Tilt type gravity molding device

A gravity casting and tilting technology, which is applied to casting molding equipment, casting molds, casting mold components, etc., can solve the problems of accelerating cooling speed and weakening strength, so as to reduce the amount of molten metal, reduce manufacturing costs, and reduce casting costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

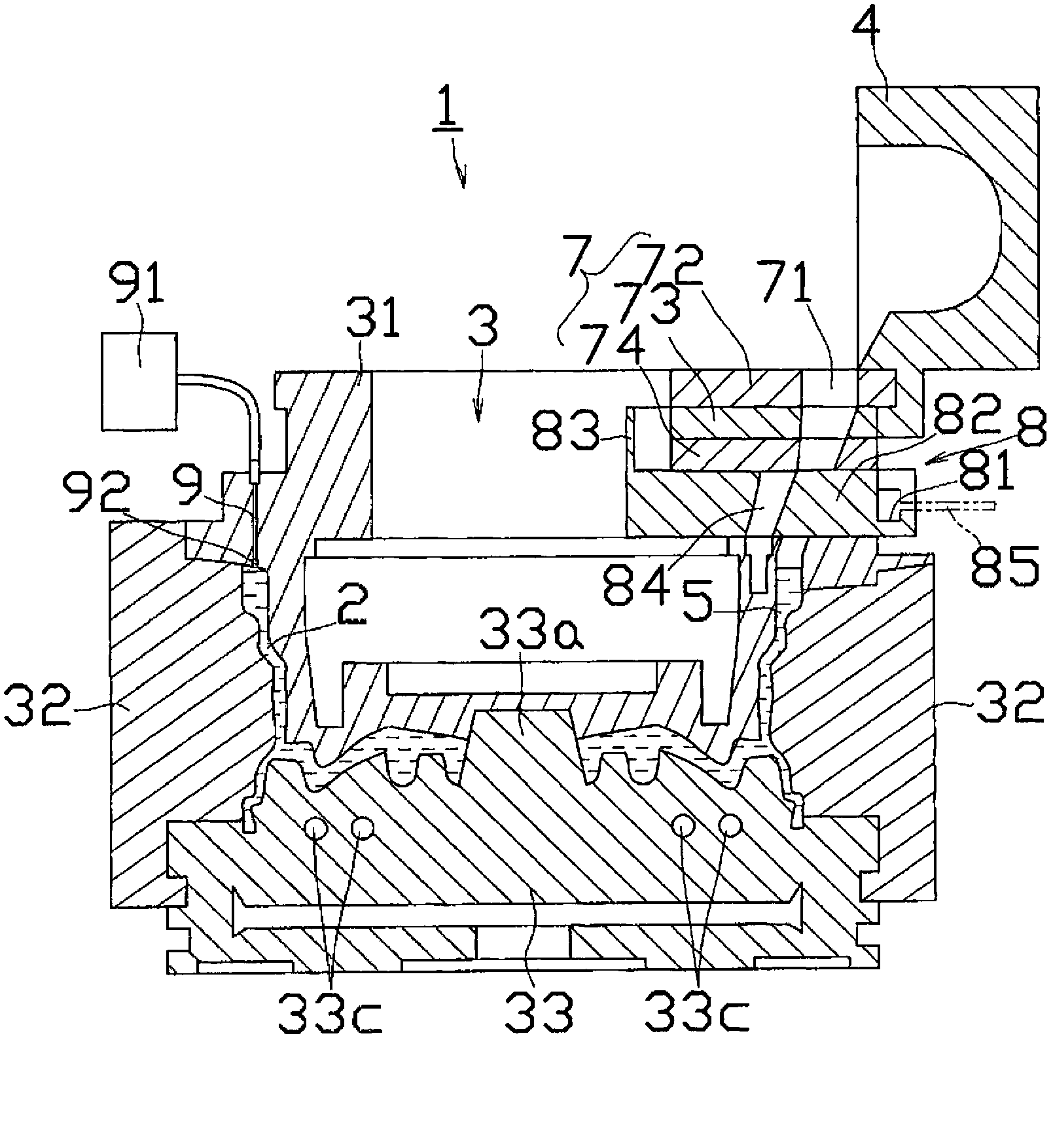

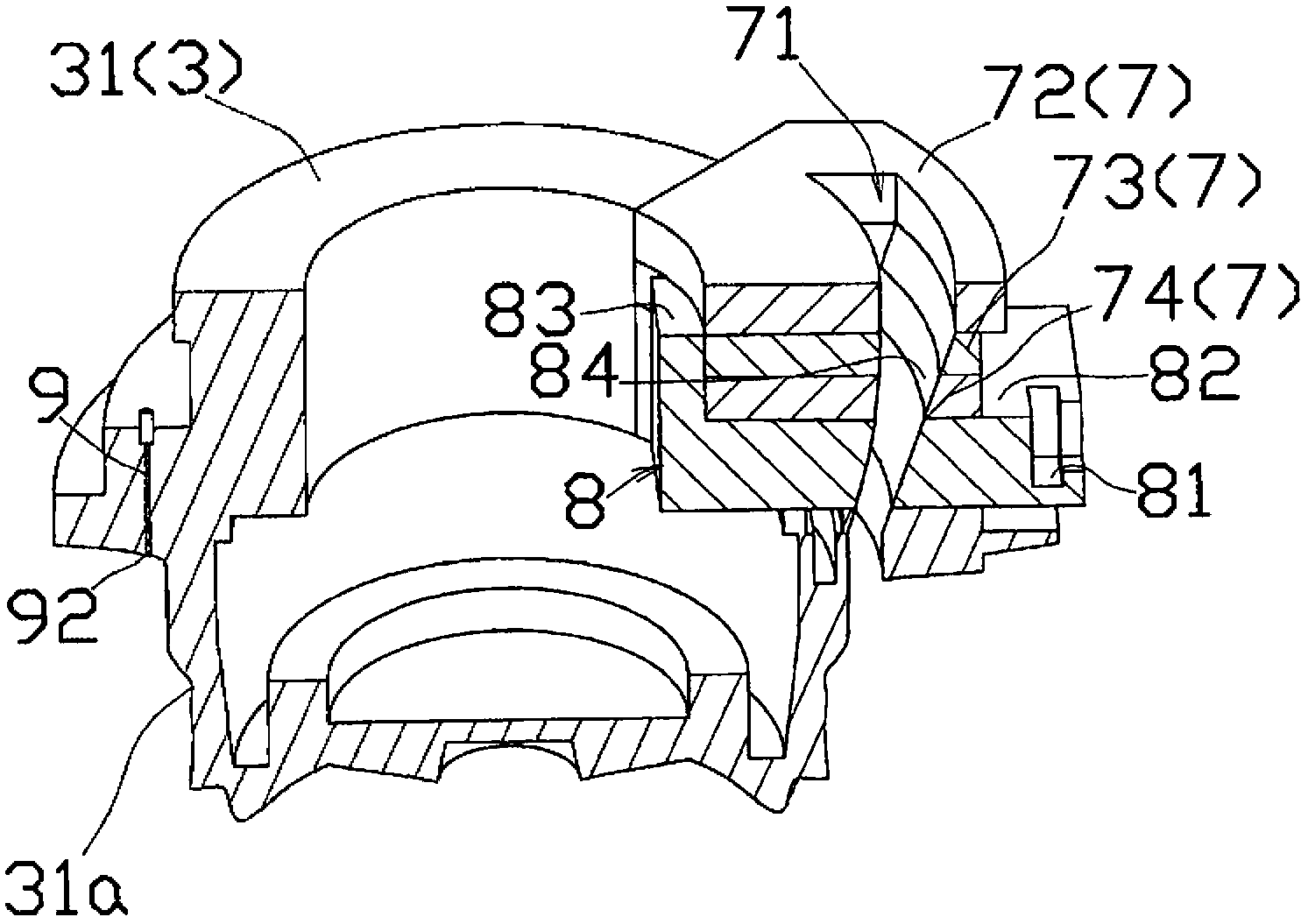

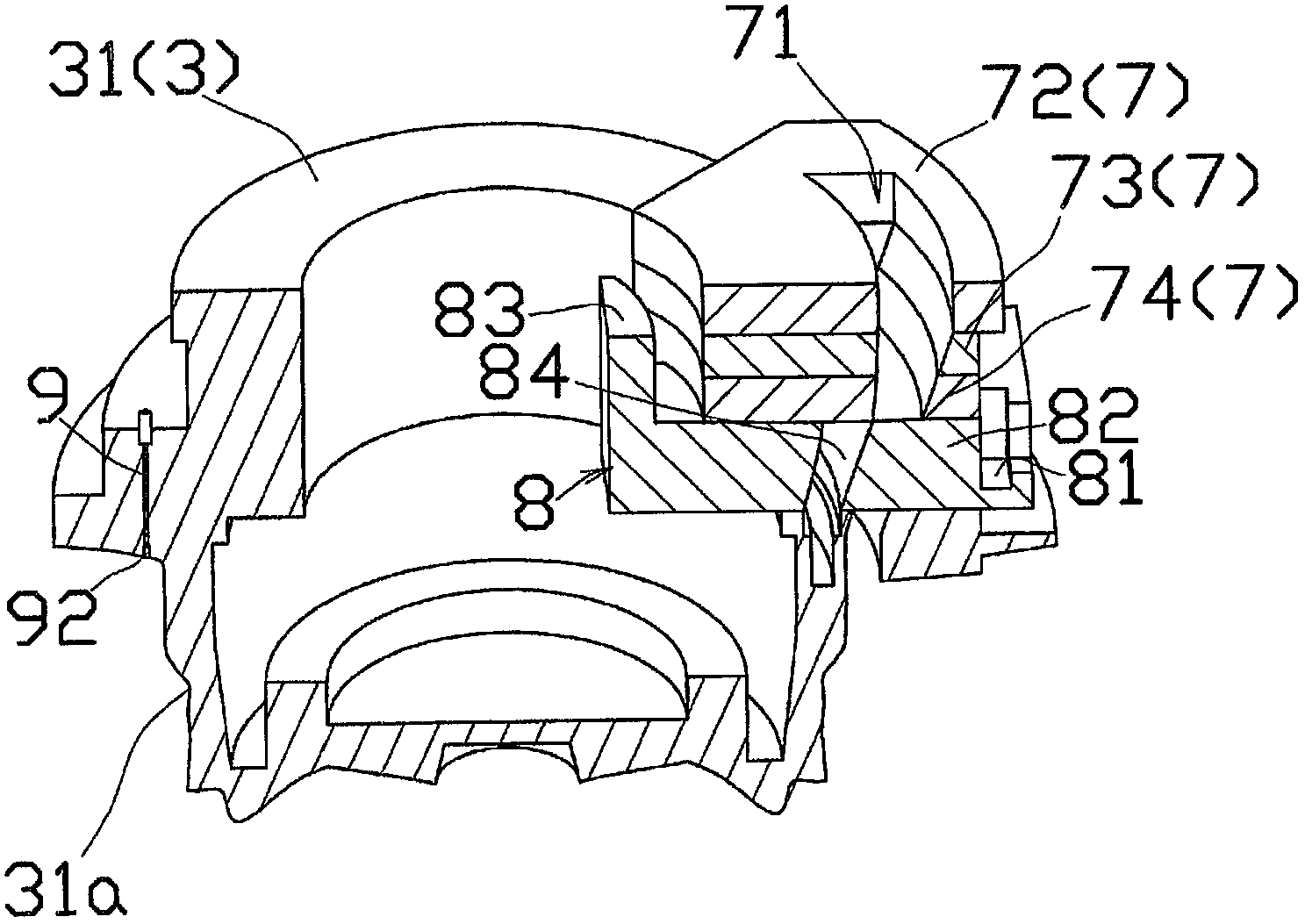

[0038] Next, preferred embodiments of the inclined gravity casting device 1 will be described with reference to the drawings. In this embodiment, the inclined gravity casting device 1 for casting a tire wheel (formed product 6 ) made of aluminum alloy is described as an example, however, the inclined gravity casting device 1 may also be used to cast, for example, an engine of an automobile. Devices for cylinders and other components. Such as figure 1 As shown, the inclined gravity casting device 1 has: a casting mold 3, which combines a plurality of detachable metal parts through a hydraulic cylinder to form a cavity 2 for a molded product 6, which can be tilted into an upside-down state and from the upside-down state The erected state raised at about 90 degrees; the bowl-shaped part 4 that stores molten metal 5 such as aluminum alloy; the gate mold formed on the upper part of the casting mold 3 in the erected state, and the gate 71 that receives the molten metal 5 is formed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com