip-form construction method of reinforced-concrete straight-drum high-rising building

A technology of reinforced concrete and construction methods, which is applied to building structures, formwork/formwork/work frames, buildings, etc., can solve problems such as difficult construction, high requirements for production and installation, and large environmental pollution, so as to reduce on-site processing and Welding, saving section steel processing costs, and reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solution of the present invention is further described below in conjunction with the accompanying drawings, but the scope of protection is not limited to the description.

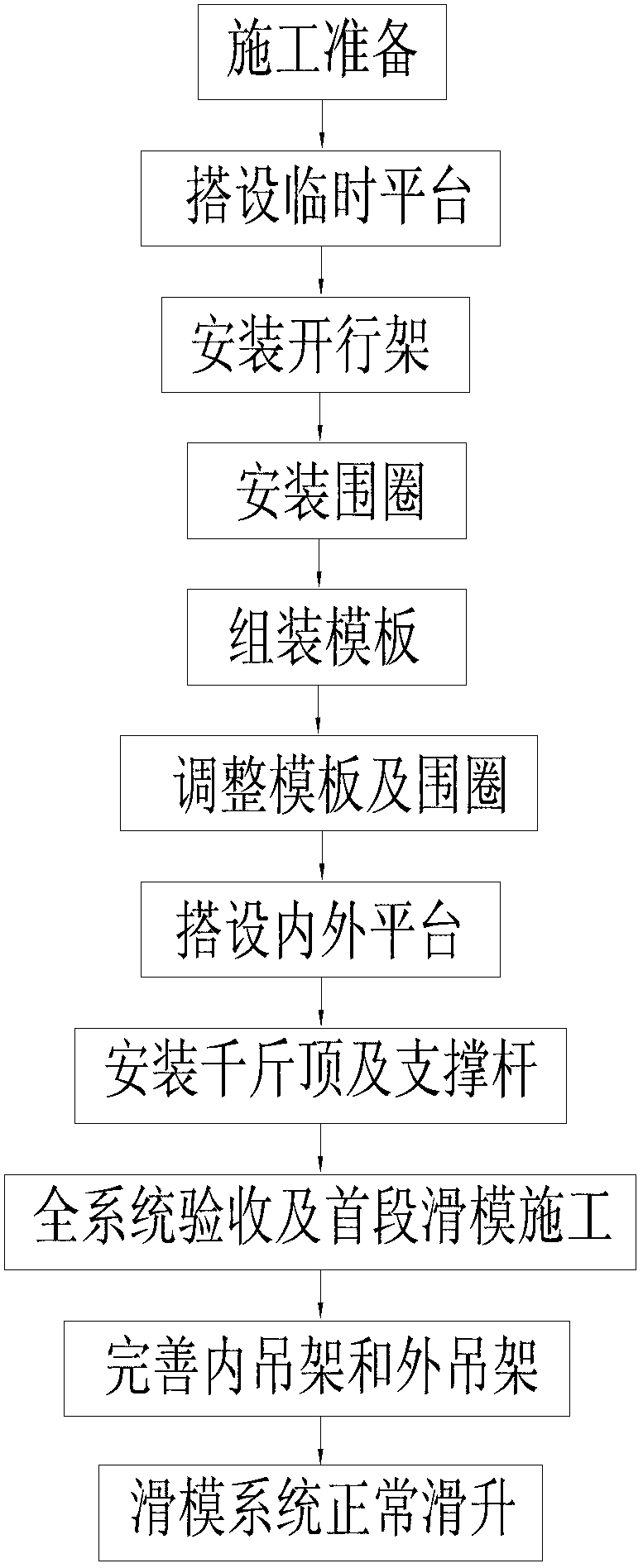

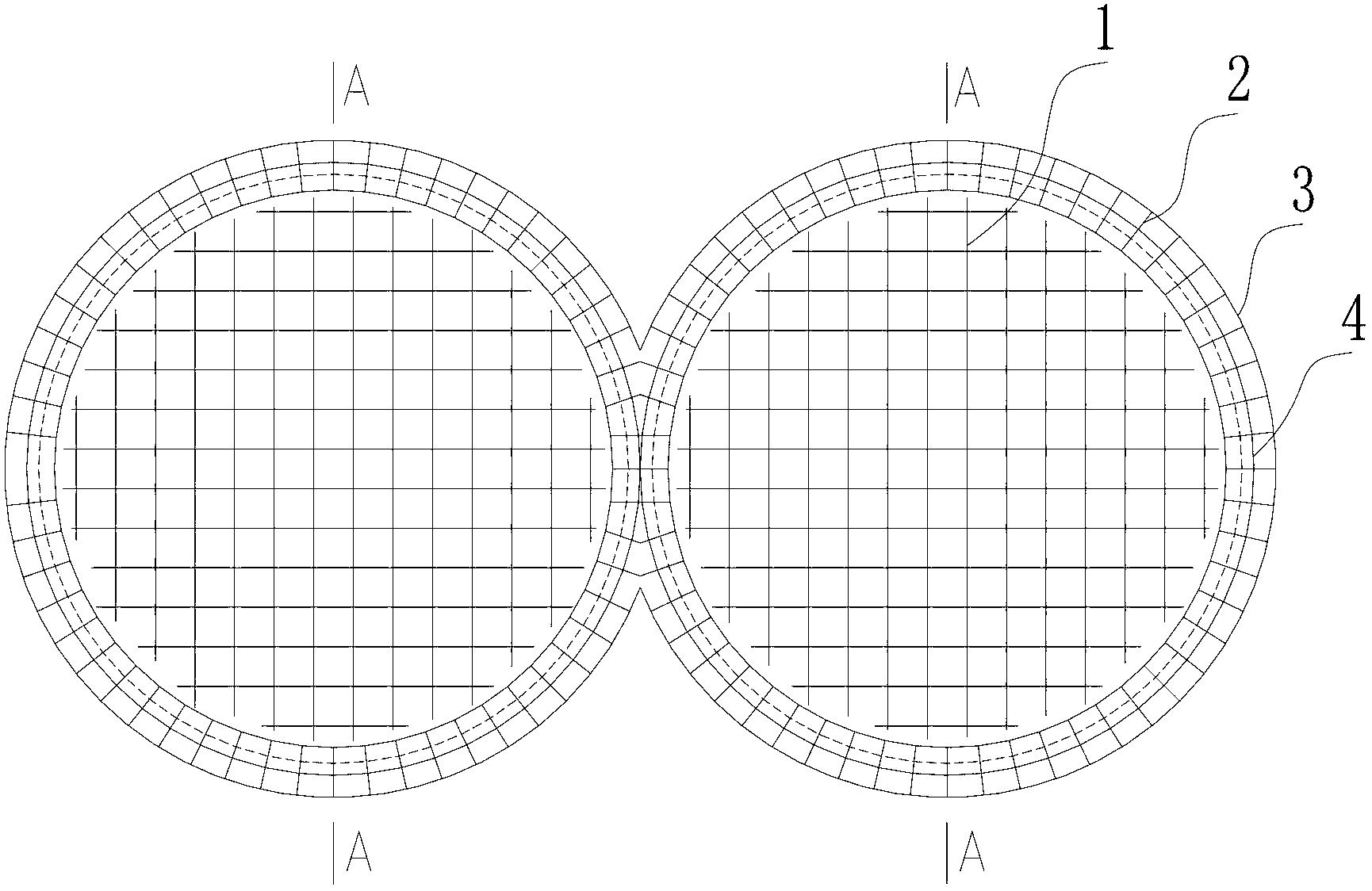

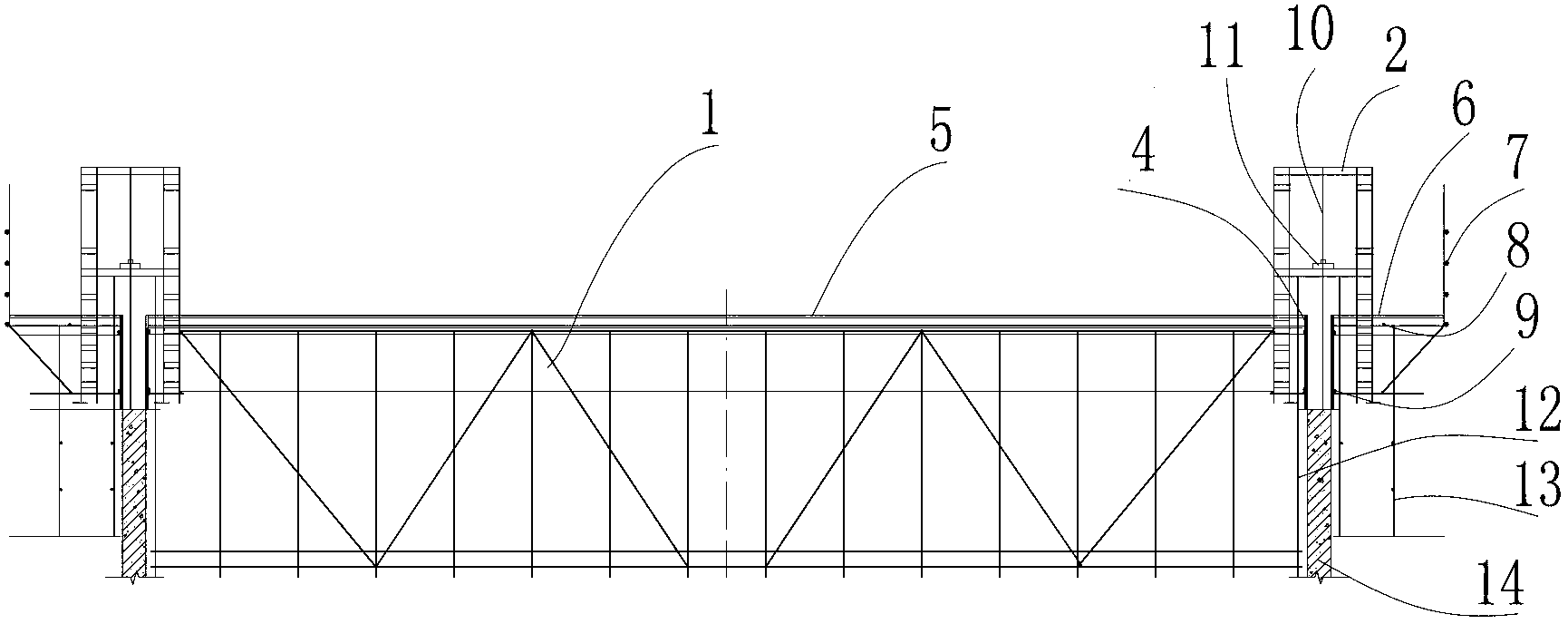

[0023] Such as Figure 1 to Figure 6 As shown, a hydraulic slipform construction method for a reinforced concrete straight-barrel high-rise structure, the specific method includes the following steps: a, erecting a temporary platform; b, installing a traveling frame 2; c, installing an enclosure 3; d, assembling a formwork 4; e , adjust the template 4 and enclosure 3; f, set up the inner platform 5 and the outer platform 6; g, install the jack 11 and the support rod 10; h, the acceptance of the whole system and the construction of the first section of the sliding form; i, improve the inner hanger 12 And the outer hanger 13; j, the sliding form system slides up normally.

[0024] The inner platform 5, the outer platform 6, the inner hanger 12, the outer hanger 13, the opening frame 2, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com