Top dressing of fire-cured tobacco as well as preparation method and use method thereof

A technology for flue-cured tobacco and tobacco leaves is applied in the field of surface materials for improving the taste of tobacco leaves and the field of preparation thereof, which can solve the problems of reducing the amount of tar released, increasing the aroma, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

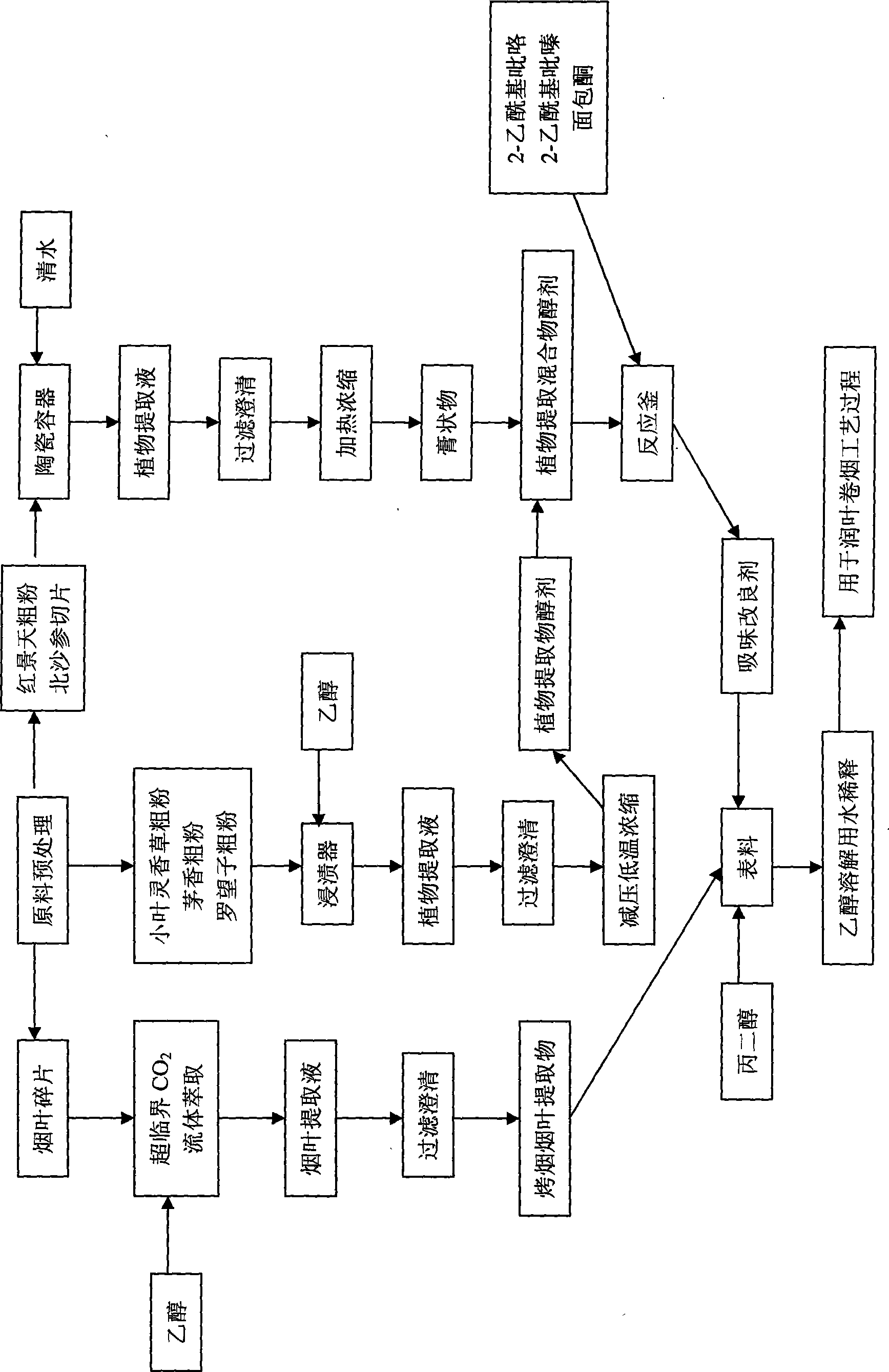

Method used

Image

Examples

Embodiment 1

[0022] One, the preparation of table material for flue-cured tobacco leaves

[0023] 1. Preparation of odor improving agent

[0024] (1) Grind the rhizome of Rhodiola rosea and pass through a 20-mesh sieve to make coarse powder; Then take the material according to the following weight ratio:

[0025] Rhodiola rosea 1.5 parts by weight,

[0026] 1.3 parts by weight of North Radix Ginseng,

[0027] Put the raw materials of the above weight parts into a ceramic container, add clear water of 6 times the weight of the raw materials (16.8 parts by weight), soak for 30 minutes, decoct for 40 minutes, filter, collect the filtrate for 24 hours, discard the precipitate, and get The supernatant was heated and concentrated to a paste.

[0028] (2) Pulverize the whole plant of Maoxiang, the whole plant of Xiaoyeling vanilla and the fruit of tamarind respectively and pass through a 20-mesh sieve to make coarse powder. Then take the material according to the following weight ratio:

[...

Embodiment 2

[0042] One, the preparation of table material for flue-cured tobacco leaves

[0043] 1. Preparation of odor improving agent

[0044] (1) Grind the rhizome of Rhodiola rosea and pass through a 20-mesh sieve to make coarse powder; Then take the material according to the following weight ratio:

[0045] Rhodiola rosea 1.6 parts by weight,

[0046] Northern Radix Ginseng 1.2 parts by weight,

[0047] Put the raw materials of the above weight parts into a ceramic container, add 6.2 times the weight of raw materials (17.36 parts by weight) of clear water, soak for 30 minutes, decoct for 40 minutes, filter, collect the filtrate for 24 hours, discard the precipitate, and get The supernatant was heated and concentrated to a paste.

[0048] (2) Pulverize the whole plant of Maoxiang, the whole plant of Xiaoyeling vanilla and the fruit of tamarind respectively and pass through a 20-mesh sieve to make coarse powder. Then take the material according to the following weight ratio:

[0...

Embodiment 3

[0062] One, the preparation of table material for flue-cured tobacco leaves

[0063] 1. Preparation of odor improving agent

[0064] (1) Grind the rhizome of Rhodiola rosea and pass through a 20-mesh sieve to make coarse powder; Then take the material according to the following weight ratio:

[0065] Rhodiola rosea 1.7 parts by weight,

[0066] 1.1 parts by weight of North Radix Ginseng,

[0067] Put the raw materials of the above weight parts into a ceramic container, add clear water of 6.5 times (18.2 parts by weight) of the raw materials, soak for 30 minutes, decoct for 40 minutes, filter, collect the filtrate for 24 hours, discard the precipitate, and obtain The supernatant was heated and concentrated to a paste.

[0068] (2) Pulverize the whole plant of Maoxiang, the whole plant of Xiaoyeling vanilla and the fruit of tamarind respectively and pass through a 20-mesh sieve to make coarse powder. Then take the material according to the following weight ratio:

[0069] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com